fuel KIA OPTIMA HYBRID 2015 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2015, Model line: OPTIMA HYBRID, Model: KIA OPTIMA HYBRID 2015Pages: 495, PDF Size: 13.38 MB

Page 394 of 495

Maintenance

22

7

NORMAL MAINTENANCE SCHEDULE (CONT.)

142,500 miles (228,000 km) or 114 months

❑ Inspect air cleaner filter

❑ Inspect HSG belt

(142,500 miles (228,000 km) or 228 months)

❑ Inspect vacuum hose

❑ Replace engine oil and filter

(142,500 miles (228,000 km) or 228 months)

❑ Add fuel additive *

1

(Every 7,500 miles (12,000 km) or 12 months)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

150,000 miles (240,000 km) or 120 months

❑Inspect air conditioning refrigerant

❑ Inspect brake fluid

❑ Inspect brake hoses and lines

❑ Inspect drive shafts and boots

❑ Inspect exhaust pipe and muffler

❑ Inspect front brake disc/pads, calipers and rotors

❑ Inspect fuel filter *

2

❑Inspect fuel lines, fuel hoses and connections

❑ Inspect fuel tank air filter (if equipped) *2

❑Inspect HSG belt

(150,000 miles (240,000 km) or 240 months)

❑ Inspect parking brake

❑ Inspect rear brake disc/pads

❑ Inspect steering gear box, linkage & boots/lower arm ball

joint, upper arm ball joint

❑ Inspect suspension mounting bolts

❑ Inspect vacuum hose

❑ Inspect vapor hose and fuel filler cap, fuel tank

❑ Inspect W/pump belt (auto-tensioner, HSG, w/pump)

(First, 60,000 miles (96,000 km or 72 months

after every 15,000 miles (24,000 km) or 24 months)

(Continued)

Page 395 of 495

723

Maintenance

NORMAL MAINTENANCE SCHEDULE (CONT.)

No check, No service required

❑Automatic transaxle fluid

(Continued)

❑Replace climate control air filter

(for evaporator and blower unit)

❑ Replace air cleaner filter

❑ Replace engine oil and filter

(150,000 miles (240,000 km) or 240 months)

❑ Replace engine coolant

(First, 120,000 miles (192,000 km) or 120 months

after every 30,000 miles (48,000 km) or 24 months)

❑ Replace inverter coolant

(First, 120,000 miles (192,000 km) or 120 months

after every 30,000 miles (48,000 km) or 24 months)

❑ Add fuel additive *

1

(Every 7,500 miles (12,000 km) or 12 months)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 398 of 495

Maintenance

26

7

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the car

is being driven in severe conditions,

more frequent oil and filter changes

are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven,

damage the emission system and

cause multiple issues such as hard

starting. If an excessive amount of

foreign matter accumulates in the

fuel tank, the filter may require

replacement more frequently.

After installing a new filter, run the

engine for several minutes, and

check for leaks at the connections.

Fuel filters should be installed by an

authorized Kia dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized Kia dealer

replace any damaged or leaking

parts immediately.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-

rectly replaced.

