engine coolant KIA Magnetis 2006 2.G User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2006, Model line: Magnetis, Model: KIA Magnetis 2006 2.GPages: 225, PDF Size: 3.77 MB

Page 184 of 225

MAINTENANCE

7-8OWNER MAINTENANCEOWNER MAINTENANCE

SCHEDULEA qualified service technician should

perform these vehicle inspections at the

indicated intervals to ensure safe and

dependable operation.

Bring any problem to the attention of an

Authorized Kia Dealer as soon as

possible.WHEN REFUELING, CHECK:• Engine oil level

• Engine coolant level

• Brake and clutch fluid level

• Washer fluid level

AT LEAST MONTHLY• Tire inflation pressuresEVERY 6 MONTHS, CHECK:• Power steering fluid level

• Automatic transaxle fluid level

You can do the following scheduled

maintenance items if you have some

mechanical ability, a few basic tools and

if you closely follow the directions in

this manual.OWNER MAINTENANCE

PRECAUTIONSImproper or incomplete service may

result in problems. This section gives

instructions only for the maintenance

items that are easy to perform.As explained earlier in this section, several

procedures can be done only by a qualified

service technician with special tools.

Improper owner maintenance during the

warranty period may affect warranty

coverage. For details, read the separate

Kia Warranty and Consumer Information

Manual provided with the vehicle. If

you’re unsure about any servicing or

maintenance procedure, have it done by

an Authorized Kia Dealer.

CAUTION

Be careful when checking your

engine coolant level. The engine

compartment will be hot and you

could be burned.

WARNING - Maintenance

Work

Performing maintenance work

on a vehicle can be dangerous.

