boot KIA OPTIMA PHEV 2018 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: OPTIMA PHEV, Model: KIA OPTIMA PHEV 2018Pages: 547, PDF Size: 11.56 MB

Page 428 of 547

Maintenance

16

8

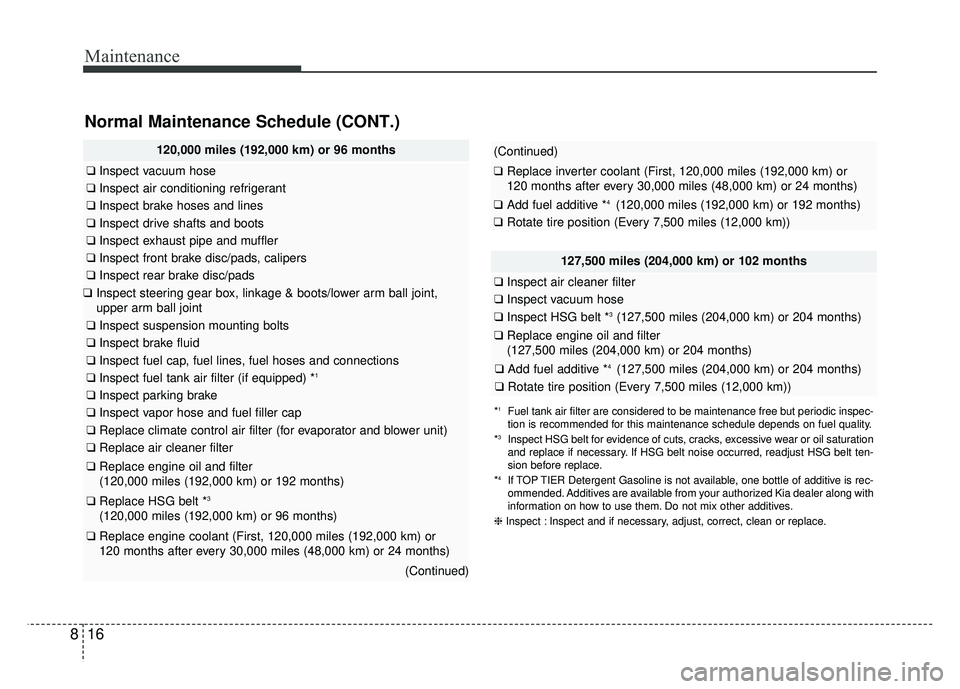

Normal Maintenance Schedule (CONT.)

120,000 miles (192,000 km) or 96 months

❑ Inspect vacuum hose

❑Inspect air conditioning refrigerant

❑Inspect brake hoses and lines

❑Inspect drive shafts and boots

❑Inspect exhaust pipe and muffler

❑Inspect front brake disc/pads, calipers

❑Inspect rear brake disc/pads

❑Inspect steering gear box, linkage & boots/lower arm ball joint,

upper arm ball joint

❑ Inspect suspension mounting bolts

❑Inspect brake fluid

❑Inspect fuel cap, fuel lines, fuel hoses and connections

❑Inspect fuel tank air filter (if equipped) *1

❑Inspect parking brake

❑Inspect vapor hose and fuel filler cap

❑Replace climate control air filter (for evaporator and blower unit)

❑Replace air cleaner filter

❑Replace engine oil and filter

(120,000 miles (192,000 km) or 192 months)

❑Replace HSG belt *3

(120,000 miles (192,000 km) or 96 months)

❑Replace engine coolant (First, 120,000 miles (192,000 km) or

120 months after every 30,000 miles (48,000 km) or 24 months)

(Continued)

*1Fuel tank air filter are considered to be maintenance free but periodic inspec-

tion is recommended for this maintenance schedule depends on fuel quality.

*

3Inspect HSG belt for evidence of cuts, cracks, excessive wear or oil saturation

and replace if necessary. If HSG belt noise occurred, readjust HSG belt ten-

sion before replace.

*

4If TOP TIER Detergent Gasoline is not available, one bottle of additive is rec-

ommended. Additives are available from your authorized Kia dealer along with

information on how to use them. Do not mix other additives.

❈ Inspect : Inspect and if necessary, adjust, correct, clean or replace.

