Start KIA NIRO 2018 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: NIRO, Model: KIA NIRO 2018Pages: 616, PDF Size: 18.3 MB

Page 490 of 616

821

Maintenance

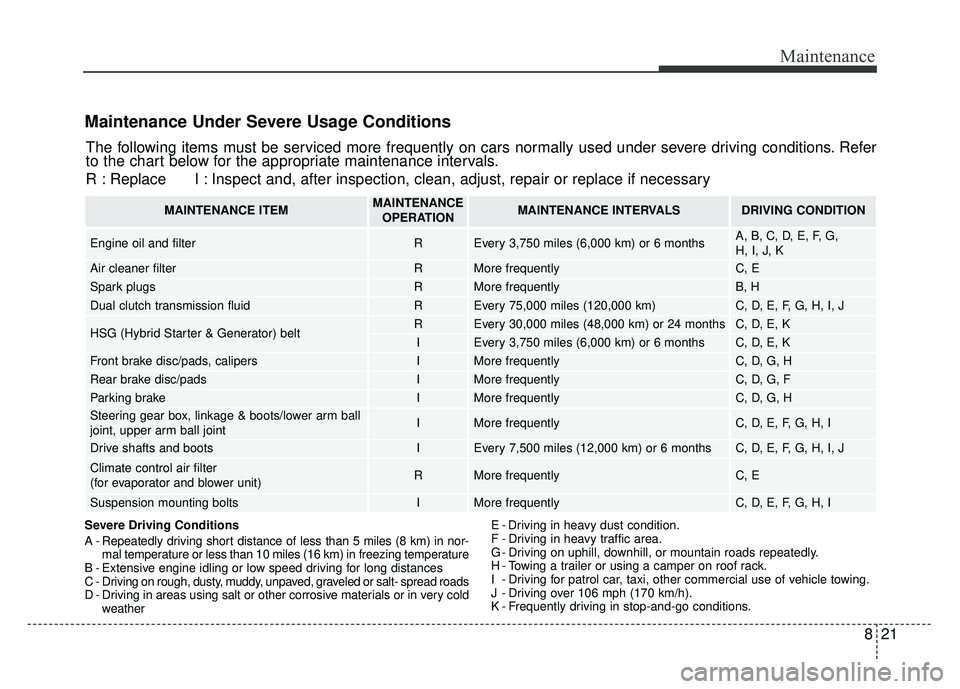

Maintenance Under Severe Usage Conditions

Severe Driving Conditions

A - Repeatedly driving short distance of less than 5 miles (8 km) in nor-mal temperature or less than 10 miles (16 km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather E - Driving in heavy dust condition.

F - Driving in heavy traffic area.

G - Driving on uphill, downhill, or mountain roads repeatedly.

H - Towing a trailer or using a camper on roof rack.

I - Driving for patrol car, taxi, other commercial use of vehicle towing.

J - Driving over 106 mph (170 km/h).

K - Frequently driving in stop-and-go conditions.

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer

to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if neces\

sary

MAINTENANCE ITEMMAINTENANCE

OPERATIONMAINTENANCE INTERVALSDRIVING CONDITION

Engine oil and filter REvery 3,750 miles (6,000 km) or 6 monthsA, B, C, D, E, F, G,

H, I, J, K

Air cleaner filterRMore frequentlyC, E

Spark plugsRMore frequentlyB, H

Dual clutch transmission fluid REvery 75,000 miles (120,000 km)C, D, E, F, G, H, I, J

HSG (Hybrid Starter & Generator) beltREvery 30,000 miles (48,000 km) or 24 monthsC, D, E, K

IEvery 3,750 miles (6,000 km) or 6 monthsC, D, E, K

Front brake disc/pads, calipersIMore frequentlyC, D, G, H

Rear brake disc/padsIMore frequentlyC, D, G, F

Parking brakeIMore frequentlyC, D, G, H

Steering gear box, linkage & boots/lower arm ball

joint, upper arm ball jointIMore frequentlyC, D, E, F, G, H, I

Drive shafts and bootsIEvery 7,500 miles (12,000 km) or 6 monthsC, D, E, F, G, H, I, J

Climate control air filter

(for evaporator and blower unit)RMore frequentlyC, E

Suspension mounting boltsIMore frequentlyC, D, E, F, G, H, I

Page 491 of 616

Maintenance

22

8

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the

vehicle is being driven in severe con-

ditions, more frequent oil and filter

changes are required.

