engine KIA NIRO PHEV 2021 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2021, Model line: NIRO PHEV, Model: KIA NIRO PHEV 2021Pages: 710, PDF Size: 14.77 MB

Page 641 of 710

777

Maintenance

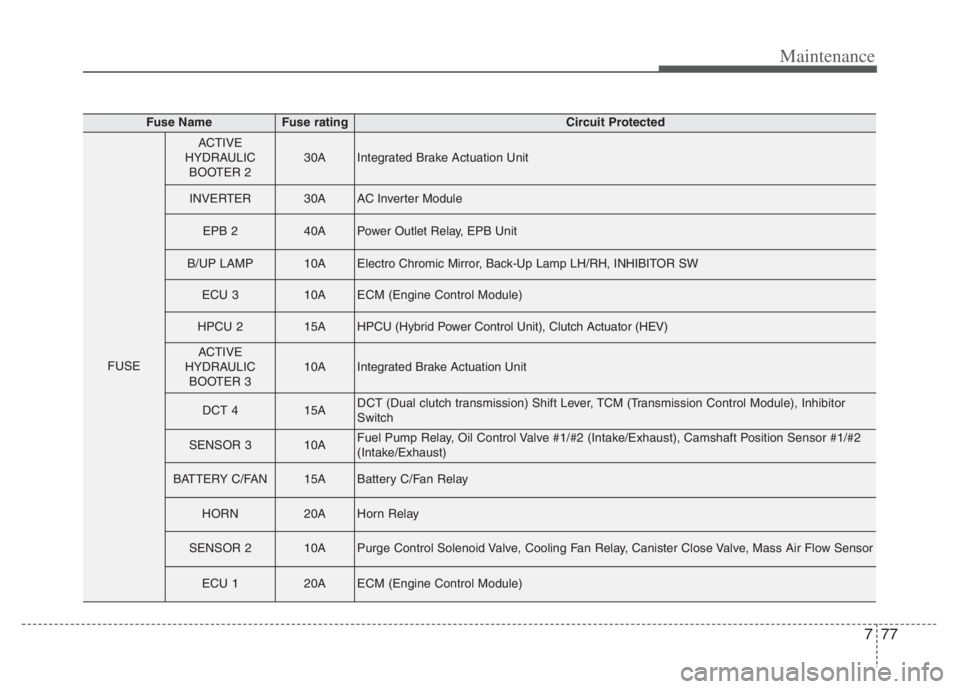

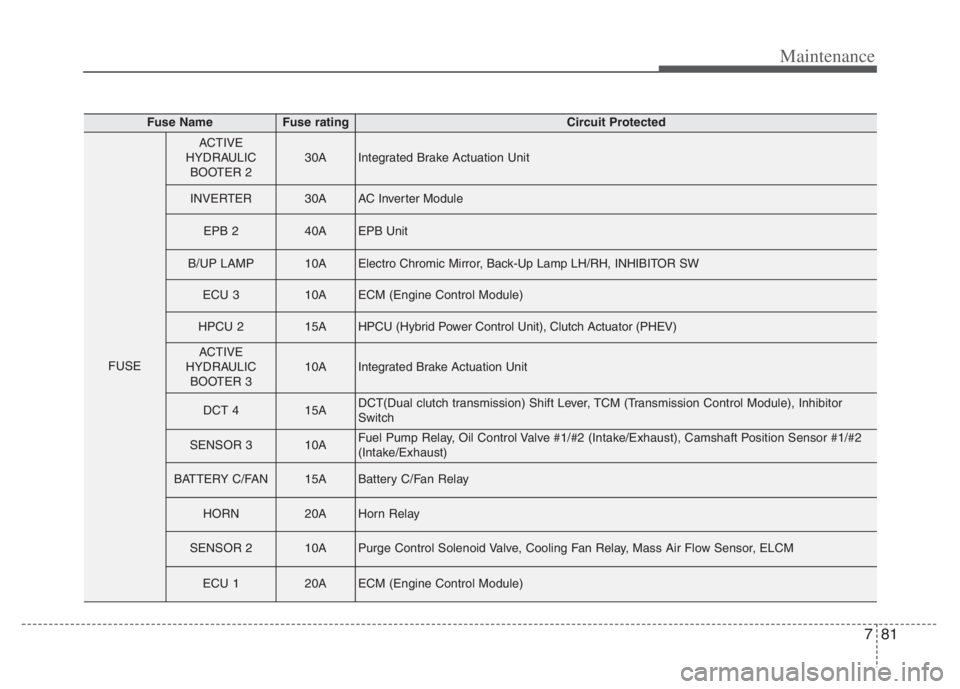

Fuse NameFuse ratingCircuit Protected

FUSE

ACTIVE

HYDRAULIC

BOOTER 230AIntegrated Brake Actuation Unit

INVERTER30AAC Inverter Module

EPB 240APower Outlet Relay, EPB Unit

B/UP LAMP10AElectro Chromic Mirror, Back-Up Lamp LH/RH, INHIBITOR SW

ECU 310AECM (Engine Control Module)

HPCU 215AHPCU (Hybrid Power Control Unit), Clutch Actuator (HEV)

ACTIVE

HYDRAULIC

