KIA Optima 2010 3.G Owner's Manual

Manufacturer: KIA, Model Year: 2010, Model line: Optima, Model: KIA Optima 2010 3.GPages: 336, PDF Size: 6.46 MB

Page 311 of 336

Maintenance

46

7

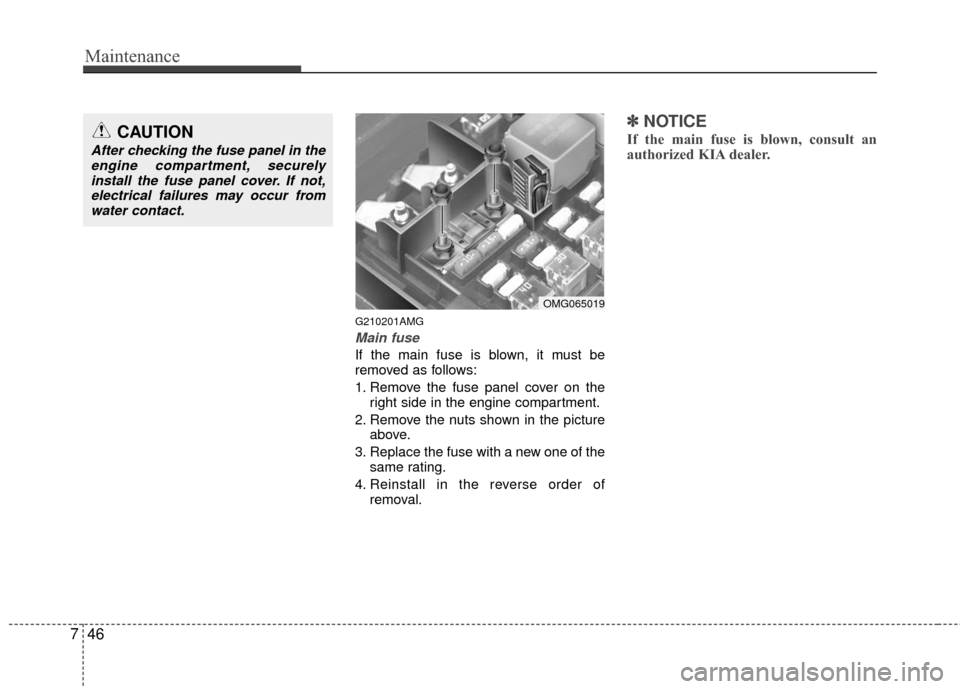

G210201AMG

Main fuse

If the main fuse is blown, it must be

removed as follows:

1. Remove the fuse panel cover on the

right side in the engine compartment.

2. Remove the nuts shown in the picture above.

3. Replace the fuse with a new one of the same rating.

4. Reinstall in the reverse order of removal.

✽ ✽NOTICE

If the main fuse is blown, consult an

authorized KIA dealer.CAUTION

After checking the fuse panel in the

engine compartment, securelyinstall the fuse panel cover. If not,electrical failures may occur fromwater contact.

OMG065019

Page 312 of 336

747

Maintenance

✽

✽NOTICE

Not all fuse panel descriptions in this

manual may be applicable to your vehi-

cle. It is accurate at the time of printing.

When you inspect the fuse panel in your

vehicle, refer to the fuse panel label.

G210300AMG-EU

Fuse/relay panel description

Inside the fuse/relay panel covers, you can find the fuse/relay label describing fuse/relay name and capacity.