Page 420 of 495

Maintenance

48

7

TIRES AND WHEELS

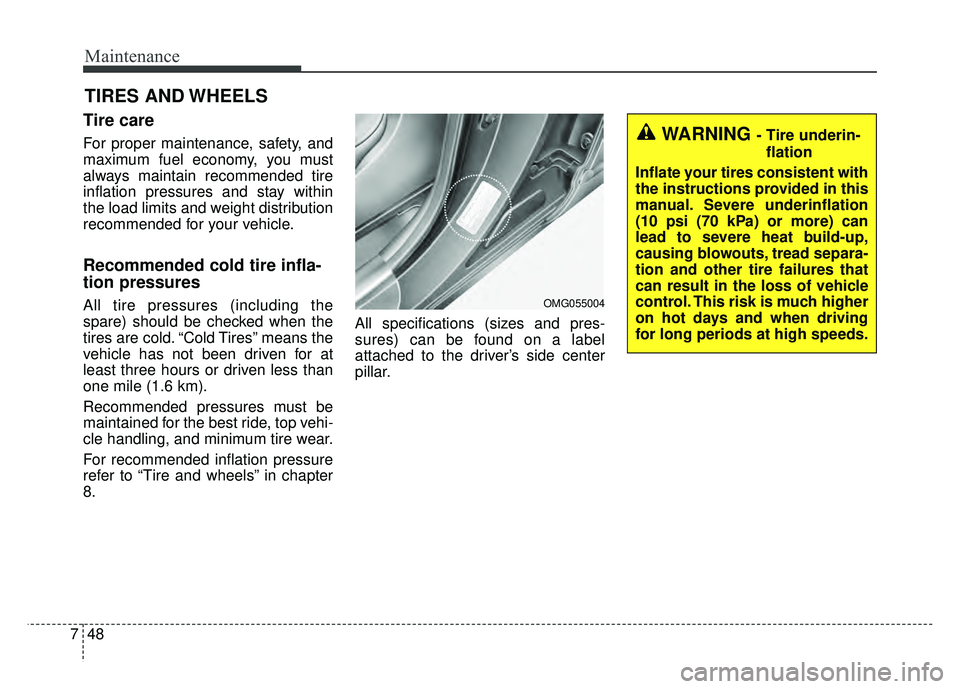

Tire care

For proper maintenance, safety, and

maximum fuel economy, you must

always maintain recommended tire

inflation pressures and stay within

the load limits and weight distribution

recommended for your vehicle.

Recommended cold tire infla-

tion pressures

All tire pressures (including the

spare) should be checked when the

tires are cold. “Cold Tires” means the

vehicle has not been driven for at

least three hours or driven less than

one mile (1.6 km).

Recommended pressures must be

maintained for the best ride, top vehi-

cle handling, and minimum tire wear.

For recommended inflation pressure

refer to “Tire and wheels” in chapter

8. All specifications (sizes and pres-

sures) can be found on a label

attached to the driver’s side center

pillar.

WARNING - Tire underin-

flation

Inflate your tires consistent with

the instructions provided in this

manual. Severe underinflation

(10 psi (70 kPa) or more) can

lead to severe heat build-up,

causing blowouts, tread separa-

tion and other tire failures that

can result in the loss of vehicle

control. This risk is much higher

on hot days and when driving

for long periods at high speeds.

