stop start KIA CEED 2014 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2014, Model line: CEED, Model: KIA CEED 2014Pages: 1206, PDF Size: 50.15 MB

Page 1023 of 1206

Driving your vehicle

74

5

Turn signals when towing a trailer

When you tow a trailer, your vehicle has

to have a different turn signal flasher and

extra wiring. The green arrows on your

instrument panel will flash whenever you

signal a turn or lane change. Properly

connected, the trailer lights will also flash

to alert other drivers you’re about to turn,

change lanes, or stop.

When towing a trailer, the green arrows

on your instrument panel will flash for

turns even if the bulbs on the trailer are

burned out. Thus, you may think drivers

behind you are seeing your signals

when, in fact, they are not. It is important

to check occasionally to be sure the trail-

er bulbs are still working. You must also

check the lights every time you discon-

nect and then reconnect the wires.

Do not connect a trailer lighting system

directly to your vehicle’s lighting system.

Use only an approved trailer wiring har-

ness.

An authorised Kia dealer can assist you

in installing the wiring harness.

Driving on grades

Reduce speed and shift to a lower gear

before you start down a long or steep

downgrade. If you don’t shift down, you

might have to use your brakes so much

that they would get hot and no longer

operate efficiently.

On a long uphill grade, shift down and

reduce your speed to around 70 km/h (45mph) to reduce the possibility of engine

and transaxle overheating.

If your trailer weighs more than the max-

imum trailer weight without trailer brakes

and you have an automatic transaxle,

you should drive in D (Drive) when tow-

ing a trailer.

Operating your vehicle in D (Drive) when

towing a trailer will minimize heat build up

and extend the life of your transaxle.

WARNING

Failure to use an approved trailer wiring harness could result in dam-

age to the vehicle electrical system

and/or personal injury.

CAUTION

When towing a trailer on steep grades (in excess of 6%) pay close

attention to the engine coolant temperature gauge to ensure theengine does not overheat.

If the coolant temperature redwarning light illuminates or the coolant temperature gauge movestowards “130”, pull over and stop as soon as it is safe to do so, and

allow the engine to idle until it cools down. You may proceed oncethe engine has cooled sufficiently.

You must decide driving speed depending on trailer weight anduphill grade to reduce the possi- bility of engine and transaxleoverheating.

JD RHD 5.QXP 4/29/2013 11:28 AM Page 74

Page 1025 of 1206

Driving your vehicle

76

5

When you are ready to leave after park- ing on a hill

1. With the manual transaxle in Neutral

or automatic transaxle in P (Park),

apply your brakes and hold the brake

pedal down whilst you:

Start your engine;

Shift into gear; and

Release the parking brake.

2. Slowly remove your foot from the brake pedal.

3. Drive slowly until the trailer is clear of the chocks.

4. Stop and have someone pick up and store the chocks. Maintenance when trailer towing

Your vehicle will need service more often

when you regularly pull a trailer.

Important items to pay particular atten-tion to include engine oil, automatic

transaxle fluid, axle lubricant and cooling

system fluid. Brake condition is another

important item to frequently check. Each

item is covered in this manual, and the

Index will help you find them quickly. If

you’re trailering, it is a good idea to

review these sections before you start

your trip.

Do not forget to also maintain your trailer

and towbar hitch. Follow the mainte-

nance schedule that accompanied your

trailer and check it periodically.

Preferably, conduct the check at the start

of each day’s driving. Most importantly,

all towbar hitch nuts and bolts should betight.CAUTION

Due to higher load during trailer

usage, overheating might occur

in hot days or during uphill driv-ing. If the coolant gauge indicatesover-heating, switch off the air conditioner and stop the vehicle

in a safe area to cool down the engine.

When towing check transaxle fluid more frequently.

If your vehicle is not equipped with an air conditioner, youshould install a condenser fan to improve engine performance

when towing a trailer.

