engine coolant KIA K900 2019 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2019, Model line: K900, Model: KIA K900 2019Pages: 580, PDF Size: 15.11 MB

Page 433 of 580

67

What to do in an emergency

IF THE ENGINE OVERHEATS

If your temperature gauge indicates

overheating, you experience a loss

of power, or hear loud pinging or

knocking, the engine will probably be

too hot. If this happens, you should:

1.Pull off the road and stop as soonas it is safe to do so.

2.Place the shift lever in P and set the parking brake. If the air condi-

tioning is on, turn it off.

3.If engine coolant is running out under the vehicle or steam is com-

ing out from underneath the hood,

stop the engine. Do not open the

hood until the coolant has stopped

running or the steaming has

stopped. If there is no visible loss

of engine coolant and no steam,

leave the engine running and

check to be sure the engine cool-

ing fan is operating. If the fan is not

running, turn the engine off. 4.Check to see if the water pump

drive belt is missing. If it is not

missing, check to see that it is

tight. If the drive belt seems to be

satisfactory, check for coolant leak-

ing from the radiator, hoses or

under the vehicle. (If the air condi-

tioning had been in use, it is nor-

mal for cold water to be draining

from it when you stop).

5.If the water pump drive belt is bro- ken or engine coolant is leaking

out, stop the engine immediately

and call the nearest authorized

K900 Kia dealer for assistance. 6.If you cannot find the cause of the

overheating, wait until the engine

temperature has returned to nor-

mal. If coolant has been lost, care-

fully add coolant to the reservoir to

bring the fluid level in the reservoir

up to the halfway mark.

7.Proceed with caution, keeping alert for further signs of overheat-

ing. If overheating happens again,

call an authorized K900 Kia dealer

for assistance.

Serious loss of coolant indicates

there is a leak in the cooling system

and this should be checked as soon

as possible by an authorized K900

Kia dealer.

WARNING - Under the hood

While the engine is running, keep hair,

hands and clothing

away from moving

parts such as the fan

and drive belts to pre-

vent injury.

WARNING - Radiator cap

Do not remove the

radiator cap when the

engine is hot. This may

result in coolant being

blown out of the open-

ing and cause serious

burns.

Page 455 of 580

Maintenance

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Maintenance services . . . . . . . . . . . . . . . . . . . . . . . . 7-5

• Owner’s responsibility . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

• Owner maintenance precautions . . . . . . . . . . . . . . . . . 7-6

Owner maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

• Owner maintenance schedule . . . . . . . . . . . . . . . . . . . 7-8

Scheduled maintenance service. . . . . . . . . . . . . . . 7-10

Explanation of scheduled maintenance items . . . 7-17

• Engine oil and filter. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

• Drive belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17\

• Fuel filter (for gasoline) . . . . . . . . . . . . . . . . . . . . . . . 7-17

• Fuel lines, fuel hoses and connections . . . . . . . . . . . . 7-17

• Vapor hose and fuel filler cap . . . . . . . . . . . . . . . . . . 7-17

• Vacuum crankcase ventilation hoses . . . . . . . . . . . . . 7-18

• Air cleaner filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

• Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

• Valve clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

• Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

• Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. 7-18

• Automatic transmission fluid . . . . . . . . . . . . . . . . . . . 7-18

• Brake hoses and lines . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

• Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19\

• Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

• Brake discs, pads, calipers and rotors. . . . . . . . . . . . 7-20• Exhaust pipe and muffler . . . . . . . . . . . . . . . . . . . . . . 7-20

