low beam KIA CARNIVAL 2007 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 1227 of 1575

Easy Access

1.Description

The easy access function permits automatic rearward movement of the driver seat when the key is removed from

the cylinder. Automatic forward movement of the driver seat will take place when the key is inserted into the

cylinder. This function will be enabled on IMS equipped vehicles when the AUTO button is pressed.

Inhibit Switch should be in P- Position for the Easy Access operation.

2. Functional Diagram

Driver Information

Cluster Indicators

1.The instument cluster indicators listed below are controlled by the In- Panel Module (IPM), Front Area Module

(FAM), or Rear Area Module (RAM) as applicable.

These indicators are:

a. Gearbox status

b. Oil pressure

c. Sediment fuel filter

d. Vacuum

e. Brake fluid

f. Washer fluid

g. Seat belt

h. Park brake

i. Charging voltage

j. Turn indicators

k. High beam

l. Front fog

m. Doors open

n. Tailgate open

o. Stop lamp failure front and rear

2. Functional Diagram

Page 1229 of 1575

switch, the status of the ABS EBD warning, the status of the brake fluid sensor and the speed of the vehicle.

The IPM sends the park brake indicator control on the CAN network.

The indicator is lighted if the vacuum switch or ABS EBD warning are on or brake fluid sensor is low or park brake

switch is on.

If the speed of the vehicle is over 10 km/h and ignition switch is on the status RUN the park brake indicator control is

blinking at 50% duty in 0.6 second if Parking Brake switch Input is active. In this case Vacuum switch, ABS EBD

warning and Brake Fluid sensor are ignored.

The park brake indicator is blinking on the same time that the chime is ringing. If a CAN signal among Vacuum switch,

EBD warning or Brake Fluid Sens switch is INVALID, out of range or not received this CAN signal is considered to be

OFF.

If VehicleSpeed CAN signal is INVALID or not received, it is considered to be 0 kph.

Charging Voltage Control

The IPM receives on analog input the voltage of generator and sends a warning.

When the voltage of generator L pass strictly above 10V, the state of the CAN variable.

Turn Indicators Status

The status of the turn indicators are sent on the CAN network when the CAN network is available.

High Beam Status

The status of the high beam is sent on the CAN network when the CAN network is available.

Front Fog Lamp Status

The status of the front fog lamp (lightning and state of the bulbs) is sent on the CAN network when the CAN network

is available.

Doors Open Warning

The RAM receives on digital input the status of the driver door open switch and sends it on the CAN network.

The RAM receives on digital input the status of the passenger door open switch and sends it on the CAN network.

The RAM receives on digital input the status of the left sliding door open switch and sends it on the CAN network.

The RAM receives on digital input the status of the right sliding door open switch and sends it on the CAN network.

When vehicle speed is under 10 kph, with ignition key not inserted and any door OPEN, DoorsOpenWngCtrl stays ON

for 20 min and then is turned OFF.

Tailgate Open Switch Status

When vehicle speed is under 10 kph, ignition key is inserted and Tailgate open switch is OPEN, Tailgate Open

warning stays ON forever (IPM can enter sleep mode).

When vehicle speed is under 10 kph, with ignition key not inserted and lgate open switch is OPEN, Tailgate Open

warning stays ON for 20 min and then is turned OFF.

Chime Control

1.The chime warns the driver that a problem is occurred.

These warning are:

a. Seat belt

b. Parking on

c. Over speed

d. Key reminder

e. Light Warning

f. Doors Open

g. Tailgate open warning

2. Chime sound priority:

a. 1st : Seatbelt warning

b. 2nd : Overspeed warning

c. 3rd : Door open warning

d. 4th : T/Gate open warning

e. 5th : Key operated warning

f. 6th : Parking Brake warning

Page 1236 of 1575

Battery Removal

a.If the battery is removed with the system in the ARM state, the system will be placed into the ARM state upon

battery reconnect.

b. The ALARM state will be re- activated if the battery is disconnected, then reconnected, with the system in an

ALARM state.

c. If the battery is disconnected and reconnected with the system in AFTER ALARM state, the alarm will be re-

activated.

d. The system will enter DISARM mode if the battery is disconnected during the ALARM WAIT state.