OMG055004

Page 421 of 495

749

Maintenance

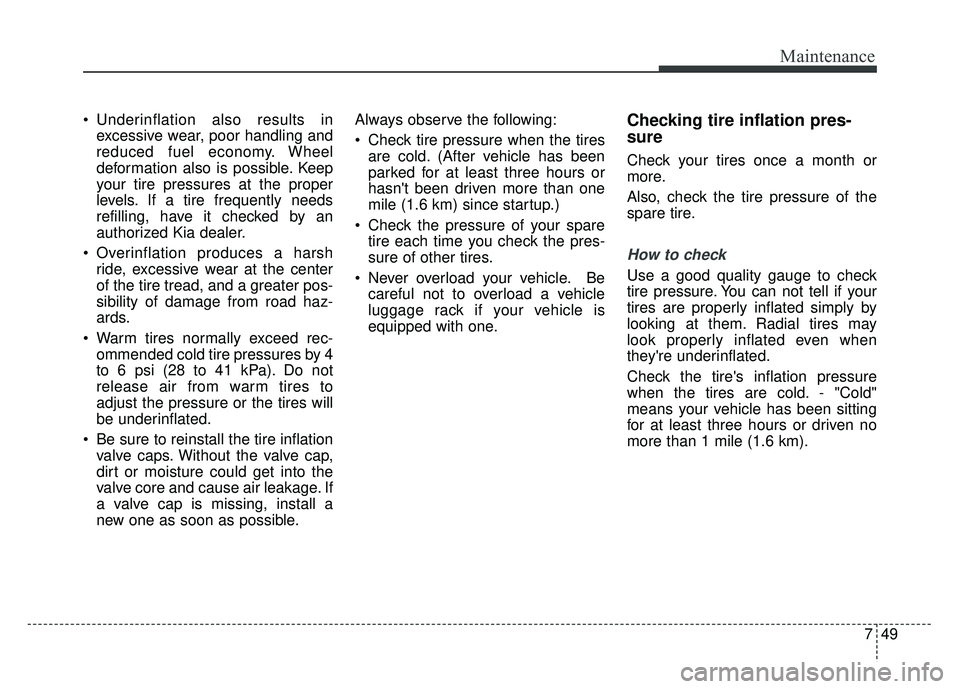

Underinflation also results inexcessive wear, poor handling and

reduced fuel economy. Wheel

deformation also is possible. Keep

your tire pressures at the proper

levels. If a tire frequently needs

refilling, have it checked by an

authorized Kia dealer.

Overinflation produces a harsh ride, excessive wear at the center

of the tire tread, and a greater pos-

sibility of damage from road haz-

ards.

Warm tires normally exceed rec- ommended cold tire pressures by 4

to 6 psi (28 to 41 kPa). Do not

release air from warm tires to

adjust the pressure or the tires will

be underinflated.

Be sure to reinstall the tire inflation valve caps. Without the valve cap,

dirt or moisture could get into the

valve core and cause air leakage. If

a valve cap is missing, install a

new one as soon as possible. Always observe the following:

Check tire pressure when the tires

are cold. (After vehicle has been

parked for at least three hours or

hasn't been driven more than one

mile (1.6 km) since startup.)

Check the pressure of your spare tire each time you check the pres-

sure of other tires.

Never overload your vehicle. Be careful not to overload a vehicle

luggage rack if your vehicle is

equipped with one.Checking tire inflation pres-

sure

Check your tires once a month or

more.

Also, check the tire pressure of the

spare tire.

How to check

Use a good quality gauge to check

tire pressure. You can not tell if your

tires are properly inflated simply by

looking at them. Radial tires may

look properly inflated even when

they're underinflated.

Check the tire's inflation pressure

when the tires are cold. - "Cold"

means your vehicle has been sitting

for at least three hours or driven no

more than 1 mile (1.6 km).

