cooling KIA FORTE 2020 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2020, Model line: FORTE, Model: KIA FORTE 2020Pages: 568, PDF Size: 8.58 MB

Page 443 of 568

Maintenance

67

Owner maintenance precau-

tions

Improper or incomplete service may

result in problems. This section gives

instructions only for the maintenance

items that are easy to perform.

As explained earlier in this section,

several procedures can be done only

by an authorized Kia dealer with spe-

cial tools.

✽ ✽NOTICE

Improper owner maintenance dur-

ing the warranty period may affect

warranty coverage. For details, read

the separate Warranty & Consumer

Information manual provided with

the vehicle. If you're unsure about

any servicing or maintenance proce-

dure, have it done by an authorized

Kia dealer.WARNING- Maintenance

work

Do not wear jewelry or loose

clothing while working under

the hood of your vehicle with

the engine running. These can

become entangled in moving

parts. If you must run the

engine while working under the

hood, make certain that you

remove all jewelry (especially

rings, bracelets, watches, and

necklaces) and all neckties,

scarves, and similar loose

clothing before getting near the

engine or cooling fans.

Page 450 of 568

713

Maintenance

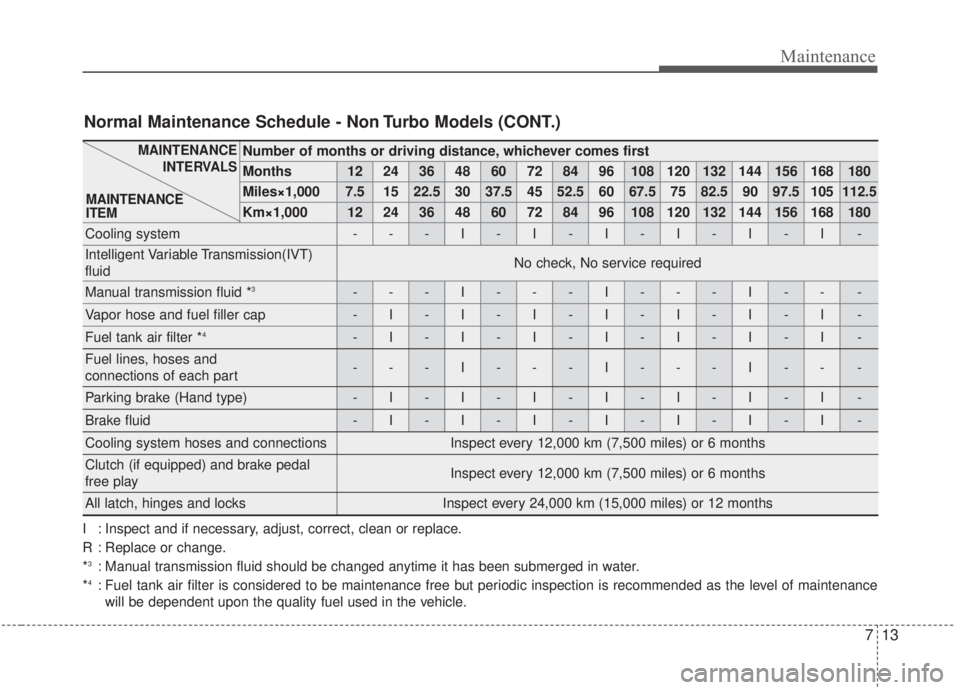

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,0007.51522.530 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5

Km×1,00012 24 36 48 60 72 84 96 108 120 132 144 156 168 180

Cooling system---I-I-I-I-I-I-

Intelligent Variable Transmission(IVT)

fluidNo check, No service required

Manual transmission fluid *3---I---I---I---

Vapor hose and fuel filler cap-I-I-I-I-I-I-I-

Fuel tank air filter *4-I-I-I-I-I-I-I-

Fuel lines, hoses and

connections of each part---I---I---I---

Parking brake (Hand type)-I-I-I-I-I-I-I-

Brake fluid-I-I-I-I-I-I-I-

Cooling system hoses and connectionsInspect every 12,000 km (7,500 miles) or 6 months

Clutch (if equipped) and brake pedal

free playInspect every 12,000 km (7,500 miles) or 6 months

All latch, hinges and locksInspect every 24,000 km (15,000 miles) or 12 months

MAINTENANCEINTERVALS

MAINTENANCE

ITEM

Normal Maintenance Schedule - Non Turbo Models (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

3: Manual transmission fluid should be changed anytime it has been submerged in water.

