brake fluid KIA FORTE 5 2018 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: FORTE 5, Model: KIA FORTE 5 2018Pages: 584, PDF Size: 15.16 MB

Page 488 of 584

Maintenance

26

7

(Continued)

❑ Replace air cleaner filter

❑ Replace engine oil and filter *4

- MPI/GDI Engine

: Every 12,000 km (7,500 miles) or 12 months

❑ Replace coolant

(First, 192,000 km (120,000 miles) or 120 months

after every 48,000 km (30,000 miles) or 24 months)

❑ Add fuel additive *

2

(Every 12,000 km (7,500 miles) or 12 months)

❑ Inspect battery condition

❑ Inspect cooling system hoses and connections

❑ Inspect clutch (if equipped) and brake pedal free paly

❑ Inspect all latch, hinges and locks

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

*

4Engine oil (1.6 TGDI) Replace every 10,000 km (6,500 miles)

or 6 months

NORMAL MAINTENANCE SCHEDULE (CONT.)

240,000 km (150,000 miles) or 120 months

❑ Inspect air conditioning refrigerant

❑ Inspect battery condition

❑ Inspect brake hoses, lines and connections

(including booster)

❑ Inspect dual clutch transmission fluid (if equipped)

❑ Inspect drive belt *

3 (First, 96,000 km (60,000 miles) or 72

months after every 24,000 km (15,000 miles) or 24 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust pipe and muffler

❑ Inspect front disc brake/pads, calipers and rotors

❑ Inspect steering gear box, linkage & boots/lower arm ball

joint, upper arm ball joint

❑ Inspect suspension mounting bolts

❑ Inspect brake/clutch (if equipped) fluid

❑ Inspect fuel lines, fuel hoses and connections

❑ Inspect fuel tank air filter (if equipped) *

1

❑Inspect rear disc brake/pads, parking brake

❑ Inspect fuel tank, fuel filler cap, ceinster, vapor hose

❑ Inspect vacuum hose

❑ Inspect intercooler, in/out hose, air intake hose

- Turbo GDI (Every 12,000 km (7,500 miles) or 12 months)

❑ Inspect manual transaxle fluid (if equipped)

❑ Rotate tires (Every 12,000 km (7,500 miles) or 12 months)

❑ Replace climate control air filter

(for evaporator and blower unit)

(Continued)

No check, No service required

❑ Automatic transaxle fluid (if equipped)

Page 493 of 584

731

Maintenance

Automatic transaxle fluid

(if equipped)

Automatic transaxle fluid should not

be checked under normal usage

conditions.

But in severe conditions, the fluid

should be changed at an authorized

Kia dealer in accordance to the

scheduled maintenance at the begin-

ning of this chapter.

✽ ✽NOTICE

Automatic transaxle fluid color is

basically red.

As the vehicle is driven, the auto-

matic transaxle fluid will begin to

look darker.

It is normal condition and you

should not judge the need to replace

the fluid based upon the changed

color.

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Brake/clutch fluid

Check brake fluid level in the brake

fluid reservoir. The level should be

between “MIN” and “MAX” marks on

the side of the reservoir. Use only

hydraulic brake fluid conforming to

DOT 3 or DOT 4 specification.

Parking brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake discs, pads, calipers

and rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Page 494 of 584

Maintenance

32

7

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Dual clutch transmission Fluid

Inspect the dual clutch transmission

fluid according to the maintenance

schedule.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age. When checking engine oil, engine

coolant, brake fluid, and washer fluid,

always be sure to clean the area

around any filler plug, drain plug, or

dipstick before checking or draining

any lubricant or fluid. This is espe-

cially important in dusty or sandy

areas and when the vehicle is used

on unpaved roads. Cleaning the plug

and dipstick areas will prevent dirt

and grit from entering the engine and

other mechanisms that could be

damaged.

