engine KIA Optima 2007 2.G Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: Optima, Model: KIA Optima 2007 2.GPages: 294, PDF Size: 3.37 MB

Page 262 of 294

715

Maintenance

DRIVE BELTSDrive belts should be checked periodical-

ly for proper tension and replaced if nec-

essary. At the same time, belts should be

examined for cracks, wear, fraying or

other evidence of deterioration and

replaced if necessary.

Belt routing should also be checked to be

sure there is no interference between the

belts and other parts of the engine.

If the belt is too loose, have it replaced by

an authorized Kia dealer.Checking the compressor drive

beltHave the drive belts checked in accor-

dance with the maintenance schedule.

Checking the power steering fluid

level With the vehicle on level ground, check

the fluid level in the power steering reser-

voir periodically. The fluid should be

between MAX and MIN marks on the

side of the reservoir at the normal tem-

perature.

Before adding power steering fluid, thor-

oughly clean the area around the reser-

voir cap to prevent power steering fluid

contamination.

If the level is low, add fluid to the MAX

level.In the event the power steering system

requires frequent addition of fluid, the

vehicle should be inspected by an

authorized Kia dealer.

✽ ✽

NOTICE• To avoid damage to the power steer-

ing pump, do not operate the vehicle

for prolonged periods with a low

power steering fluid level.

• Never start the engine when the reser- voir tank is empty.

• When adding fluid, be careful that dirt does not get into the tank.

• Insufficient fluid can result in increased steering effort; excessive

noise may also be present as the steer-

ing wheel is turned.

• The use of the non-specified fluid could reduce the effectiveness of the

power steering wheel and cause dam-

age to it.Use only the specified power steering

fluid. (Refer to "Recommended Lubricants" later in this section.)Power steering hoseCheck the hoses and hose connections

for leaks or damage before driving the

vehicle.

POWER STEERING (IF EQUIPPED)

OMG075008

Page 263 of 294

Maintenance16

7AUTOMATIC TRANSAXLE (IF EQUIPPED)Checking the automatic transaxle

fluid level The automatic transaxle fluid level

should be checked regularly.

The volume of the transaxle fluid

changes with temperature. Although it is

best to check the level after having driv-

en the vehicle for at least 30 minutes, the

level can be checked after warming the

fluid using the following procedure.

1. Park the vehicle on level ground and

firmly apply the parking brake.

2. Allow the engine to idle for about 2 minutes.

3. Depress the brake pedal and move the shift lever slowly through all ranges

then set it in P (Park). 4. With the engine still idling, pull out the

dipstick, wipe it clean and reinsert it

fully.

5. Pull out the dipstick again and check the fluid level.

✽ ✽NOTICE• Low fluid level causes transaxle slip-

page. Overfilling can cause foaming,

loss of fluid and transaxle malfunc-

tion.

• The use of a non-specified fluid could result in transaxle malfunction and

failure.

If the fluid has been warmed to normal

operating temperature of approximately

70~80°C (158~176°F), the fluid level

should be within “HOT” range.

“COLD” scale is for reference only

and should NOT be used to determine

transaxle fluid level.

WARNING -

Transaxle fluid

The transaxle fluid level should be

checked when the engine is at nor-

mal operating temperature. This

means that the engine, radiator,

radiator hose and exhaust system

etc., are very hot. Exercise great

care not to burn yourself during this

procedure.

WARNING

- Parking brake

To avoid sudden movement of the

vehicle, apply parking brake and

depress the brake pedal before

moving the shift lever.

OMG075009

OMG075010

Page 264 of 294

717

Maintenance

New automatic transaxle fluid should

be red. The red dye is added so the

assembly plant can identify it as auto-

matic transaxle fluid and distinguish it

from engine oil or antifreeze. The red

dye, which is not an indicator of fluid

quality, is not permanent. As the vehi-

cle is driven, the automatic transaxle

fluid will begin to look darker. The

color may eventually appear light

brown.✽ ✽NOTICEHave an Authorized Kia dealer inspect

or change the automatic transaxle fluid

according to the Scheduled

Maintenance at the beginning of this

section.Changing automatic transaxle

fluidHave automatic transaxle fluid changed

by an authorized Kia dealer according to

the Maintenance Schedule at the begin-

ning of this section.