*4: Fuel tank air filter is considered to be maintenance free but periodic inspection is recommended as the level of maintenance will be dependent upon the quality fuel used in the vehicle.

Page 455 of 568

Maintenance

18

7

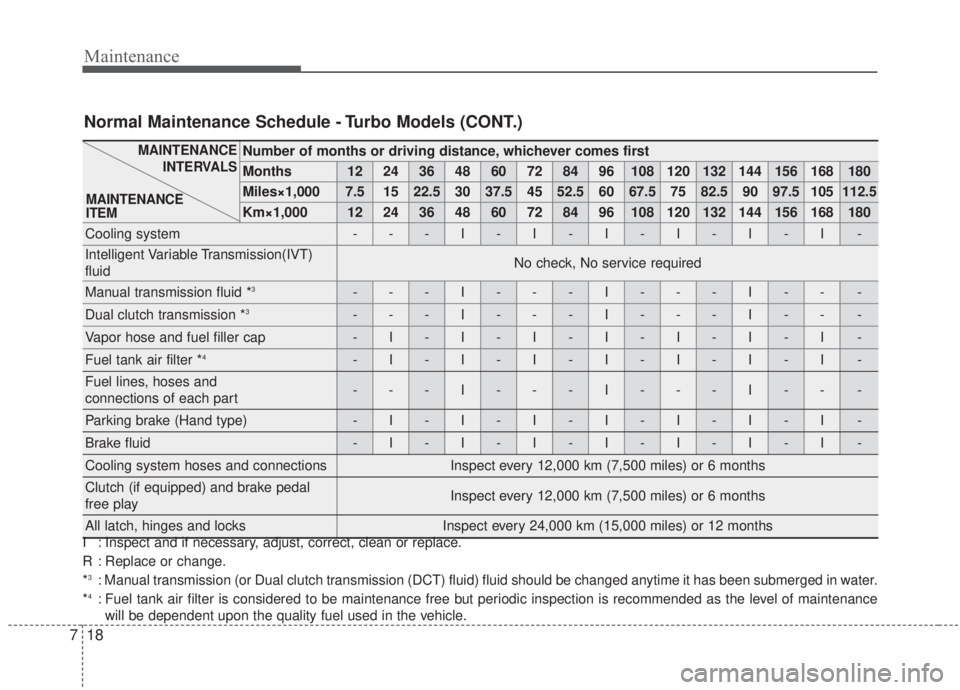

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,0007.51522.530 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5

Km×1,00012 24 36 48 60 72 84 96 108 120 132 144 156 168 180

Cooling system---I-I-I-I-I-I-

Intelligent Variable Transmission(IVT)

fluidNo check, No service required

Manual transmission fluid *3---I---I---I---

Dual clutch transmission *3---I---I---I---

Vapor hose and fuel filler cap-I-I-I-I-I-I-I-

Fuel tank air filter *4-I-I-I-I-I-I-I-

Fuel lines, hoses and

connections of each part---I---I---I---

Parking brake (Hand type)-I-I-I-I-I-I-I-

Brake fluid-I-I-I-I-I-I-I-

Cooling system hoses and connectionsInspect every 12,000 km (7,500 miles) or 6 months

Clutch (if equipped) and brake pedal

free playInspect every 12,000 km (7,500 miles) or 6 months

All latch, hinges and locksInspect every 24,000 km (15,000 miles) or 12 months

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

Normal Maintenance Schedule - Turbo Models (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

3: Manual transmission (or Dual clutch transmission (DCT) fluid) fluid should be changed anytime it has been submerged in water.

*4: Fuel tank air filter is considered to be maintenance free but periodic inspection is recommended as the level of maintenance will be dependent upon the quality fuel used in the vehicle.

Page 459 of 568

Maintenance

22

7

Vacuum crankcase ventilation

hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration.

Pay particular attention to the hose

surfaces nearest to high heat

sources, such as the exhaust mani-

fold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Air cleaner filter

A Genuine Kia air cleaner filter is rec-

ommended when the filter is replaced.

Spark plugs

Make sure to install new spark plugs

of the correct heat range.