BOOTER 310AIntegrated Brake Actuation Unit

DCT 415ADCT (Dual clutch transmission) Shift Lever, TCM (Transmission Control Module), Inhibitor

Switch

SENSOR 310AFuel Pump Relay, Oil Control Valve #1/#2 (Intake/Exhaust), Camshaft Position Sensor #1/#2

(Intake/Exhaust)

BATTERY C/FAN15ABattery C/Fan Relay

HORN20AHorn Relay

SENSOR 210APurge Control Solenoid Valve, Cooling Fan Relay, Canister Close Valve, Mass Air Flow Sensor

ECU 120AECM (Engine Control Module)

Page 642 of 710

Maintenance

78 7

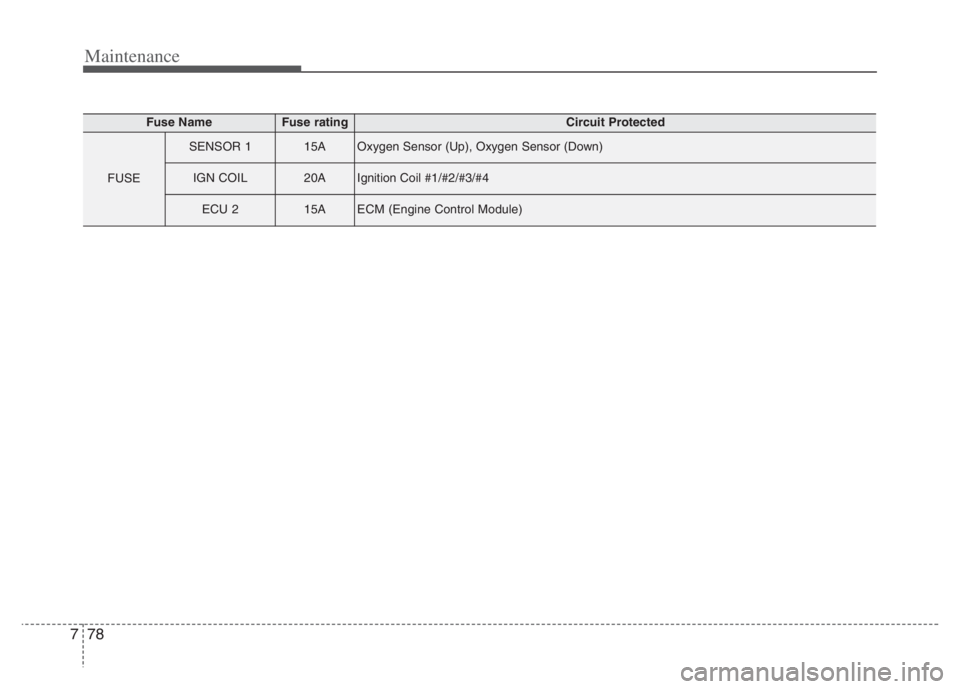

Fuse NameFuse ratingCircuit Protected

FUSE

SENSOR 115AOxygen Sensor (Up), Oxygen Sensor (Down)

