brake sensor KIA NIRO PHEV 2021 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2021, Model line: NIRO PHEV, Model: KIA NIRO PHEV 2021Pages: 710, PDF Size: 14.77 MB

Page 538 of 710

What to do in an emergency

18 6

You may not be able to identify a low

tire by simply looking at it. Always

use a good quality tire pressure

gauge to measure the tire's inflation

pressure. Please note that a tire that

is hot (from being driven) will have a

higher pressure measurement than a

tire that is cold (from sitting station-

ary for at least 3 hours and driven

less than 1 mile (1.6 km) during that

3 hour period).

Allow the tire to cool before measur-

ing the inflation pressure. Always be

sure the tire is cold before inflating to

the recommended pressure.

A cold tire means the vehicle has

been sitting for 3 hours and driven for

less than 1 mile (1.6 km) in that 3

hour period.

Never use tire sealant if your vehicle

is equipped with a Tire Pressure

Monitoring System. The liquid

sealant can damage the tire pres-

sure sensors. The TPMS cannot alert you to

severe and sudden tire damage

caused by external factors such as

nails or road debris.

If you feel any vehicle instability,

immediately take your foot off the

accelerator, apply the brakes grad-

ually and with light force, and slow-

ly move to a safe position off the

road.

✽ ✽

NOTICE - Protecting TPMS

Tampering with, modifying, or dis-

abling the Tire Pressure Monitoring

System (TPMS) components may

interfere with the system's ability to

warn the driver of low tire pressure

conditions and/or TPMS malfunc-

tions. Tampering with, modifying,

or disabling the Tire Pressure

Monitoring System (TPMS) compo-

nents may void the warranty for

that portion of the vehicle.

This device complies with Part

15 of the FCC rules.

Operation is subject to the following

two conditions:

1. This device may not cause harm-

ful interference, and

2. This device must accept any inter-

ference received, including inter-

ference that may cause undesired

operation.

3. Changes or modifications not

expressly approved by the party

responsible for compliance could

void the user’s authority to operate

the device.

Page 550 of 710

What to do in an emergency

30 6

Notes on the safe use of the

Tire Mobility Kit

Park your car at the side of the

road so that you can work with the

Tire Mobility Kit away from moving

traffic.

To be sure your vehicle will not

move, even when you're on fairly

level ground, always set your park-

ing brake.

Only use the Tire Mobility Kit for

sealing/inflation passenger car

tires. Only punctured areas located

within the tread region of the tire

can be sealed using the Tire

Mobility Kit.

Do not use on motorcycles, bicy-

cles or any other type of tires.

When the tire and wheel are dam-

aged, do not use Tire Mobility Kit

for your safety. Use of the Tire Mobility Kit may not

be effective for tire damage larger

than approximately 0.16 in. (4

mm).

Please contact the nearest Kia

dealership if the tire cannot be

made roadworthy with the Tire

Mobility Kit.

Do not use the Tire Mobility Kit if a

tire is severely damaged by driving

run flat or with insufficient air pres-

sure.

Do not remove any foreign objects

such as nails or screws that have

penetrated the tire.

Provided the car is outdoors, leave

the engine running. Otherwise

operating the compressor may

eventually drain the car battery.

Never leave the Tire Mobility Kit

unattended while it is being used.

Do not leave the compressor run-

ning for more than 10 min. at a time

or it may overheat.

Do not use the Tire Mobility Kit if

the ambient temperature is below -

22°F (-30°C).

WARNING

Do not use the Tire sealant after

the sealant has expired (i.e.

past the expiration date on the

sealant container). This can

increase the risk of tire failure.

CAUTION

When repairing a flat tire with

the Tire Mobility Kit (TMK),

quickly remove the sealant on

the tire pressure sensor and

wheel. When installing the

repaired tire and wheel, tighten

the wheel nut to a torque value

of 11 ~ 13 kgf·m.

WARNING - Sealant

Keep out of reach of children.

Avoid contact with eyes.

