air filter KIA PICANTO 2011 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2011, Model line: PICANTO, Model: KIA PICANTO 2011Pages: 336, PDF Size: 24.51 MB

Page 271 of 336

Maintenance

18

7

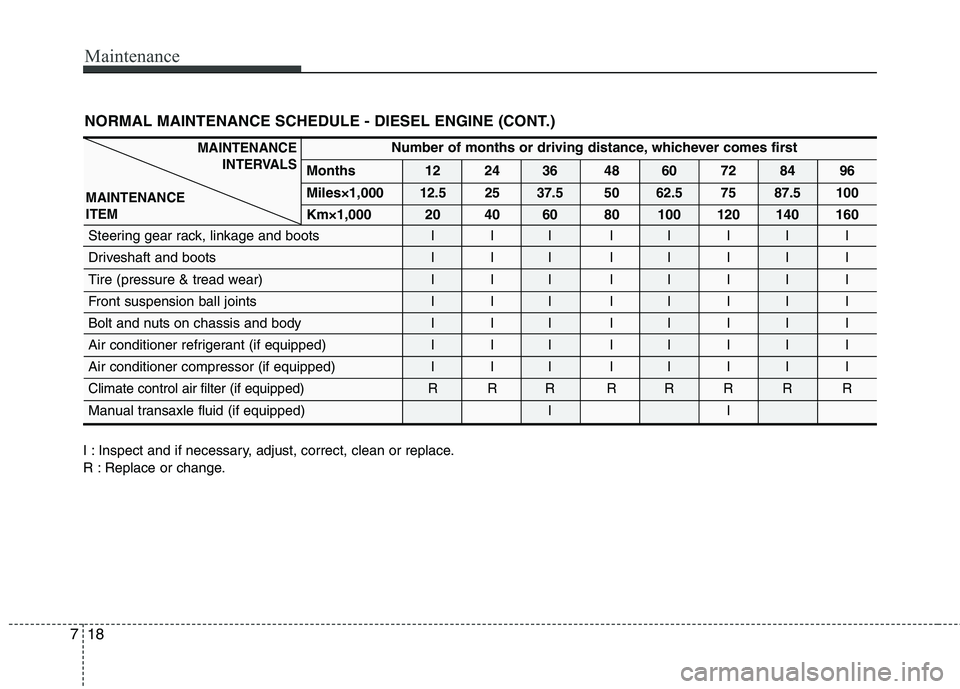

NORMAL MAINTENANCE SCHEDULE - DIESEL ENGINE (CONT.)