Panic

a.If RKE PANIC signal is received, Siren output and hazard lamp operate for 27 seconds and the system return to

the previous state as soon as the PANIC function finishes.

b. The PANIC function will be stopped if any RKE signal is received during PANIC activation..

c. If Key reminder switch is ON during PANIC function is operating, PANIC is stopped immediately.

d. If the system goes to ALARM mode during PANIC function is operating, PANIC is stopped immediately and then

ALARM function should be activated.

e. During ALARM state;

If RKE PANIC signal is received, ALARM mode is maintained and PANIC function should be ignored. ALARM has

higher priority than PANIC function.

f. During AFTER_ALARM state;

If RKE PANIC signal is received, AFTR_ALARM mode is maintained and PANIC function should be activated.

Safe & Rescue Mode

The goal of those modes is to be able to cope with failures that may happen on some of the most critical

functionalities (for the driver security) of the system.

Safe Mode

The safe mode is entered in case of system problems such as:

a. Incoherent inputs on monitored signals. In this case, safe mode is the debouncing time before the inputs are

considered INVALID. Note that today, we have no way to detect if the rain/light sensor is in working operation or

not. It means that a driver action will be required in case of failure of this sensor;

b. Loss of the CAN frame containing the monitored signal:

c. Loss of the CAN network: CAN goes to BUS OFF state, safe mode is the time necessary for detecting the BUS

OFF state.

In all cases, the action in safe mode is to maintain the previous state of the system (for lighting and wiping). The list of

monitored signals is the same as in rescue mode

Exiting Safe Mode

The software safe mode is exited and the module goes back to the normal mode when: a. On IPM, hardware inputs return to a coherent state;

b. The lost CAN signal comes back while timeout has not elapsed;

c. The CAN network returns to a normal state without reaching BUS OFF state.

Software safe mode is also exited when the software rescue mode is entered (problem does not disappear).

Hardware safe mode is exited and the module goes back to normal mode if the internal problem disappears (watchdog

is properly triggered again). If the problem stays, hardware safe mode is exited to enter hardware rescue mode.

Rescue Modes

The rescue mode consists in activating some safety functions when IGN2 = ON: a. Switch on the low beams (FAM), park lamps (FAM), tail lamps (RAM) and cluster backlighting (IPM);

b. Unlock of all the doors when the rescue mode is entered with IGN2 = ON

c. Front wipers do not need to be turned on by software in rescue mode because wipers can be turned on by

manually setting the MF switch to low speed. The FAM software must keep the same state as before entering the

rescue mode.

d. When IGN2 = OFF, low beams, park/tail lamps and cluster backlighting are turned off.

Entering Rescue Modes

Page 1240 of 1575

2.The IPM communicates with the diagnostic tester directly. But other units operate self diagnostic, input/output

monitoring and actuator operation via the IPM using the CAN communication.

INPUT MONITORING

IPM (In- Panel Module)

No. Input switch Unit

1 IPM Node Availability PRESENT/NOT PRESENT

2 FAM Node Availability PRESENT/NOT PRESENT

3 RAM Node Availability PRESENT/NOT PRESENT

4 DDM Node Availability PRESENT/NOT PRESENT

5 ADM Node Availability PRESENT/NOT PRESENT

6 IMS Node Availability PRESENT/NOT PRESENT

7 CLU Node Availability PRESENT/NOT PRESENT

8 IPM Node Failure FAILURE/ O.K

9 FAM Node Failurey FAILURE/ O.K

10 RAM Node Failure FAILURE/ O.K

11 DDM Node Failure FAILURE/ O.K

12 ADM Node Failure FAILURE/ O.K

13 IMS Node Failure FAILURE/ O.K

14 CLU Node Failure FAILURE/ O.K

15 Auto Head lamp ON/OFF

16 Headlamp low beam ON/OFF

17 High beam ON/OFF

Page 1434 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

The Rain sensing windshield wiper system is a wiper system that, in addition to providing normal wiper functions off,

mist, manual low speed, manual high speed, and wash, provides automatic control of automatic intermittent automatic

low, and automatic high speeds.