CHECKING FLUID LEVELS

Page 500 of 584

Maintenance

38

7

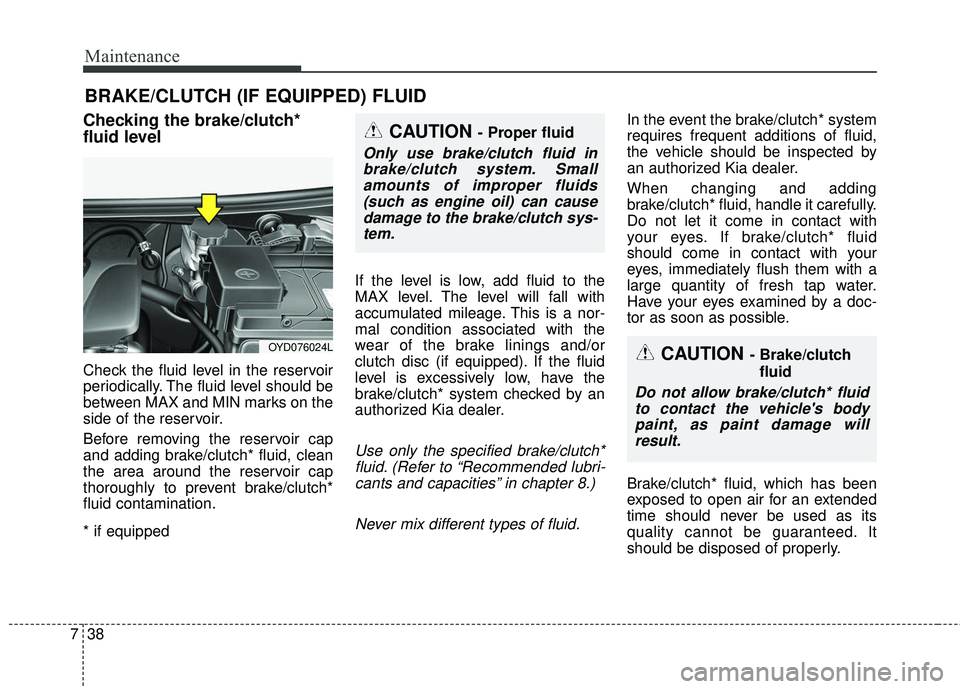

BRAKE/CLUTCH (IF EQUIPPED) FLUID

Checking the brake/clutch*

fluid level

Check the fluid level in the reservoir

periodically. The fluid level should be

between MAX and MIN marks on the

side of the reservoir.

Before removing the reservoir cap

and adding brake/clutch* fluid, clean

the area around the reservoir cap

thoroughly to prevent brake/clutch*

fluid contamination.

* if equipped If the level is low, add fluid to the

MAX level. The level will fall with

accumulated mileage. This is a nor-

mal condition associated with the

wear of the brake linings and/or

clutch disc (if equipped). If the fluid

level is excessively low, have the

brake/clutch* system checked by an

authorized Kia dealer.

Use only the specified brake/clutch*

fluid. (Refer to “Recommended lubri-cants and capacities” in chapter 8.)

Never mix different types of fluid.

In the event the brake/clutch* system

requires frequent additions of fluid,

the vehicle should be inspected by

an authorized Kia dealer.

When changing and adding

brake/clutch* fluid, handle it carefully.

Do not let it come in contact with

your eyes. If brake/clutch* fluid

should come in contact with your

eyes, immediately flush them with a

large quantity of fresh tap water.

Have your eyes examined by a doc-

tor as soon as possible.

Brake/clutch* fluid, which has been

exposed to open air for an extended

time should never be used as its

quality cannot be guaranteed. It

should be disposed of properly.

CAUTION - Brake/clutch fluid

Do not allow brake/clutch* fluidto contact the vehicle's bodypaint, as paint damage willresult.

CAUTION - Proper fluid

Only use brake/clutch fluid inbrake/clutch system. Smallamounts of improper fluids(such as engine oil) can causedamage to the brake/clutch sys-tem.