Number of months or driving distance, whichever comes first

Months 12 24 36 48 60 72 84 96 Miles×1,000

12.5 25 37.5 50 62.5 75 87.5 100

Km×1,000 20 40 60 80 100 120 140 160

Steering gear rack, linkage and boots I I I I I I I I

Driveshaft and boots I I I I I I I I

Tire (pressure & tread wear) I I I I I I I I

Front suspension ball joints I I I I I I I I

Bolt and nuts on chassis and body I I I I I I I I

Air conditioner refrigerant (if equipped) I I I I I I I I

Air conditioner compressor (if equipped) I I I I I I I I

Climate control air filter (if equipped) R R R R R R R R

Manual transaxle fluid (if equipped) I I

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

MAINTENANCE

INTERVALS

MAINTENANCE ITEM

Page 272 of 336

719

Maintenance

G040400ASA

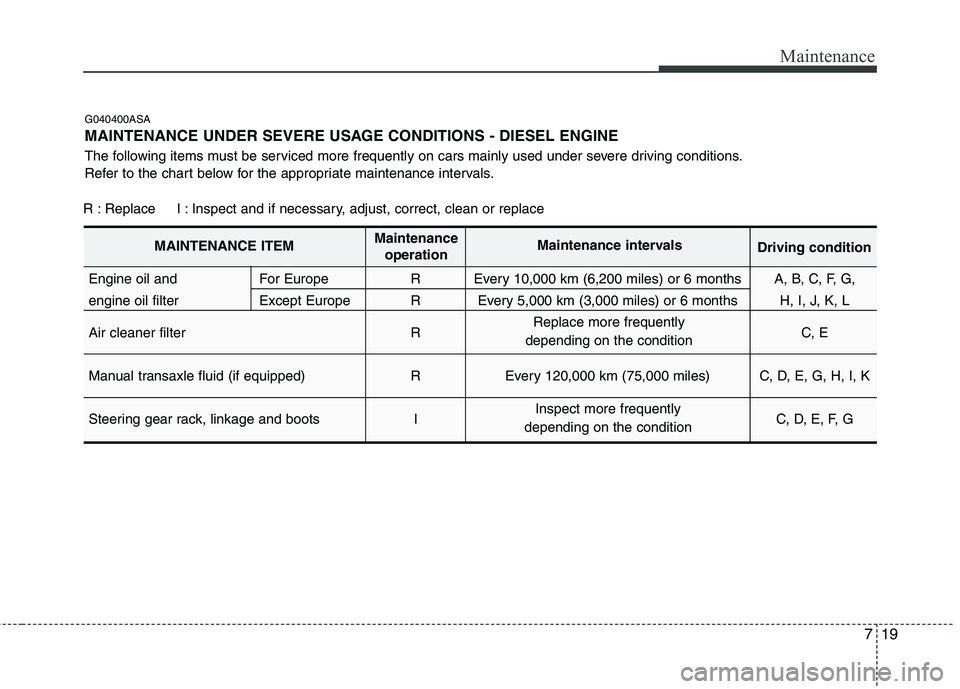

MAINTENANCE UNDER SEVERE USAGE CONDITIONS - DIESEL ENGINE

The following items must be serviced more frequently on cars mainly used under severe driving conditions.

Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and if necessary, adjust, correct, clean or replace

MAINTENANCE ITEMMaintenance

operation Maintenance intervals

Driving condition

Replace more frequently

depending on the condition

Engine oil and For Europe R Every 10,000 km (6,200 miles) or 6 months A, B, C, F, G,

engine oil filter Except Europe R Every 5,000 km (3,000 miles) or 6 months H, I, J, K, L

Air cleaner filter R

C, E

Manual transaxle fluid (if equipped) R Every 120,000 km (75,000 miles) C, D, E, G, H, I, K

Steering gear rack, linkage and boots I C, D, E, F, G

Inspect more frequently

depending on the condition

Page 273 of 336

Maintenance

20

7

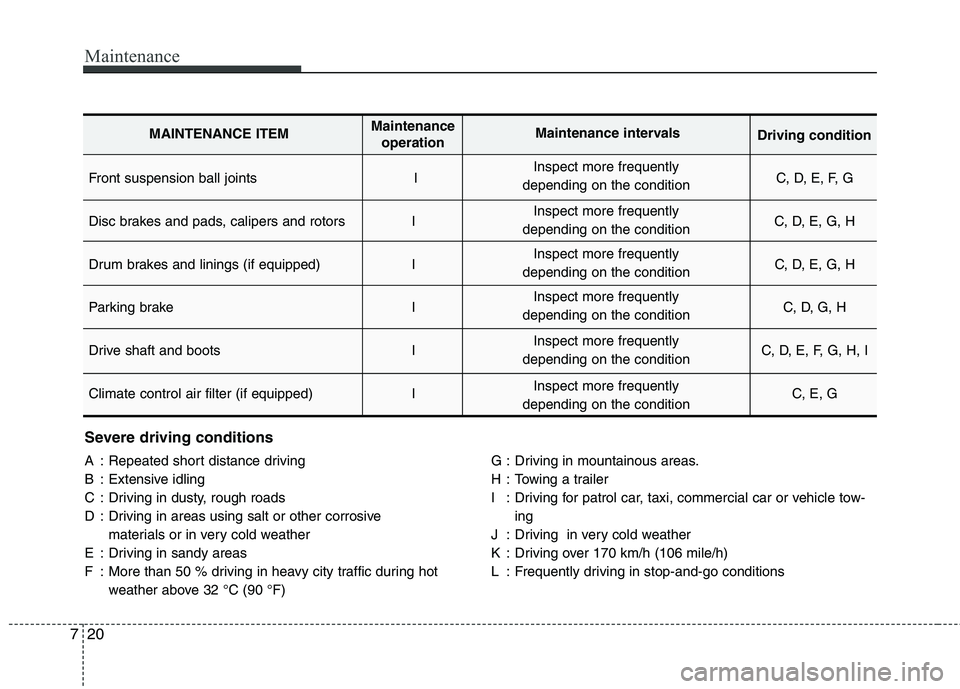

Severe driving conditions

A : Repeated short distance driving

B : Extensive idling

C : Driving in dusty, rough roads

D : Driving in areas using salt or other corrosive

materials or in very cold weather

E : Driving in sandy areas

F : More than 50 % driving in heavy city traffic during hot weather above 32 °C (90 °F) G : Driving in mountainous areas.

