fuel cap KIA CEED 2017 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2017, Model line: CEED, Model: KIA CEED 2017Pages: 653, PDF Size: 54.59 MB

Page 478 of 653

This chapter will guide you in the proper

loading of your vehicle and/or trailer, to

keep your loaded vehicle weight within its

design rating capability, with or without a

trailer. Properly loading your vehicle will

provide maximum return of the vehicle

design performance. Before loading your

vehicle, familiarize yourself with the fol-

lowing terms for determining your vehi-

cle's weight ratings, with or without a

trailer, from the vehicle's specifications

and the certification label: Base curb weight

This is the weight of the vehicle including a full tank of fuel and all standard equip-

ment. It does not include passengers,

cargo, or optional equipment.

Vehicle curb weight

This is the weight of your new vehicle

when you picked it up from your dealer

plus any aftermarket equipment.

Cargo weight

This figure includes all weight added to

the Base Curb Weight, including cargoand optional equipment.GAW (Gross axle weight)

This is the total weight placed on each

axle (front and rear) - including vehicle

curb weight and all payload.

GAWR (Gross axle weight rating)

This is the maximum allowable weight

that can be carried by a single axle (front

or rear). These numbers are shown on

the certification label.

The total load on each axle must never

exceed its GAWR.

GVW (Gross vehicle weight)

This is the Base Curb Weight plus actual

Cargo Weight plus passengers.

GVWR (Gross vehicle weight rat- ing)

This is the maximum allowable weight of

the fully loaded vehicle (including all

options, equipment, passengers and

cargo). The GVWR is shown on the cer-tification label.

Overloading

VEHICLE WEIGHT

5100

Driving your vehicle

WARNING -

Vehicle weight

The gross axle weight rating

(GAWR) and the gross vehicle

weight rating (GVWR) for your vehi-

cle are on the certification label

attached to the driver's (or front

passenger’s) door. Exceedingthese ratings can cause an acci-

dent or vehicle damage. You can

calculate the weight of your load byweighing the items (and people)

before putting them in the vehicle.

Be careful not to overload your

vehicle.

Page 519 of 653

Maintenance

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Maintenance services . . . . . . . . . . . . . . . . . . . . . . . . 7-7 Owner’s responsibility . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Owner maintenance precautions . . . . . . . . . . . . . . . . 7-7

Engine compartment precautions (Diesel engine). . . 7-8

Owner maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 7-9 Owner maintenance schedule . . . . . . . . . . . . . . . . . . . 7-9

Scheduled maintenance service . . . . . . . . . . . . . . . 7-11 Normal maintenance schedule - for Europe (Except Russia). . . . . . . . . . . . . . . . . . . 7-12

Maintenance under severe usage conditions - for Europe (Except Russia). . . . . . . . . . . . . . . . . . . 7-16

Normal maintenance schedule - except Europe (Including Russia) . . . . . . . . . . . . . 7-18

Maintenance under severe usage conditions - except Europe (Including Russia) . . . . . . . . . . . . . 7-22

Explanation of scheduled maintenance items . . . . 7-24

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27 Checking the engine oil level . . . . . . . . . . . . . . . . . . . . 7-27

Changing the engine oil and filter . . . . . . . . . . . . . . . 7-28

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29 Checking the coolant level . . . . . . . . . . . . . . . . . . . . . . 7-29

Changing the coolant . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Brake/clutch fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32 Checking the brake fluid level . . . . . . . . . . . . . . . . . . 7-32 Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

Checking the washer fluid level . . . . . . . . . . . . . . . . . 7-33

Parking brake - hand type . . . . . . . . . . . . . . . . . . . 7-33 Checking the parking brake . . . . . . . . . . . . . . . . . . . . 7-33

Fuel filter (for Diesel) . . . . . . . . . . . . . . . . . . . . . . . 7-34 Draining water from fuel filter . . . . . . . . . . . . . . . . . . 7-34

Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35 Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

Climate control air filter . . . . . . . . . . . . . . . . . . . . . 7-37 Filter inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

Wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39 Blade inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

Blade replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42 For best battery service . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Battery capacity label . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

Battery recharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

Reset items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Tires and wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45 Tire care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

Recommended cold tire inflation pressures. . . . . . . . 7-45

Checking tire inflation pressure . . . . . . . . . . . . . . . . . 7-47

Tire rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Wheel alignment and tire balance . . . . . . . . . . . . . . . 7-49

7

JD PE eng 7.QXP 03.01.2017 17:16 Page 1

Page 524 of 653

Maintenance

6

7

OJD075101L

❈

The actual engine room in the vehicle may differ from the illustration. 1. Engine oil filler cap

2. Brake/clutch fluid reservoir

3. Positive battery terminal

4. Negative battery terminal

5. Fuse box

6. Air cleaner

7. Radiator cap

8. Engine coolant reservoir

9. Engine oil dipstick

10. Windshield washer fluid reservoir

11. Fuel filter

■■

Diesel engine (UII)

JD PE eng 7.QXP 03.01.2017 17:16 Page 6

Page 533 of 653

715

Maintenance

NORMAL MAINTENANCE SCHEDULE - FOR EUROPE (EXCEPT RUSSIA) (CONT.)