Engine compartment

OMG065007/OMG065006

Driver’s side panel

Page 313 of 336

Maintenance

48

7

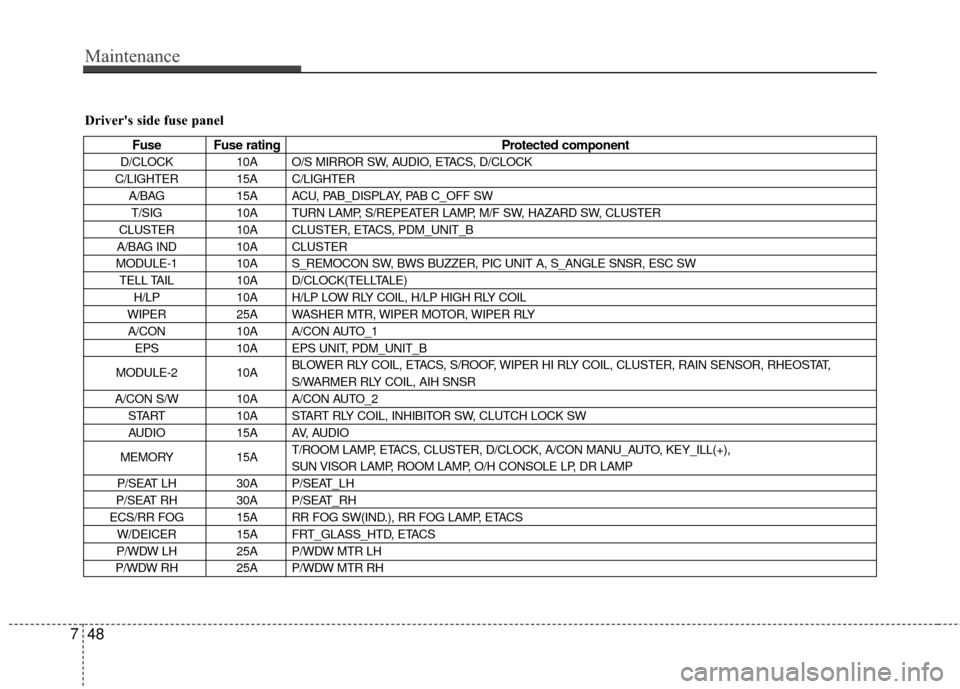

Driver's side fuse panel

Fuse Fuse rating Protected component

D/CLOCK10A O/S MIRROR SW, AUDIO, ETACS, D/CLOCK

C/LIGHTER 15A C/LIGHTER A/BAG 15A ACU, PAB_DISPLAY, PAB C_OFF SW

T/SIG 10A TURN LAMP, S/REPEATER LAMP, M/F SW, HAZARD SW, CLUSTER

CLUSTER 10A CLUSTER, ETACS, PDM_UNIT_B

A/BAG IND 10A CLUSTER

MODULE-1 10A S_REMOCON SW, BWS BUZZER, PIC UNIT A, S_ANGLE SNSR, ESC SW TELL TAIL 10A D/CLOCK(TELLTALE)

H/LP 10A H/LP LOW RLY COIL, H/LP HIGH RLY COIL

WIPER 25A WASHER MTR, WIPER MOTOR, WIPER RLY

A/CON 10A A/CON AUTO_1

EPS 10A EPS UNIT, PDM_UNIT_B

MODULE-2 10A BLOWER RLY COIL, ETACS, S/ROOF, WIPER HI RLY COIL, CLUSTER, RAIN SENSOR, RHEOSTAT,

S/WARMER RLY COIL, AIH SNSR

A/CON S/W 10A A/CON AUTO_2 START 10A START RLY COIL, INHIBITOR SW, CLUTCH LOCK SW

AUDIO 15A AV, AUDIO

MEMORY 15AT/ROOM LAMP, ETACS, CLUSTER, D/CLOCK, A/CON MANU_AUTO, KEY_ILL(+),

SUN VISOR LAMP, ROOM LAMP, O/H CONSOLE LP, DR LAMP

P/SEAT LH 30A P/SEAT_LH

P/SEAT RH 30A P/SEAT_RH

ECS/RR FOG 15A RR FOG SW(IND.), RR FOG LAMP, ETACS W/DEICER 15A FRT_GLASS_HTD, ETACS

P/WDW LH 25A P/WDW MTR LH

P/WDW RH 25A P/WDW MTR RH

Page 314 of 336

749

Maintenance

Fuse Fuse ratingProtected component

SAFETY PWR 20A SAFETY WDW

MIRR HTD 10A RR MIRROR HTD

T/LID OPEN 15A F/FILLER ACTR, LATCH_T_LID, ETACS ADJ PEDAL 10A KEY SOL, ATM SOL, ADJ PEDAL SW, ADJ PEDAL MTR, ATM&K/LOCK CTRL UNIT STOP LP 15A STOP LAMP, HIGH MOUNTED STOP LAMPHAZARD 15A TURN LAMP, S/REPEATER LAMP, CLUSTER, ETACS, OBDII

