cooling KIA PICANTO 2008 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2008, Model line: PICANTO, Model: KIA PICANTO 2008Pages: 335, PDF Size: 12.98 MB

Page 267 of 335

Maintenance

16

7

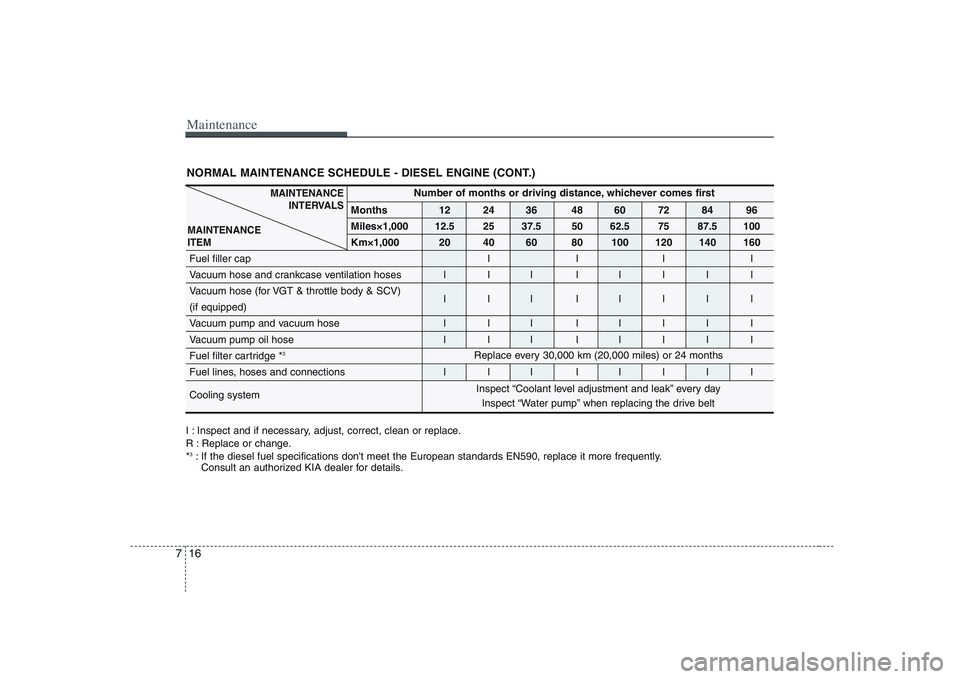

NORMAL MAINTENANCE SCHEDULE - DIESEL ENGINE (CONT.)

Number of months or driving distance, whichever comes first

Months 12 24 36 48 60 72 84 96 Miles×1,000

12.5 25 37.5 50 62.5 75 87.5 100

Km×1,000 20 40 60 80 100 120 140 160

Fuel filler cap I I I I

Vacuum hose and crankcase ventilation hoses I I I I I I I I

Vacuum hose (for VGT & throttle body & SCV) III IIIII

(if equipped)

Vacuum pump and vacuum hose I I I I I I I I

Vacuum pump oil hose I I I I I I I I

Fuel filter cartridge * 3

Fuel lines, hoses and connections I I I I I I I I Cooling system Inspect “Coolant level adjustment and leak” every day

Replace every 30,000 km (20,000 miles) or 24 months

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.*

3

: If the diesel fuel specifications don't meet the European standards EN590, replace it more frequently.

Consult an authorized KIA dealer for details.

MAINTENANCE

INTERVALS

MAINTENANCE ITEM

Inspect “Water pump” when replacing the drive belt

Page 273 of 335

Maintenance

22

7

G050800AUN

Air cleaner filter

A Genuine KIA air cleaner filter is recom- mended when the filter is replaced.

G050900AUN

Spark plugs (for gasoline engine)

Make sure to install new spark plugs of

the correct heat range.

G051000AUN

Valve clearance (if equipped)

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorized KIA dealer should perform

the operation.

G051100AUN Cooling system

Check the cooling system components,

such as radiator, coolant reservoir, hoses

and connections for leakage and dam-

age. Replace any damaged parts. G051200AUN Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

G051300AUN

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

G051400AUN

Automatic transaxle fluid (if equipped)

The fluid level should be in the "HOT"

range of the dipstick, after the engine

and transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine run-

ning and the transaxle in neutral, with the

parking brake properly applied.