IGN COIL20AIgnition Coil #1/#2/#3/#4

ECU 215AECM (Engine Control Module)

Page 643 of 710

779

Maintenance

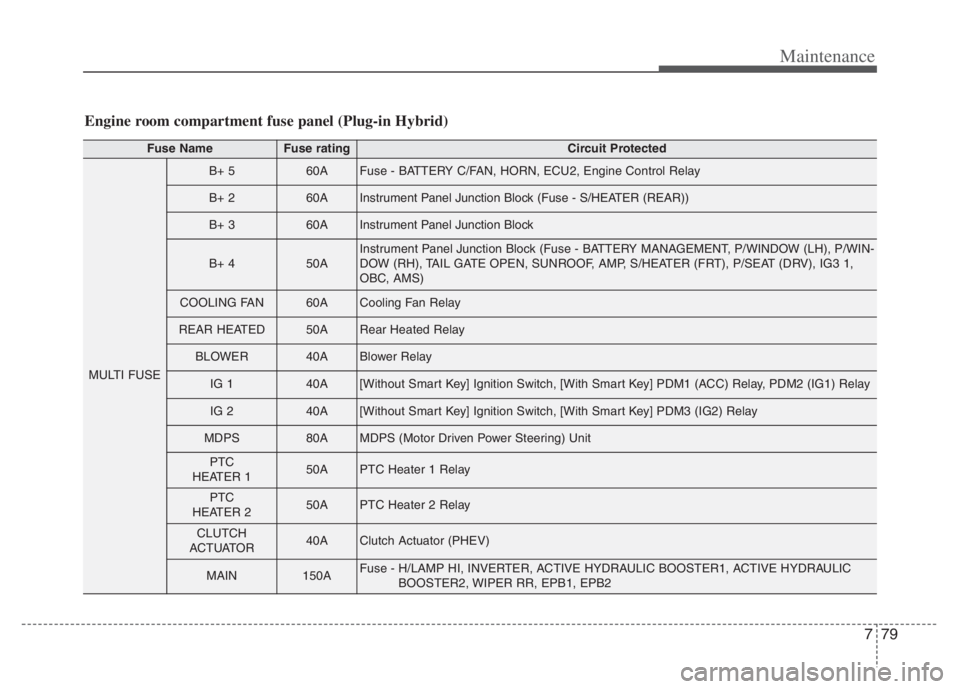

Engine room compartment fuse panel (Plug-in Hybrid)

Fuse NameFuse ratingCircuit Protected

MULTI FUSE

B+ 560AFuse - BATTERY C/FAN, HORN, ECU2, Engine Control Relay

B+ 260AInstrument Panel Junction Block (Fuse - S/HEATER (REAR))

B+ 360AInstrument Panel Junction Block

B+ 450AInstrument Panel Junction Block (Fuse - BATTERY MANAGEMENT, P/WINDOW (LH), P/WIN-

DOW (RH), TAIL GATE OPEN, SUNROOF, AMP, S/HEATER (FRT), P/SEAT (DRV), IG3 1,

OBC, AMS)

COOLING FAN60ACooling Fan Relay

REAR HEATED50ARear Heated Relay

BLOWER40ABlower Relay

IG 140A[Without Smart Key] Ignition Switch, [With Smart Key] PDM1 (ACC) Relay, PDM2 (IG1) Relay

IG 240A[Without Smart Key] Ignition Switch, [With Smart Key] PDM3 (IG2) Relay

MDPS80AMDPS (Motor Driven Power Steering) Unit

PTC

HEATER 150APTC Heater 1 Relay

PTC

HEATER 250APTC Heater 2 Relay

CLUTCH

ACTUATOR40AClutch Actuator (PHEV)