OYD076024L

Page 501 of 584

739

Maintenance

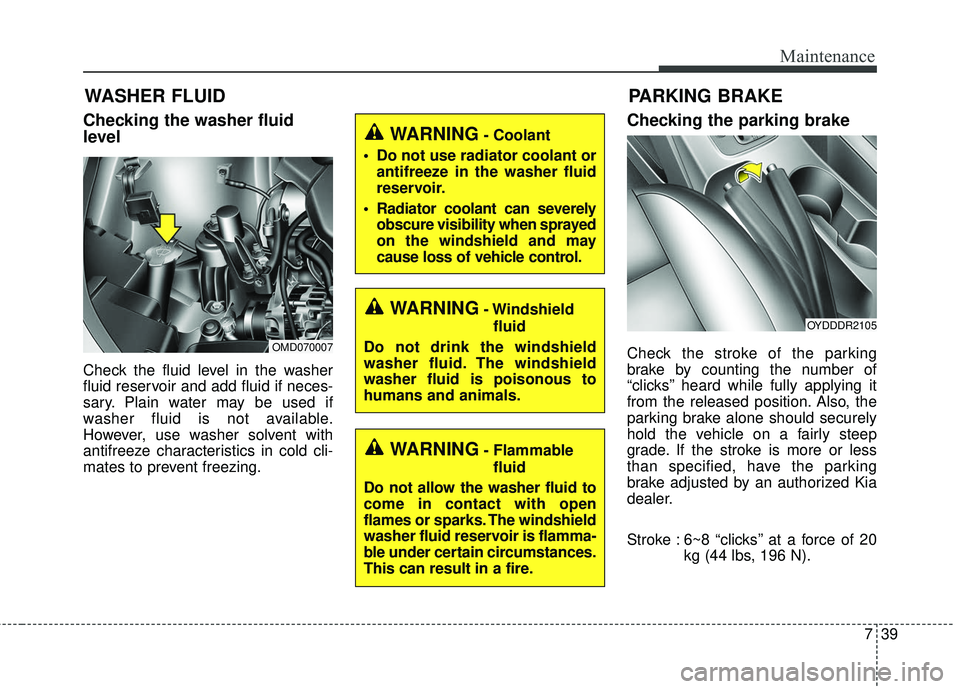

WASHER FLUID

Checking the washer fluid

level

Check the fluid level in the washer

fluid reservoir and add fluid if neces-

sary. Plain water may be used if

washer fluid is not available.

However, use washer solvent with

antifreeze characteristics in cold cli-

mates to prevent freezing.

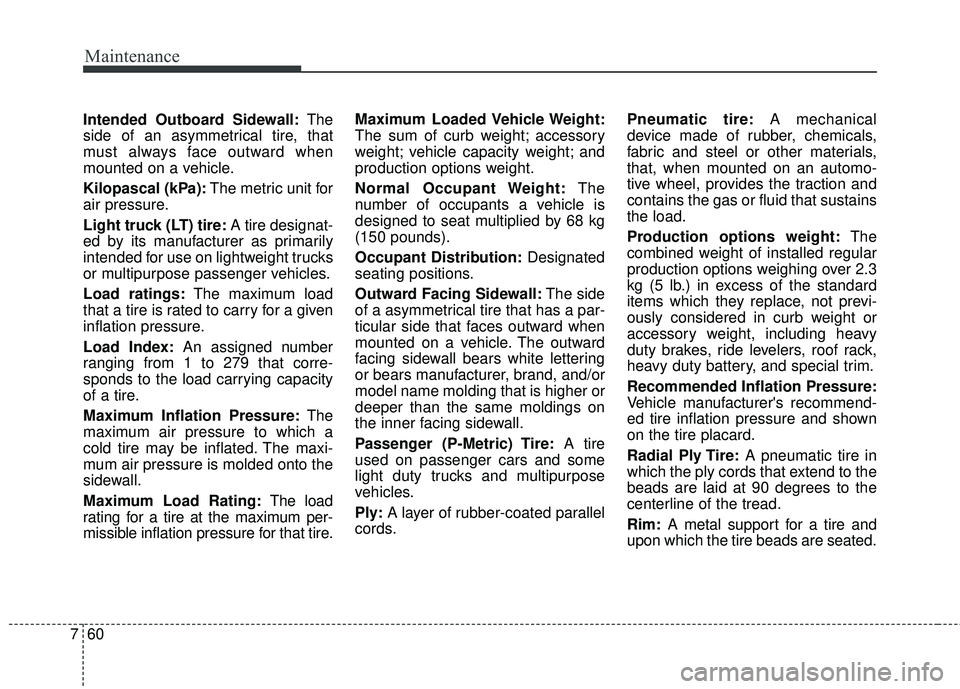

Checking the parking brake

Check the stroke of the parking

brake by counting the number of

“clicks’’ heard while fully applying it

from the released position. Also, the

parking brake alone should securely

hold the vehicle on a fairly steep

grade. If the stroke is more or less

than specified, have the parking

brake adjusted by an authorized Kia

dealer.

Stroke : 6~8 “clicks’’ at a force of 20kg (44 lbs, 196 N).

WARNING- Windshield

fluid

Do not drink the windshield

washer fluid. The windshield

washer fluid is poisonous to

humans and animals.

WARNING- Coolant

Do not use radiator coolant or antifreeze in the washer fluid

reservoir.

Radiator coolant can severely obscure visibility when sprayed

on the windshield and may

cause loss of vehicle control.