H : Towing a trailer

I : Driving for patrol car, taxi, commercial car or vehicle tow-

ing

J : Driving in very cold weather

K : Driving over 170 km/h (106 mile/h)

L : Frequently driving in stop-and-go conditions

Front suspension ball joints I C, D, E, F, G

Disc brakes and pads, calipers and rotors I C, D, E, G, H

Drum brakes and linings (if equipped) I C, D, E, G, H

Parking brake I C, D, G, H

Drive shaft and boots I C, D, E, F, G, H, I

Climate control air filter (if equipped) I C, E, G

MAINTENANCE ITEMMaintenance

operation Maintenance intervals

Driving condition

Inspect more frequently

depending on the condition

Inspect more frequently

depending on the condition

Inspect more frequently

depending on the condition

Inspect more frequently

depending on the condition

Inspect more frequently

depending on the condition

Inspect more frequently

depending on the condition

Page 275 of 336

Maintenance

22

7

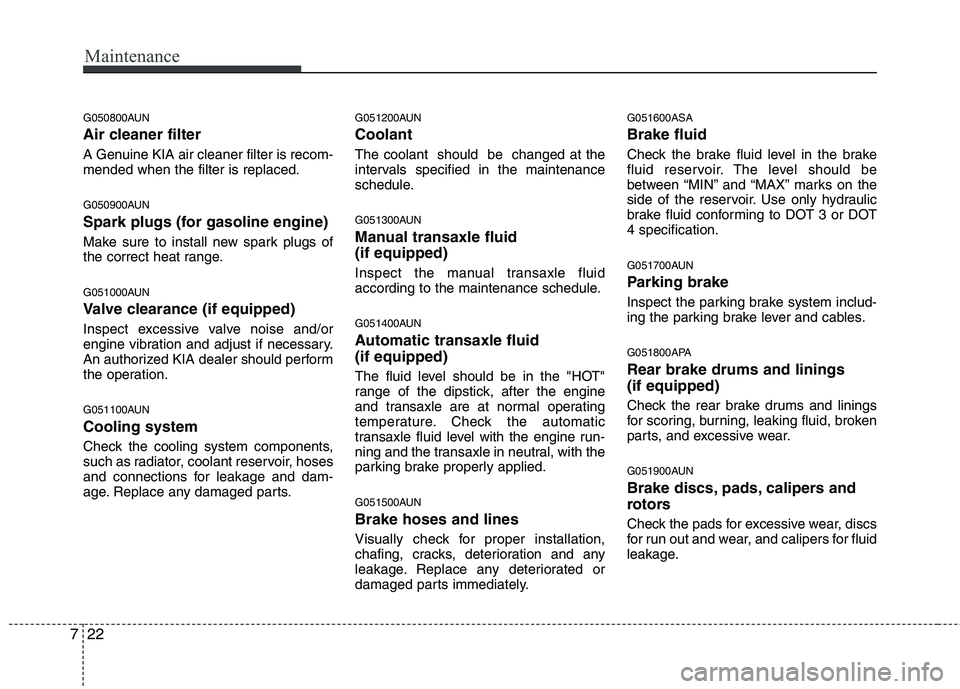

G050800AUN

Air cleaner filter

A Genuine KIA air cleaner filter is recom- mended when the filter is replaced.

G050900AUN

Spark plugs (for gasoline engine)

Make sure to install new spark plugs of

the correct heat range.

G051000AUN

Valve clearance (if equipped)

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorized KIA dealer should perform

the operation.

