service KIA CEED 2013 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2013, Model line: CEED, Model: KIA CEED 2013Pages: 1168, PDF Size: 48.01 MB

Page 1070 of 1168

733

Maintenance

Air cleaner filter

We recommend that the air cleaner filter

be replaced by an authorised Kia dealer.

Spark plugs (for petrol engine)

Make sure to install new spark plugs of

the correct heat range.

Valve clearance

(for petrol engine)

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

We recommend that the valve clearance

be serviced by an authorised Kia dealer. Cooling system

Check the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Double clutch transmission fluid (if equipped)

Inspect the double clutch transmission fluid according to the maintenance

schedule.

Automatic transaxle fluid (if equipped)

Automatic transaxle fluid should not be

checked under normal usage conditions.

But in severe conditions, we recommend

that the system be serviced by an autho-

rised Kia dealer in accordance to the

maintenance schedule.

✽✽

NOTICE

Automatic transaxle fluid colour is basi-

cally red. As the vehicle is driven, the automatic

transaxle fluid will begin to look darker.It is normal condition and you should

not judge the need to replace the fluid

based upon the changed colour.

CAUTION

The use of a non-specified fluid could result in transaxle malfunc-

tion and failure.

Use only specified automatictransaxle fluid. (Refer to“Recommended lubricants and capacities” in section 8.)

JD RHD 7.QXP 7/21/2012 12:47 PM Page 33

Page 1078 of 1168

741

Maintenance

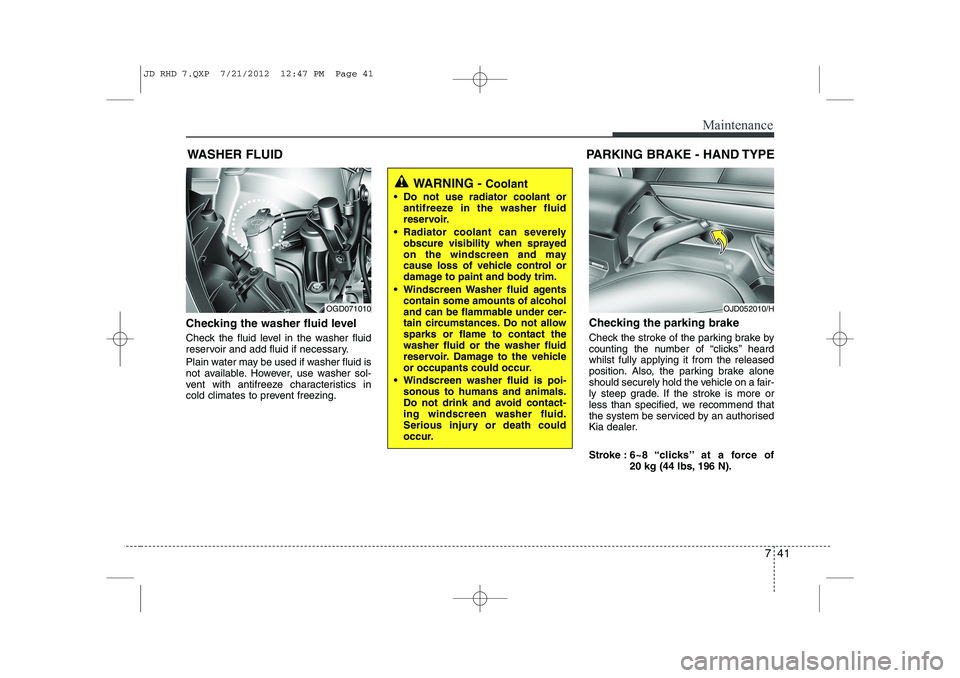

WASHER FLUID

Checking the washer fluid level

Check the fluid level in the washer fluid

reservoir and add fluid if necessary.