You can be seriously injured

while performing some

maintenance procedures. If you

lack sufficient knowledge,

experience or the proper tools

and equipment to do the work,

have it done by a qualified

technician.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 8

Page 186 of 225

MAINTENANCE

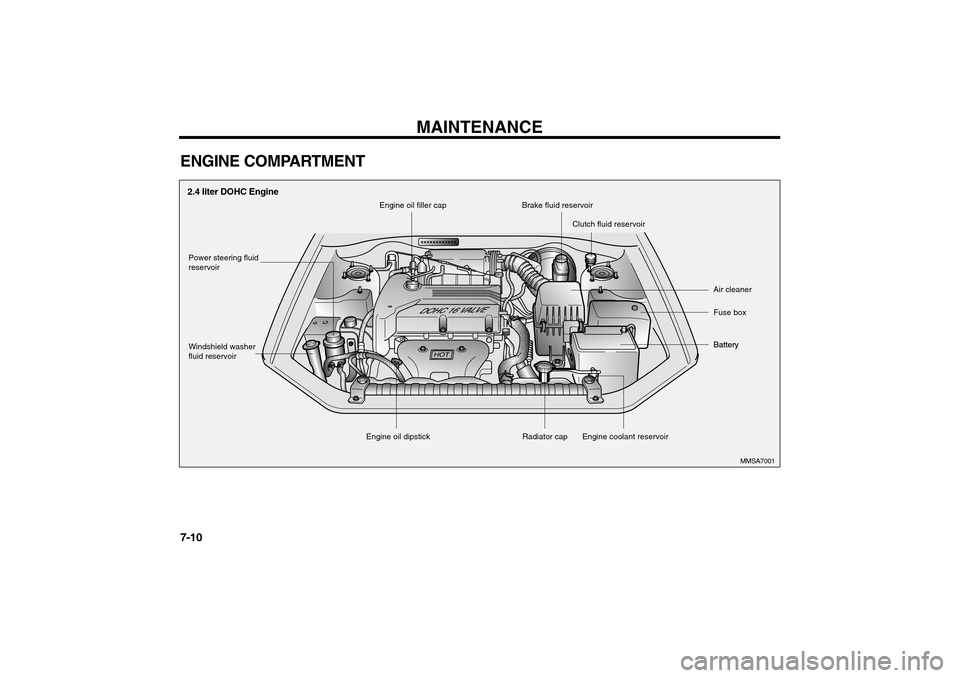

7-10ENGINE COMPARTMENT

MMSA7001

Air cleaner

Fuse box

Battery Battery

Windshield washer

fluid reservoir Power steering fluid

reservoirBrake fluid reservoir

Clutch fluid reservoir

Engine coolant reservoir Radiator cap Engine oil filler cap

Engine oil dipstick

2.4 liter DOHC Engine

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 10

Page 187 of 225

7-11

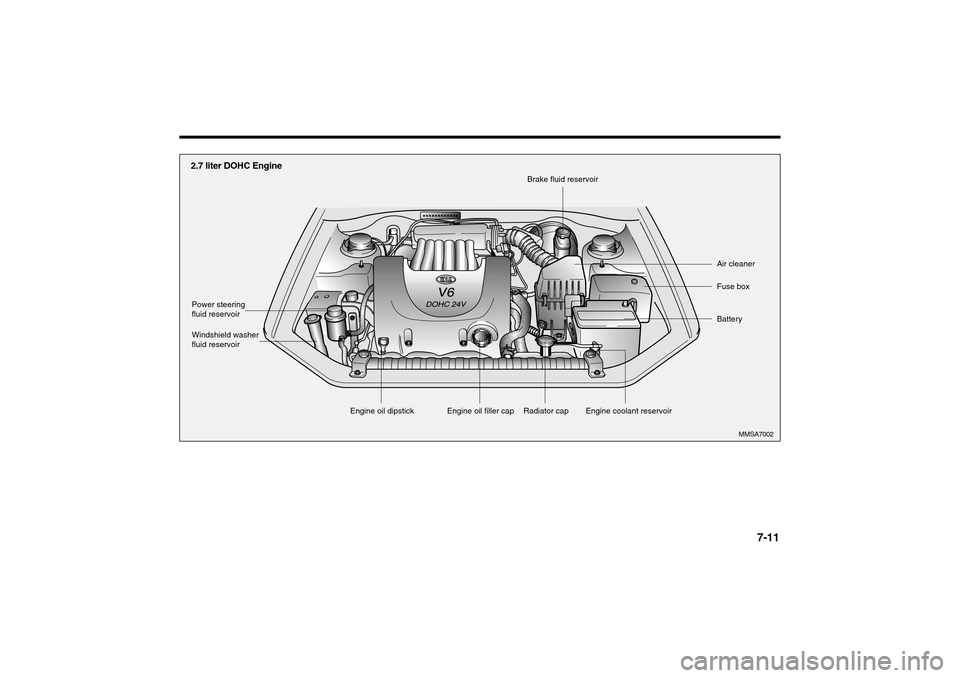

MMSA7002

2.7 liter DOHC Engine

Air cleaner

Fuse box

Battery

Windshield washer

fluid reservoir Power steering

fluid reservoirBrake fluid reservoir

Engine coolant reservoir Radiator cap Engine oil dipstick

Engine oil filler cap

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 11

Page 190 of 225

MAINTENANCE

7-14ENGINE COOLING

SYSTEMThe cooling system is a high-pressure

type with a reservoir and is filled with

year-round antifreeze coolant at the

factory.

Check the antifreeze protection and

coolant level at least once a year, at the

beginning of the winter season, and

before traveling to a colder climate.

CHECKING THE

COOLANT LEVEL

WARNING - Removing

Radiator Cap

Never attempt to remove the

radiator cap while the engine

is operating. Doing so might

lead to cooling system

and/or engine damage and

could result in serious

personal injury from

escaping hot coolant or

steam.

Turn the engine off and wait

until it has cooled. Even then,

use extreme care when

removing the radiator cap.

Wrap a thick towel around it,

and turn it counterclockwise

slowly to the first stop. Step

back while the pressure is

released from the cooling

system. When you are sure

all the pressure has been

released, press down on the

cap, using a thick towel, and

continue turning

counterclockwise to remove

it.