Use only the specified automatic

transaxle fluid. (Refer to "Recommended

Lubricants" later in this section.)

Checking the washer fluid level The reservoir is translucent so that you

can check the level with a quick visual

inspection.

Check the fluid level in the washer fluid

reservoir and add fluid if necessary. Plain

water may be used if washer fluid is not

available. However, use washer solvent

with antifreeze characteristics in cold cli-

mates to prevent freezing.

Body lubrication All moving points of the body, such as

door hinges, hood hinges, and locks,

should be lubricated each time the

engine oil is changed. Use a non-freez-

ing lubricant on locks during cold weath-

er.

Make sure the engine hood secondary

latch keeps the hood from opening when

the primary latch is released.

LUBRICANTS AND FLUIDS

WARNING

- Coolant

Do not use radiator coolant or

antifreeze in the washer fluid

reservoir.

(Continued)

(Continued)

Radiator coolant can severelyobscure visibility when sprayed

on the windshield and may cause

loss of vehicle control or damage

to paint and body trim.

Windshield washer fluid agents contain some amounts of alcohol

and can be flammable under cer-

tain circumstances. Do not allow

sparks or flame to contact the

washer fluid or the washer fluid

reservoir. Damage to the vehicle

or it's occupants could occur.

Windshield washer fluid is poi- sonous to humans and animals.

Do not drink and avoid contacting

windshield washer fluid. Serious

injury or death could occur.

OMG075011

Page 265 of 294

Maintenance18

7Element cleaningThis element may be air cleaned or

replaced, depending on its condition.

Unless it is very dirty, merely shake it to

remove foreign particles. Each time this

filter is inspected, wipe the inside of the

air cleaner housing and cover with a

damp cloth. If the vehicle is operated in

extremely dusty or sandy areas, clean or

replace this element more often than at

the usual recommended intervals.

✽ ✽

NOTICEDo not drive with the air cleaner ele-

ment removed; this will result in exces-

sive engine wear.

AIR CLEANER

OMG075012

CAUTION -

Air cleaner

Operating the engine without the air

cleaner may result in poor perform-ance, emission control malfunction,and/or engine damage.

Page 269 of 294

Maintenance22

7

For best battery service : Keep the battery securely mounted.

Keep the top of the battery clean and

dry.

Keep the terminals and connections clean, tight, and coated with petroleum

jelly or terminal grease.

Rinse any spilled electrolyte from the battery immediately with a solution of

water and baking soda.

If the vehicle is not going to be used for an extended time, disconnect the bat-

tery cables.

Battery recharging Your vehicle has a maintenance-free,

calcium-based battery.

If the battery becomes discharged in ashort time (because, for example, the

headlights or interior lights were left on

while the vehicle was not in use),

recharge it by slow charging (trickle)

for 10 hours.

If the battery gradually discharges because of high electric load while the

vehicle is being used, recharge it at 20-

30A for two hours.Items to be reset after the battery hasbeen discharged or the battery hasbeen disconnected. Clock (See Chapter 3)

Climate control system (See Chapter 4)

Audio (See Chapter 3)

Sunroof (See Chapter 3)

(Continued)

When lifting a plastic-cased bat- tery, excessive pressure on the

case may cause battery acid to

leak, resulting in personal injury.

Lift with a battery carrier or with

your hands on opposite corners.

Never attempt to charge the bat- tery when the battery cables are

connected.

The electrical ignition system works with high voltage. Never

touch these components with the

engine running or the ignition

switched on.

Failure to follow the above warn-

ings can result in serious bodily

injury or death.

OMG075021

Page 270 of 294

723

Maintenance

✽

✽NOTICE• Before performing maintenance or

recharging the battery, turn off all

accessories and stop the engine.

• The negative battery cable must be removed first and installed last when

the battery is disconnected.

WARNING

- Recharging

battery

When recharging the battery,

observe the following precautions:

The battery must be removed

from the vehicle and placed in an

area with good ventilation.

Do not allow cigarettes, sparks, or flame near the battery.

Watch the battery during charg- ing, and stop or reduce the charg-

ing rate if the battery cells begin

gassing (boiling) violently or if

the temperature of the electrolyte

of any cell exceeds 49°C (120°F).

Wear eye protection when check- ing the battery during charging.

Disconnect the battery charger in the following order.