TPMS (if equipped) 10A DR WARN PIC SW, PIC UNIT_A, FOB_HOLDER_EXTN

DR LOCK 25A D/LOCK MOTOR, T/TURN UNLOCK MTR, ETACSTAIL LH 10A FRT FOG RLY COIL, COMBI LP_LH, LICENSE LAMP_LH, POS.LP LH

TAIL RH 10A POS.LP RH, GLOVE BOX LP, COMBI LP_RH, LICENSE LAMP_RH, RR.FOG SW,

P/WINDOW SW, ESP SW, HAZARD SW, A/CON SW, SEAT WARMER SW, A.CON SW,

S_REMOCON_SW, SPORT_MODE_SW

BLOWER MTR 10A BLOWER_MTR SPARE 10A -PDM-1 10A PDM_UNIT_B, SSB

PDM-2 20A PDM_UNIT_A

Page 315 of 336

Maintenance

50

7

Engine compartment

Description Fuse rating Protected component

ALT150A(2.7L)

FUSIBLE LINK, FUSE

125A(2.4L)

IGN1 30A

FUSE (A/BAG, TURN, CLUSTER, TELTAIL, A/BAG IND., 21, PCU, MODULE-1, SPARE)

IGN2 30A FUSE (MODULE-2, H/LP, A/CON, WIPER, SPARE, SATRT), BUTTON RELAY

TAIL 20A TAIL_LP_LH, TAIL_LP_RH

FUSIBLE RR HTD 40A MIRR HTD, RR_HTD_RELAY

LINK BLOWER 40A BLOWER MTR, FUSE (A/CON SW)

I/P B+1 30A FUSE (HAZARD, STOP LP, TPMS, T/LID, PEDAL ADJ, DR_LOCK)

I/P B+2 50AP/WINDOW RELAY, FUSE (RR FOG, P/SEAT_LH, P/SEAT_RH, W/DEICER,

POWER CONNECTOR, PDM_1, PDM_2)

ECU RLY 30A PCU, IGN COIL, INJECTOR, SENSOR

1 RAD FAN 40A(2.7L)

RAD FAN MTR

30A(2.4L)

2 ABS1 40A ABS/ESC UNIT

3 ABS2 40A ABS/ESC UNIT

4 A/CON 10A A/CON COMPRESSOR

5 S/WARMER 25A S/WARMER_LH, S/WARMER_RH

FUSE 6 P/AMP 20A P/AMP, AV-AMP

7 S/ROOF 20A S/ROOF MTR

8 P/OUTLET 25A P/OUTLET

9 FRT FOG 15A FRT FOG LAMP

10 HEAD LP HI 15A HEAD LP HI

11 HEAD LP LOW 15A HEAD LP LOW

12 HORN 15A HORN, B/ALARM HORN, HORN SW

Page 316 of 336

751

Maintenance

Description Fuse ratingProtected component

13 SNSR115A MAP, MAF, CMP, CCV, VIS, CPSV, ISCA, OCV, EGR, CAM, CKP, TDC SENSOR

14 SNSR2 15A O2 SENSOR, EGR ACTR

15 SNSR3 10A INJECTOR, PCU

16 IGN COIL 20A IGN COIL, PCU, O2 SENSOR

17 ECU-1 20A PCU

FUSE 18 F/PUMP 20A F/PUMP MTR

19 ECU 10A PCU

20 ATM 20A TCU, ATM_SOLENOID

21 BACK UP 10A BACK UP LAMP, ECM MIRROR, BWS UNIT

22 ABS 10A ABS/ESC UNIT

23 PCU 10A PCU, SPEED SENSOR

24 DRL 15A DRL CONTROL MODULE

Page 317 of 336

Maintenance

52

7

APPEARANCE CARE

Exterior care

G230101AUN

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning and

caution statements that appear on the

label.

G230102ABH

Finish maintenance

Washing

To help protect your vehicle’s finish from

rust and deterioration, wash it thoroughly

and frequently at least once a month with

lukewarm or cold water.

If you use your vehicle for off-road driv-

ing, you should wash it after each off-

road trip. Pay special attention to the

removal of any accumulation of salt, dirt,

mud, and other foreign materials. Make

sure the drain holes in the lower edges of

the doors and rocker panels are kept

clear and clean. Insects, tar, tree sap, bird droppings,

industrial pollution and similar deposits

can damage your vehicle’s finish if not

removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used.

After washing, rinse the vehicle thor-

oughly with lukewarm or cold water. Do

not allow soap to dry on the finish.

WARNING - Wet brakes

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

CAUTION

Do not use strong soap, chemical

detergents or hot water, and donot wash the vehicle in directsunlight or when the body of the vehicle is warm.

Be careful when washing the side windows of your vehicle.Especially, with high-pressurewater. Water may leak through thewindows and wet the interior.