MAINTENANCE INTERVALS

MAINTENANCE ITEM Number of months or driving distance, whichever comes first

Months

244872 96120 144168 192

Kmx1,000

306090 120150 180210 240

Milesx1,000

204060 80100 120140 160

Fuel lines, fuel hoses and connections (Diesel)IIIIIIII

Fuel lines, fuel hoses and connections (Gasoline)IIII

Fuel filler cap (Diesel)IIII

Intercooler, in/out hose, air intake hose (Gasoline T-GDI)Inspect every 15,000 km (10,000 miles)

Manual transaxle fluid (if equipped) * 8IIII

Parking brake (Hand type)IIIIIIII

Spark plugs (Gamma MPI, Nickel)RRRR

Spark plugs (Gamma/Kappa T-GDI ,Iridium)Replace every 75,000 km (50,000 miles) or 60 months

Spark plugs (Gamma GDI, Kappa MPI, Iridium)Replace every 150,000 km (100,000 miles) or 120 months

Steering gear rack, linkage and bootsIIIIIIII

Tire (pressure & tread wear)Inspect every 30,000km(20,000miles) or 12 months

Valve clearance (Gasoline) *11II

Vapor hose and fuel filler cap (Gasoline)IIII

Automatic transaxle fluidNo check, No service required

JD PE eng 7.QXP 03.01.2017 17:17 Page 15

Page 539 of 653

721

Maintenance

NORMAL MAINTENANCE SCHEDULE - EXCEPT EUROPE (INCLUDING RUSSIA) (CONT.)

MAINTENANCE INTERVALS

MAINTENANCE ITEM Number of months or driving distance, whichever comes first

Months

122436 4860 7284 96

Kmx1,000

153045 6075 90105 120

Milesx1,000

102030 4050 6070 80

Fuel filler cap (Diesel) II

Fuel tank air filter (Gasoline, if equipped)IRIR

Fuel lines, fuel hoses and connections (Diesel)IIII

Fuel lines, fuel hoses and connections (Gasoline)II

Intercooler, in/out hose, air intake hose

(Gasoline T-GDI)IIIIIIII

Manual transaxle fluid (if equipped) II

Parking brake (Hand type)IIII

Spark plugs (Gamma MPI, Nickel)RR

Spark plugs (Gamma/Kappa T-GDI ,Iridium) * 5Replace every 75,000 km (50,000 miles) or 60 months

Spark plugs (Gamma GDI, Kappa MPI, Iridium)Replace every 150,000 km (100,000 miles) or 120 months

Steering gear rack, linkage and bootsIIIIIIII

Tire (pressure & tread wear)IIIIIIII

Valve clearance (Gasoline) *6I

Vapor hose and fuel filler cap (Gasoline)II

Automatic transaxle fluidNo check, No service required

ERA-GLONASS system battery (if equipped)Replace every 3 years

JD PE eng 7.QXP 03.01.2017 17:17 Page 21

Page 542 of 653

Maintenance

24

7

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-quent oil and filter changes are required. Drive belts

Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation

and replace if necessary. Drive belts

should be checked periodically for proper

tension and adjusted as necessary.

Fuel filter (cartridge) A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. We recommend that

the fuel filter be replaced by an author-

ized Kia dealer. Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. We

recommend that the fuel lines, fuel hoses

and connections be replaced by an

authorized Kia dealer.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap iscorrectly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

WARNING -

Diesel only

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High pressure pump, rail, injectorsand high pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touch the body.

People using pacemakers should

not move more than 30cm closer tothe ECU or wiring harness within

the engine room while engine is

running, since the high currents in

the Common Rail system produce

considerable magnetic fields.

JD PE eng 7.QXP 03.01.2017 17:17 Page 24

Page 564 of 653

Maintenance

46

7

WARNING - Tire inflation

Overinflation or underinflation

can reduce tire life, adversely

affect vehicle handling, and

lead to sudden tire failure. This

could result in loss of vehicle

control and potential injury.

CAUTION - Tire pressure

Always observe the following:

Check tire pressure when the tires are cold. (After vehiclehas been parked for at leastthree hours or hasn't been driven more than 1.6 km (1mile) since startup.)

Check the pressure of your spare tire each time you checkthe pressure of other tires.

Never overload your vehicle. Be careful not to overload avehicle luggage rack if yourvehicle is equipped with one.

Worn, old tires can cause acci- dents. If your tread is badlyworn, or if your tires have been damaged, replace them.

CAUTION

Underinflation also results in excessive wear, poor handlingand reduced fuel economy.Wheel deformation also ispossible. Keep your tire pres-sures at the proper levels. If a tire frequently needs refilling,we recommend that the sys-tem be checked by an author- ized Kia dealer.

Overinflation produces a harsh ride, excessive wear atthe center of the tire tread, anda greater possibility of dam- age from road hazards.

CAUTION

Warm tires normally exceed recommended cold tire pres-sures by 28 to 41 kPa (4 to 6 psi). Do not release air fromwarm tires to adjust the pres-sure or the tires will be under- inflated.