1. Turn off the battery charger main switch.

2. Unhook the negative clamp from the negative battery terminal.

3. Unhook the positive clamp from the positive battery terminal.

Page 282 of 294

735

Maintenance

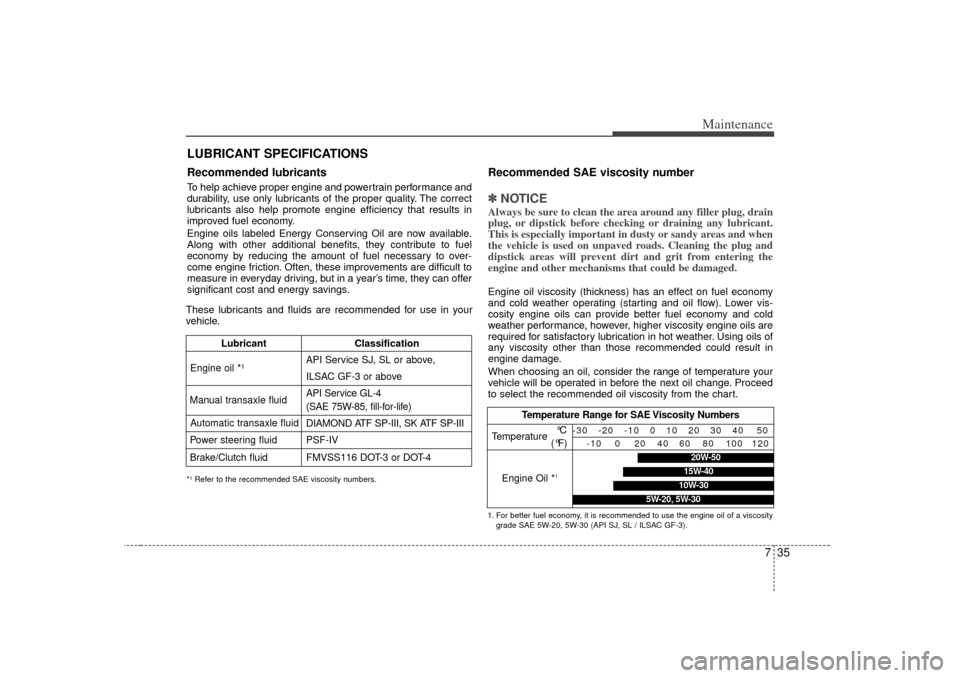

LUBRICANT SPECIFICATIONSRecommended lubricants To help achieve proper engine and powertrain performance and

durability, use only lubricants of the proper quality. The correct

lubricants also help promote engine efficiency that results in

improved fuel economy.

Engine oils labeled Energy Conserving Oil are now available.

Along with other additional benefits, they contribute to fuel

economy by reducing the amount of fuel necessary to over-

come engine friction. Often, these improvements are difficult to

measure in everyday driving, but in a year’s time, they can offer

significant cost and energy savings.

Recommended SAE viscosity number ✽ ✽NOTICEAlways be sure to clean the area around any filler plug, drain

plug, or dipstick before checking or draining any lubricant.

This is especially important in dusty or sandy areas and when

the vehicle is used on unpaved roads. Cleaning the plug and

dipstick areas will prevent dirt and grit from entering the

engine and other mechanisms that could be damaged. Engine oil viscosity (thickness) has an effect on fuel economy

and cold weather operating (starting and oil flow). Lower vis-

cosity engine oils can provide better fuel economy and cold

weather performance, however, higher viscosity engine oils are

required for satisfactory lubrication in hot weather. Using oils of

any viscosity other than those recommended could result in

engine damage.

When choosing an oil, consider the range of temperature your

vehicle will be operated in before the next oil change. Proceed

to select the recommended oil viscosity from the chart.

*¹ Refer to the recommended SAE viscosity numbers.These lubricants and fluids are recommended for use in your

vehicle.

Lubricant Classification

API Service SJ, SL or above,

ILSAC GF-3 or above

Manual transaxle fluid API Service GL-4

(SAE 75W-85, fill-for-life)

DIAMOND ATF SP-III, SK ATF SP-III

Power steering fluid PSF-IV

Brake/Clutch fluid FMVSS116 DOT-3 or DOT-4

Engine oil

*¹

Automatic transaxle fluid

Temperature Range for SAE Viscosity Numbers

Temperature

Engine Oil *

1°C

(°F)

-30 -20 -10 0 10 20 30 40 50

-10 0 20 40 60 80 100 120

1. For better fuel economy, it is recommended to use the engine oil of a viscositygrade SAE 5W-20, 5W-30 (API SJ, SL / ILSAC GF-3).