WARNING- Flammable

fluid

Do not allow the washer fluid to

come in contact with open

flames or sparks. The windshield

washer fluid reservoir is flamma-

ble under certain circumstances.

This can result in a fire.

OMD070007

OYDDDR2105

PARKING BRAKE

Page 522 of 584

Maintenance

60

7

Intended Outboard Sidewall: The

side of an asymmetrical tire, that

must always face outward when

mounted on a vehicle.

Kilopascal (kPa): The metric unit for

air pressure.

Light truck (LT) tire: A tire designat-

ed by its manufacturer as primarily

intended for use on lightweight trucks

or multipurpose passenger vehicles.

Load ratings: The maximum load

that a tire is rated to carry for a given

inflation pressure.

Load Index: An assigned number

ranging from 1 to 279 that corre-

sponds to the load carrying capacity

of a tire.

Maximum Inflation Pressure: The

maximum air pressure to which a

cold tire may be inflated. The maxi-

mum air pressure is molded onto the

sidewall.

Maximum Load Rating: The load

rating for a tire at the maximum per-

missible inflation pressure for that tire. Maximum Loaded Vehicle Weight:

The sum of curb weight; accessory

weight; vehicle capacity weight; and

production options weight.

Normal Occupant Weight:

The

number of occupants a vehicle is

designed to seat multiplied by 68 kg

(150 pounds).

Occupant Distribution: Designated

seating positions.

Outward Facing Sidewall: The side

of a asymmetrical tire that has a par-

ticular side that faces outward when

mounted on a vehicle. The outward

facing sidewall bears white lettering

or bears manufacturer, brand, and/or

model name molding that is higher or

deeper than the same moldings on

the inner facing sidewall.

Passenger (P-Metric) Tire: A tire

used on passenger cars and some

light duty trucks and multipurpose

vehicles.

Ply: A layer of rubber-coated parallel

cords. Pneumatic tire:

A mechanical

device made of rubber, chemicals,

fabric and steel or other materials,

that, when mounted on an automo-

tive wheel, provides the traction and

contains the gas or fluid that sustains

the load.

Production options weight: The

combined weight of installed regular

production options weighing over 2.3

kg (5 lb.) in excess of the standard

items which they replace, not previ-

ously considered in curb weight or

accessory weight, including heavy

duty brakes, ride levelers, roof rack,

heavy duty battery, and special trim.

Recommended Inflation Pressure:

Vehicle manufacturer's recommend-

ed tire inflation pressure and shown

on the tire placard.

Radial Ply Tire: A pneumatic tire in

which the ply cords that extend to the

beads are laid at 90 degrees to the

centerline of the tread.

Rim: A metal support for a tire and

upon which the tire beads are seated.

Page 557 of 584

795

Maintenance

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major

repair expense.

✽ ✽NOTICE

If your vehicle is damaged and

requires any metal repair or

replacement, be sure the body shop

applies anti-corrosion materials to

the parts repaired or replaced.

Bright-metal maintenance

To remove road tar and insects,

use a tar remover, not a scraper or

other sharp object.

To protect the surfaces of bright- metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

Underbody maintenance

Road salt and other corrosive chemi-

cals are used in cold weather states to

melt snow and prevent ice accumula-

tion. If these chemicals are not regu-

larly removed, they will corrode the

vehicle underbody and over time dam-

age fuel lines, the fuel tank retention

system, the vehicle suspension, the

exhaust system, and even the body

frame. The National Highway Traffic

Safety Administration has warned all

vehicle owners of all brands of the

need to take the following steps:

Wash the undercarriage of yourvehicle regularly during the winter

and whenever your vehicle has

been exposed to such salts or

chemicals.

Do a thorough washing of the undercarriage at the end of the

winter.

Use professional service techni- cians or governmental inspection

stations to annually inspect for cor-

rosion. Immediately seek an inspection of

your vehicle if you become visually

aware of corrosion flaking or scal-

ing or if you become aware of a

change in vehicle performance,

such as soft or spongey brakes,

fluids leaking, impairment of direc-

tional control, suspension noises

or rattling metal straps.

Aluminum wheel maintenance

The aluminum wheels are coated with

a clear protective finish.

Do not use any abrasive cleaner, pol-ishing compound, solvent, or wire

brushes on aluminum wheels. They

may scratch or damage the finish.

Clean the wheel when it has cooled.

Use only a mild soap or neutral deter- gent, and rinse thoroughly with water.