127,500 miles (204,000 km) or 102 months

❑Inspect air cleaner filter

❑Inspect vacuum hose

❑Inspect HSG belt *3(127,500 miles (204,000 km) or 204 months)

❑Replace engine oil and filter

(127,500 miles (204,000 km) or 204 months)

❑ Add fuel additive *4 (127,500 miles (204,000 km) or 204 months)

❑Rotate tire position (Every 7,500 miles (12,000 km))

(Continued)

❑Replace inverter coolant (First, 120,000 miles (192,000 km) or

120 months after every 30,000 miles (48,000 km) or 24 months)

❑ Add fuel additive *4 (120,000 miles (192,000 km) or 192 months)

❑Rotate tire position (Every 7,500 miles (12,000 km))

Page 429 of 547

817

Maintenance

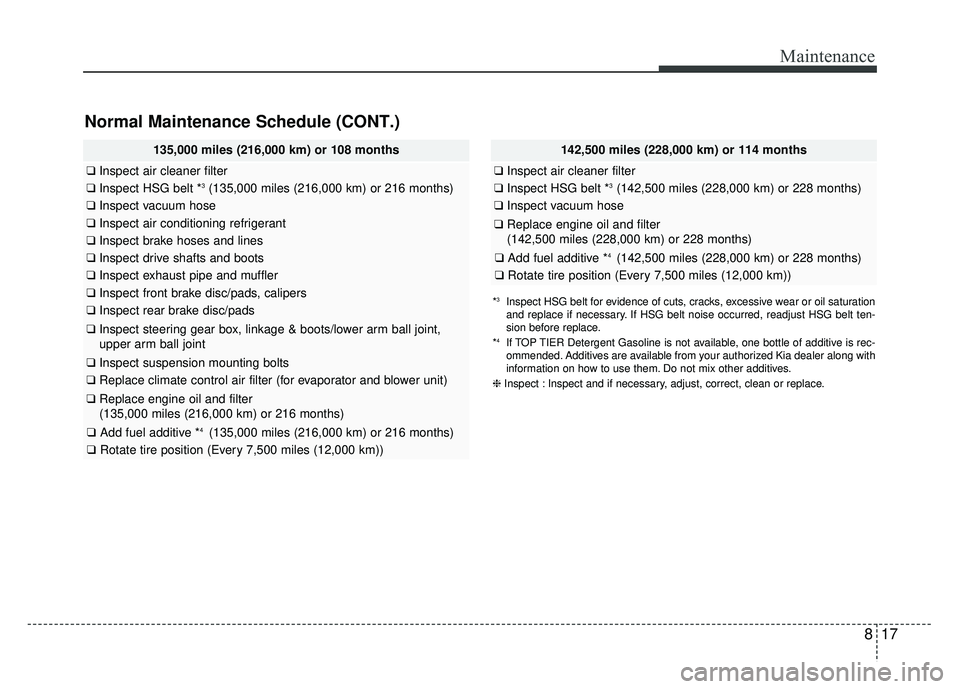

Normal Maintenance Schedule (CONT.)

135,000 miles (216,000 km) or 108 months

❑Inspect air cleaner filter

❑Inspect HSG belt *3(135,000 miles (216,000 km) or 216 months)

❑Inspect vacuum hose

❑Inspect air conditioning refrigerant

❑Inspect brake hoses and lines

❑Inspect drive shafts and boots

❑Inspect exhaust pipe and muffler

❑Inspect front brake disc/pads, calipers

❑Inspect rear brake disc/pads

❑Inspect steering gear box, linkage & boots/lower arm ball joint,

upper arm ball joint

❑ Inspect suspension mounting bolts

❑Replace climate control air filter (for evaporator and blower unit)

❑Replace engine oil and filter

(135,000 miles (216,000 km) or 216 months)

❑ Add fuel additive *4 (135,000 miles (216,000 km) or 216 months)

❑Rotate tire position (Every 7,500 miles (12,000 km))

142,500 miles (228,000 km) or 114 months

❑Inspect air cleaner filter

❑Inspect HSG belt *3(142,500 miles (228,000 km) or 228 months)

❑Inspect vacuum hose

❑Replace engine oil and filter

(142,500 miles (228,000 km) or 228 months)

❑ Add fuel additive *4 (142,500 miles (228,000 km) or 228 months)

❑Rotate tire position (Every 7,500 miles (12,000 km))

*3Inspect HSG belt for evidence of cuts, cracks, excessive wear or oil saturation

and replace if necessary. If HSG belt noise occurred, readjust HSG belt ten-

sion before replace.

*

4If TOP TIER Detergent Gasoline is not available, one bottle of additive is rec-

ommended. Additives are available from your authorized Kia dealer along with

information on how to use them. Do not mix other additives.