JD RHD 5.QXP 4/29/2013 11:28 AM Page 76

Page 1032 of 1206

63

What to do in an emergency

IN CASE OF AN EMERGENCY WHILST DRIVING

If the engine stalls at a crossroad

or crossing

If the engine stalls at a crossroad or crossing, set the shift lever in the N

(Neutral) position and then push the

vehicle to a safe place.

If your vehicle has a manual transaxle not equipped with a ignition lock

switch, the vehicle can move forward

by shifting to the 2(Second) or 3(Third)

gear and then turning the starter with-out depressing the clutch pedal. If you have a flat tyre whilst driv- ing

If a tyre goes flat whilst you are driving:

1. Take your foot off the accelerator pedal

and let the vehicle slow down whilst

driving straight ahead. Do not apply the

brakes immediately or attempt to pull

off the road as this may cause a loss of

control. When the vehicle has slowed

to such a speed that it is safe to do so,

brake carefully and pull off the road.

Drive off the road as far as possible

and park on firm, level ground. If you

are on a divided highway, do not park

in the median area between the two

traffic lanes.

2. When the vehicle is stopped, turn on your emergency hazard flashers, set

the parking brake and put the transaxle

in P (automatic transaxle) or reverse

(manual transaxle).

3. Have all passengers get out of the vehicle. Be sure they all get out on the

side of the vehicle that is away from

traffic.

4. When changing a flat tyre, follow the instruction provided later in this sec-tion. If engine stalls whilst driving

1. Reduce your speed gradually, keeping

a straight line. Move cautiously off the

road to a safe place.

2. Turn on your emergency flashers.

3. Try to start the engine again. If your vehicle does not start, we recommend

that you consult an authorised Kia

dealer.

JD RHD 6.QXP 4/29/2013 11:30 AM Page 3

Page 1052 of 1206

623

What to do in an emergency

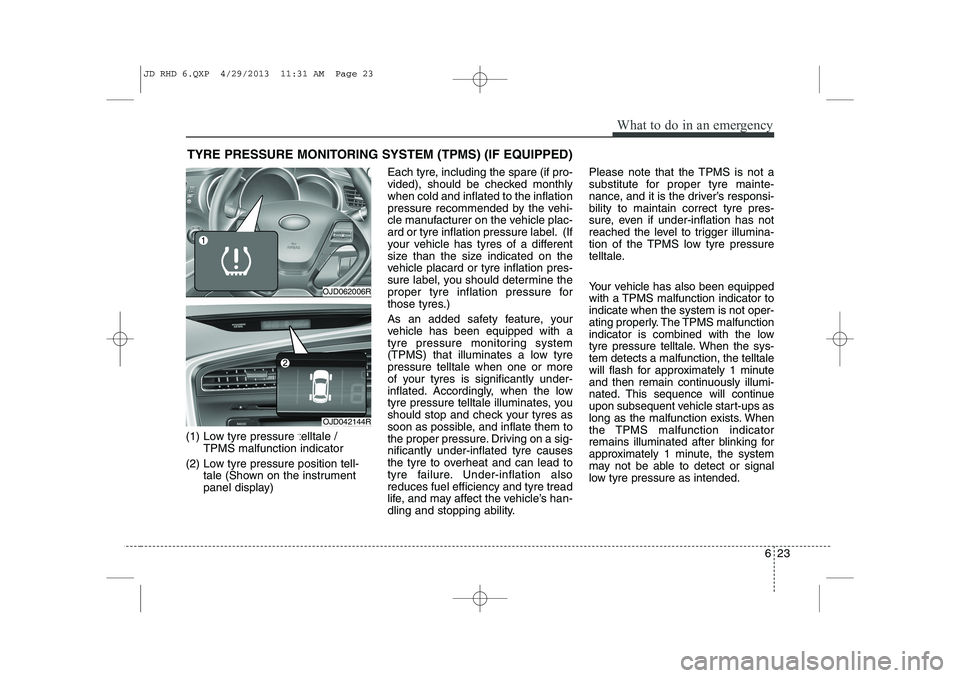

TYRE PRESSURE MONITORING SYSTEM (TPMS) (IF EQUIPPED)