Page 429 of 495

757

Maintenance

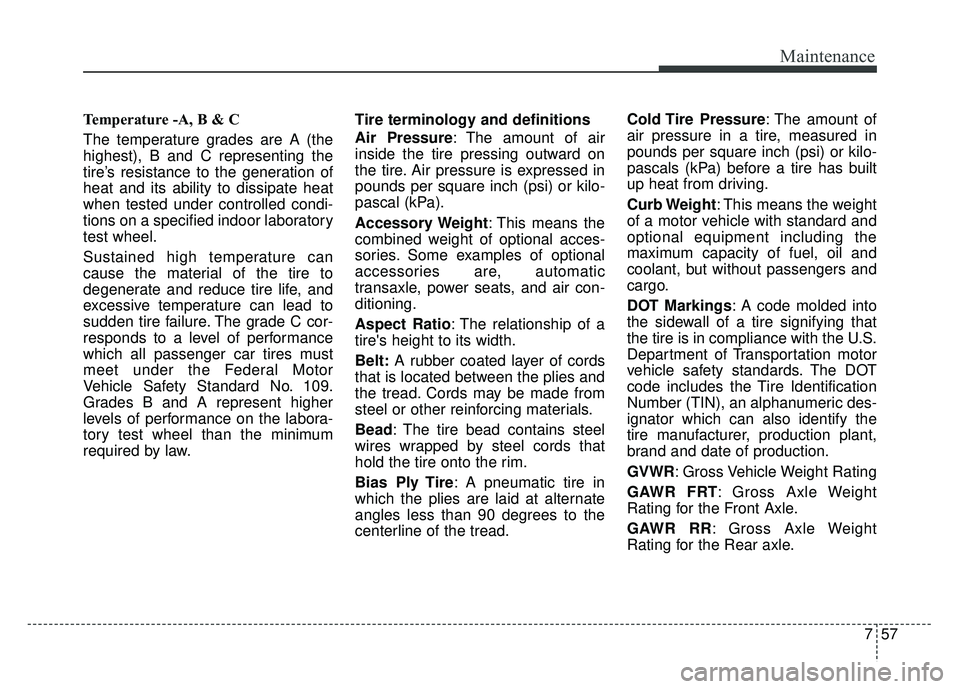

Temperature -A, B & C

The temperature grades are A (the

highest), B and C representing the

tire’s resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled condi-

tions on a specified indoor laboratory

test wheel.

Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. The grade C cor-

responds to a level of performance

which all passenger car tires must

meet under the Federal Motor

Vehicle Safety Standard No. 109.

Grades B and A represent higher

levels of performance on the labora-

tory test wheel than the minimum

required by law.Tire terminology and definitions

Air Pressure: The amount of air

inside the tire pressing outward on

the tire. Air pressure is expressed in

pounds per square inch (psi) or kilo-

pascal (kPa).

Accessory Weight

: This means the

combined weight of optional acces-

sories. Some examples of optional

accessories are, automatic

transaxle, power seats, and air con-

ditioning.

Aspect Ratio : The relationship of a

tire's height to its width.

Belt: A rubber coated layer of cords

that is located between the plies and

the tread. Cords may be made from

steel or other reinforcing materials.

Bead: The tire bead contains steel

wires wrapped by steel cords that

hold the tire onto the rim.

Bias Ply Tire : A pneumatic tire in

which the plies are laid at alternate

angles less than 90 degrees to the

centerline of the tread. Cold Tire Pressure: The amount of

air pressure in a tire, measured in

pounds per square inch (psi) or kilo-

pascals (kPa) before a tire has built

up heat from driving.

Curb Weight: This means the weight

of a motor vehicle with standard and

optional equipment including the

maximum capacity of fuel, oil and

coolant, but without passengers and

cargo.

DOT Markings: A code molded into

the sidewall of a tire signifying that

the tire is in compliance with the U.S.

Department of Transportation motor

vehicle safety standards. The DOT

code includes the Tire Identification

Number (TIN), an alphanumeric des-

ignator which can also identify the

tire manufacturer, production plant,

brand and date of production.

GVWR: Gross Vehicle Weight Rating

GAWR FRT: Gross Axle Weight

Rating for the Front Axle.

GAWR RR: Gross Axle Weight

Rating for the Rear axle.