• Suspension mounting bolts . . . . . . . . . . . . . . . . . . . . . 7-20

• Steering gear box, linkage &

boots/lower arm ball joint . . . . . . . . . . . . . . . . . . . . 7-20

• Drive shafts and boots. . . . . . . . . . . . . . . . . . . . . . . . . 7-20

• Air conditioning refrigerant . . . . . . . . . . . . . . . . . . . 7-20

Checking fluid levels . . . . . . . . . . . . . . . . . . . . . . . 7-20

Engine oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

• Checking the engine oil level . . . . . . . . . . . . . . . . . . . 7-21

• Changing the engine oil and filter . . . . . . . . . . . . . . . 7-22

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

• Checking the coolant level . . . . . . . . . . . . . . . . . . . . . 7-23

• Changing the coolant . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

• Checking the brake fluid level . . . . . . . . . . . . . . . . . . 7-26

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

• Checking the washer fluid level . . . . . . . . . . . . . . . . . 7-27

Air cleaner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

• Replace the filter according to the Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-\

28

Climate control air filter . . . . . . . . . . . . . . . . . . . . 7-29

• Filter inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

• Blade inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

• Blade replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

7

Page 458 of 580

Maintenance

47

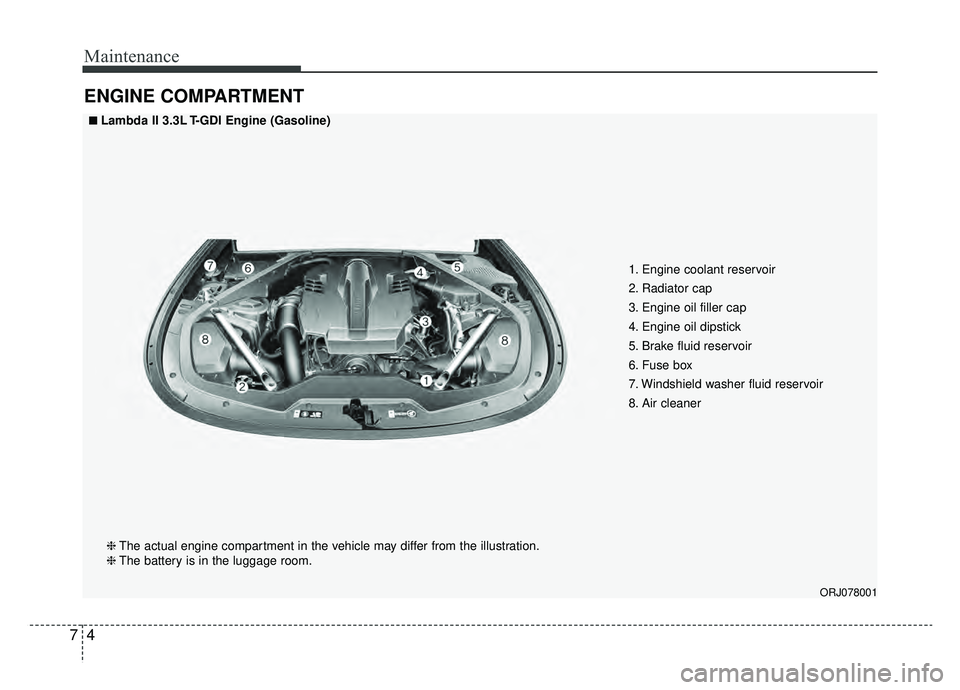

ENGINE COMPARTMENT

ORJ078001

■ ■Lambda II 3.3L T-GDI Engine (Gasoline)❈ The actual engine compartment in the vehicle may differ from the illustration.

❈ The battery is in the luggage room. 1. Engine coolant reservoir

2. Radiator cap

3. Engine oil filler cap

4. Engine oil dipstick

5. Brake fluid reservoir

6. Fuse box

7. Windshield washer fluid reservoir

8. Air cleaner

Page 462 of 580

Maintenance

87

OWNER MAINTENANCE

The following lists are vehicle checks

and inspections that should be per-

formed by the owner or an author-

ized K900 Kia dealer at the frequen-

cies indicated to help ensure safe,

dependable operation of your vehi-

cle.

Any adverse conditions should be

brought to the attention of your deal-

er as soon as possible.