HSG (Hybrid starter & genera-

tor) belt

The HSG belt should be changed at

the intervals specified in the mainte-

nance schedule.

Fuel filter (for gasoline)

Kia gasoline vehicle is equipped a

lifetime fuel filter that integrated with

the fuel tank. Regular maintenance

or replacement is not needed but

depends on fuel quality. If there are

some important safety matters like

fuel flow restriction, surging, loss of

power, hard starting problem etc, fuel

filter inspection or replace is needed.

The fuel filter be Inspected or

replaced by an authorized Kia dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized Kia dealer

replace any damaged or leaking

parts immediately.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-

rectly replaced.

Page 493 of 616

Maintenance

24

8

✽

✽

NOTICE - NHTSA Safety

Corrosion Alert

NHTSA has warned all vehicle own-

ers of all brands that they must main-

tain their vehicles in a manner which

will prevent brake hose and brake line

failures due to corrosion when such

vehicles are exposed to winter road

salt and related chemicals. While seri-

ous corrosion conditions typically only

manifest themselves as safety issues

after 7 years of vehicle use, the corro-

sion process starts immediately and

thus underbody cleaning maintenance

must commence from your vehicle's

first exposure to road salts and chem-

icals. NHTSA urges vehicle owners to

take the following steps to prevent

corrosion:

(Continued)(Continued)

1. Wash the undercarriage of your

vehicle regularly throughout the

winter and do a thorough washing

in the spring to remove road salt

and other de-icing chemicals.

2. Monitor the brake system for signs of corrosion by having regu-

lar professional inspections and

watching for signs of problems,

including loss of brake fluid,

unusual leaks and soft or spongy

feel in the brake pedal.

3. Replace the entire brake pipe assembly if you find severe corro-

sion that causes scaling or flaking

of brake components.

Brake fluid

Check the brake fluid level in the

brake fluid reservoir. The level should

be between “MIN” and “MAX” marks

on the side of the reservoir. Use only

hydraulic brake fluid conforming to

DOT 3 or DOT 4 specification.

Parking brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake discs, pads, calipers

and rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Page 494 of 616

825

Maintenance

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.When checking engine oil, engine

coolant, brake fluid, and washer fluid,

always be sure to clean the area

around any filler plug, drain plug, or

dipstick before checking or draining

any lubricant or fluid. This is espe-

cially important in dusty or sandy

areas and when the vehicle is used

on unpaved roads. Cleaning the plug

and dipstick areas will prevent dirt

and grit from entering the engine and

other mechanisms that could be

damaged.

CHECKING FLUID LEVELS

Page 495 of 616

Maintenance

26

8

ENGINE OIL

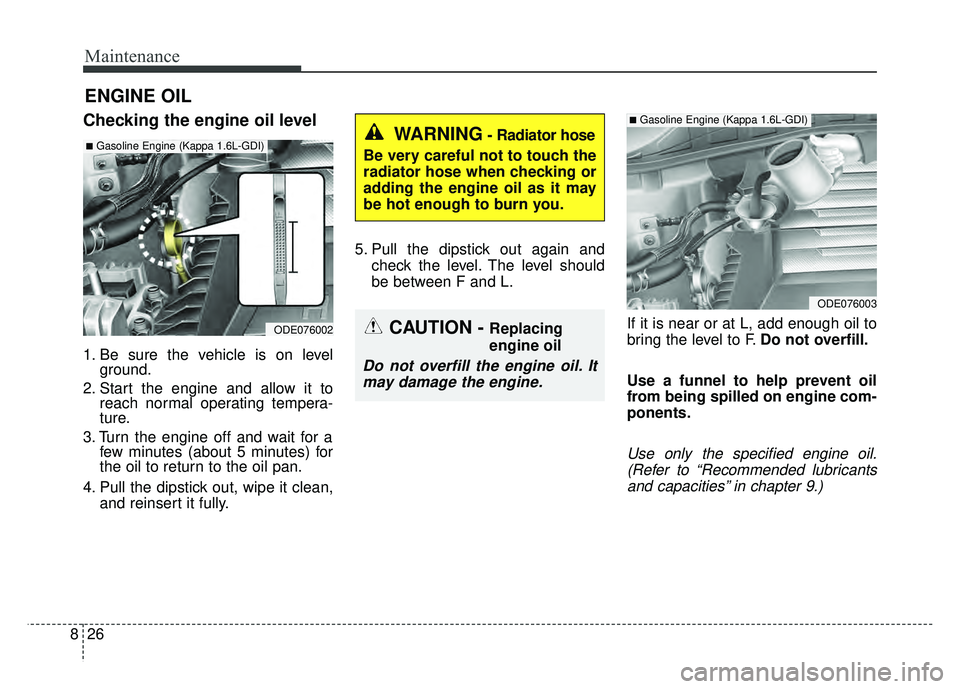

Checking the engine oil level

1. Be sure the vehicle is on level

ground.