G051500AUN Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.G051600ASA Brake fluid

Check the brake fluid level in the brake

fluid reservoir. The level should be

between “MIN” and “MAX” marks on the

side of the reservoir. Use only hydraulic

brake fluid conforming to DOT 3 or DOT4 specification.

G051700AUN

Parking brake

Inspect the parking brake system includ-

ing the parking brake pedal and cables.

G051800APA Rear brake drums and linings (if equipped)

Check the rear brake drums and linings

for scoring, burning, leaking fluid, broken

parts, and excessive wear.

G051900AUN

Brake discs, pads, calipers and

rotors

Check the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage.

Page 276 of 335

725

Maintenance

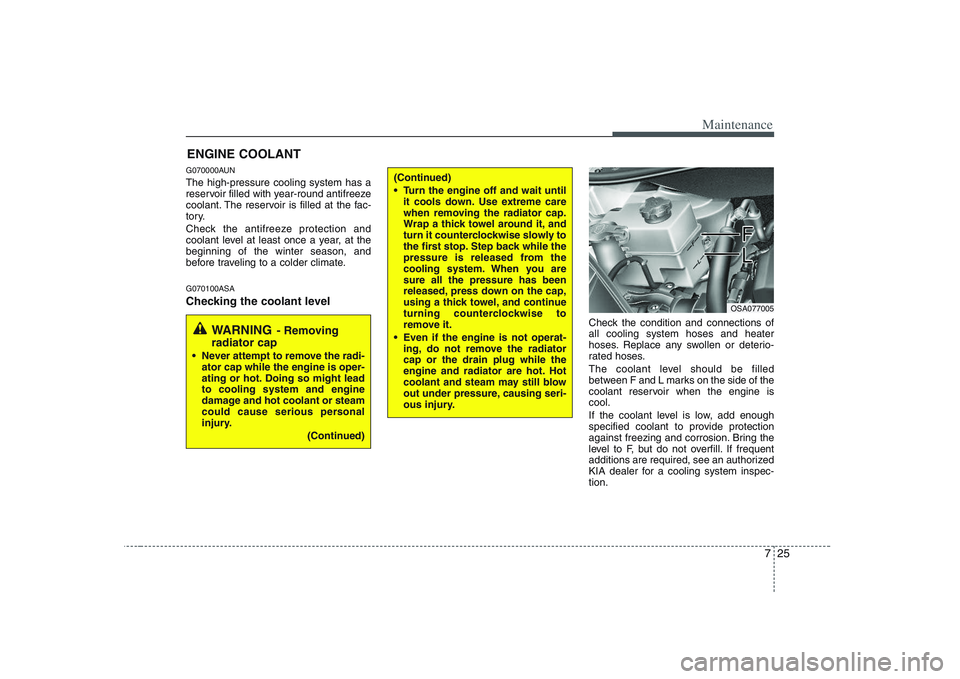

ENGINE COOLANT

G070000AUN The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the fac-

tory.

Check the antifreeze protection and

coolant level at least once a year, at thebeginning of the winter season, and

before traveling to a colder climate. G070100ASA

Checking the coolant level Check the condition and connections of all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F and L marks on the side of the

coolant reservoir when the engine iscool.

If the coolant level is low, add enough

specified coolant to provide protection

against freezing and corrosion. Bring the

level to F, but do not overfill. If frequent

additions are required, see an authorized

KIA dealer for a cooling system inspec-tion.

WARNING- Removing

radiator cap

Never attempt to remove the radi- ator cap while the engine is oper-

ating or hot. Doing so might leadto cooling system and engine

damage and hot coolant or steam

could cause serious personal

injury.

(Continued)

(Continued)

Turn the engine off and wait untilit cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the

cooling system. When you aresure all the pressure has been

released, press down on the cap,

using a thick towel, and continue

turning counterclockwise to

remove it.

Even if the engine is not operat- ing, do not remove the radiatorcap or the drain plug while the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

OSA077005