These Owner Maintenance Checks

are generally not covered by war-

ranties and you may be charged for

labor, parts and lubricants used.Owner maintenance schedule

When you stop for fuel:

Check the engine oil level.

Check the coolant level in coolantreservoir.

Check the windshield washer fluid level.

Look for low or under-inflated tires.

While operating your vehicle:

Note any changes in the sound of the exhaust or any smell of

exhaust fumes in the vehicle.

Check for vibrations in the steering wheel. Notice any increased steer-

ing effort or looseness in the steer-

ing wheel, or change in its straight-

ahead position.

Notice if your vehicle constantly turns slightly or “pulls” to one side

when traveling on smooth, level

road.

When stopping, listen and check for unusual sounds, pulling to one

side, increased brake pedal travel

or “hard-to-push” brake pedal.

If any slipping or changes in the operation of your transmission

occurs, check the transmission

fluid level.

Check the automatic transmission P (Park) function.

Check the parking brake.

Check for fluid leaks under your vehicle (water dripping from the air

conditioning system during or after

use is normal).

WARNING- Hot coolant

Be careful when checking your

engine coolant level when the

engine is hot. Scalding hot

coolant and steam may blow

out under pressure.

Page 463 of 580

79

Maintenance

At least monthly:

Check the coolant level in theengine coolant reservoir.

Check the operation of all exterior lights, including the stoplights, turn

signals and hazard warning flash-

ers.

Check the inflation pressures of all tires including the spare.

At least twice a year

(i.e., every Spring and Fall) :

Check the radiator, heater and air conditioning hoses for leaks or

damage.

Check the windshield washer spray and wiper operation. Clean

the wiper blades with clean cloth

dampened with washer fluid.

Check the headlight alignment.

Check the muffler, exhaust pipes, shields and clamps.

Check the lap/shoulder belts for wear and function.

Check for worn tires and loose wheel lug nuts.

At least once a year :

Clean the body and door drainholes.

Lubricate the door hinges and check the hood hinges.

Lubricate the door and hood locks and latches.

Lubricate the door rubber weather- strips.

Check the air conditioning system.

Inspect and lubricate automatic transmission linkage and controls.

Clean the battery and terminals.

Check the brake fluid level.

Page 466 of 580

Maintenance

12

7

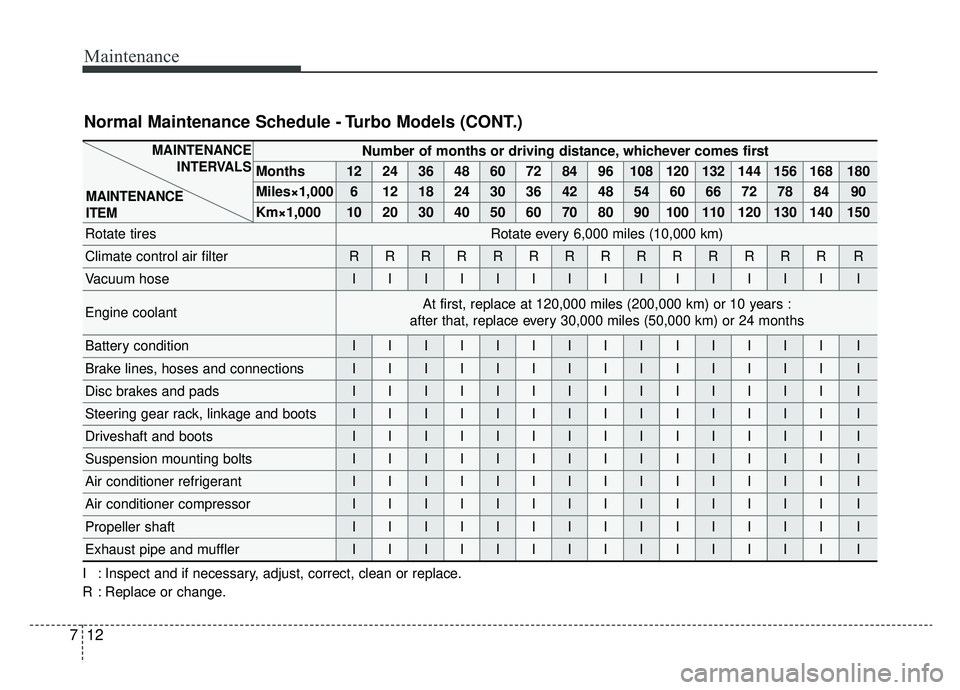

Normal Maintenance Schedule - Turbo Models (CONT.)