❈ Inspect : Inspect and if necessary, adjust, correct, clean or replace.

Page 430 of 547

Maintenance

18

8

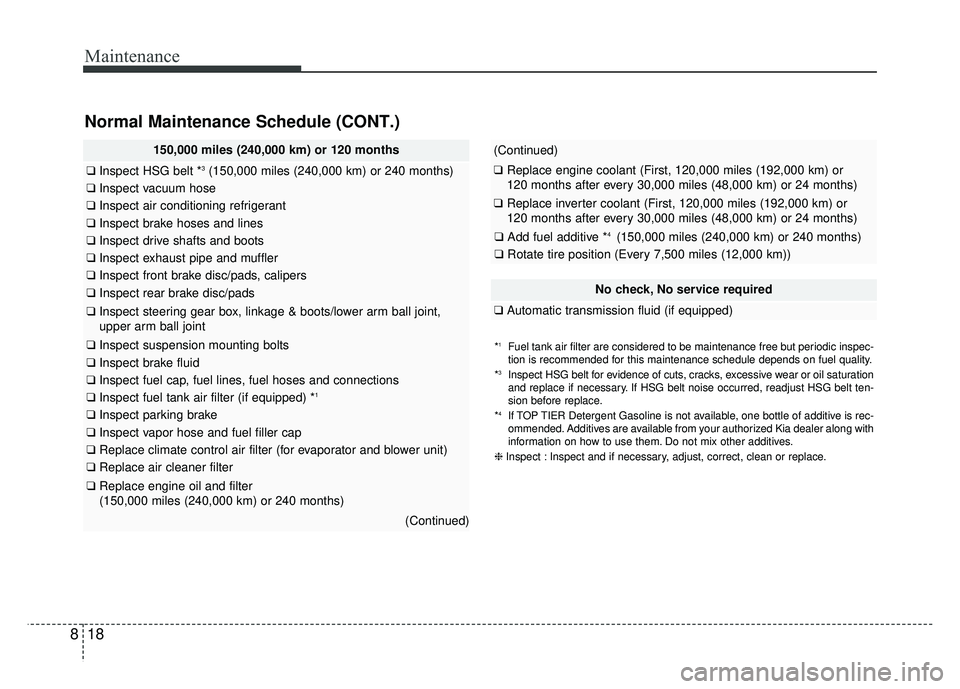

Normal Maintenance Schedule (CONT.)

150,000 miles (240,000 km) or 120 months

❑ Inspect HSG belt *3(150,000 miles (240,000 km) or 240 months)

❑Inspect vacuum hose

❑Inspect air conditioning refrigerant

❑Inspect brake hoses and lines

❑Inspect drive shafts and boots

❑Inspect exhaust pipe and muffler

❑Inspect front brake disc/pads, calipers

❑Inspect rear brake disc/pads

❑Inspect steering gear box, linkage & boots/lower arm ball joint,

upper arm ball joint

❑ Inspect suspension mounting bolts

❑Inspect brake fluid

❑Inspect fuel cap, fuel lines, fuel hoses and connections

❑Inspect fuel tank air filter (if equipped) *1

❑Inspect parking brake

❑Inspect vapor hose and fuel filler cap

❑Replace climate control air filter (for evaporator and blower unit)

❑Replace air cleaner filter

❑Replace engine oil and filter

(150,000 miles (240,000 km) or 240 months)

(Continued)

(Continued)

❑Replace engine coolant (First, 120,000 miles (192,000 km) or

120 months after every 30,000 miles (48,000 km) or 24 months)

❑Replace inverter coolant (First, 120,000 miles (192,000 km) or

120 months after every 30,000 miles (48,000 km) or 24 months)

❑ Add fuel additive *4 (150,000 miles (240,000 km) or 240 months)

❑Rotate tire position (Every 7,500 miles (12,000 km))

No check, No service required

❑Automatic transmission fluid (if equipped)

*1Fuel tank air filter are considered to be maintenance free but periodic inspec-

tion is recommended for this maintenance schedule depends on fuel quality.

*

3Inspect HSG belt for evidence of cuts, cracks, excessive wear or oil saturation

and replace if necessary. If HSG belt noise occurred, readjust HSG belt ten-

sion before replace.

*

4If TOP TIER Detergent Gasoline is not available, one bottle of additive is rec-

ommended. Additives are available from your authorized Kia dealer along with

information on how to use them. Do not mix other additives.