20W-5015W-4010W-30

5W-20, 5W-30

Page 283 of 294

Maintenance36

7EXTERIOR CARE Exterior general caution It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning and

caution statements that appear on the

label.Finish maintenanceWashing To help protect your vehicle’s finish from

rust and deterioration, wash it thoroughly

and frequently at least once a month with

lukewarm or cold water.

If you use your vehicle for off-road driv-

ing, you should wash it after each off-

road trip. Pay special attention to the

removal of any accumulation of salt, dirt,

mud, and other foreign materials. Make

sure the drain holes in the lower edges of

the doors and rocker panels are kept

clear and clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar deposits

can damage your vehicle’s finish if not

removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used. After washing, rinse the vehicle thor-

oughly with lukewarm or cold water. Do

not allow soap to dry on the finish.

✽ ✽

NOTICEDo not use strong soap, chemical deter-

gents or hot water, and do not wash the

vehicle in direct sunlight or when the

body of the vehicle is warm. ✽ ✽NOTICE• Water washing in the engine compart-

ment may cause the failure of electri-

cal circuits located in the engine com-

partment.

• Never allow water or other liquids to come in contact with electrical/elec-

tronic components inside the vehicle

as this may damage them.

WaxingWax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.✽ ✽ NOTICE• Wiping dust or dirt off the body with

a dry cloth will scratch the finish.

• Do not use steel wool, abrasive clean- ers, or strong detergents containing

highly alkaline or caustic agents on

chrome-plated or anodized aluminum

parts. This may result in damage to

the protective coating and cause dis-

coloration or paint deterioration.

WARNING

- Wet brakes

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

Page 288 of 294

83

Specifications

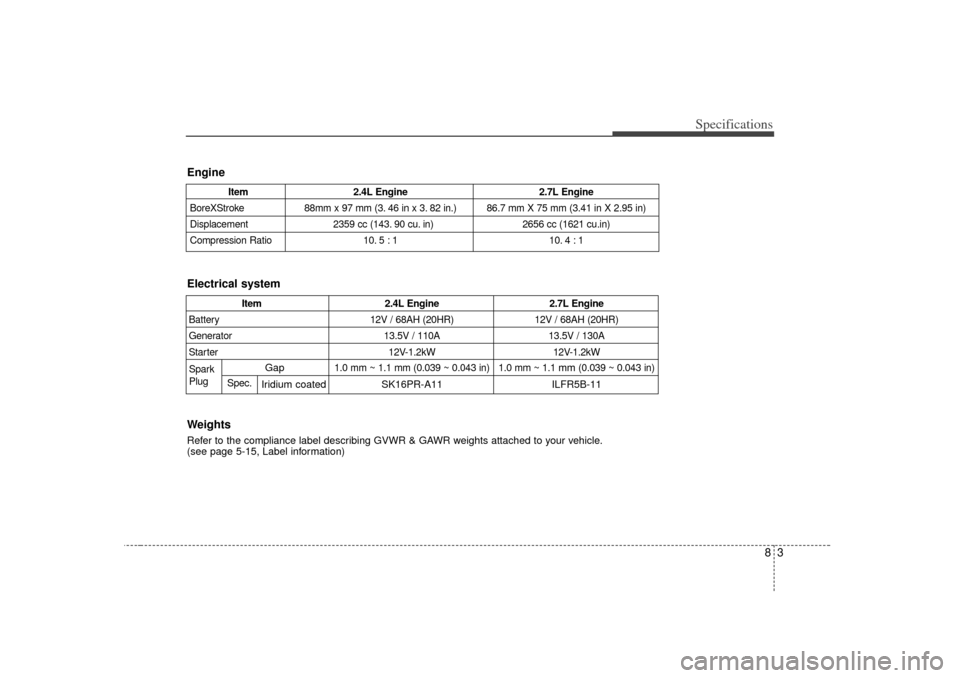

Engine

Item2.4L Engine 2.7L Engine

BoreXStroke 88mm x 97 mm (3. 46 in x 3. 82 in.) 86.7 mm X 75 mm (3.41 in X 2.95 in)