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,00061218243036424854606672788490

Km×1,000102030405060708090100110120130140150

Rotate tiresRotate every 6,000 miles (10,000 km)

Climate control air filterRRRRRRRRRRRRRRR

Vacuum hoseIIIIIIIIIIIIIII

Engine coolantAt first, replace at 120,000 miles (200,000 km) or 10 years :

after that, replace every 30,000 miles (50,000 km) or 24 months

Battery conditionIIIIIIIIIIIIIII

Brake lines, hoses and connectionsIIIIIIIIIIIIIII

Disc brakes and padsIIIIIIIIIIIIIII

Steering gear rack, linkage and bootsIIIIIIIIIIIIIII

Driveshaft and bootsIIIIIIIIIIIIIII

Suspension mounting boltsIIIIIIIIIIIIIII

Air conditioner refrigerantIIIIIIIIIIIIIII

Air conditioner compressorIIIIIIIIIIIIIII

Propeller shaftIIIIIIIIIIIIIII

Exhaust pipe and mufflerIIIIIIIIIIIIIII

MAINTENANCE INTERVALS

MAINTENANCE

ITEM

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

Page 472 of 580

Maintenance

18

7

Vacuum crankcase ventilation

hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration.

Pay particular attention to the hose

surfaces nearest to high heat

sources, such as the exhaust mani-

fold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Air cleaner filter

A Genuine Kia air cleaner filter is rec-

ommended when the filter is replaced.

Spark plugs

Make sure to install new spark plugs

of the correct heat range.

Valve clearance (if equipped)

Inspect for excessive valve noise

and/or engine vibration and adjust if

necessary. An authorized K900 Kia

dealer should perform this procedure.

Cooling system

Check the cooling system compo-

nents, such as the radiator, coolant

reservoir, hoses and connections for

leakage and damage. Replace any

damaged parts.

Coolant

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Automatic transmission fluid

Automatic transmission fluid should

not be checked under normal usage

conditions.

But in severe conditions, the fluid

should be changed at an authorized

K900 Kia dealer in accordance to the

scheduled maintenance at the begin-

ning of this chapter.

✽ ✽

NOTICE

Automatic transmission fluid color

is usually red.

As the vehicle is driven, the auto-

matic transmission fluid will begin

to look darker.

This is normal, and you should not

judge the need to replace the fluid

based upon the changed color.

Page 474 of 580

Maintenance

20

7

Parking brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake discs, pads, calipers

and rotors

Check the pads and discs for exces-

sive wear and calipers for fluid leak-

age.

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and damage. When checking engine oil, engine

coolant, brake fluid, and washer fluid,

always be sure to clean the area

around any filler plug, drain plug, or

dipstick before checking or draining

any lubricant or fluid. This is espe-

cially important in dusty or sandy

areas and when the vehicle is used

on unpaved roads. Cleaning the plug

and dipstick areas will prevent dirt

and grit from entering the engine and

other mechanisms that could be

damaged.

CHECKING FLUID LEVELS

Page 477 of 580

723

Maintenance

ENGINE COOLANT

The high-pressure cooling system

has a reservoir filled with year round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level at least once a year: at

the beginning of the winter season,

and before traveling to a colder cli-

mate.Checking the coolant level Turn the engine off and wait until itcools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the cool-

ing system.

When you are sure all the pressure

has been released, press down on

the cap, using a thick towel, and

continue turning counterclockwise

to remove it.