Plain water may be used if washer fluid is

not available. However, use washer sol-

vent with antifreeze characteristics in

cold climates to prevent freezing. Checking the parking brake

Check the stroke of the parking brake by

counting the number of “clicks’’ heardwhilst fully applying it from the released

position. Also, the parking brake alone

should securely hold the vehicle on a fair-

ly steep grade. If the stroke is more or

less than specified, we recommend that

the system be serviced by an authorised

Kia dealer.

Stroke :

6~8 “clicks’’ at a force of

20 kg (44 lbs, 196 N).

OGD071010

WARNING - Coolant

Do not use radiator coolant or antifreeze in the washer fluid

reservoir.

Radiator coolant can severely obscure visibility when sprayed

on the windscreen and may

cause loss of vehicle control or

damage to paint and body trim.

Windscreen Washer fluid agents contain some amounts of alcohol

and can be flammable under cer-

tain circumstances. Do not allowsparks or flame to contact thewasher fluid or the washer fluid

reservoir. Damage to the vehicle

or occupants could occur.

Windscreen washer fluid is poi- sonous to humans and animals.

Do not drink and avoid contact-ing windscreen washer fluid.

Serious injury or death could

occur.

PARKING BRAKE - HAND TYPE

OJD052010/H

JD RHD 7.QXP 7/21/2012 12:47 PM Page 41

Page 1079 of 1168

Maintenance

42

7

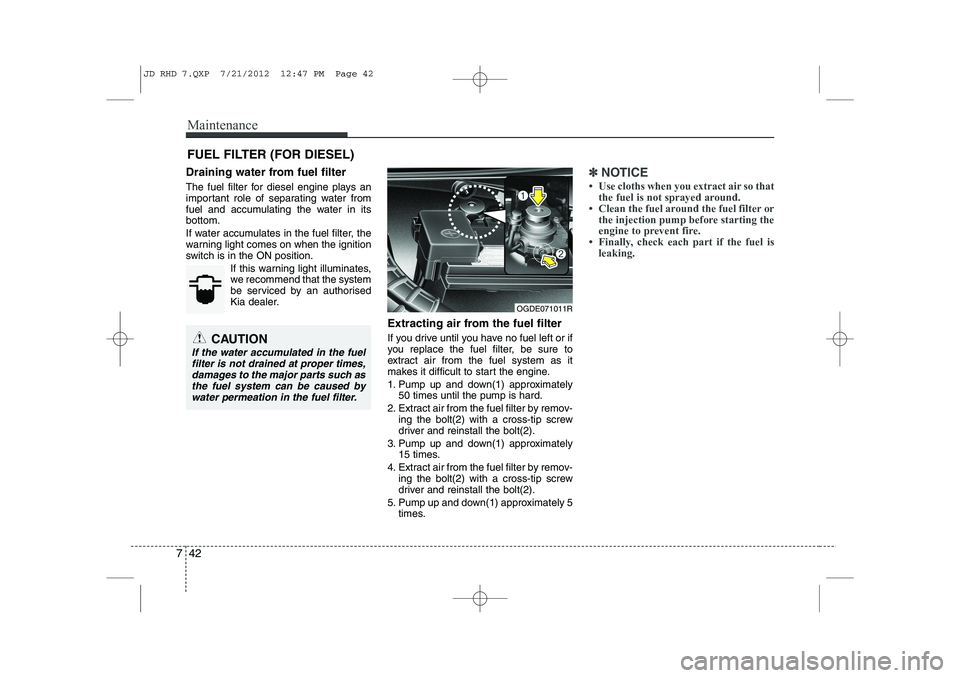

FUEL FILTER (FOR DIESEL)

Draining water from fuel filter

The fuel filter for diesel engine plays an

important role of separating water from

fuel and accumulating the water in itsbottom.

If water accumulates in the fuel filter, the

warning light comes on when the ignition

switch is in the ON position. If this warning light illuminates,

we recommend that the system

be serviced by an authorised

Kia dealer.