(1) Low tyre pressure telltale / TPMS malfunction indicator

(2) Low tyre pressure position tell- tale (Shown on the instrument

panel display) Each tyre, including the spare (if pro-

vided), should be checked monthlywhen cold and inflated to the inflation

pressure recommended by the vehi-

cle manufacturer on the vehicle plac-

ard or tyre inflation pressure label. (If

your vehicle has tyres of a different

size than the size indicated on the

vehicle placard or tyre inflation pres-

sure label, you should determine the

proper tyre inflation pressure for

those tyres.)

As an added safety feature, your

vehicle has been equipped with a

tyre pressure monitoring system

(TPMS) that illuminates a low tyrepressure telltale when one or more

of your tyres is significantly under-

inflated. Accordingly, when the low

tyre pressure telltale illuminates, you

should stop and check your tyres as

soon as possible, and inflate them to

the proper pressure. Driving on a sig-nificantly under-inflated tyre causes

the tyre to overheat and can lead to

tyre failure. Under-inflation alsoreduces fuel efficiency and tyre tread

life, and may affect the vehicle’s han-

dling and stopping ability. Please note that the TPMS is not a

substitute for proper tyre mainte-

nance, and it is the driver’s responsi-bility to maintain correct tyre pres-

sure, even if under-inflation has not

reached the level to trigger illumina-

tion of the TPMS low tyre pressure

telltale.

Your vehicle has also been equipped

with a TPMS malfunction indicator toindicate when the system is not oper-

ating properly. The TPMS malfunction

indicator is combined with the low

tyre pressure telltale. When the sys-tem detects a malfunction, the telltale

will flash for approximately 1 minute

and then remain continuously illumi-

nated. This sequence will continue

upon subsequent vehicle start-ups as

long as the malfunction exists. When

the TPMS malfunction indicator

remains illuminated after blinking for

approximately 1 minute, the system

may not be able to detect or signal

low tyre pressure as intended.

OJD062006R

OJD042144R

JD RHD 6.QXP 4/29/2013 11:31 AM Page 23

Page 1068 of 1206

77

Maintenance

Engine compartment precautions (Diesel engine)

• The injector operates at high voltage(maximum 200v). Therefore, the follow-

ing accidents may occur.

- Direct contact with the injector or

injector wiring may cause electric

shock or damage your muscle or

nerve system.

- The electromagnetic wave from the operating injector may cause the arti-

ficial heart pacemaker to malfunction.

Follow the safety tips provided below, when you are checking the engine

room whilst the engine is running.

- Do not touch the injector, injector

wirings, and the engine computer

whilst the engine is running.

- Do not remove the injector connector whilst the engine is running.

- People using pacemakers must not go near the engine whilst the engine

is starting or running.

WARNING - Maintenance

work

Performing maintenance work on a vehicle can be dangerous. You

can be seriously injured whilst

performing some maintenance

procedures. If you lack sufficient

knowledge and experience or the

proper tools and equipment to do

the work, we recommend that the

system be serviced by an autho-

rised Kia dealer.

Working under the bonnet with the engine running is dangerous.

It becomes even more dangerous

when you wear jewelry or loose

clothing. These can become

entangled in moving parts and

result in injury. Therefore, if you

must run the engine whilst work-

ing under the bonnet, make cer-

tain that you remove all jewelry

(especially rings, bracelets,

watches, and necklaces) and all

neckties, scarves, and similar

loose clothing before gettingnear the engine or cooling fans.WARNING - Diesel Engine

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High-pressure pump, rail, injectorsand high-pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touches the body.