Do not swallow.

Page 641 of 710

777

Maintenance

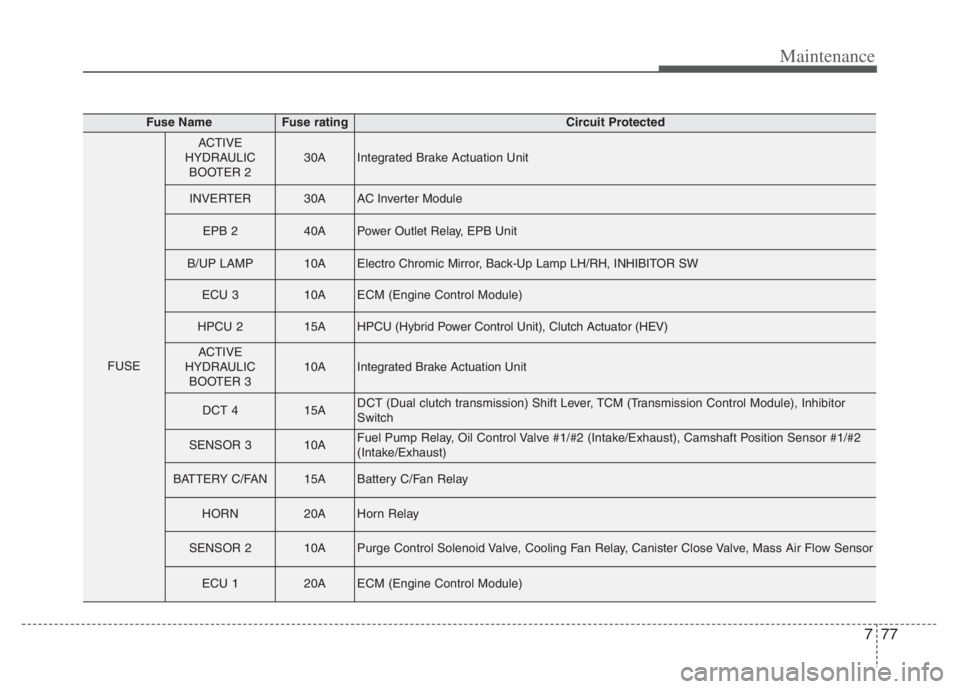

Fuse NameFuse ratingCircuit Protected

FUSE

ACTIVE

HYDRAULIC

BOOTER 230AIntegrated Brake Actuation Unit

INVERTER30AAC Inverter Module

EPB 240APower Outlet Relay, EPB Unit

B/UP LAMP10AElectro Chromic Mirror, Back-Up Lamp LH/RH, INHIBITOR SW

ECU 310AECM (Engine Control Module)

HPCU 215AHPCU (Hybrid Power Control Unit), Clutch Actuator (HEV)

ACTIVE

HYDRAULIC

BOOTER 310AIntegrated Brake Actuation Unit

DCT 415ADCT (Dual clutch transmission) Shift Lever, TCM (Transmission Control Module), Inhibitor

Switch

SENSOR 310AFuel Pump Relay, Oil Control Valve #1/#2 (Intake/Exhaust), Camshaft Position Sensor #1/#2

(Intake/Exhaust)

BATTERY C/FAN15ABattery C/Fan Relay

HORN20AHorn Relay

SENSOR 210APurge Control Solenoid Valve, Cooling Fan Relay, Canister Close Valve, Mass Air Flow Sensor

ECU 120AECM (Engine Control Module)