G051100AUN Cooling system

Check the cooling system components,

such as radiator, coolant reservoir, hoses

and connections for leakage and dam-

age. Replace any damaged parts. G051200AUN Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

G051300AUN

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

G051400AUN

Automatic transaxle fluid (if equipped)

The fluid level should be in the "HOT"

range of the dipstick, after the engine

and transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine run-

ning and the transaxle in neutral, with the

parking brake properly applied.

G051500AUN Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.G051600ASA Brake fluid

Check the brake fluid level in the brake

fluid reservoir. The level should be

between “MIN” and “MAX” marks on the

side of the reservoir. Use only hydraulic

brake fluid conforming to DOT 3 or DOT4 specification.

G051700AUN

Parking brake

Inspect the parking brake system includ-

ing the parking brake lever and cables.

G051800APA Rear brake drums and linings (if equipped)

Check the rear brake drums and linings

for scoring, burning, leaking fluid, broken

parts, and excessive wear.

G051900AUN

Brake discs, pads, calipers and

rotors

Check the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage.

Page 286 of 336

733

Maintenance

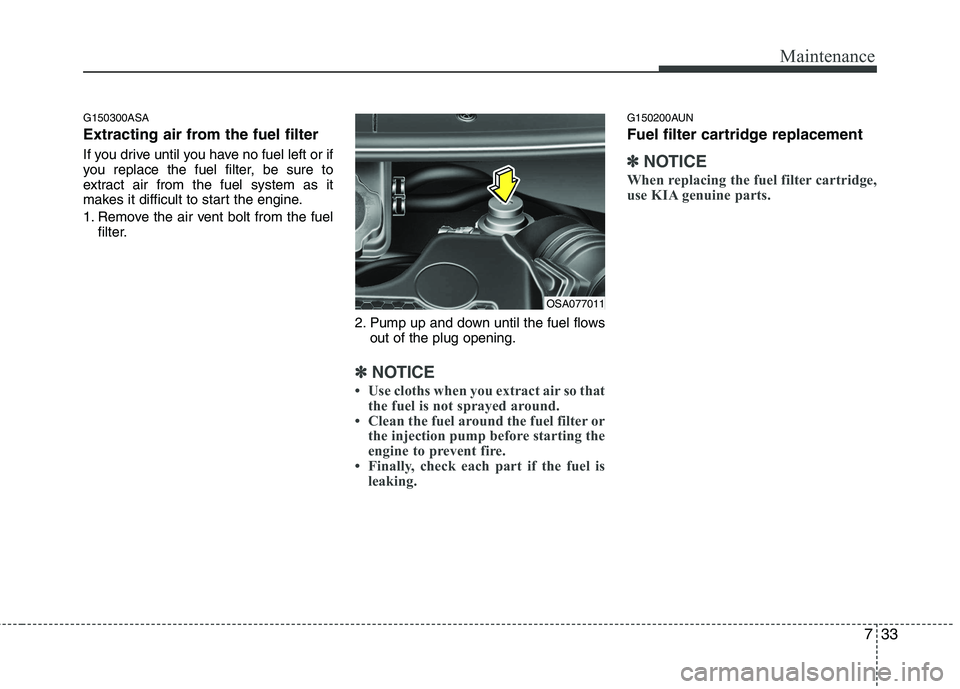

G150300ASA

Extracting air from the fuel filter

If you drive until you have no fuel left or if

you replace the fuel filter, be sure to

extract air from the fuel system as it

makes it difficult to start the engine.

1. Remove the air vent bolt from the fuelfilter.

2. Pump up and down until the fuel flowsout of the plug opening.

✽✽ NOTICE

Use cloths when you extract air so that the fuel is not sprayed around.

Clean the fuel around the fuel filter or the injection pump before starting the

engine to prevent fire.

Finally, check each part if the fuel is

leaking.

G150200AUN

Fuel filter cartridge replacement

✽✽ NOTICE

When replacing the fuel filter cartridge,

use KIA genuine parts.