Extracting air from the fuel filter

If you drive until you have no fuel left or if

you replace the fuel filter, be sure to

extract air from the fuel system as it

makes it difficult to start the engine.

1. Pump up and down(1) approximately50 times until the pump is hard.

2. Extract air from the fuel filter by remov- ing the bolt(2) with a cross-tip screw

driver and reinstall the bolt(2).

3. Pump up and down(1) approximately 15 times.

4. Extract air from the fuel filter by remov- ing the bolt(2) with a cross-tip screw

driver and reinstall the bolt(2).

5. Pump up and down(1) approximately 5 times.

✽✽ NOTICE

Page 1087 of 1168

Maintenance

50

7

BATTERY

For best battery service

Keep the battery securely mounted.

Keep the battery top clean and dry.

Keep the terminals and connections clean, tight, and coated with petroleum

jelly or terminal grease.

Rinse any spilled electrolyte from the battery immediately with a solution of

water and baking soda.

If the vehicle is not going to be used for an extended time, disconnect the bat-

tery cables.

WARNING - Battery

dangers

Always read the following

instructions carefully when

handling a battery.

Keep lighted cigarettes and all other flames or sparks

away from the battery.

Hydrogen, a highly com- bustible gas, is always

present in battery cells and

may explode if ignited.

Keep batteries out of the reach of children because

batteries contain highly

corrosive SULFURIC ACID.

Do not allow battery acid to

contact your skin, eyes,

clothing or paint finish.

(Continued)

OGDE071015R

(Continued)If any electrolyte gets intoyour eyes, flush your eyes

with clean water for at least

15 minutes and get immedi-ate medical attention.

If electrolyte gets on your

skin, thoroughly wash the

contacted area. If you feel a

pain or a burning sensa-

tion, get medical attention

immediately.

Wear eye protection when charging or working near a

battery. Always provide

ventilation when working in

an enclosed space.

An inappropriately disposed battery can be harmful to

the environment and human

health. Dispose the battery

according to your local

law(s) or regulation.

(Continued)

Pb

JD RHD 7.QXP 7/21/2012 12:48 PM Page 50

Page 1098 of 1168

761

Maintenance

4. Tyre ply composition and material

The number of layers or plies of rub-

ber-coated fabric are in the tyre. Tyre

manufacturers also must indicate the

materials in the tyre, which include

steel, nylon, polyester, and others.

The letter "R" means radial ply con-

struction; the letter "D" means diago-

nal or bias ply construction; and theletter "B" means belted-bias ply con-

struction.

5. Maximum permissible inflationpressure

This number is the greatest amount of air pressure that should be put in

the tyre. Do not exceed the maximum

permissible inflation pressure. Refer

to the Tyre and Loading Information

label for recommended inflation

pressure.

6. Maximum load rating

This number indicates the maximum

load in kilograms and pounds that

can be carried by the tyre. When

replacing the tyres on the vehicle,

always use a tyre that has the same

load rating as the factory installed

tyre.

7. Uniform tyre quality grading

Quality grades can be found where

applicable on the tyre sidewall

between tread shoulder and maxi-

mum section width.

For example:

TREADWEAR 200

TRACTION AA

TEMPERATURE A Tread wear

The tread wear grade is a compara-

tive rating based on the wear rate ofthe tyre when tested under controlled

conditions on a specified govern-

ment test course. For example, a tyre

graded 150 would wear one-and-a-

half times (1½) as well on the gov-

ernment course as a tyre graded100.

The relative performance of tyres depends upon the actual conditions

of their use, however, and may

depart significantly from the norm

because of variations in driving

habits, service practices and differ-

ences in road characteristics and cli-

mate.

These grades are molded on the

side-walls of passenger vehicle

tyres. The tyres available as standard

or optional equipment on your vehi-

cles may vary with respect to grade.

WARNING - Tyre age

Tyres degrade over time, even

when they are not being used.