Even if the engine is not

operating, do not remove the

radiator cap or the drain plug

while the engine and radiator

are hot. Hot coolant and

steam may still blow out

under pressure, causing

serious injury.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 14

Page 191 of 225

7-15

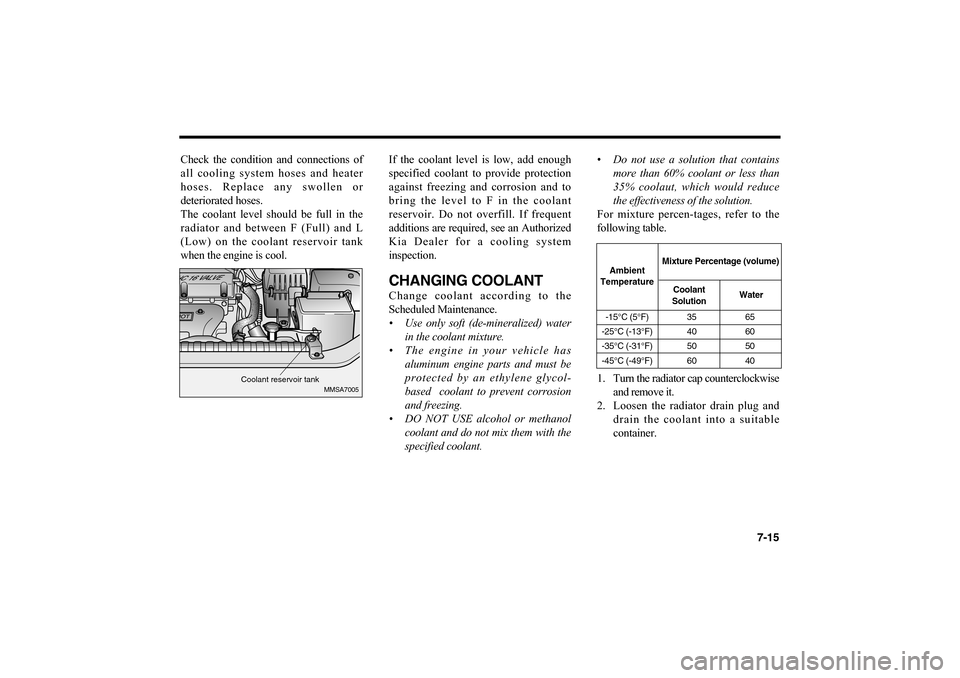

Check the condition and connections of

all cooling system hoses and heater

hoses. Replace any swollen or

deteriorated hoses.

The coolant level should be full in the

radiator and between F (Full) and L

(Low) on the coolant reservoir tank

when the engine is cool.If the coolant level is low, add enough

specified coolant to provide protection

against freezing and corrosion and to

bring the level to F in the coolant

reservoir. Do not overfill. If frequent

additions are required, see an Authorized

Kia Dealer for a cooling system

inspection.

CHANGING COOLANTChange coolant according to the

Scheduled Maintenance.

• Use only soft (de-mineralized) water

in the coolant mixture.

• The engine in your vehicle has

aluminum engine parts and must be

protected by an ethylene glycol-

based coolant to prevent corrosion

and freezing.

• DO NOT USE alcohol or methanol

coolant and do not mix them with the

specified coolant.•Do not use a solution that contains

more than 60% coolant or less than

35% coolaut, which would reduce

the effectiveness of the solution.

For mixture percen-tages, refer to the

following table.

1. Turn the radiator cap counterclockwise

and remove it.

2. Loosen the radiator drain plug and

drain the coolant into a suitable

container.

MMSA7005

Coolant reservoir tank

-15°C (5°F) 35 65

-25°C (-13°F) 40 60

-35°C (-31°F) 50 50

-45°C (-49°F) 60 40Ambient

TemperatureMixture Percentage (volume)