OSA077011

Page 287 of 336

Maintenance

34

7

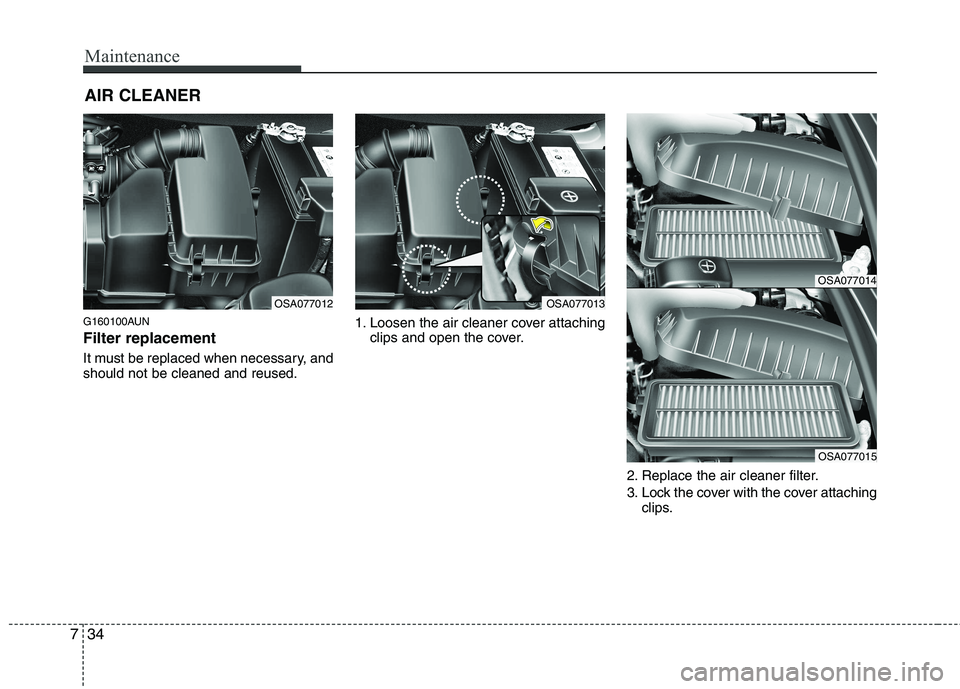

AIR CLEANER

G160100AUN Filter replacement

It must be replaced when necessary, and should not be cleaned and reused. 1. Loosen the air cleaner cover attaching

clips and open the cover.

2. Replace the air cleaner filter.

3. Lock the cover with the cover attachingclips.

OSA077012OSA077013

OSA077014

OSA077015

Page 288 of 336

735

Maintenance

Replace the filter according to the

Maintenance Schedule.

If the vehicle is operated in extremelydusty or sandy areas, replace the ele-ment more often than the usual recom-

mended intervals. (Refer to“Maintenance under severe usage condi-tions” in this section.)

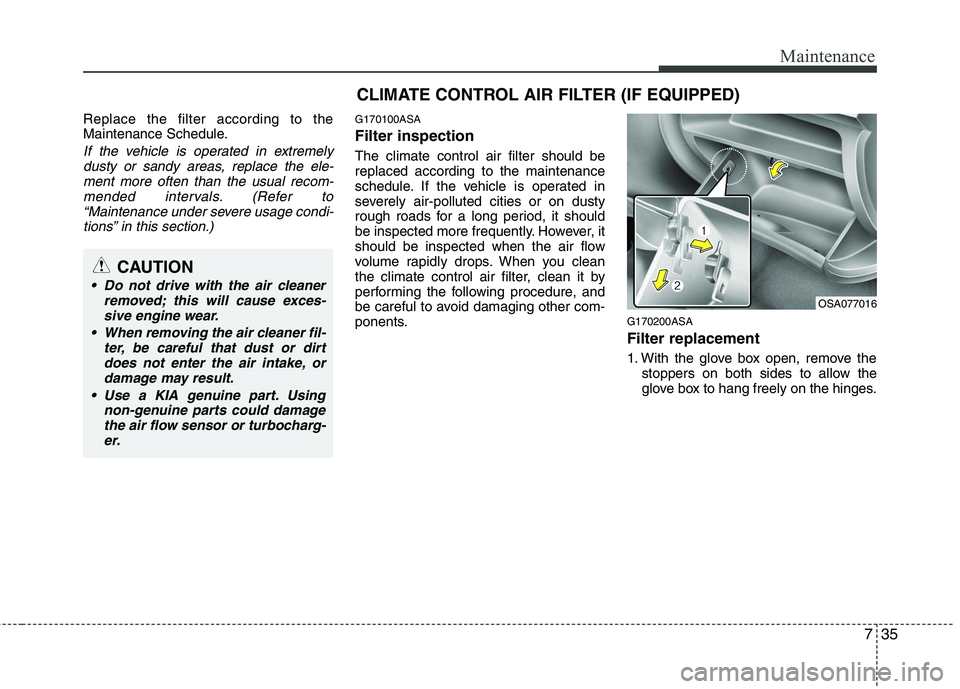

G170100ASA Filter inspection The climate control air filter should be replaced according to the maintenance