Cooling system

Check the cooling system compo-

nents, such as the radiator, coolant

reservoir, hoses and connections for

leakage and damage. Replace any

damaged parts.

Coolant

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Dual clutch transmission fluid

(if equipped)

Inspect the dual clutch transmission

fluid according to the maintenance

schedule.

Intelligent Variable

Transmission (IVT) fluid

The Intelligent Variable Transmission

(IVT) fluid should not be checked

under normal usage conditions.

But in severe conditions, the fluid

should be changed at an authorized

Kia dealer in accordance to the

scheduled maintenance at the begin-

ning of this chapter.

(Refer to the “Maintenance Under

Severe Usage Conditions” section in

Chapter 7.)

✽ ✽

NOTICE

The Intelligent Variable

Transmission (IVT) fluid color is

amber.

As the vehicle is driven, the

Intelligent Variable Transmission

(IVT) fluid will begin to look darker.

This is normal, and you should not

judge the need to replace the fluid

based upon the changed color.

Page 465 of 568

Maintenance

28

7

ENGINE COOLANT

The high-pressure cooling system

has a reservoir filled with year round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level at least once a year: at

the beginning of the winter season,

and before traveling to a colder cli-

mate.Checking the coolant level Turn the engine off and wait until it

cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the cool-

ing system.

When you are sure all the pressure

has been released, press down on

the cap, using a thick towel, and

continue turning counterclockwise

to remove it.

Even if the engine is not operating, do not remove the radiator cap or

the drain plug while the engine and

radiator are hot. Hot coolant and

steam may still blow out under

pressure, causing serious injury.

WARNING

Removing radiator

cap

Never attempt to remove the

radiator cap while the engine is

operating or hot. Doing so

might lead to cooling system

and engine damage and could

result in serious personal injury

from escaping hot coolant or

steam.

Page 466 of 568

729

Maintenance

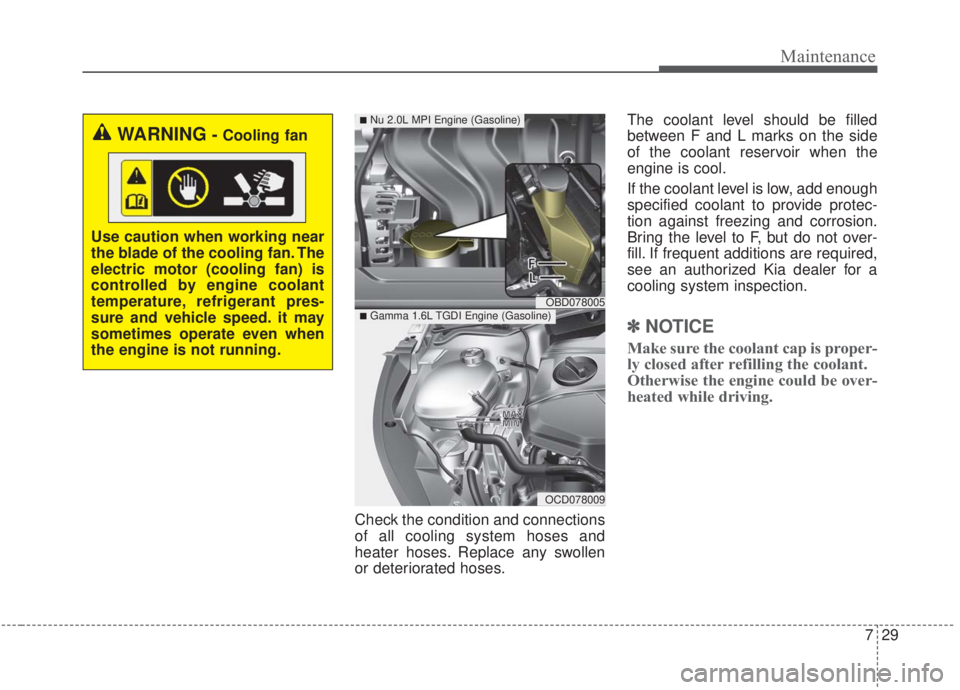

Check the condition and connections

of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses.The coolant level should be filled

between F and L marks on the side

of the coolant reservoir when the

engine is cool.

If the coolant level is low, add enough

specified coolant to provide protec-

tion against freezing and corrosion.