Also, be sure to clean the wheels

after driving on salted roads. This

helps prevent corrosion.

Avoid washing the wheels with high- speed car wash brushes.

Do not use any alkaline or acid deter- gent. It may damage and corrode the

aluminum wheels coated with a clear

protective finish.

Page 572 of 584

88

Specifications & Consumer information

*1Refer to the recommended SAE viscosity numbers on the next page.

*2Engine oils labeled Energy Conserving Oil are now available. Along with other additional benefits, they contribute to fuel econ-

omy by reducing the amount of fuel necessary to overcome engine friction. Often, these improvements are difficult to measure

in everyday driving, but in a year’s time, they can offer significant cost and energy savings.

*

3If the API service SM engine oil is not available in your country, you are able to use API service SL.

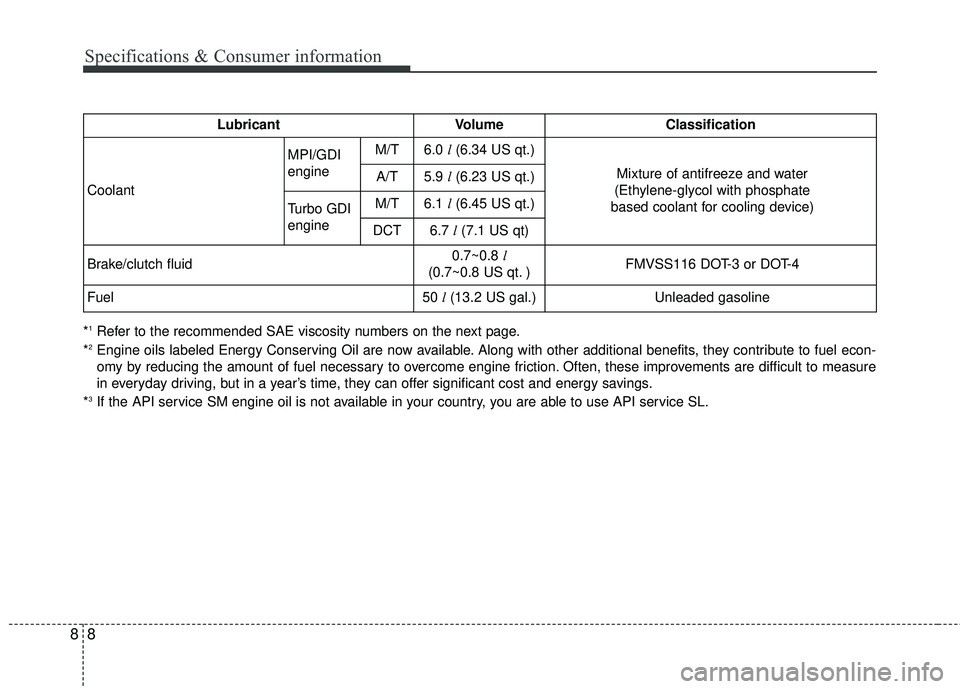

LubricantVolumeClassification

Coolant

MPI/GDI

engineM/T6.0 l(6.34 US qt.)

Mixture of antifreeze and water

(Ethylene-glycol with phosphate

based coolant for cooling device)A/T5.9 l(6.23 US qt.)

Turbo GDI

engineM/T6.1 l(6.45 US qt.)

DCT6.7 l(7.1 US qt)

Brake/clutch fluid0.7~0.8 l

(0.7~0.8 US qt. )FMVSS116 DOT-3 or DOT-4

Fuel50 l(13.2 US gal.)Unleaded gasoline

Page 578 of 584

I3

Index

BSD (Blind Spot Detection) /LCA (Lane Change Assist) . . . . . . . . . . . . . . . . . . . 5-75

Limitations condition . . . . . . . . . . . . . . . . . . . . . . . . 5-79

RCTA (Rear Cross Traffic Alert) . . . . . . . . . . . . . . . 5-78

Brake system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34 Anti-lock brake system (ABS) . . . . . . . . . . . . . . . . . 5-37

Electronic stability control (ESC) . . . . . . . . . . . . . . 5-39

Good braking practices . . . . . . . . . . . . . . . . . . . . . . . 5-45

Hill-start assist control (HAC) . . . . . . . . . . . . . . . . . 5-43

Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

Power brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

Vehicle stability management (VSM) . . . . . . . . . . . 5-43

Brake/clutch fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38 Checking the brake/clutch* fluid level . . . . . . . . . . . 7-38