When the ignition key is in the ON position, the rain sensor will be activated.

SYSTEM FUNCTION

BASIC PRINCIPLE

Emitted Beam from luminosity diode is reflected entirely against the windshield exterior, and then turn into photo diode.

If there is water on the windshield exterior, beam seperates optically, and the degree of remained beam is measured

in the photo diode.

What there is water in the windshield, it means beam is not reflected all, so the degree of lost beam indicates the

degree of glass surface wet.

Rainsensor consist of two luminosity diode, two photo diode, optic fiber and coupling pad.

OPERATION CONTROL

Wiper ECU transmits the signal as a rainsesor, and then the rainsensor perceives the rainwater to transmit to the

wiping order wiper ECU, wiper ECU controls the wiper motor according to the signal.

CONTACT INFLUENCE

The rain sensor can malfunction due to the following conditions : a. Contamination of the measurement surface.

b. Air bubbles between the windshield and the coupling pad contact surface.

c. The movement of coupling pad by vibration.

d. Damaged wiper blade.

AUTO OPERATION

1.Operation Condition

Operation mode Operation condition

Direct mode Switch AUTO is basic operation condition that rain sensor perceives dry

windshield. From this condition, the rain sensor decides the wiper operation

mode depend on the quantity and time of measured rainwater

Intermittent mode Operation pauses between 0.5~5 seconds, then the wipers switch to

intermittent mode

Low speed Operate continuously at low speed

High speed Operate continuously at high speed

Page 1469 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Loose the mounting bolts (2EA).

3.Remove the head lamp assembly after disconnecting the lamp connectors.

Take care that holding clip (A) is not to be damaged.

4.Remove the head lamp rear cover and pulling up head lamp bulb fixing wire clip.

5.Replace the bulb.