schedule. If the vehicle is operated in

severely air-polluted cities or on dusty

rough roads for a long period, it should

be inspected more frequently. However, it

should be inspected when the air flow

volume rapidly drops. When you clean

the climate control air filter, clean it by

performing the following procedure, and

be careful to avoid damaging other com-

ponents. G170200ASA Filter replacement

1. With the glove box open, remove the

stoppers on both sides to allow the

glove box to hang freely on the hinges.

CAUTION

Do not drive with the air cleaner

removed; this will cause exces-sive engine wear.

When removing the air cleaner fil- ter, be careful that dust or dirt

does not enter the air intake, ordamage may result.

Use a KIA genuine part. Using non-genuine parts could damagethe air flow sensor or turbocharg-

er.

CLIMATE CONTROL AIR FILTER (IF EQUIPPED)

OSA077016

Page 289 of 336

Maintenance

36

7

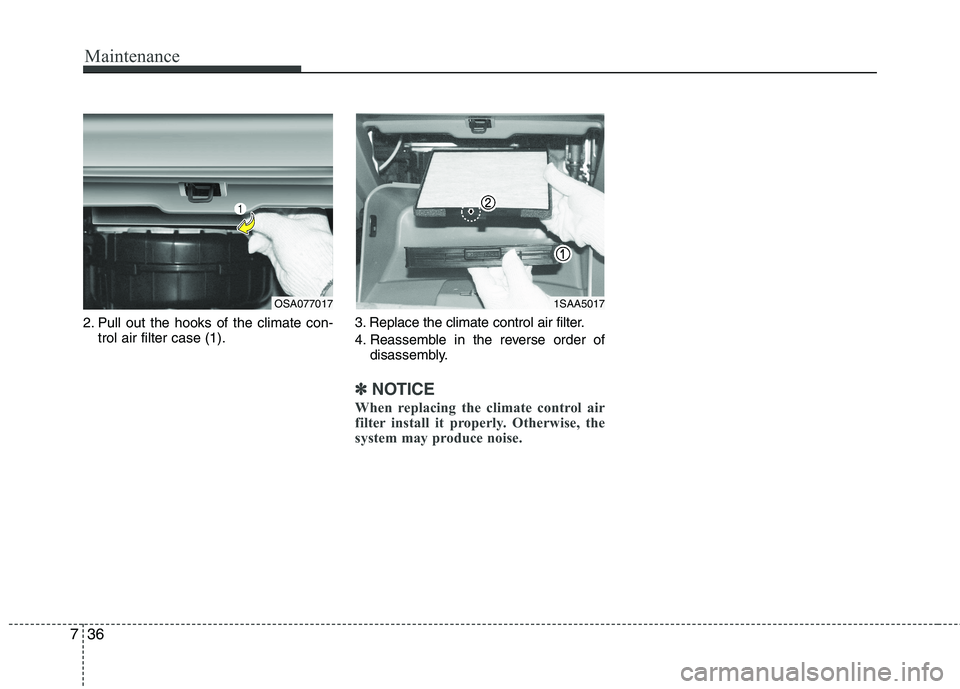

2. Pull out the hooks of the climate con-

trol air filter case (1). 3. Replace the climate control air filter.

4. Reassemble in the reverse order of

disassembly.

✽✽ NOTICE

When replacing the climate control air

filter install it properly. Otherwise, the

system may produce noise.