MAIN150AFuse - H/LAMP HI, INVERTER, ACTIVE HYDRAULIC BOOSTER1, ACTIVE HYDRAULIC

BOOSTER2, WIPER RR, EPB1, EPB2

Page 644 of 710

Maintenance

80 7

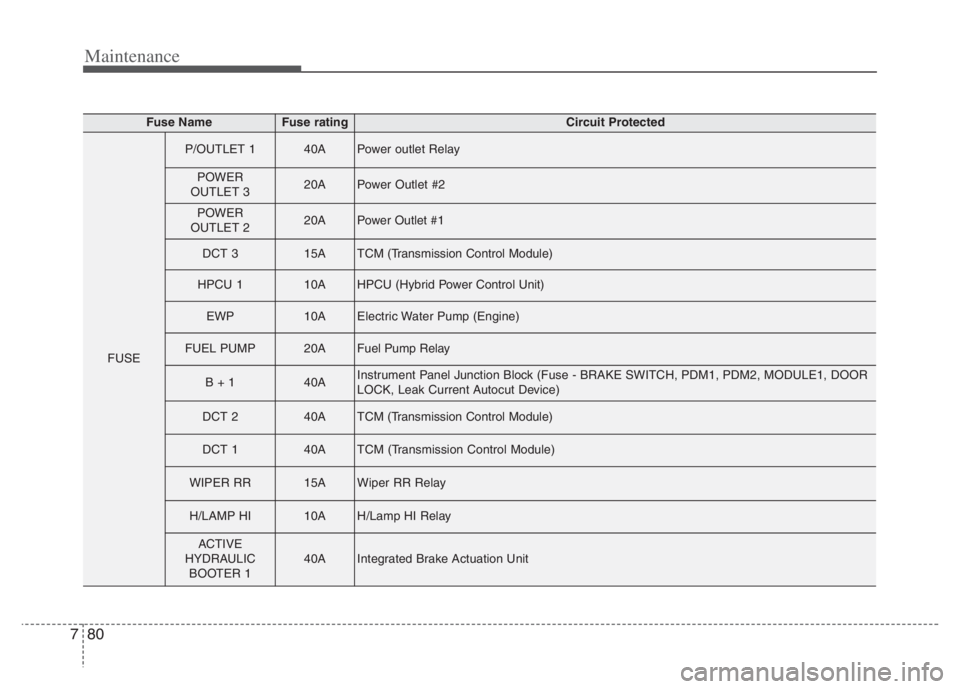

Fuse NameFuse ratingCircuit Protected

FUSE

P/OUTLET 140APower outlet Relay

POWER

OUTLET 320APower Outlet #2

POWER

OUTLET 220APower Outlet #1

DCT 315ATCM (Transmission Control Module)

HPCU 110AHPCU (Hybrid Power Control Unit)

EWP10AElectric Water Pump (Engine)

FUEL PUMP20AFuel Pump Relay

B + 140AInstrument Panel Junction Block (Fuse - BRAKE SWITCH, PDM1, PDM2, MODULE1, DOOR

LOCK, Leak Current Autocut Device)

DCT 240ATCM (Transmission Control Module)

DCT 140ATCM (Transmission Control Module)

WIPER RR15AWiper RR Relay

H/LAMP HI10AH/Lamp HI Relay

ACTIVE

HYDRAULIC

BOOTER 140AIntegrated Brake Actuation Unit

Page 645 of 710

781

Maintenance

Fuse NameFuse ratingCircuit Protected

FUSE

ACTIVE

HYDRAULIC

BOOTER 230AIntegrated Brake Actuation Unit

INVERTER30AAC Inverter Module

EPB 240AEPB Unit

B/UP LAMP10AElectro Chromic Mirror, Back-Up Lamp LH/RH, INHIBITOR SW

ECU 310AECM (Engine Control Module)

HPCU 215AHPCU (Hybrid Power Control Unit), Clutch Actuator (PHEV)

ACTIVE

HYDRAULIC

BOOTER 310AIntegrated Brake Actuation Unit

DCT 415ADCT(Dual clutch transmission) Shift Lever, TCM (Transmission Control Module), Inhibitor