Be sure to reinstall the tire inflation valve caps. Withoutthe valve cap, dirt or moisturecould get into the valve core and cause air leakage. If avalve cap is missing, install anew one as soon as possible.

JD PE eng 7.QXP 03.01.2017 17:19 Page 46

Page 625 of 653

7107

Maintenance

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Warranty &

Maintenance book in your vehicle.

Your vehicle is equipped with an emis- sion control system to meet all emission

regulations. There are three emission control sys-

tems which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system(3) Exhaust emission control system In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by an author-

ized Kia dealer in accordance with the

maintenance schedule. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability Control

(ESC) system off by pressing the

ESC switch.

After dynamometer testing is com- pleted, turn the ESC system back on

by pressing the ESC switch again.

1. Crankcase emission control system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valveinto the induction system. 2. Evaporative emission control

System

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

Canister

Fuel vapors generated inside the fuel tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.

Purge Control Solenoid Valve (PCSV)

The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant temper-

ature is low during idling, the PCSV clos-

es so that evaporated fuel is not taken

into the engine. After the engine warms-

up during ordinary driving, the PCSV

opens to introduce evaporated fuel to the

engine.

JD PE eng 7.QXP 03.01.2017 17:24 Page 107

Page 637 of 653

89

Specifications & Consumer information

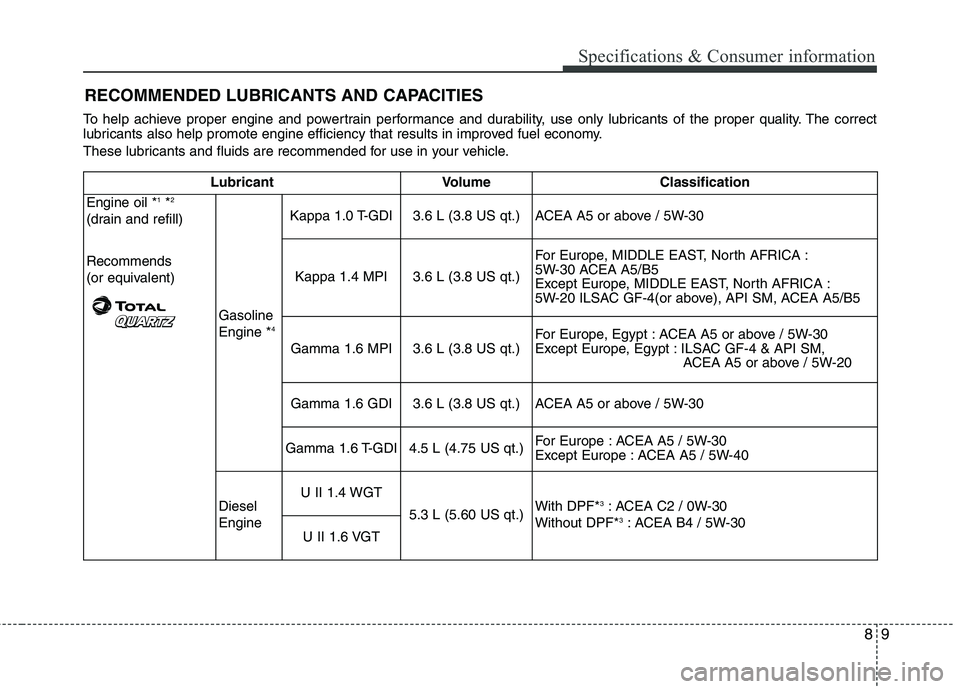

To help achieve proper engine and powertrain performance and durability, use only lubricants of the proper quality. The correct

lubricants also help promote engine efficiency that results in improved fuel economy.

These lubricants and fluids are recommended for use in your vehicle.RECOMMENDED LUBRICANTS AND CAPACITIES

Lubricant Volume Classification

Engine oil * 1

*2

(drain and refill) Recommends

(or equivalent)

GasolineEngine *4Kappa 1.0 T-GDI 3.6 L (3.8 US qt.) ACEA A5 or above / 5W-30

Kappa 1.4 MPI 3.6 L (3.8 US qt.) For Europe, MIDDLE EAST, North AFRICA :

5W-30 ACEA A5/B5

Except Europe, MIDDLE EAST, North AFRICA :

5W-20 ILSAC GF-4(or above), API SM, ACEA A5/B5

Gamma 1.6 MPI 3.6 L (3.8 US qt.) For Europe, Egypt : ACEA A5 or above / 5W-30

Except Europe, Egypt : ILSAC GF-4 & API SM,

ACEA A5 or above / 5W-20

Gamma 1.6 GDI 3.6 L (3.8 US qt.) ACEA A5 or above / 5W-30

Gamma 1.6 T-GDI 4.5 L (4.75 US qt.) For Europe : ACEA A5 / 5W-30

Except Europe : ACEA A5 / 5W-40

Diesel Engine U II 1.4 WGT

5.3 L (5.60 US qt.) With DPF*

3

: ACEA C2 / 0W-30

Without DPF* 3

: ACEA B4 / 5W-30

U II 1.6 VGT