Regardless of the remaining

tread, it is recommended that

tyres generally be replaced

after six (6) years of normal

service. Heat caused by hot cli-mates or frequent high loadingconditions can accelerate the

aging process. Failure to follow

this Warning can result in sud-

den tyre failure, which could

lead to a loss of control and an

accident involving serious

injury or death.

JD RHD 7.QXP 7/21/2012 12:48 PM Page 61

Page 1131 of 1168

Maintenance

94

7

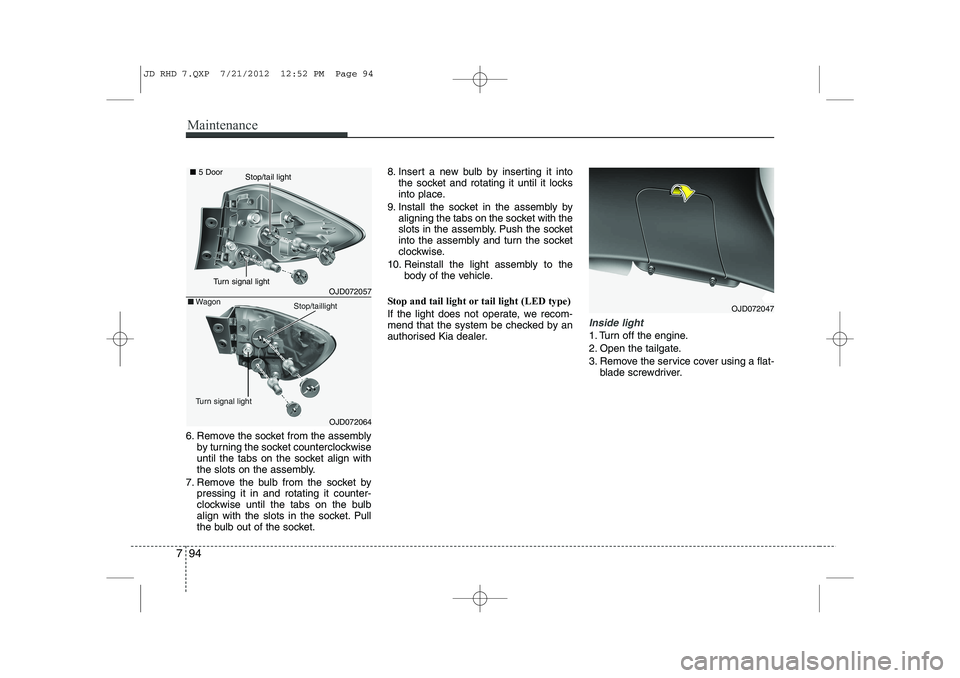

6. Remove the socket from the assembly

by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly.

7. Remove the bulb from the socket by pressing it in and rotating it counter-

clockwise until the tabs on the bulb

align with the slots in the socket. Pull

the bulb out of the socket. 8. Insert a new bulb by inserting it into

the socket and rotating it until it locks

into place.

9. Install the socket in the assembly by aligning the tabs on the socket with the

slots in the assembly. Push the socket

into the assembly and turn the socket

clockwise.

10. Reinstall the light assembly to the body of the vehicle.

Stop and tail light or tail light (LED type)

If the light does not operate, we recom-

mend that the system be checked by an

authorised Kia dealer.