Switch

SENSOR 310AFuel Pump Relay, Oil Control Valve #1/#2 (Intake/Exhaust), Camshaft Position Sensor #1/#2

(Intake/Exhaust)

BATTERY C/FAN15ABattery C/Fan Relay

HORN20AHorn Relay

SENSOR 210APurge Control Solenoid Valve, Cooling Fan Relay, Mass Air Flow Sensor, ELCM

ECU 120AECM (Engine Control Module)

Page 646 of 710

Maintenance

82 7

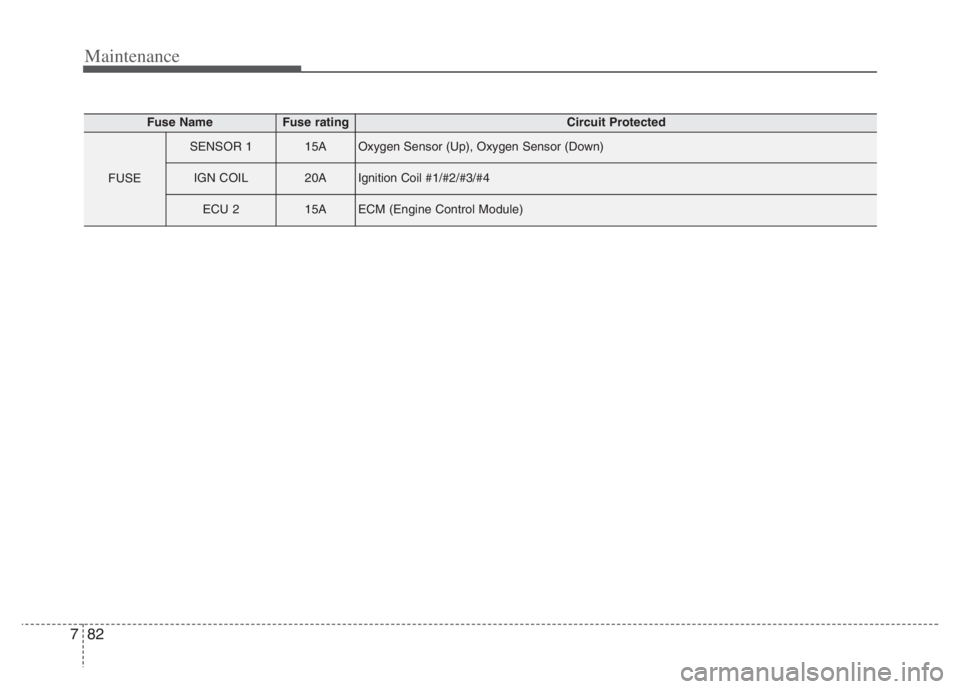

Fuse NameFuse ratingCircuit Protected

FUSE

SENSOR 115AOxygen Sensor (Up), Oxygen Sensor (Down)

IGN COIL20AIgnition Coil #1/#2/#3/#4

ECU 215AECM (Engine Control Module)