Coolant

SolutionWater

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 15

Page 192 of 225

MAINTENANCE

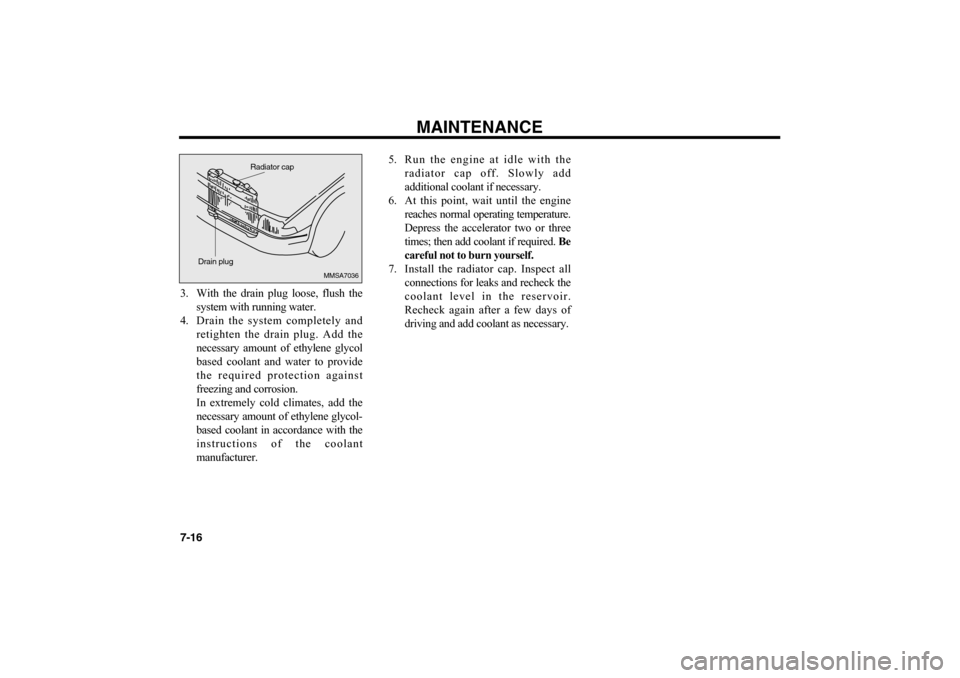

7-163. With the drain plug loose, flush the

system with running water.

4. Drain the system completely and

retighten the drain plug. Add the

necessary amount of ethylene glycol

based coolant and water to provide

the required protection against

freezing and corrosion.

In extremely cold climates, add the

necessary amount of ethylene glycol-

based coolant in accordance with the

instructions of the coolant

manufacturer.5. Run the engine at idle with the

radiator cap off. Slowly add

additional coolant if necessary.

6. At this point, wait until the engine

reaches normal operating temperature.

Depress the accelerator two or three

times; then add coolant if required. Be

careful not to burn yourself.

7. Install the radiator cap. Inspect all

connections for leaks and recheck the

coolant level in the reservoir.

Recheck again after a few days of

driving and add coolant as necessary.

MMSA7036

Drain plugRadiator cap

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 16

Page 197 of 225

7-21

BODY LUBRICATIONAll moving points of the body, such as

doors, hood hinges and locks, should be

lubricated each time the engine oil is

changed.

Use a non-freezing lubricant on locks

during cold weather.

Make sure the engine hood secondary

latch keeps the hood from opening when

the primary latch is released.

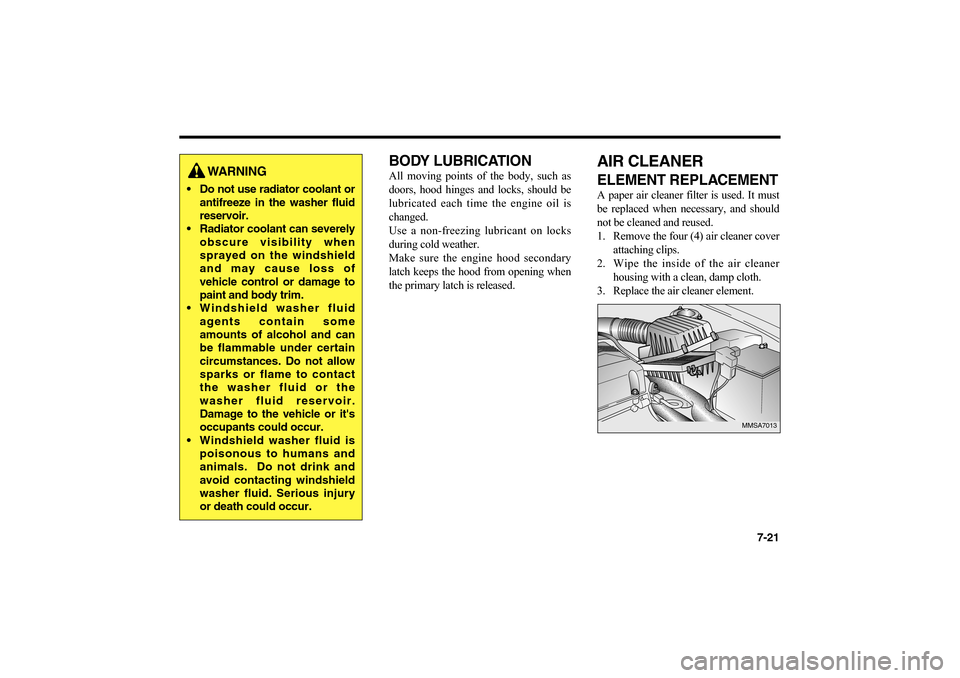

AIR CLEANERELEMENT REPLACEMENTA paper air cleaner filter is used. It must

be replaced when necessary, and should

not be cleaned and reused.