Displacement 2359 cc (143. 90 cu. in) 2656 cc (1621 cu.in)

Compression Ratio 10. 5 : 1 10. 4 : 1

Item2.4L Engine 2.7L Engine

Battery 12V / 68AH (20HR)12V / 68AH (20HR)

Generator 13.5V / 110A13.5V / 130A

Starter 12V-1.2kW12V-1.2kW

Gap

1.0 mm ~ 1.1 mm (0.039 ~ 0.043 in) 1.0 mm ~ 1.1

mm

(0.039 ~ 0.043 in

)

Iridium coated SK16PR-A11 ILFR5B-11

Spark

Plug Spec.Electrical system

WeightsRefer to the compliance label describing GVWR & GAWR weights attached to your vehicle.

(see page 5-15, Label information)

Page 289 of 294

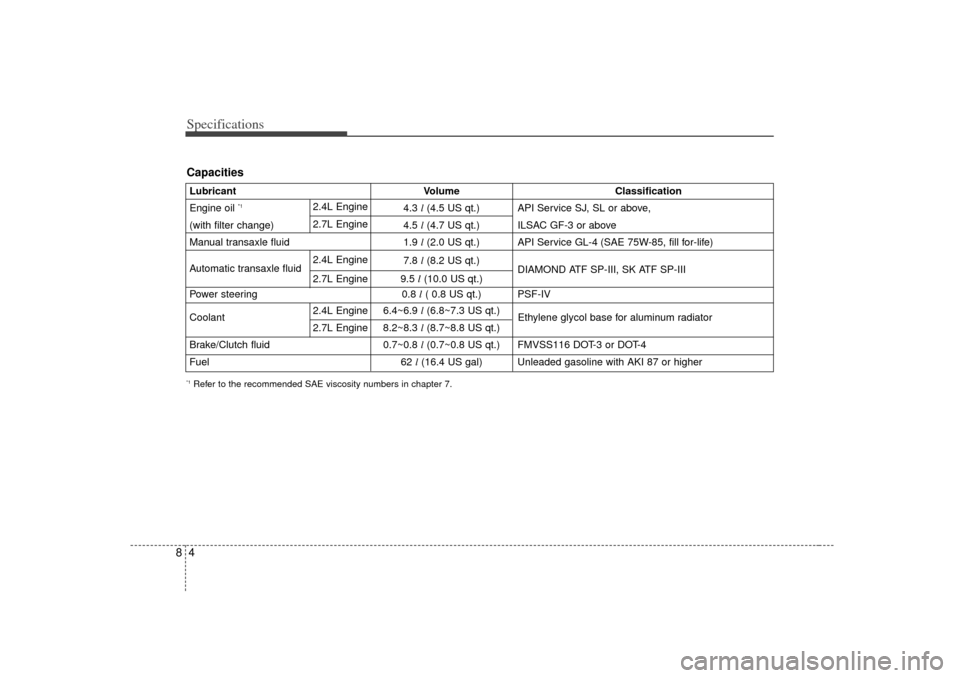

Specifications48*1Refer to the recommended SAE viscosity numbers in chapter 7.LubricantVolume Classification

Engine oil

*1

4.3 l(4.5 US qt.) API Service SJ, SL or above,

(with filter change) 4.5 l (4.7 US qt.) ILSAC GF-3 or above

Manual transaxle fluid 1.9 l(2.0 US qt.) API Service GL-4 (SAE 75W-85, fill for-life)

Automatic transaxle fluid 7.8

l(8.2 US qt.)

9.5 l(10.0 US qt.) DIAMOND ATF SP-III, SK ATF SP-III

Power steering 0.8 l( 0.8 US qt.) PSF-IV

Coolant 6.4~6.9

l(6.8~7.3 US qt.)

Ethylene glycol base for aluminum radiator

8.2~8.3 l(8.7~8.8 US qt.)

Brake/Clutch fluid 0.7~0.8 l (0.7~0.8 US qt.) FMVSS116 DOT-3 or DOT-4

Fuel 62 l(16.4 US gal) Unleaded gasoline with AKI 87 or higher

2.4L Engine

2.7L Engine2.4L Engine

2.7L Engine2.4L Engine

2.7L Engine

Capacities