People using pacemakers should

not move than 30cm closer to theECU or wiring harness within the

engine room whilst engine is run-

ning, since the high currents in the

electronic engine control system

produce considerable magneticfields.

JD RHD 7.QXP 4/29/2013 11:32 AM Page 7

Page 1095 of 1206

Maintenance

34

7

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-quent oil and filter changes are required. Drive belts

Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation

and replace if necessary. Drive belts

should be checked periodically for proper

tension and adjusted as necessary.

Fuel filter (cartridge) A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. We recommend that

the fuel filter be replaced by an autho-

rised Kia dealer. Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. We

recommend that the fuel lines, fuel hoses

and connections be replaced by an

authorised Kia dealer.

Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervals

specified in the maintenance schedule.

Make sure that a new vapour hose or fuelfiller cap is correctly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

WARNING -

Diesel only

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High pressure pump, rail, injectorsand high pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touch the body.

People using pacemakers should

not move more than 30cm closer tothe ECU or wiring harness within

the engine room whilst engine is

running, since the high currents in

the Common Rail system produce

considerable magnetic fields.

JD RHD 7.QXP 4/29/2013 11:32 AM Page 34

Page 1134 of 1206

773

Maintenance

No.Fuse ratingSymbolFuse NameProtected component

147.5AA/CONCluster Ionizer, A/C Control Module, Blower Relay, PTC Relay

157.5AIG2IG2ICM Relay Box (Head Lamp Washer Relay), Rain Sensor, BCM, Electro Chromic Mirror,

Panorama Sunroof, Smart, Key Control Module, Passenger Seat Warmer Module,

Driver Seat Warmer Module

1610AHTD MIRRDriver/Passenger Outside Mirror, ECU, A/C Control Module

177.5AINTERIORLAMPGlove Box Lamp, Luggage Lamp, Vanity Lamp LH/RH, Room Lamp,

Overhead Console Lamp

187.5A2PDM 2Smart Key Control Module, Start/Stop Button Switch

197.5AB/HORNICM Relay Box (Burglar Alarm Horn Relay)

2020ASUNROOFPanorama Sunroof

2110AMODULE 2MODULE 2

Electric Parking Brake Module, DC-DC Convertor (With ISG),

Head Lamp Levelling Device Switch, A/C Control Module, Rear Parking Assist Sensor,

Smart Parking Assist Control Module, Head Lamp LH/RH, ATM Shift Lever IND.,

Centre Facia Switch, Crash Pad Lower Switch, Driver/Passenger Seat Warmer Module,

Driver IMS Module

2215AHTD STRGSteering Wheel Heater

2320AIG1IG1E/R Fuse & Relay Box (ECU4, B/UP LAMP, ABS3, TCU2 FUSE)

2425AFRTWIPERWiper Relay , ICM Relay Box (Rain Sensor Relay), Front Wiper Motor

JD RHD 7.QXP 4/29/2013 11:34 AM Page 73

Page 1135 of 1206

Maintenance

74

7

No.Fuse ratingSymbolFuse NameProtected component

257.5AMEMORY2MEMORY 2Immobiliser Module (W/O Smart Key)

267.5AMEMORY1MEMORY 1

Driver/Passenger Outside Mirror (Folding), Driver/Passenger Smart Key Outside Handle, Driver IMS Module, Centre Facia Switch, Instrument Cluster, T yre Pressure Monitoring

Module, BCM, A/C Control Module, ICM Relay Box (Outside Mirror Folding/Unfolding Relay),