Inside light

1. Turn off the engine.

2. Open the tailgate.

3. Remove the service cover using a flat- blade screwdriver.

OJD072047

OJD072057

OJD072064

■5 Door

■Wagon

Turn signal light

Stop/taillight

Turn signal light

Stop/tail light

JD RHD 7.QXP 7/21/2012 12:52 PM Page 94

Page 1132 of 1168

795

Maintenance

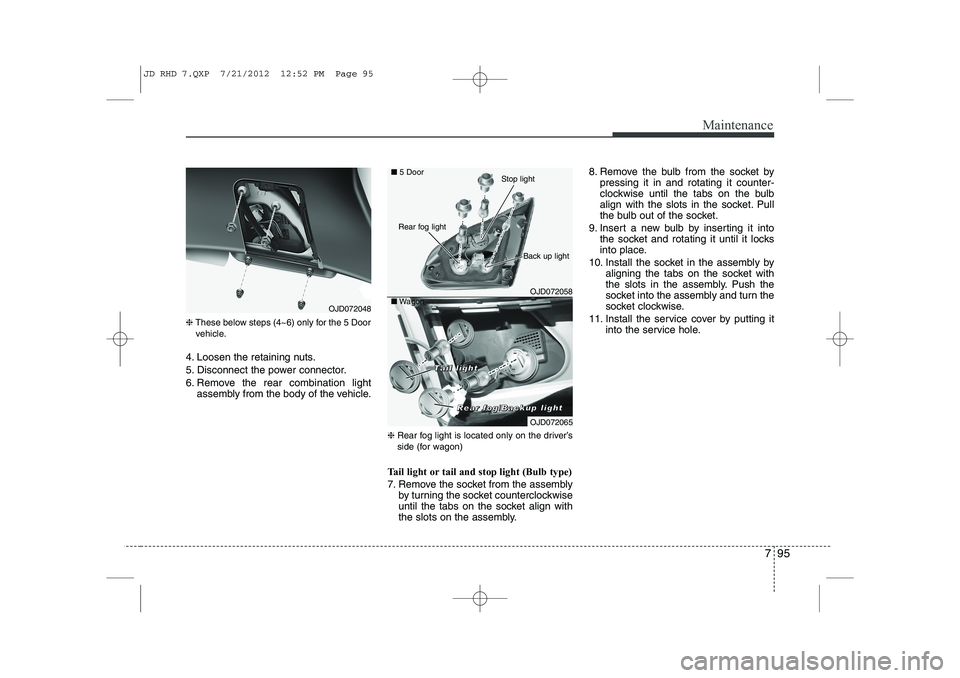

❈These below steps (4~6) only for the 5 Door

vehicle.

4. Loosen the retaining nuts.

5. Disconnect the power connector.

6. Remove the rear combination light assembly from the body of the vehicle.

❈Rear fog light is located only on the driver’s

side (for wagon)

Tail light or tail and stop light (Bulb type)

7. Remove the socket from the assembly by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly. 8. Remove the bulb from the socket by

pressing it in and rotating it counter-

clockwise until the tabs on the bulb

align with the slots in the socket. Pull

the bulb out of the socket.

9. Insert a new bulb by inserting it into the socket and rotating it until it locks

into place.

10. Install the socket in the assembly by aligning the tabs on the socket with

the slots in the assembly. Push the

socket into the assembly and turn the

socket clockwise.

11. Install the service cover by putting it into the service hole.

OJD072048

OJD072058

■5 Door

■ Wagon

Rear fog light

Back up light

Stop light

OJD072065

RRRReeeeaaaarrrr ffffoooogggg////BBBBaaaacccckkkkuuuupppp lllliiiigggghhhhtttt

TTTTaaaaiiiillll lllliiiigggghhhhtttt

JD RHD 7.QXP 7/21/2012 12:52 PM Page 95

Page 1141 of 1168

Maintenance

104

7

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Service Passport

in your vehicle.

Your vehicle is equipped with an emis- sion control system to meet all emission

regulations. There are three emission control sys-

tems which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system(3) Exhaust emission control system In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by an autho-

rised Kia dealer in accordance with the

maintenance schedule. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability Control

(ESC) system off by pressing the

ESC switch.

After dynamometer testing is com- pleted, turn the ESC system back on

by pressing the ESC switch again.

1. Crankcase emission control system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valveinto the induction system. 2. Evaporative emission control

System

The Evaporative Emission Control

System is designed to prevent fuel

vapours from escaping into the atmos-

phere.