Bring the level to F, but do not over-

fill. If frequent additions are required,

see an authorized Kia dealer for a

cooling system inspection.

✽ ✽

NOTICE

Make sure the coolant cap is proper-

ly closed after refilling the coolant.

Otherwise the engine could be over-

heated while driving.

WARNING- Cooling fan

Use caution when working near

the blade of the cooling fan. The

electric motor (cooling fan) is

controlled by engine coolant

temperature, refrigerant pres-

sure and vehicle speed. it may

sometimes operate even when

the engine is not running.

OBD078005

■Nu 2.0L MPI Engine (Gasoline)

OCD078009

■Gamma 1.6L TGDI Engine (Gasoline)

Page 509 of 568

Maintenance

72

7

Engine room compartment fuse panel

Fuse Name Fuse ratingCircuit Protected

MULTI

FUSE-1ALTERNATOR

200A

(NU 2.0L AKS) 150A

(GAMMA 1.6L T-GDI)

Fuse : BURGLAR ALARM, ABS1, ABS2, POWER OUTLET1, Alternator

MDPS80AMDPS (Motor Driven Power Steering) Unit

MULTI

FUSE-2

B+560AFuse : ECU 3, ECU 4, HORN, WIPER, A/C, Engine Control Relay

B+260AInstrument Panel Junction Block

B+360AInstrument Panel Junction Block

B+450AInstrument Panel Junction Block (Fuse : POWER WINDOW LH, POWER WINDOW RH,

TRUNK, SUNROOF 1, SEAT HEATER FRONT, AMP, POWER SEAT DRIVER)

COOLING FAN 160A[GAMMA 1.6L T-GDI] Cooling Fan 1 Relay

REAR HEATED40ARear Heated Relay

BLOWER40ABLOWER Relay

IG140AIgnition Switch, PDM #2 (ACC) Relay, PDM #3 (IG1) Relay

IG240AIgnition Switch, PDM #4 (IG2) Relay, START Relay

MULTI

FUSE-3PTC HEATER50APTC Heater Relay

Page 510 of 568

![KIA FORTE 2020 User Guide 773

Maintenance

Fuse Name Fuse ratingCircuit Protected

FUSE

POWER OUTLET 220AFront Power Outlet

TCU 115A [GAMMA 1.6L T-GDI] TCM (Transmission Control Module)

VACUUM PUMP20A[GAMMA 1.6L T-GDI] Vacuum P KIA FORTE 2020 User Guide 773

Maintenance

Fuse Name Fuse ratingCircuit Protected

FUSE

POWER OUTLET 220AFront Power Outlet

TCU 115A [GAMMA 1.6L T-GDI] TCM (Transmission Control Module)

VACUUM PUMP20A[GAMMA 1.6L T-GDI] Vacuum P](/img/2/40395/w960_40395-509.png)

773

Maintenance

Fuse Name Fuse ratingCircuit Protected

FUSE

POWER OUTLET 220AFront Power Outlet

TCU 115A [GAMMA 1.6L T-GDI] TCM (Transmission Control Module)

VACUUM PUMP20A[GAMMA 1.6L T-GDI] Vacuum Pump

FUEL PUMP20AFuel Pump Relay

COOLING FAN 230A[NU 2.0L AKS] Cooling Fan 2 Relay, Cooling Fan 3 Relay

B+140AInstrument Panel Junction Block (Long Term Load Latch Relay, Fuse : (BRAKE SWITCH, IBU

1, AIR BAG 2, DOOR LOCK, SEAT HEATER REAR, MODULE 1))

DCT 140A[GAMMA 1.6L T-GDI] TCM (Transmission Control Module)

DCT 240A[GAMMA 1.6L T-GDI] TCM (Transmission Control Module)

ABS 140AABS (Anti-lock brake system) Module, ESC (Electronic Stability Control) Module

ABS 230AABS (Anti-lock brake system) Module, ESC (Electronic Stability Control) Module

POWER OUTLET 140APower Outlet Relay

SENSOR 210A

[NU 2.0L AKS] Purge Control Solenoid Valve, Oil Control Valve #1/#2/#3, Canister Close

Valve, Mass Air Folw Sensor, A/Con Relay, E/R Junction Block (Cooling Fan Relay 1), Variable