Bulb wattage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Checking fluid levels. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Child restraint system . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27 Using a child restraint system . . . . . . . . . . . . . . . . . 3-28

Clean air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-\

132

Climate control air filter . . . . . . . . . . . . . . . . . . . . . . . . 7-42 Filter inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Cruise Control system . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58 Cruise control switch . . . . . . . . . . . . . . . . . . . . . . . . 5-58

To cancel cruise control . . . . . . . . . . . . . . . . . . . . . . 5-61 To decrease the cruising speed: . . . . . . . . . . . . . . . . 5-60

To increase cruise control set speed: . . . . . . . . . . . . 5-60

To resume cruising speed at more than approximately 40 km/h (25 mph) . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

To set cruise control speed: . . . . . . . . . . . . . . . . . . . 5-59

To temporarily accelerate with the cruise control on . . 5-60

To turn cruise control off . . . . . . . . . . . . . . . . . . . . . 5-62

Defroster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-\

108 Front wiper deicer. . . . . . . . . . . . . . . . . . . . . . . . . . 4-108

Rear window defroster . . . . . . . . . . . . . . . . . . . . . . 4-108

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-\

2

Door locks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-\

17 Auto door lock/unlock feature . . . . . . . . . . . . . . . . . 4-20

Child-protector rear door lock . . . . . . . . . . . . . . . . . 4-21

Impact sensing door unlock system . . . . . . . . . . . . . 4-20

Operating door locks from inside the vehicle . . . . . 4-18

Operating door locks from outside the vehicle . . . . 4-17

Speed sensing door lock system . . . . . . . . . . . . . . . . 4-20

Drive mode integrated control system . . . . . . . . . . . . . 5-63 DRIVE mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

Dual Clutch Transmission (DCT) . . . . . . . . . . . . . . . . . 5-24 Dual clutch transmission operation . . . . . . . . . . . . . 5-24

Paddle shifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Good driving practices . . . . . . . . . . . . . . . . . . . . . . . 5-32

C

D

YDM CAN (ENG) Index.qxp 9/11/2017 12:44 PM Page 3

Page 584 of 584

I9

Index

GAWR (Gross axle weight rating) . . . . . . . . . . . . . . 5-96

GVW (Gross vehicle weight) . . . . . . . . . . . . . . . . . . 5-96

GVWR (Gross vehicle weight rating) . . . . . . . . . . . 5-96

Vehicle curb weight . . . . . . . . . . . . . . . . . . . . . . . . . 5-96

Warning and indicator lights . . . . . . . . . . . . . . . . . . . . . 4-80 Indicator Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-88

Warning lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-80

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39 Checking the washer fluid level . . . . . . . . . . . . . . . . 7-39

Weight/volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Welcome system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-107 Headlamp welcome . . . . . . . . . . . . . . . . . . . . . . . . 4-107

Interior light welcome . . . . . . . . . . . . . . . . . . . . . . 4-107

Puddle lamp and pocket lamp . . . . . . . . . . . . . . . . 4-107

Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

4-31 Power windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Windshield defrosting and defogging . . . . . . . . . . . . . 4-129 Automatic climate control system . . . . . . . . . . . . . 4-130

Defogging logic . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-131

Manual climate control system . . . . . . . . . . . . . . . . 4-129

Winter driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-88 Carry emergency equipment . . . . . . . . . . . . . . . . . . . 5-90

Change to "winter weight" oil if necessary . . . . . . . 5-89

Check battery and cables . . . . . . . . . . . . . . . . . . . . . 5-89

Check spark plugs and ignition system . . . . . . . . . . 5-89 Don't let ice and snow accumulate underneath . . . . 5-90

Don't let your parking brake freeze . . . . . . . . . . . . . 5-90

Snowy or Icy conditions . . . . . . . . . . . . . . . . . . . . . . 5-88

To keep locks from freezing . . . . . . . . . . . . . . . . . . . 5-89

Use approved window washer anti-freeze in system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-89

Use high quality ethylene glycol coolant . . . . . . . . . 5-89

Wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44 Blade inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Blade replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Wipers and washers . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-100 Rear window wiper and washer switch (5 Door) . . 4-102

Windshield washers (front). . . . . . . . . . . . . . . . . . . 4-101

Windshield wipers . . . . . . . . . . . . . . . . . . . . . . . . . 4-100

W

YDM CAN (ENG) Index.qxp 9/11/2017 12:44 PM Page 9