Page 442 of 495

Maintenance

70

7

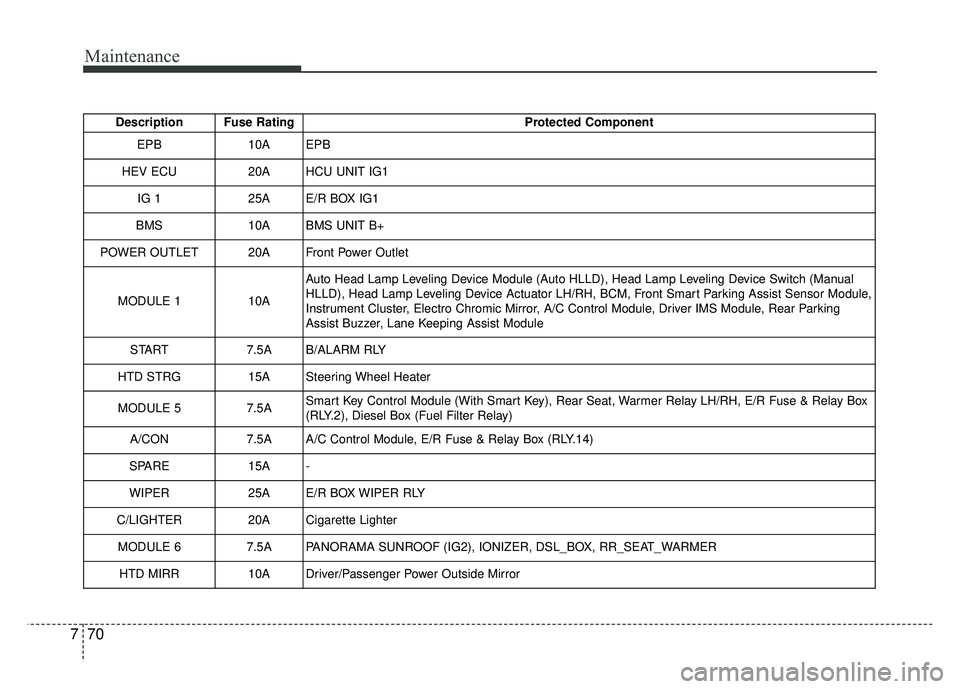

Description Fuse Rating Protected Component

EPB10AEPB

HEV ECU20AHCU UNIT IG1

IG 125AE/R BOX IG1

BMS 10A BMS UNIT B+

POWER OUTLET 20A Front Power Outlet

MODULE 1 10AAuto Head Lamp Leveling Device Module (Auto HLLD), Head Lamp Leveling Device Switch (Manual

HLLD), Head Lamp Leveling Device Actuator LH/RH, BCM, Front Smart Parking Assist Sensor Module,

Instrument Cluster, Electro Chromic Mirror, A/C Control Module, Driver IMS Module, Rear Parking

Assist Buzzer, Lane Keeping Assist Module

START 7.5A B/ALARM RLY

HTD STRG 15A Steering Wheel Heater

MODULE 5 7.5ASmart Key Control Module (With Smart Key), Rear Seat, Warmer Relay LH/RH, E/R Fuse & Relay Box

(RLY.2), Diesel Box (Fuel Filter Relay)

A/CON 7.5A A/C Control Module, E/R Fuse & Relay Box (RLY.14)