2. Start the engine and allow it to reach normal operating tempera-

ture.

3. Turn the engine off and wait for a few minutes (about 5 minutes) for

the oil to return to the oil pan.

4. Pull the dipstick out, wipe it clean, and reinsert it fully. 5. Pull the dipstick out again and

check the level. The level should

be between F and L.

If it is near or at L, add enough oil to

bring the level to F.Do not overfill.

Use a funnel to help prevent oil

from being spilled on engine com-

ponents.

Use only the specified engine oil. (Refer to “Recommended lubricantsand capacities” in chapter 9.)

CAUTION - Replacing

engine oil

Do not overfill the engine oil. Itmay damage the engine.

WARNING- Radiator hose

Be very careful not to touch the

radiator hose when checking or

adding the engine oil as it may

be hot enough to burn you.

ODE076002

■Gasoline Engine (Kappa 1.6L-GDI)

ODE076003

■Gasoline Engine (Kappa 1.6L-GDI)

Page 518 of 616

849

Maintenance

Underinflation also results inexcessive wear, poor handling and

reduced fuel economy. Wheel

deformation also is possible. Keep

your tire pressures at the proper

levels. If a tire frequently needs

refilling, have it checked by an

authorized Kia dealer.

Overinflation produces a harsh ride, excessive wear at the center

of the tire tread, and a greater pos-

sibility of damage from road haz-

ards.

Warm tires normally exceed rec- ommended cold tire pressures by 4

to 6 psi (28 to 41 kPa). Do not

release air from warm tires to

adjust the pressure or the tires will

be underinflated.

Be sure to reinstall the tire inflation valve caps. Without the valve cap,

dirt or moisture could get into the

valve core and cause air leakage. If

a valve cap is missing, install a

new one as soon as possible.Tire pressure

Always observe the following:

Check tire pressure when the tiresare cold. (After vehicle has been

parked for at least three hours or

hasn't been driven more than one

mile (1.6 km) since startup.)

Check the pressure of your spare tire each time you check the pres-

sure of other tires.

Never overload your vehicle. Be careful not to overload a vehicle

luggage rack if your vehicle is

equipped with one.

Checking tire inflation pres-

sure

Check your tires once a month or

more.

Also, check the tire pressure of the

spare tire.

How to check

Use a good quality gauge to check

tire pressure. You can not tell if your

tires are properly inflated simply by

looking at them. Radial tires may

look properly inflated even when

they're underinflated.

Check the tire's inflation pressure

when the tires are cold. - "Cold"

means your vehicle has been sitting

for at least three hours or driven no

more than 1 mile (1.6 km).

WARNING - Tire Inflation

Overinflation or underinflation

can reduce tire life, adversely

affect vehicle handling, and

lead to sudden tire failure. This

could result in loss of vehicle

control and potential injury.