1. Remove the four (4) air cleaner cover

attaching clips.

2. Wipe the inside of the air cleaner

housing with a clean, damp cloth.

3. Replace the air cleaner element.

MMSA7013

WARNING

Do not use radiator coolant or

antifreeze in the washer fluid

reservoir.

Radiator coolant can severely

obscure visibility when

sprayed on the windshield

and may cause loss of

vehicle control or damage to

paint and body trim.

Windshield washer fluid

agents contain some

amounts of alcohol and can

be flammable under certain

circumstances. Do not allow

sparks or flame to contact

the washer fluid or the

washer fluid reservoir.

Damage to the vehicle or it's

occupants could occur.

Windshield washer fluid is

poisonous to humans and

animals. Do not drink and

avoid contacting windshield

washer fluid. Serious injury

or death could occur.

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 21

Page 218 of 225

MAINTENANCE

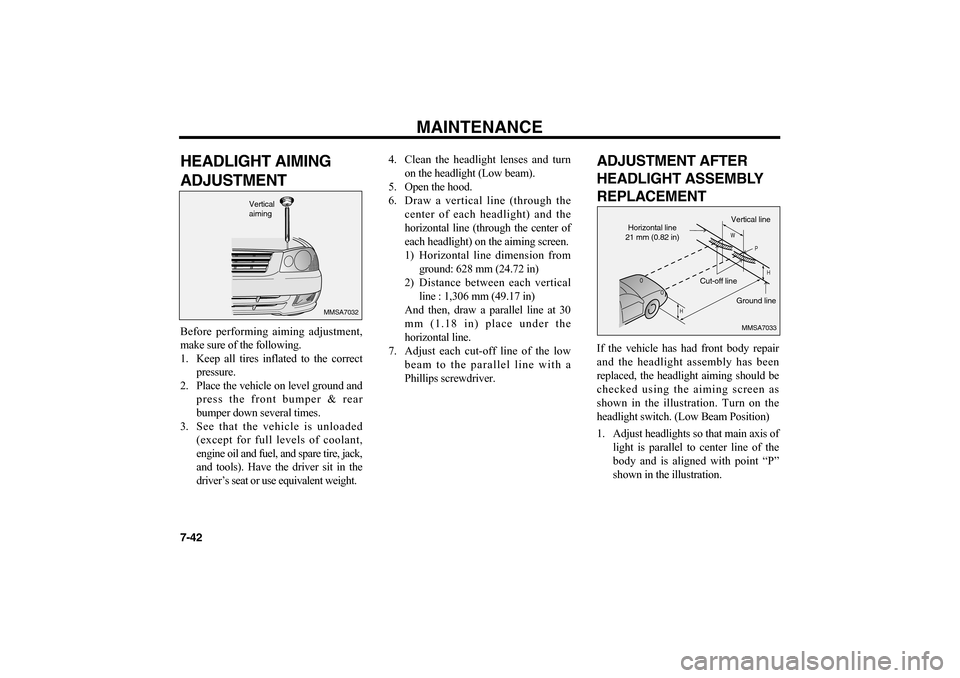

7-42HEADLIGHT AIMING

ADJUSTMENTBefore performing aiming adjustment,

make sure of the following.

1. Keep all tires inflated to the correct

pressure.

2. Place the vehicle on level ground and

press the front bumper & rear

bumper down several times.

3. See that the vehicle is unloaded

(except for full levels of coolant,

engine oil and fuel, and spare tire, jack,

and tools). Have the driver sit in the

driver’s seat or use equivalent weight.4. Clean the headlight lenses and turn

on the headlight (Low beam).

5. Open the hood.

6. Draw a vertical line (through the

center of each headlight) and the

horizontal line (through the center of

each headlight) on the aiming screen.