6. Installation is the reverse of removal.

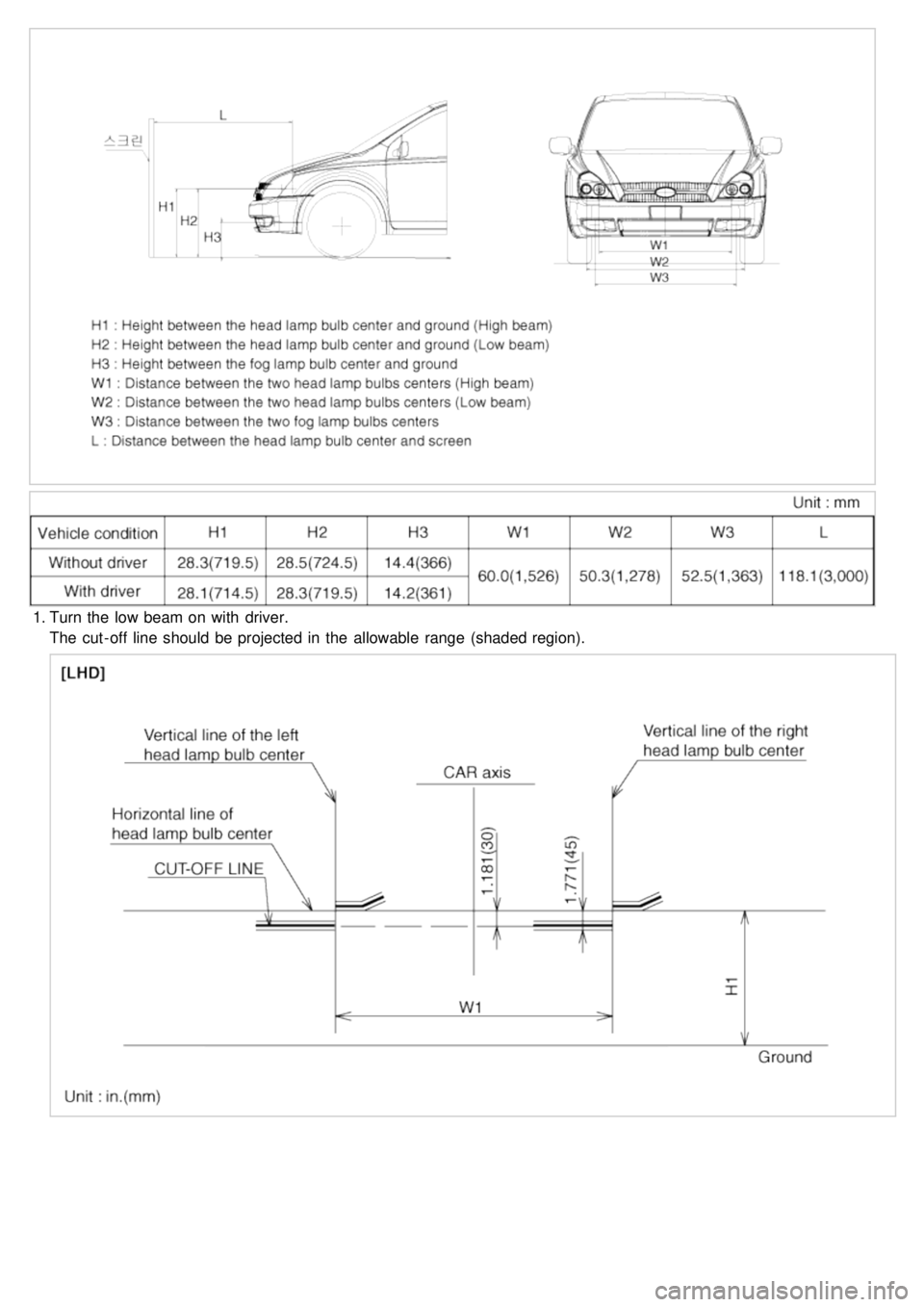

HEAD LAMP AIMING INSTRUCTIONS

Alternately turn the adjusting gear to adjust the head lamp aiming. If beam- setting equipment is not available, proceed

as follows :

1. Inflate the tires to the specified pressure and remove any loads from the vehicle except the driver, spare tire, and

tools.

Page 1470 of 1575

2.The vehicle should be placed on a flat floor.

3. Check the suspension spring.

4. Draw vertical lines (Vertical lines passing through respective head lamp centers) and a horizontal line (Horizontal

line passing through center of head lamps) on the screen.

5. With the head lamp and battery in normal condition, aim the head lamps so the brightest portion falls on the

horizontal and vertical lines.

Make vertical and horizontal adjustments to the lower beam using the adjusting wheel.

FRONT FOG LAMP AIMING

The front fog lamps should be aimed as the same manner used to adjust the head lamps.

With the front fog lamps and battery normal condition, aim the front fog lamps by turning the adjusting gear (A).

HEAD LAMP AND FOG LAMP AIMING POINT

Page 1471 of 1575

1.Turn the low beam on with driver.

The cut- off line should be projected in the allowable range (shaded region).

Page 1496 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

While operating the auto light switch, check if the operations are normal as shown in the timing chart.

1. Auto light sensor value is always read at IGN ON.

2. Light is turned ON after 1sec±0.1sec when auto light sensor value is same as light ON input value.

3. Light is turned OFF after 2sec±0.2sec when sensor value is same as light OFF input value.

4. Tail lamp and head lamp are turned ON when sensor value is same as tail lamp ON input value.

5. Light ON value of sensor is based on the below table.

6. Head lamp signal is output when head lamp switch is ON. After head lamp is turned OFF, head lamp signal output

is immediately stopped if head lamp OFF luminance condition is met at auto light switch ON.

TAIL LAMP, AV LAMP HEAD LAMP

(low beam)

ON 1.77V+/ - 0.08V 0.63V+/ - 0.06V

OFF 3.47V+/ - 0.10V 1.02V+/ - 0.06V

T1 : 2 ± 0.2 sec

T2 : 2 ± 0.2 sec.

REPLACEMENT

Photo & auto light sensor inspection

1. Disconnect the crash pad (Refer to Body group - Crash pad).

2. Remove the Photo & auto light sensor (B) from crash pad.

3.Installation is the reverse of removal.