Intake Sensor

[GAMMA 1.6L T-GDI] Purge Control Solenoid Valve, Oil Control Valve #1/#2, Canister Close

Valve, RCV Control Solenoid Valve, E/R Junction Block (Cooling Fan Relay 1)

ECU 210A[GAMMA 1.6L T-GDI] ECM (Engine Control Module)

ECU 120A[NU 2.0L AKS] PCM (Power train Control Module)

[GAMMA 1.6L T-GDI] ECM (Engine Control Module)

INJECTOR15A[NU 2.0L AKS] Injector #1~#4

Engine room compartment fuse panel

Page 512 of 568

775

Maintenance

Relay

Relay NameType

COOLING FAN 3 RelayMICRO

COOLING FAN 2 RelayMICRO

PDM 3 (IG1) RelayMICRO

START RelayMICRO

PDM 4 (IG2) RelayMICRO

FUEL PUMP RelayMICRO

PDM 2 (ACC) RelayMICRO

COOLING FAN 1 RelayMINI

BLOWER RelayMINI

PTC HEATER RelayMICRO

REAR HEATED RelayMICRO

POWER OUTLET RelayMICRO

Page 554 of 568

89

Specifications & Consumer information

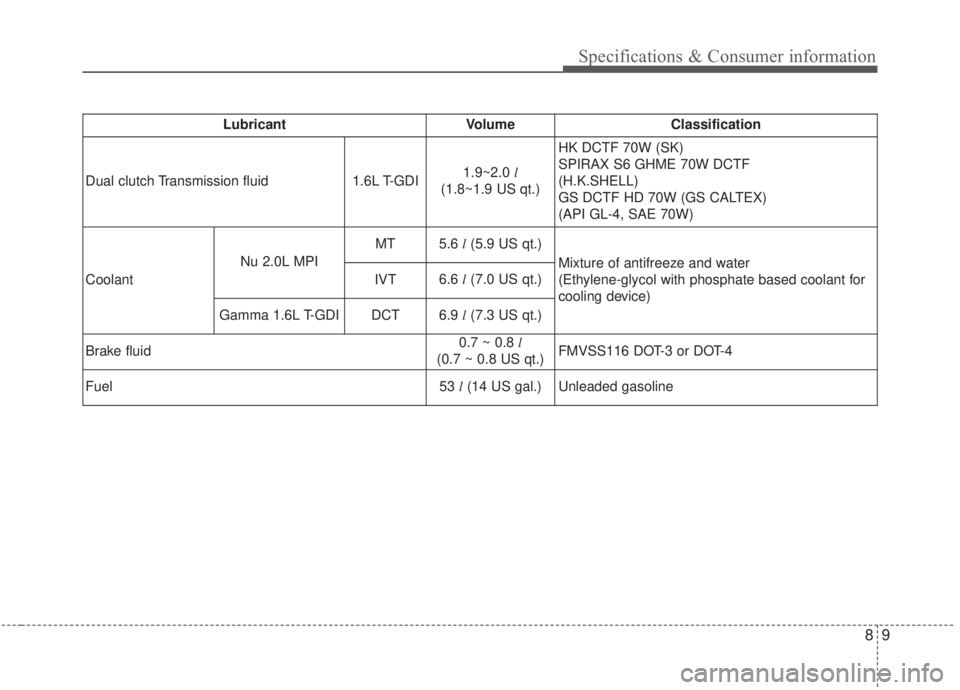

LubricantVolumeClassification

Dual clutch Transmission fluid 1.6L T-GDI

1.9~2.0 l

(1.8~1.9 US qt.) HK DCTF 70W (SK)

SPIRAX S6 GHME 70W DCTF

(H.K.SHELL)

GS DCTF HD 70W (GS CALTEX)

(API GL-4, SAE 70W)

Coolant Nu 2.0L MPIMT

5.6

l(5.9 US qt.)

Mixture of antifreeze and water

(Ethylene-glycol with phosphate based coolant for

cooling device)

IVT

6.6

l(7.0 US qt.)

Gamma 1.6L T-GDI DCT

6.9 l(7.3 US qt.)

Brake fluid

0.7 ~ 0.8 l

(0.7 ~ 0.8 US qt.) FMVSS116 DOT-3 or DOT-4

Fuel53

l(14 US gal.)Unleaded gasoline