❈ Inspect : Inspect and if necessary, adjust, correct, clean or replace.

Page 431 of 547

819

Maintenance

Maintenance Under Severe Usage Conditions

Severe Driving Conditions

A - Repeatedly driving short distance of less than 5 miles (8 km) in normaltemperature or less than 10 miles (16 km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in heavy dust condition. F - Driving in heavy traffic area.

G - Driving on uphill, downhill, or mountain roads repeatedly.

H - Towing a trailer or using a camper on roof rack.

I - Driving for patrol car, taxi, other commercial use of vehicle towing.

J - Driving over 106 mph (170 km/h).

K - Frequently driving in stop-and-go conditions.

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer

to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if neces\

sary

MAINTENANCE ITEMMAINTENANCE

OPERATIONMAINTENANCE INTERVALSDRIVING CONDITION

Engine oil and filter REvery 3,750 miles (6,000 km) or 6 monthsA, B, C, D, E, F, G,

H, I, J, K

Air cleaner filterRMore frequentlyC, E

Spark plugsRMore frequentlyB, H

Automatic transmission fluidREvery 60,000 miles (96,000 km)A, C, D, E, F, G, H, I, K

HSG (Hybrid Starter & Generator) beltREvery 30,000 miles (48,000 km) or 24 monthsC, D, E, K

IEvery 3,750 miles (6,000 km) or 6 monthsC, D, E, K

Front brake disc/pads, calipersIMore frequentlyC, D, G, H

Rear brake disc/padsIMore frequentlyC, D, G, F

Parking brakeIMore frequentlyC, D, G, H

Steering gear box, linkage & boots/lower arm ball joint,

upper arm ball jointIMore frequentlyC, D, E, F, G, H, I

Drive shafts and bootsIEvery 7,500 miles (12,000 km) or 6 monthsC, D, E, F, G, H, I, J

Climate control air filter (for evaporator and blower unit)RMore frequentlyC, E

Suspension mounting boltsIMore frequentlyC, D, E, F, G, H, I

Page 435 of 547

823

Maintenance

Exhaust pipe and muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.When checking engine oil, engine

coolant, brake fluid, and washer fluid,

always be sure to clean the area

around any filler plug, drain plug, or

dipstick before checking or draining

any lubricant or fluid. This is espe-

cially important in dusty or sandy

areas and when the vehicle is used

on unpaved roads. Cleaning the plug

and dipstick areas will prevent dirt

and grit from entering the engine and

other mechanisms that could be

damaged.

CHECKING FLUID LEVELS

Page 480 of 547

Maintenance

68

8

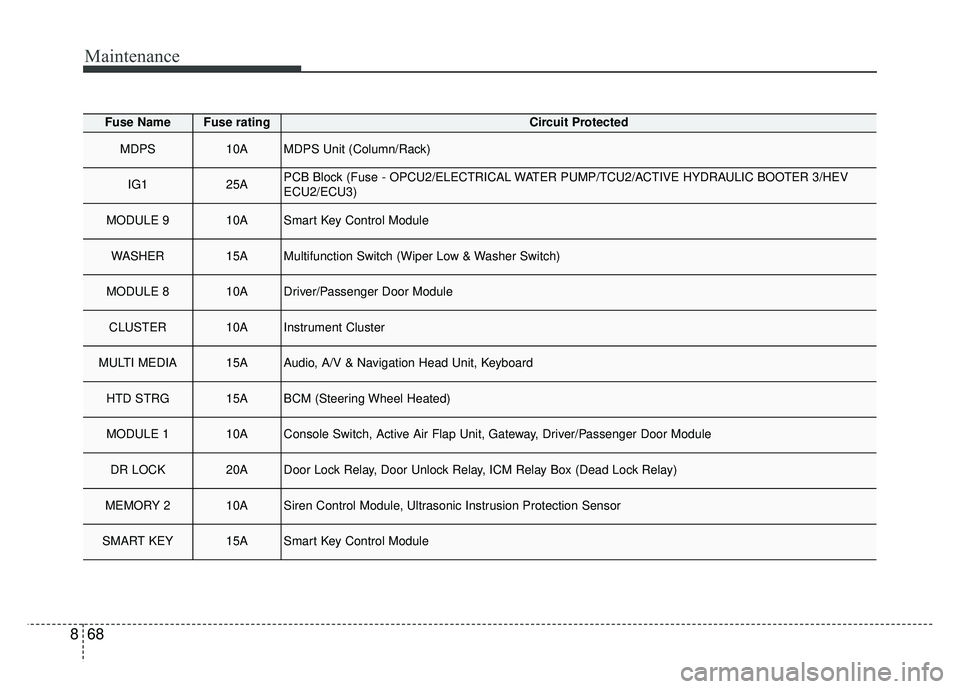

Fuse NameFuse ratingCircuit Protected

MDPS10AMDPS Unit (Column/Rack)