Even if the engine is not operating, do not remove the radiator cap or

the drain plug while the engine and

radiator are hot. Hot coolant and

steam may still blow out under

pressure, causing serious injury.

WARNING

Removing radiator

cap

Never attempt to remove the

radiator cap while the engine is

operating or hot. Doing so

might lead to cooling system

and engine damage and could

result in serious bodily injury

from escaping hot coolant or

steam.

Page 478 of 580

Maintenance

24

7

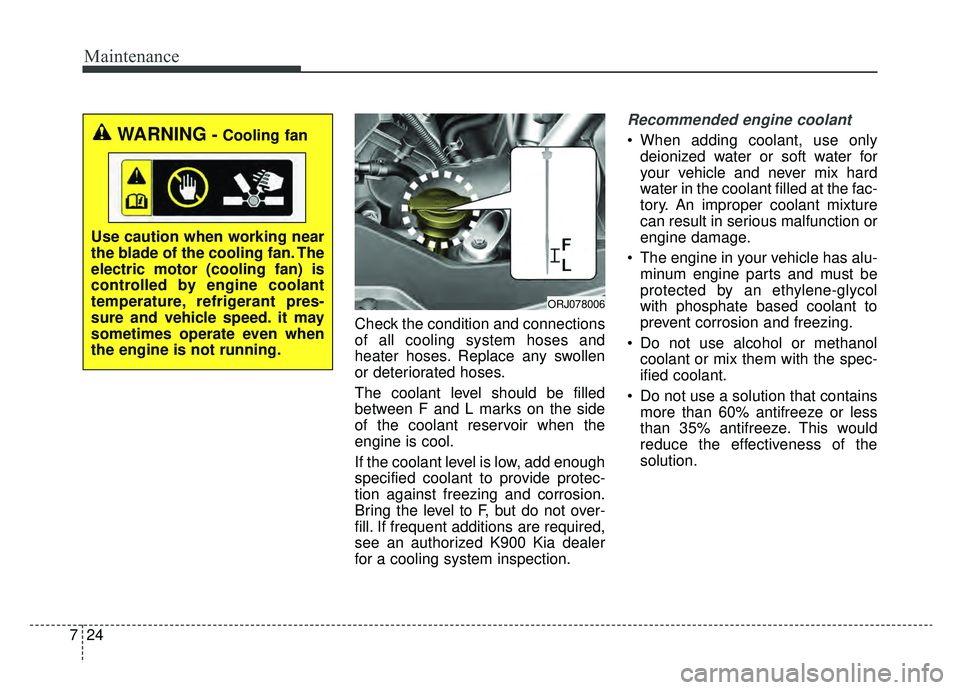

Check the condition and connections

of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses.

The coolant level should be filled

between F and L marks on the side

of the coolant reservoir when the

engine is cool.

If the coolant level is low, add enough

specified coolant to provide protec-

tion against freezing and corrosion.

Bring the level to F, but do not over-

fill. If frequent additions are required,

see an authorized K900 Kia dealer

for a cooling system inspection.

Recommended engine coolant

When adding coolant, use only

deionized water or soft water for

your vehicle and never mix hard

water in the coolant filled at the fac-

tory. An improper coolant mixture

can result in serious malfunction or

engine damage.

The engine in your vehicle has alu- minum engine parts and must be

protected by an ethylene-glycol

with phosphate based coolant to

prevent corrosion and freezing.

Do not use alcohol or methanol coolant or mix them with the spec-

ified coolant.

Do not use a solution that contains more than 60% antifreeze or less

than 35% antifreeze. This would

reduce the effectiveness of the

solution.

ORJ078006

WARNING- Cooling fan

Use caution when working near

the blade of the cooling fan. The

electric motor (cooling fan) is

controlled by engine coolant

temperature, refrigerant pres-

sure and vehicle speed. it may

sometimes operate even when

the engine is not running.