Ignition Key ILL. & Door Warning Switch, Rear Parking Assist Switch,

Data Link Connector, Buzzer

2710ABRAKE

SWITCHBRAKE

SWITCHSmart Key Control Module, Stop Lamp Switch

287.5ACLUSTERCLUSTERInstrument Cluster, Digital Clock

297.5A1POWER

STEERINGEPS Unit

307.5ASPARESPARE-

317.5ASTARTStart Relay, ECU, Ignition Lock Switch, Transaxle Range Switch,

TCU, Smart Key Control Module

3215AMULTI

MEDIAMULTI MEDIAA/V & Navigation Head Unit (W/O ISG), Audio (W/O ISG),

DC-DC Convertor (With ISG), Digital Clock

3310ASPARESPARE-

3425A1PDM 1Smart Key Control Module

3515APOWER

OUTLET1P/OUTLET 1Front Power Outlet

JD RHD 7.QXP 4/29/2013 11:35 AM Page 74

Page 1146 of 1206

785

Maintenance

FuseFuse ratingSymbolFuse NameProtected component

MULTIFUSE

80A1POWER

STEERINGEPS Unit

60AB+1B+1Inner Fuse Panel, IPS1 (H/LAMP HI LH,H/LAMP LOW LH, FRT TURN LH, POSITION LAMP LH),

IPS2 (STATIC BENDING LAMP LH/RH, DRL LH/RH)

40A1ABS1ESC Control Module, ABS Control Module

40A2ABS2ESC Control Module, ABS Control Module, Multipurpose Check Connector

40AIG2IG2W/O Smart Key : Ignition Switch, START RELAYWith Smart Key : IG2 RELAY, START RELAY, INNER FUSE PANEL (Fuse No. - 14/24/22/15/10)

60AB+2B+2Inner Fuse Panel, IPS3 (H/LAMP HI RH,H/LAMP LOW RH, FRT TURN RH,

POSITION LAMP RH), IPS4 (FRT FOG LAMP LH/RH, REAR TURN LH/RH),

IPS5 (REAR FOG LAMP, INT TAIL LAMP)

FUSE

40ARR

HTDRR HTDRR HTD RELAY , RR HTD

40AIG1IG1W/O Smart Key : Ignition Switch

With Smart Key : IG1 RELAY, ACC RELAY, INNER FUSE PANEL ( Fuse No. - 38/36/21/37/

23/29/28, Fuse No. - 13/8/35)

30A1EPB1Electric Parking Brake Module

30A2EPB2Electric Parking Brake Module

50AC/FANC/FAN LO RELAY, C/FAN HI RELAY

15ADEICERICM Relay Box (Front Deicer Relay)

15ASTOP

LAMPSTOP LAMPStop Signal Electronic Relay, HAC RELAY

Engine compartment main fuse panel (for diesel engine)

JD RHD 7.QXP 4/29/2013 11:35 AM Page 85

Page 1148 of 1206

787

Maintenance

SymbolRelay NameType

LOCOOLING FAN LOW RELAYPLUG MICRO

HICOOLING FAN HIGH RELAYPLUG MICRO

ESSESS RELAYPLUG MICRO

BLOWER RELAYPLUG MICRO

RR

HTDREAR DEFOGGER RELAYPLUG MICRO

4 (IG2)IG2 RELAYPLUG MICRO

FRT WIPER RELAYPLUG MICRO

3 (IG1)IG1 RELAYPLUG MICRO

1START RELAYPLUG MICRO

2 (ACC)ACC RELAYPLUG MICRO

FUEL HEATER RELAYPLUG MINI

HACHAC RELAYPLUG MICRO

Fuse ratingSymbolFuse NameRelay Name

15ASPARESPARE-

15AHORNHORN RELAY

10A2ECU2Oil Level Sensor, Fuel

Pressure Control Valve

20ASPARESPARE-

10A9SENSOR2

E/R Fuse & Relay Box

(COOLING FAN LOW RELAY),Lambda Sensor (D4FB), Stop Lamp Switch

20A1ECU1ECU

10A8SENSOR1

DSL Box (PTC1 RELAY,

GLOW RELAY),

VGT Control Sensor,

Camshaft Position Sensor,

Electrical EGR Valve

JD RHD 7.QXP 4/29/2013 11:35 AM Page 87