Page 533 of 616

Maintenance

64

8

✽

✽

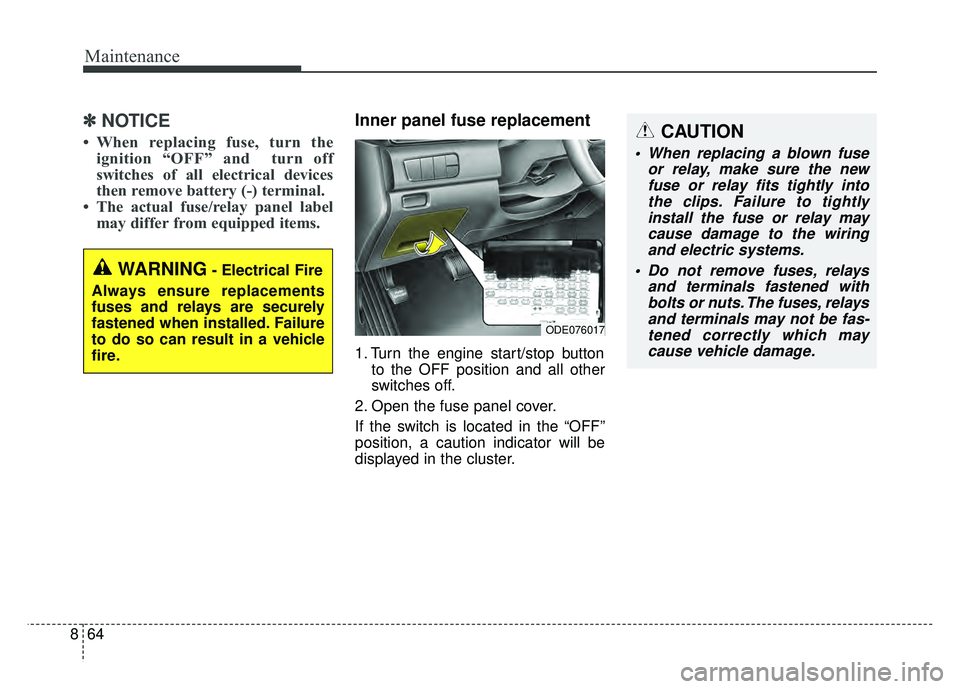

NOTICE

• When replacing fuse, turn the

ignition “OFF” and turn off

switches of all electrical devices

then remove battery (-) terminal.

• The actual fuse/relay panel label may differ from equipped items.

Inner panel fuse replacement

1. Turn the engine start/stop button

to the OFF position and all other

switches off.

2. Open the fuse panel cover.

If the switch is located in the “OFF”

position, a caution indicator will be

displayed in the cluster.

WARNING- Electrical Fire

Always ensure replacements

fuses and relays are securely

fastened when installed. Failure

to do so can result in a vehicle

fire.

CAUTION

When replacing a blown fuse or relay, make sure the newfuse or relay fits tightly intothe clips. Failure to tightlyinstall the fuse or relay maycause damage to the wiringand electric systems.

Do not remove fuses, relays and terminals fastened withbolts or nuts. The fuses, relaysand terminals may not be fas-tened correctly which maycause vehicle damage.

ODE076017

Page 535 of 616

Maintenance

66

8

Fuse switch

Always set the fuse switch to the ON

position before using the vehicle.

If you move the switch to the OFF

position, some items such as audio

and digital clock must be reset and

transmitter (or smart key) may not

work properly. When the switch is

Off, the caution indicator will be dis-

played on the instrument cluster.

Always place the fuse switch in the

ON position while driving the vehicle.

If the switch is located in the “OFF”

position, a caution indicator will be

displayed in the cluster.

Engine compartment fuse

replacement

1. Turn the engine start/stop button

to the OFF position and all other

switches off.

2. Remove the fuse panel cover by pressing the tab and pulling the

cover up. When the blade type

fuse is disconnected, remove it by

using the clip designed for chang-

ing fuses located in the engine

compartment fuse box. Upon

removal, securely insert reserve

fuse of the same rating. 3. Check the removed fuse; replace it

if it is blown. To remove or insert

the fuse, use the fuse puller in the

engine compartment fuse panel.

4. Push in a new fuse of the same rating, and make sure it fits tightly

in the clips. If it fits loosely, consult

an authorized Kia dealer.

CAUTION

After checking the fuse panel inthe engine compartment,securely install the fuse panelcover through the audible click-ing sound.

If not, electrical failures mayoccur from water contact.

ODE076018

ODE076021

Page 540 of 616

871

Maintenance

Instrument panel (Driver’s side fuse panel) (Hybrid)

Fuse NameFuse ratingCircuit Protected

MODULE 510A

Electro Chromic Mirror, Audio/Video & Navigation Head Unit, Audio, Driver IMS (Integrated memory system)

Module, VESS (Virtual Engine Sound System) Unit, Shift Lever Indicator, Air Conditioner Control Module,

Rear Seat Warmer Control Module, Front Air Ventilation Seat Control Module, Front Seat Warmer Control

Module, Head Lamp LH/RH

MODULE 410ALane Keeping Assist Control Module, Crash Pad Switch, AEB Module, Blind Spot Detection Radar LH/RH,

AFLS (Adaptive Front Lighting System) Unit

INTERIORLAMP10AFront Vanity Lamp LH/RH, Room Lamp, Overhead Console Lamp, Ignition Key ILL. & Door Warning Switch,

Luggage Lamp

A/BAG15ASRS (Supplemental Restraint System) Control Module, Passenger Occupant Detection Sensor