SPARE 15A -

WIPER 25A E/R BOX WIPER RLY

C/LIGHTER 20A Cigarette Lighter

MODULE 6 7.5A PANORAMA SUNROOF (IG2), IONIZER, DSL_BOX, RR_SEAT_WARMER

HTD MIRR 10A Driver/Passenger Power Outside Mirror

Page 444 of 495

Maintenance

72

7

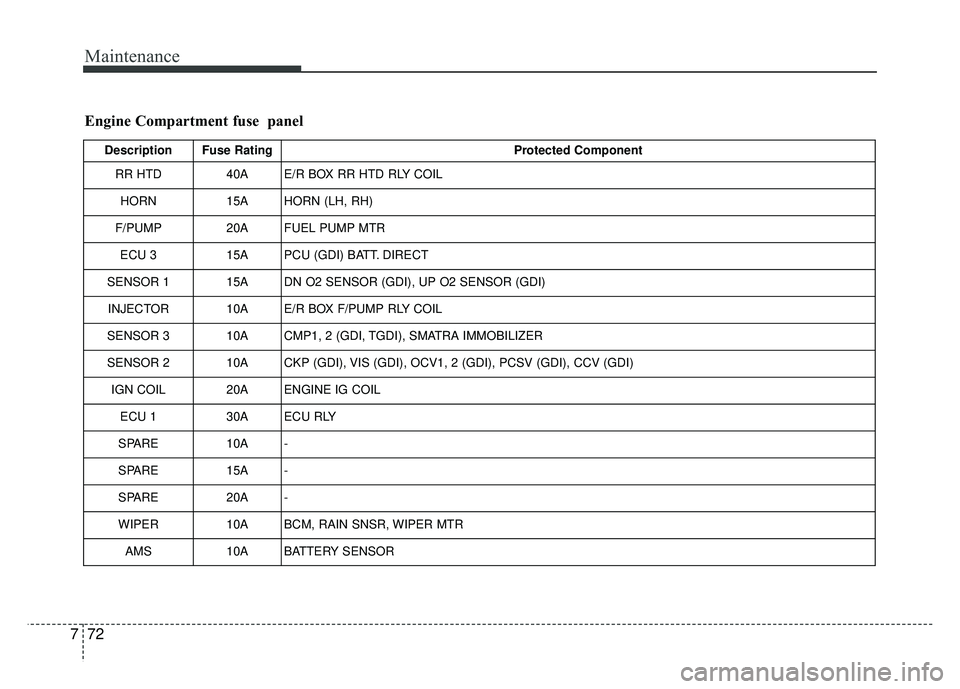

Engine Compartment fuse panel

Description Fuse Rating Protected Component

RR HTD 40A E/R BOX RR HTD RLY COIL

HORN 15A HORN (LH, RH)

F/PUMP 20A FUEL PUMP MTR

ECU 3 15A PCU (GDI) BATT. DIRECT

SENSOR 1 15A DN O2 SENSOR (GDI), UP O2 SENSOR (GDI) INJECTOR 10A E/R BOX F/PUMP RLY COIL

SENSOR 3 10A CMP1, 2 (GDI, TGDI), SMATRA IMMOBILIZER

SENSOR 2 10A CKP (GDI), VIS (GDI), OCV1, 2 (GDI), PCSV (GDI), CCV (GDI) IGN COIL 20A ENGINE IG COIL ECU 1 30A ECU RLY

SPARE 10A -

SPARE 15A -

SPARE 20A -

WIPER 10A BCM, RAIN SNSR, WIPER MTR

AMS 10A BATTERY SENSOR

Page 461 of 495

789

Maintenance

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major

repair expense.

If your vehicle is damaged and

requires any metal repair or replace-

ment, be sure the body shop applies

anti-corrosion materials to the parts

repaired or replaced.

Bright-metal maintenance

To remove road tar and insects,use a tar remover, not a scraper or

other sharp object.

To protect the surfaces of bright- metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may

collect on the underbody. If these

materials are not removed, acceler-

ated rusting can occur on underbody

parts such as the fuel lines, frame,

floor pan and exhaust system, even

though they have been treated with

rust protection.

Thoroughly flush the vehicle under-

body and wheel openings with luke-

warm or cold water once a month,

after off-road driving and at the end

of each winter. Pay special attention

to these areas because it is difficult

to see all the mud and dirt. It will do

more harm than good to wet down

the road grime without removing it.

The lower edges of doors, rocker pan-

els, and frame members have drain

holes that should not be allowed to

clog with dirt; trapped water in these

areas can cause rusting.

Page 466 of 495

Maintenance

94

7

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the

Warranty & Consumer Information

manual in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

applicable emission regulations.

There are three emission control

systems, as follows.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control system

In order to assure the proper function

of the emission control systems, it is

recommended that you have your

vehicle inspected and maintained by

an authorized Kia dealer in accor-

dance with the maintenance sched-

ule in this manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from mis-

firing during dynamometer test-

ing, turn the Electronic Stability

Control (ESC) system off by

pressing the ESC switch.

After dynamometer testing is completed, turn the ESC system

back on by pressing the ESC

switch again.1. Crankcase emission control system

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.

This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative emission con-trol (including ORVR:

Onboard Refueling Vapor

Recovery)

system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

(The ORVR system is designed to

allow the vapors from the fuel tank to

be loaded into a canister while refu-

eling at the gas station, preventing

the escape of fuel vapors into the

atmosphere.)