1) Horizontal line dimension from

ground: 628 mm (24.72 in)

2) Distance between each vertical

line : 1,306 mm (49.17 in)

And then, draw a parallel line at 30

mm (1.18 in) place under the

horizontal line.

7. Adjust each cut-off line of the low

beam to the parallel line with a

Phillips screwdriver.

ADJUSTMENT AFTER

HEADLIGHT ASSEMBLY

REPLACEMENTIf the vehicle has had front body repair

and the headlight assembly has been

replaced, the headlight aiming should be

checked using the aiming screen as

shown in the illustration. Turn on the

headlight switch. (Low Beam Position)

1. Adjust headlights so that main axis of

light is parallel to center line of the

body and is aligned with point “P”

shown in the illustration.

MMSA7032

Vertical

aiming

HH W

P

MMSA7033

Horizontal line

21 mm (0.82 in)

Cut-off line

Ground line Vertical line

MS-CNA-Eng 7.QXD 7/25/2005 5:09 PM Page 42

Page 223 of 225

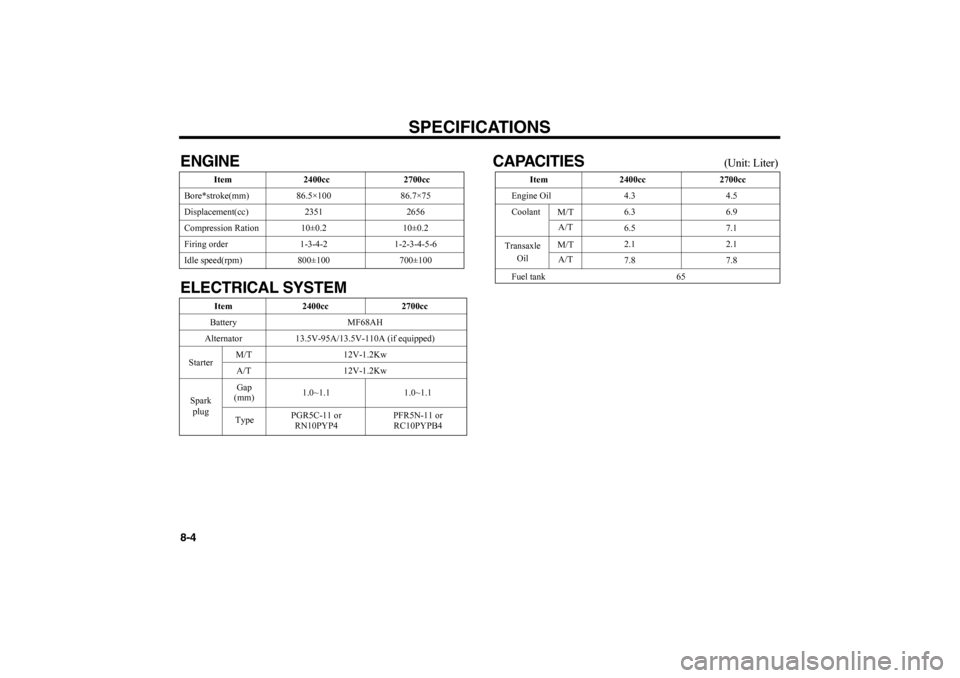

ENGINE

ELECTRICAL SYSTEMCAPACITIES

(Unit: Liter)

SPECIFICATIONS

8-4

Item 2400cc 2700cc

Battery MF68AH

Alternator 13.5V-95A/13.5V-110A (if equipped)

M/T 12V-1.2Kw

A/T 12V-1.2Kw

1.0~1.1 1.0~1.1

PGR5C-11 or PFR5N-11 or

RN10PYP4 RC10PYPB4 Starter

Gap

(mm)

Type Spark

plugItem 2400cc 2700cc

Bore*stroke(mm) 86.5×100 86.7×75

Displacement(cc) 2351 2656

Compression Ration 10±0.2 10±0.2

Firing order 1-3-4-2 1-2-3-4-5-6

Idle speed(rpm) 800±100 700±100

Item 2400cc 2700cc

Engine Oil 4.3 4.5

Coolant 6.3 6.9

6.5 7.1

2.1 2.1

7.8 7.8

Fuel tank 65

Transaxle

OilM/T

A/T

M/T

A/T

MS-CNA-Eng 8.QXD 7/25/2005 5:07 PM Page 4