Page 645 of 710

781

Maintenance

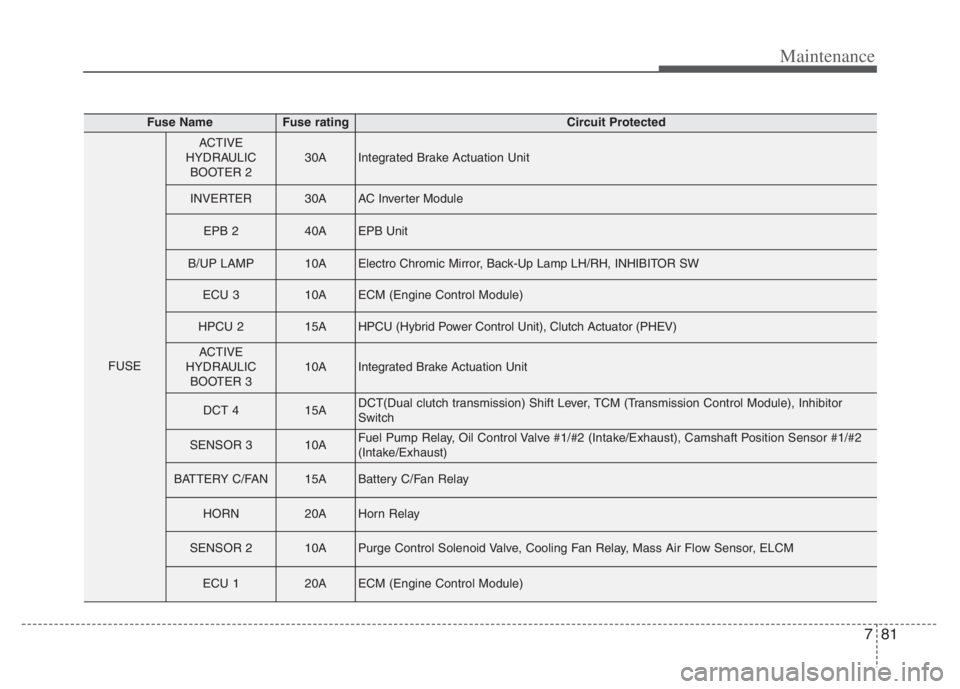

Fuse NameFuse ratingCircuit Protected

FUSE

ACTIVE

HYDRAULIC

BOOTER 230AIntegrated Brake Actuation Unit

INVERTER30AAC Inverter Module

EPB 240AEPB Unit

B/UP LAMP10AElectro Chromic Mirror, Back-Up Lamp LH/RH, INHIBITOR SW

ECU 310AECM (Engine Control Module)

HPCU 215AHPCU (Hybrid Power Control Unit), Clutch Actuator (PHEV)

ACTIVE

HYDRAULIC

BOOTER 310AIntegrated Brake Actuation Unit

DCT 415ADCT(Dual clutch transmission) Shift Lever, TCM (Transmission Control Module), Inhibitor

Switch

SENSOR 310AFuel Pump Relay, Oil Control Valve #1/#2 (Intake/Exhaust), Camshaft Position Sensor #1/#2

(Intake/Exhaust)

BATTERY C/FAN15ABattery C/Fan Relay

HORN20AHorn Relay

SENSOR 210APurge Control Solenoid Valve, Cooling Fan Relay, Mass Air Flow Sensor, ELCM

ECU 120AECM (Engine Control Module)