IG 125AEngine Room Junction Block (Fuse - DCT4, HPCU2, ACTIVE HYDRAULIC BOOSTER3, ECU3)

CLUSTER10AInstrument Cluster

MODULE 310ABCM (Body Control Module), DCT (Dual Clutch Transmission) Shift Lever, Stop Lamp Switch, Driver Door

Module, Passenger Door Module

MEMORY 27.5AActive Air Flap Unit

MODULE 810AActive Air Flap Unit, Electric Water Pump (Engine), VPD Sensor, Engine Room Junction Block (Battery

C/Fan Relay), BMS (Battery Management System) Control Module

A/BAG IND7.5AAir Conditioner Control Module, Instrument Cluster

START7.5A[Without Smart Key & Without Immobilizer] Burglar alarm Relay

[With Smart Key/With Immobilizer] Inhibitor Switch

Page 542 of 616

873

Maintenance

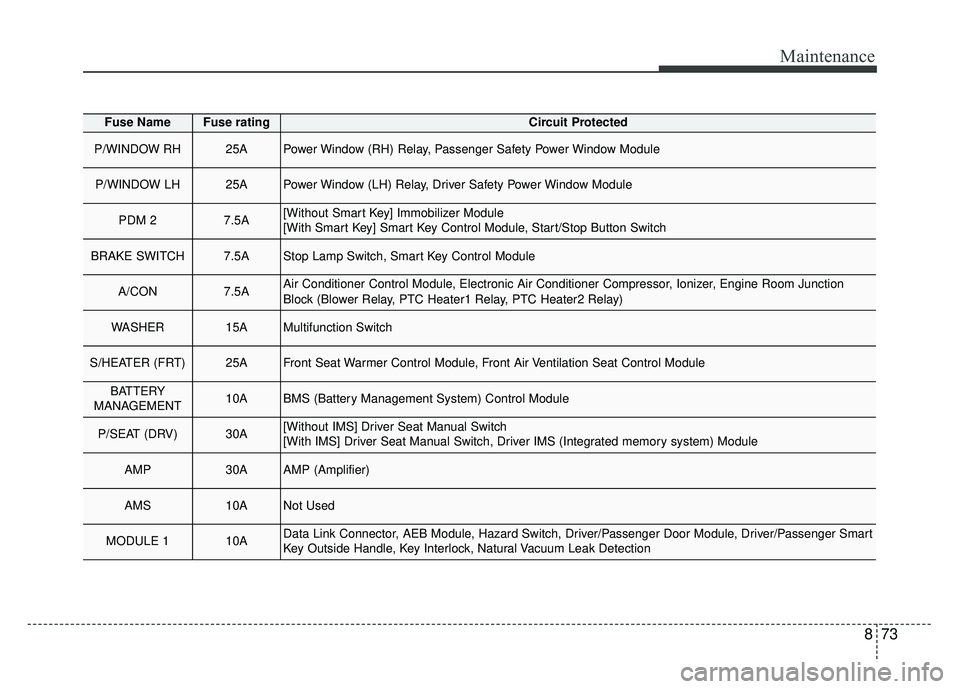

Fuse NameFuse ratingCircuit Protected

P/WINDOW RH25APower Window (RH) Relay, Passenger Safety Power Window Module

P/WINDOW LH25APower Window (LH) Relay, Driver Safety Power Window Module

PDM 27.5A[Without Smart Key] Immobilizer Module

[With Smart Key] Smart Key Control Module, Start/Stop Button Switch

BRAKE SWITCH7.5AStop Lamp Switch, Smart Key Control Module

A/CON7.5AAir Conditioner Control Module, Electronic Air Conditioner Compressor, Ionizer, Engine Room Junction

Block (Blower Relay, PTC Heater1 Relay, PTC Heater2 Relay)

WASHER15AMultifunction Switch

S/HEATER (FRT)25AFront Seat Warmer Control Module, Front Air Ventilation Seat Control Module

BATTERY

MANAGEMENT10ABMS (Battery Management System) Control Module

P/SEAT (DRV)30A[Without IMS] Driver Seat Manual Switch

[With IMS] Driver Seat Manual Switch, Driver IMS (Integrated memory system) Module

AMP30AAMP (Amplifier)

AMS10ANot Used

MODULE 110AData Link Connector, AEB Module, Hazard Switch, Driver/Passenger Door Module, Driver/Passenger Smart

Key Outside Handle, Key Interlock, Natural Vacuum Leak Detection