To prevent damage to the plastic parts, do not clean with chemicalsolvents or strong detergents.

Page 318 of 336

753

Maintenance

Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.G230103AUN

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust

and may develop into a major repair

expense.

✽ ✽NOTICE

If your vehicle is damaged and requires

any metal repair or replacement, be sure

the body shop applies anti-corrosion

materials to the parts repaired or

replaced.

G230104AUN

Bright-metal maintenance

To remove road tar and insects, use a

tar remover, not a scraper or other

sharp object.

To protect the surfaces of bright-metal parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

During winter weather or in coastal areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.

CAUTION

Wiping dust or dirt off the body with a dry cloth will scratch thefinish.

Do not use steel wool, abrasive cleaners, or strong detergentscontaining highly alkaline orcaustic agents on chrome-platedor anodized aluminum parts. Thismay result in damage to the pro-tective coating and cause discol-oration or paint deterioration.

CAUTION

Water washing in the engine com- partment including high pressurewater washing may cause the fail-ure of electrical circuits or engineand related part located in theengine compartment.

Never allow water or other liquids to come in contact with electri-cal/electronic components andair duct inside the vehicle as thismay damage them.

OJB037800

Page 319 of 336

Maintenance

54

7

G230105AUN

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on underbody parts such as the

fuel lines, frame, floor pan and exhaust

system, even though they have been

treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month, after off-road

driving and at the end of each winter. Pay

special attention to these areas because

it is difficult to see all the mud and dirt. It

will do more harm than good to wet down

the road grime without removing it. The

lower edges of doors, rocker panels, and

frame members have drain holes that

should not be allowed to clog with dirt;

trapped water in these areas can cause

rusting.

G230106AUN

Aluminum wheel maintenance

The aluminum wheels are coated with a

clear protective finish.

Do not use any abrasive cleaner, pol-

ishing compound, solvent, or wire

brushes on aluminum wheels. They

may scratch or damage the finish.

Use only a mild soap or neutral deter- gent, and rinse thoroughly with water.

Also, be sure to clean the wheels after

driving on salted roads. This helps pre-

vent corrosion.

Avoid washing the wheels with high- speed car wash brushes.

Do not use any cleaners containing acid or acid detergents. It may damage

and corrode the aluminum wheels

coate with a clear protective finish.

WARNING

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

Page 320 of 336

755

Maintenance

G230107AUN

Corrosion protection

Protecting your vehicle from corrosion

By using the most advanced design and

construction practices to combat corro-

sion, we produces cars of the highest

quality. However, this is only part of the

job. To achieve the long-term corrosion

resistance your vehicle can deliver, the

owner's cooperation and assistance is

also required.

Common causes of corrosion

The most common causes of corrosion

on your car are:

allowed to accumulate underneath the

car.

Removal of paint or protective coatings by stones, gravel, abrasion or minor

scrapes and dents which leave unpro-

tected metal exposed to corrosion.

High-corrosion areas

If you live in an area where your car is

regularly exposed to corrosive materials,

corrosion protection is particularly impor-

tant. Some of the common causes of

accelerated corrosion are road salts,

dust control chemicals, ocean air and

industrial pollution. Moisture breeds corrosion

Moisture creates the conditions in which

corrosion is most likely to occur. For

example, corrosion is accelerated by

high humidity, particularly when tempera-

tures are just above freezing. In such

conditions, the corrosive material is kept

in contact with the car surfaces by mois-

ture that is slow to evaporate.

Mud is particularly corrosive because it is

slow to dry and holds moisture in contact

with the vehicle. Although the mud

appears to be dry, it can still retain the

moisture and promote corrosion.

High temperatures can also accelerate

corrosion of parts that are not properly

ventilated so the moisture can be dis-

persed. For all these reasons, it is par-

ticularly important to keep your car clean

and free of mud or accumulations of

other materials. This applies not only to

the visible surfaces but particularly to the

underside of the car.

To help prevent corrosion

You can help prevent corrosion from get-

ting started by observing the following:

Keep your car clean

The best way to prevent corrosion is to

keep your car clean and free of corrosive

materials. Attention to the underside of

the car is particularly important.

If you live in a high-corrosion area —

where road salts are used, near the

ocean, areas with industrial pollution,

acid rain, etc.—, you should take extra

care to prevent corrosion. In winter,

hose off the underside of your car at

least once a month and be sure to

clean the underside thoroughly when

winter is over.