Page 650 of 710

Maintenance

86 7

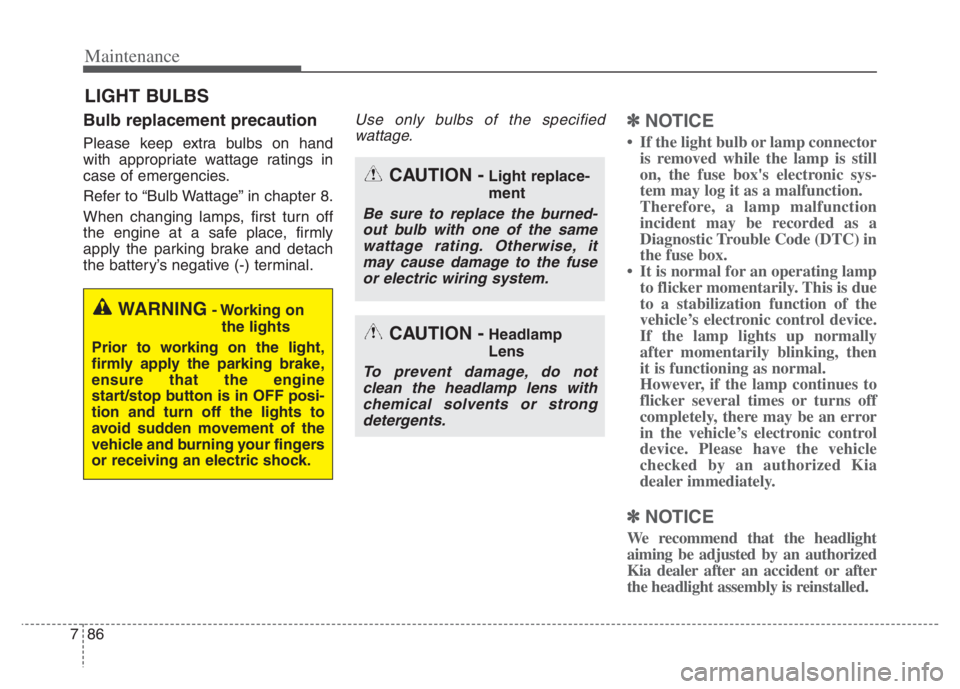

LIGHT BULBS

Bulb replacement precaution

Please keep extra bulbs on hand

with appropriate wattage ratings in

case of emergencies.

Refer to “Bulb Wattage” in chapter 8.

When changing lamps, first turn off

the engine at a safe place, firmly

apply the parking brake and detach

the battery’s negative (-) terminal.

Use only bulbs of the specified

wattage.✽ ✽

NOTICE

• If the light bulb or lamp connector

is removed while the lamp is still

on, the fuse box's electronic sys-

tem may log it as a malfunction.

Therefore, a lamp malfunction

incident may be recorded as a

Diagnostic Trouble Code (DTC) in

the fuse box.

• It is normal for an operating lamp

to flicker momentarily. This is due

to a stabilization function of the

vehicle’s electronic control device.

If the lamp lights up normally

after momentarily blinking, then

it is functioning as normal.

However, if the lamp continues to

flicker several times or turns off

completely, there may be an error

in the vehicle’s electronic control

device. Please have the vehicle

checked by an authorized Kia

dealer immediately.

✽ ✽

NOTICE

We recommend that the headlight

aiming be adjusted by an authorized

Kia dealer after an accident or after

the headlight assembly is reinstalled.

WARNING- Working on

the lights

Prior to working on the light,

firmly apply the parking brake,

ensure that the engine

start/stop button is in OFF posi-

tion and turn off the lights to

avoid sudden movement of the

vehicle and burning your fingers

or receiving an electric shock.

CAUTION -Light replace-

ment

Be sure to replace the burned-

out bulb with one of the same

wattage rating. Otherwise, it

may cause damage to the fuse

or electric wiring system.

CAUTION -Headlamp

Lens

To prevent damage, do not

clean the headlamp lens with

chemical solvents or strong

detergents.