IG125APCB Block (Fuse - OPCU2/ELECTRICAL WATER PUMP/TCU2/ACTIVE HYDRAULIC BOOTER 3/HEV

ECU2/ECU3)

MODULE 910ASmart Key Control Module

WASHER15AMultifunction Switch (Wiper Low & Washer Switch)

MODULE 810ADriver/Passenger Door Module

CLUSTER10AInstrument Cluster

MULTI MEDIA15AAudio, A/V & Navigation Head Unit, Keyboard

HTD STRG15ABCM (Steering Wheel Heated)

MODULE 110AConsole Switch, Active Air Flap Unit, Gateway, Driver/Passenger Door Module

DR LOCK20ADoor Lock Relay, Door Unlock Relay, ICM Relay Box (Dead Lock Relay)

MEMORY 210ASiren Control Module, Ultrasonic Instrusion Protection Sensor

SMART KEY15ASmart Key Control Module

Page 488 of 547

Maintenance

76

8

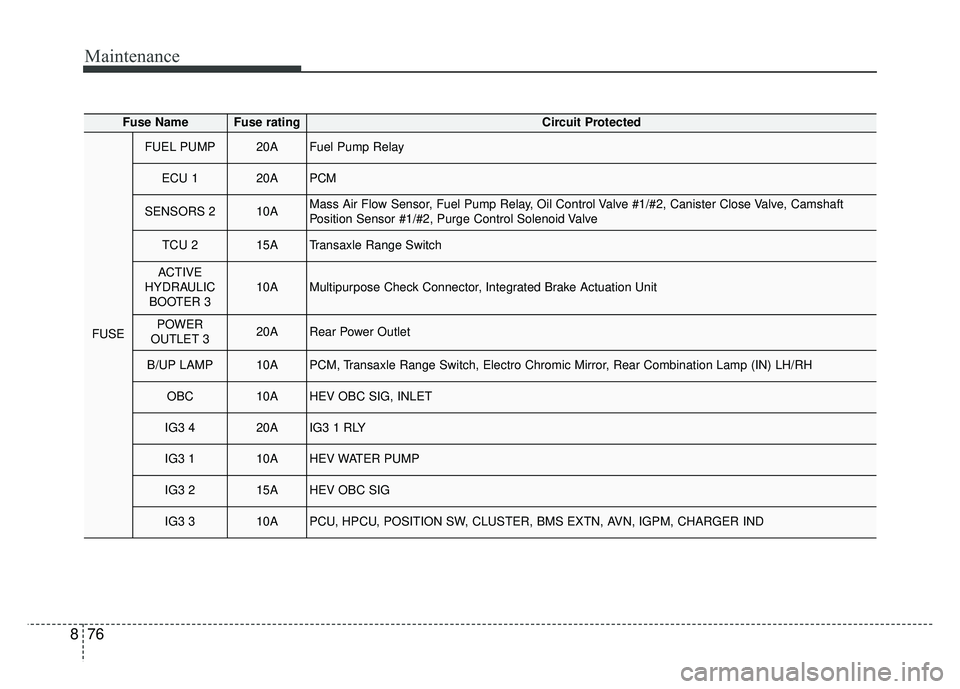

Fuse NameFuse ratingCircuit Protected

FUSE

FUEL PUMP20AFuel Pump Relay

ECU 120APCM

SENSORS 210AMass Air Flow Sensor, Fuel Pump Relay, Oil Control Valve #1/#2, Canister Close Valve, Camshaft

Position Sensor #1/#2, Purge Control Solenoid Valve

TCU 2 15ATransaxle Range Switch

ACTIVE

HYDRAULIC BOOTER 310AMultipurpose Check Connector, Integrated Brake Actuation Unit

POWER

OUTLET 320ARear Power Outlet

B/UP LAMP10APCM, Transaxle Range Switch, Electro Chromic Mirror, Rear Combination Lamp (IN) LH/RH

OBC10AHEV OBC SIG, INLET

IG3 420AIG3 1 RLY

IG3 110AHEV WATER PUMP

IG3 215AHEV OBC SIG

IG3 310APCU, HPCU, POSITION SW, CLUSTER, BMS EXTN, AVN, IGPM, CHARGER IND

Page 506 of 547

Maintenance

94

8

APPEARANCE CARE

Exterior care

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning

and caution statements that appear

on the label.