Page 702 of 710

Index

4I

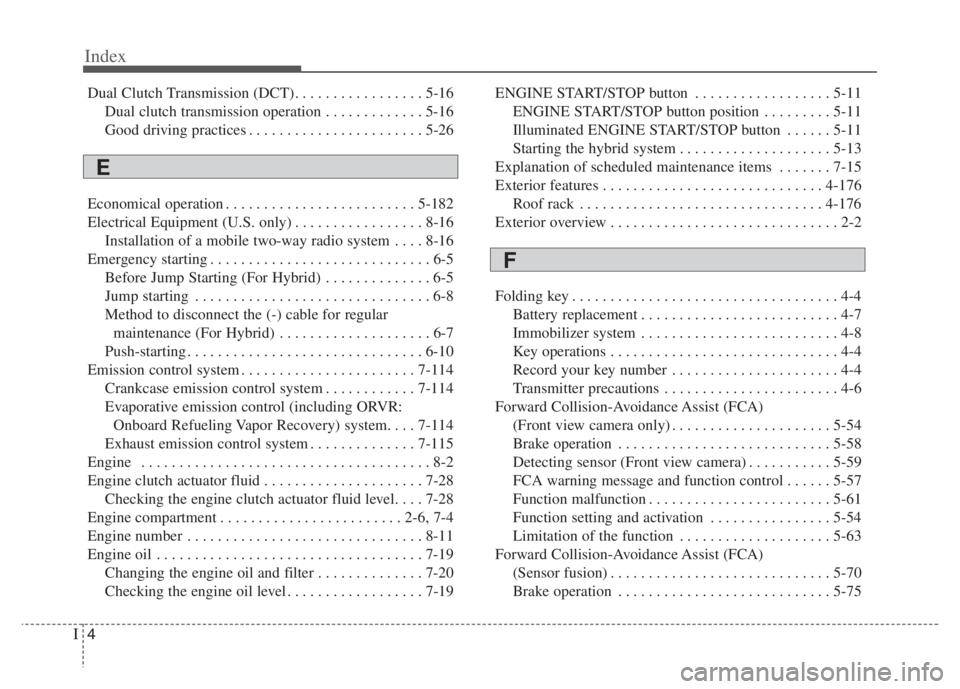

Dual Clutch Transmission (DCT). . . . . . . . . . . . . . . . . 5-16

Dual clutch transmission operation . . . . . . . . . . . . . 5-16

Good driving practices . . . . . . . . . . . . . . . . . . . . . . . 5-26

Economical operation . . . . . . . . . . . . . . . . . . . . . . . . . 5-182

Electrical Equipment (U.S. only) . . . . . . . . . . . . . . . . . 8-16

Installation of a mobile two-way radio system . . . . 8-16

Emergency starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Before Jump Starting (For Hybrid) . . . . . . . . . . . . . . 6-5

Jump starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Method to disconnect the (-) cable for regular

maintenance (For Hybrid) . . . . . . . . . . . . . . . . . . . . 6-7

Push-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Emission control system . . . . . . . . . . . . . . . . . . . . . . . 7-114

Crankcase emission control system . . . . . . . . . . . . 7-114

Evaporative emission control (including ORVR:

Onboard Refueling Vapor Recovery) system. . . . 7-114

Exhaust emission control system . . . . . . . . . . . . . . 7-115

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Engine clutch actuator fluid . . . . . . . . . . . . . . . . . . . . . 7-28

Checking the engine clutch actuator fluid level. . . . 7-28

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 2-6, 7-4

Engine number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Changing the engine oil and filter . . . . . . . . . . . . . . 7-20

Checking the engine oil level . . . . . . . . . . . . . . . . . . 7-19ENGINE START/STOP button . . . . . . . . . . . . . . . . . . 5-11

ENGINE START/STOP button position . . . . . . . . . 5-11

Illuminated ENGINE START/STOP button . . . . . . 5-11

Starting the hybrid system . . . . . . . . . . . . . . . . . . . . 5-13

Explanation of scheduled maintenance items . . . . . . . 7-15

Exterior features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-176

Roof rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-176

Exterior overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Folding key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Battery replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Immobilizer system . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Key operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Record your key number . . . . . . . . . . . . . . . . . . . . . . 4-4

Transmitter precautions . . . . . . . . . . . . . . . . . . . . . . . 4-6

Forward Collision-Avoidance Assist (FCA)

(Front view camera only) . . . . . . . . . . . . . . . . . . . . . 5-54

Brake operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Detecting sensor (Front view camera) . . . . . . . . . . . 5-59

FCA warning message and function control . . . . . . 5-57

Function malfunction . . . . . . . . . . . . . . . . . . . . . . . . 5-61

Function setting and activation . . . . . . . . . . . . . . . . 5-54

Limitation of the function . . . . . . . . . . . . . . . . . . . . 5-63

Forward Collision-Avoidance Assist (FCA)

(Sensor fusion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

Brake operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

E

F