Page 669 of 710

7105

Maintenance

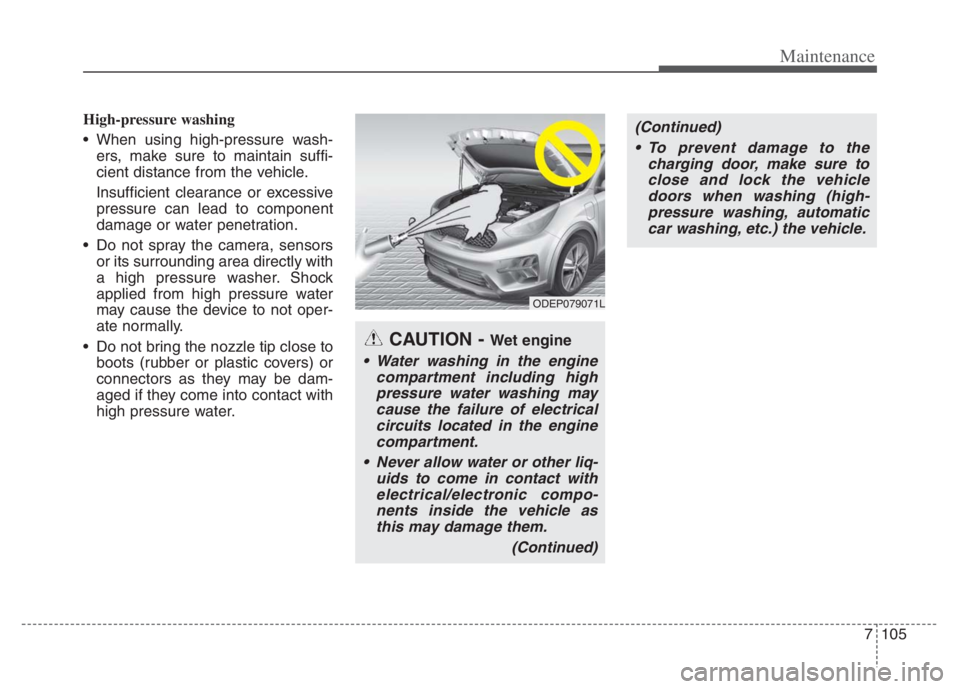

High-pressure washing

When using high-pressure wash-

ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors

or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to

boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water.

ODEP079071L

CAUTION - Wet engine

Water washing in the engine

compartment including high

pressure water washing may

cause the failure of electrical

circuits located in the engine

compartment.

Never allow water or other liq-

uids to come in contact with

electrical/electronic compo-

nents inside the vehicle as

this may damage them.

(Continued)

(Continued)

To prevent damage to the

charging door, make sure to

close and lock the vehicle

doors when washing (high-

pressure washing, automatic

car washing, etc.) the vehicle.

Page 679 of 710

7115

Maintenance

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in

the canister are drawn into the surge

tank through the purge control sole-

noid valve.

Purge Control Solenoid Valve

(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

orated fuel is not taken into the

engine. After the engine warms up

during ordinary driving, the PCSV

opens to introduce evaporated fuel to

the engine.

3. Exhaust emission control

system

The Exhaust Emission Control

System is a highly effective system

which controls exhaust emissions

while maintaining good vehicle per-

formance.

Engine exhaust gas precautions

(carbon monoxide)

Carbon monoxide can be present

with other exhaust fumes.

Therefore, if you smell exhaust

fumes of any kind inside your vehi-

cle, have it inspected and repaired

immediately. If you ever suspect

exhaust fumes are coming into

your vehicle, drive it only with all

the windows fully open. Have your

vehicle checked and repaired

immediately.

WARNING - Exhaust

Engine exhaust gases contain

carbon monoxide (CO). Though

colorless and odorless, it is

dangerous and could be lethal if

inhaled. Follow the instructions

on this page to avoid CO poi-

soning.

Page 680 of 710

Maintenance

116 7

Do not operate the engine in con-

fined or closed areas (such as

garages) any more than what is

necessary to move the vehicle in or

out of the area.

When the vehicle is stopped in an

open area for more than a short

time with the engine running,

adjust the ventilation system (as

needed) to draw outside air into the

vehicle.

Never sit in a parked or stopped

vehicle for any extended time with

the engine running.

When the engine stalls or fails to

start, excessive attempts to restart

the engine may cause damage to

the emission control system.Operating precautions for catalyt-

ic converters (if equipped)

WARNING- Catalytic

converter

Keep away from the catalytic

converter and exhaust system

while the vehicle is running or

immediately thereafter. The

exhaust and catalytic systems

are very hot and may burn you.

WARNING- Fire

Do not park, idle or drive the

vehicle over or near flamma-

ble objects, such as grass,

vegetation, paper, leaves, etc.

A hot exhaust system can

ignite flammable items under

your vehicle.

Also, do not remove the heat

sink around the exhaust sys-

tem, do not seal the bottom of

the vehicle and do not coat

the vehicle for corrosion con-

trol. It may present a fire risk

under certain conditions.