Canister

Fuel vapours generated inside the fuel tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapours absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.

Purge Control Solenoid Valve (PCSV)

The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant temper-

ature is low during idling, the PCSV clos-

es so that evaporated fuel is not taken

into the engine. After the engine warms-

up during ordinary driving, the PCSV

opens to introduce evaporated fuel to the

engine.

JD RHD 7.QXP 7/21/2012 12:53 PM Page 104

Page 1150 of 1168

Specifications & Consumer information

6

8

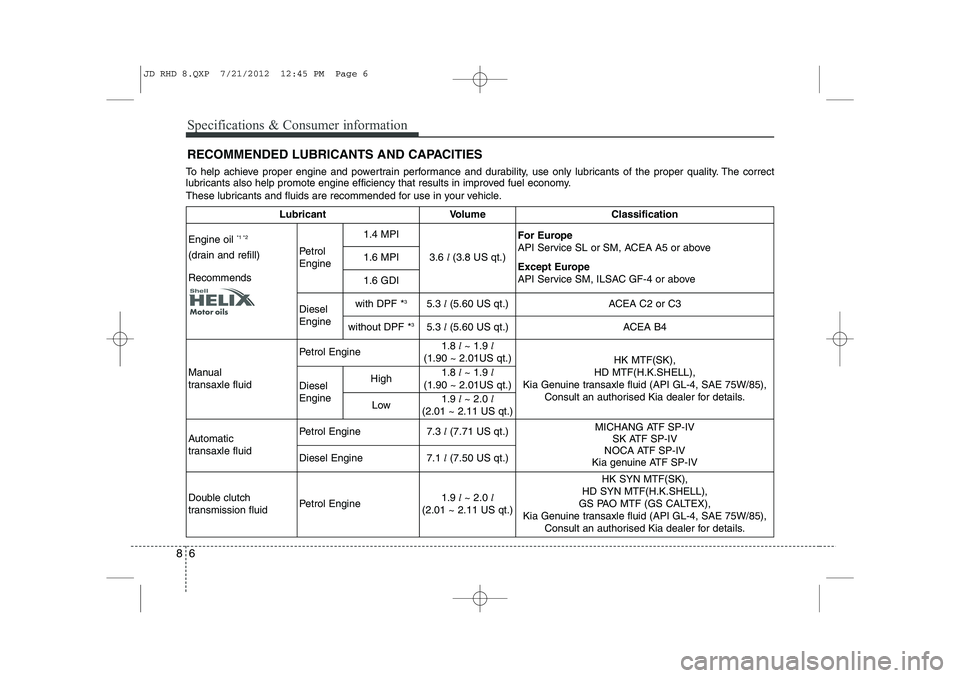

To help achieve proper engine and powertrain performance and durability, use only lubricants of the proper quality. The correct

lubricants also help promote engine efficiency that results in improved fuel economy.

These lubricants and fluids are recommended for use in your vehicle. RECOMMENDED LUBRICANTS AND CAPACITIES

Lubricant Volume Classification

Engine oil *1 *2

(drain and refill) Recommends Petrol Engine1.4 MPI

3.6 l(3.8 US qt.) For Europe

API Service SL or SM, ACEA A5 or above

Except Europe

API Service SM, ILSAC GF-4 or above

1.6 MPI 1.6 GDI

Diesel Engine with DPF *

3

5.3 l(5.60 US qt.)

ACEA C2 or C3

without DPF * 3

5.3 l(5.60 US qt.)

ACEA B4

Manual

transaxle fluid Petrol Engine

1.8

l ~ 1.9 l

(1.90 ~ 2.01US qt.) HK MTF(SK),

HD MTF(H.K.SHELL),

Kia Genuine transaxle fluid (API GL-4, SAE 75W/85), Consult an authorised Kia dealer for details.

DieselEngine High

1.8

l ~ 1.9 l

(1.90 ~ 2.01US qt.)