Finish maintenance

Washing

To help protect your vehicle’s finish

from rust and deterioration, wash it

thoroughly and frequently at least

once a month with lukewarm or cold

water.

If you use your vehicle for off-road

driving, you should wash it after each

off-road trip. Pay special attention to

the removal of any accumulation of

salt, dirt, mud, and other foreign mate-

rials. Make sure the drain holes in the

lower edges of the doors and rocker

panels are kept clear and clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar

deposits can damage your vehicle’s

finish if not removed immediately. Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used.

After washing, rinse the vehicle thor-

oughly with lukewarm or cold water.

Do not allow soap to dry on the finish.

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired, dry

the brakes by applying them lightly

while maintaining a slow forward

speed.

High-pressure washing

When using high-pressure wash-

ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water.

Page 538 of 547

Index

6I

Engine start/stop button . . . . . . . . . . . . . . . . . . . . . . . . . 6-6Illuminated engine start/stop button. . . . . . . . . . . . . . 6-6

Engine start/stop button position . . . . . . . . . . . . . . . . 6-6

Starting the hybrid system . . . . . . . . . . . . . . . . . . . . . 6-8

Engine start/stop button illumination . . . . . . . . . . . . . . . 6-6

Engine start/stop button position . . . . . . . . . . . . . . . . . . 6-6

Engine will not start . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Evaporative emission control (including ORVR: Onboard Refueling Vapor Recovery) system . . . . . 8-102

Exhaust emission control system . . . . . . . . . . . . . . . . 8-103

Explanation of scheduled maintenance items . . . . . . . 8-20 Engine oil and filter . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Hybrid starter & generator belt . . . . . . . . . . . . . . . . 8-20

Fuel filter (for gasoline) . . . . . . . . . . . . . . . . . . . . . . 8-20

Fuel lines, fuel hoses and connections . . . . . . . . . . . 8-20

Vapor hose and fuel filler cap . . . . . . . . . . . . . . . . . 8-20

Vacuum crankcase ventilation hoses . . . . . . . . . . . . 8-20

Air cleaner filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

Spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

Coolant (Engine / Inverter) . . . . . . . . . . . . . . . . . . . 8-21

Automatic transaxle fluid . . . . . . . . . . . . . . . . . . . . . 8-21

Brake hoses and lines . . . . . . . . . . . . . . . . . . . . . . . . 8-21

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Brake discs, pads, calipers and rotors . . . . . . . . . . . 8-22

Exhaust pipe and muffler . . . . . . . . . . . . . . . . . . . . . 8-23

Suspension mounting bolts . . . . . . . . . . . . . . . . . . . 8-23 Steering gear box, linkage & boots/

lower arm ball joint . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Drive shafts and boots . . . . . . . . . . . . . . . . . . . . . . . 8-23

Air conditioning refrigerant . . . . . . . . . . . . . . . . . . . 8-23

Exterior care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-94

Exterior overview (Front) . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Exterior overview (Rear) . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Flat tires, see tire mobility kit. . . . . . . . . . . . . . . . . . . . 7-16

Floor mat anchor(s) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-140

Fluid Checking fluid levels . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Folding the outside rearview mirror . . . . . . . . . . . . . . . 4-50

"Front passenger andrear seat 3-point system withcombination locking retractor" . . . . . . . . . . . . . 3-25

Front passenger's seat belt warning . . . . . . . . . . . . . . . 3-23

Front seat adjustment (manual) . . . . . . . . . . . . . . . . . . . 3-7

Front seat adjustment (power) . . . . . . . . . . . . . . . . . . . . 3-8

Front turn signal lamp bulb replacement . . . . . . . . . . . 8-85

Fuel filler lid (Hybrid) . . . . . . . . . . . . . . . . . . . . . . . . . 4-29 Emergency fuel filler lid release . . . . . . . . . . . . . . . 4-32

Fuel filler lid (Plug-in Hybrid) . . . . . . . . . . . . . . . . . . . 4-33 Emergency fuel filler lid release . . . . . . . . . . . . . . . 4-35

Fuel Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55\

F