Low 1.9

l ~ 2.0 l

(2.01 ~ 2.11 US qt.)

Automatic

transaxle fluid Petrol Engine

7.3

l(7.71 US qt.) MICHANG ATF SP-IV

SK ATF SP-IV

NOCA ATF SP-IV

Kia genuine ATF SP-IV

Diesel Engine7.1 l(7.50 US qt.)

Double clutch

transmission fluidPetrol Engine1.9 l ~ 2.0 l

(2.01 ~ 2.11 US qt.)

HK SYN MTF(SK),

HD SYN MTF(H.K.SHELL),

GS PAO MTF (GS CALTEX),

Kia Genuine transaxle fluid (API GL-4, SAE 75W/85), Consult an authorised Kia dealer for details.

JD RHD 8.QXP 7/21/2012 12:45 PM Page 6

Page 1163 of 1168

Index

8

I

Label

Air bag warning label . . . . . . . . . . . . . . . . . . . . . . . 3-63

Air conditioner compressor label . . . . . . . . . . . . . . 8-11

Refrigerant label . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Tyre sidewall labeling . . . . . . . . . . . . . . . . . . . . . . . . 7-59

Tyre specification and pressure label . . . . . . . . . . . 8-10

Vehicle certification label . . . . . . . . . . . . . . . . . . . . . . 8-9

Lane Departure Warning System . . . . . . . . . . . . . . . 5-59

Lane Departure Warning System Mode. . . . . . . . . . 4-67

Lap/shoulder belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

LCD display information . . . . . . . . . . . . . . . . . . . . . . 4-71LCD display warnings and indicators (instrument panel display) . . . . . . . . . . . . . . . . . . . . 4-88

Calender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-88

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-88

Icy road warning . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-89

Outside ambient Temperature . . . . . . . . . . . . . . . . 4-88

LDWS (Lane Departure Warning System) . . . . . . . 5-59

Light bulbs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-81

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-110 AFLS (Adaptive Front Lighting System) . . . . . . . 4-117

Auto light/AFLS position . . . . . . . . . . . . . . . . . . . . 4-112

Battery saver function . . . . . . . . . . . . . . . . . . . . . . 4-110

Daytime running light (DRL) . . . . . . . . . . . . . . . . 4-115

Front fog light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-115 Headlamp delay function . . . . . . . . . . . . . . . . . . . . 4-110

Headlight (Headlamp) welcome function . . . . . . . 4-110

Headlight levelling device . . . . . . . . . . . . . . . . . . . 4-116

Headlight position . . . . . . . . . . . . . . . . . . . . . . . . . . 4-112

High - beam operation . . . . . . . . . . . . . . . . . . . . . . 4-113

Position light position . . . . . . . . . . . . . . . . . . . . . . . 4-111

Rear fog light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-115

Static bending light . . . . . . . . . . . . . . . . . . . . . . . . . 4-111

Turn signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-114

Lubricants and capacities . . . . . . . . . . . . . . . . . . . . . . 8-6

Luggage net (holder) . . . . . . . . . . . . . . . . . . . . . . . . 4-159

Luggage rail system . . . . . . . . . . . . . . . . . . . . . . . . . 4-164

Luggage room lamp . . . . . . . . . . . . . . . . . . . . . . . . . 4-124

Luggage side tray . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-153

Luggage tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-153

Lumbar support (Automatic Seat) . . . . . . . . . . . . . . . 3-7

Lumbar support (Manual seat) . . . . . . . . . . . . . . . . . . 3-5

Main fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-66 Maintenance Explanation of scheduled maintenance items . . . . 7-32

Maintenance services . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Maintenance under severe usage conditions (except Europe, for Russia) . . . . . . . . . . . . . . . . . . 7-30

Maintenance under severe usage conditions (for Europe, except Russia) . . . . . . . . . . . . . . . . . . 7-19

M

L

JD RHD Index.QXP 7/21/2012 1:10 PM Page 8