OSA0770171SAA5017

Page 310 of 336

757

Maintenance

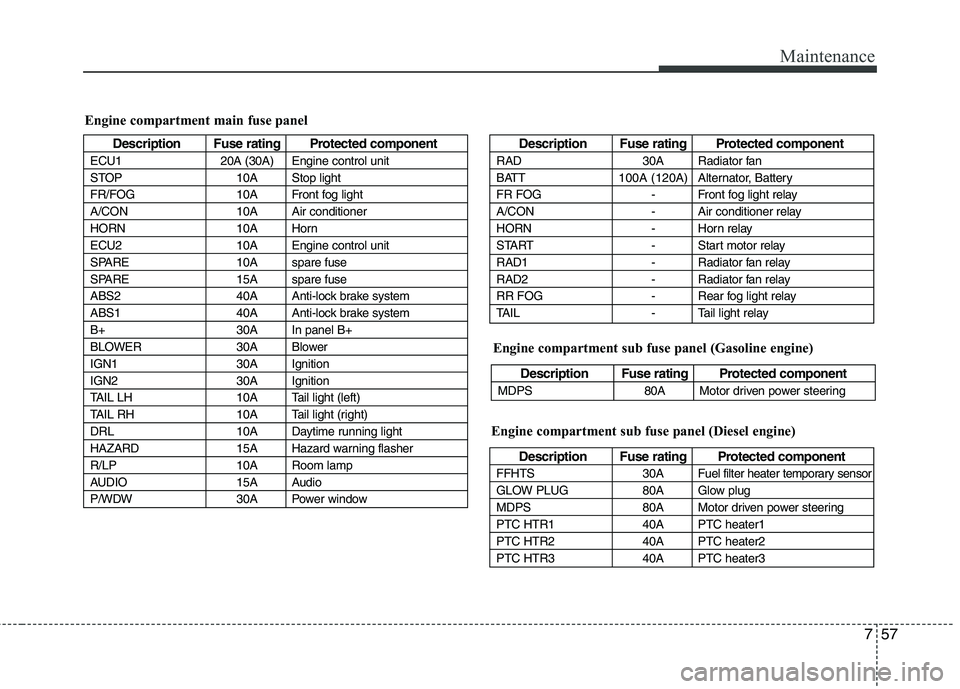

Engine compartment main fuse panel

Description Fuse rating Protected component

ECU1 20A (30A) Engine control unit

STOP 10A Stop light

FR/FOG 10A Front fog light

A/CON 10A Air conditioner

HORN 10A Horn

ECU2 10A Engine control unit

SPARE 10A spare fuse

SPARE 15A spare fuse

ABS2 40A Anti-lock brake system

ABS1 40A Anti-lock brake system

B+ 30A In panel B+

BLOWER 30A Blower

IGN1 30A Ignition

IGN2 30A Ignition

TAIL LH 10A Tail light (left)

TAIL RH 10A Tail light (right)

DRL 10A Daytime running light

HAZARD 15A Hazard warning flasher

R/LP 10A Room lamp

AUDIO 15A Audio

P/WDW 30A Power windowDescription Fuse rating Protected component

RAD 30A Radiator fan

BATT 100A (120A) Alternator, Battery

FR FOG - Front fog light relay

A/CON - Air conditioner relay

HORN - Horn relay

START - Start motor relay

RAD1 - Radiator fan relay

RAD2 - Radiator fan relay

RR FOG - Rear fog light relay

TAIL - Tail light relay

Engine compartment sub fuse panel (Diesel engine)

Description Fuse rating Protected component

FFHTS 30A

Fuel filter heater temporary sensor

GLOW PLUG 80A Glow plug

MDPS 80A Motor driven power steering

PTC HTR1 40A PTC heater1

PTC HTR2 40A PTC heater2

PTC HTR3 40A PTC heater3

Engine compartment sub fuse panel (Gasoline engine)

Description Fuse rating Protected component

MDPS 80A Motor driven power steering

Page 323 of 336

Maintenance

70

7

EMISSION CONTROL SYSTEM (IF EQUIPPED)

G270000AUN

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Warranty &

Maintenance booklet in your vehicle.

Your vehicle is equipped with an emis-

sion control system to meet all applicable

emission regulations. There are three emission control sys-

tems, as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system(3) Exhaust emission control system In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by an author-

ized KIA dealer in accordance with the

maintenance schedule in this manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Program (ESP) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability

Program (ESP) system off by press-

ing the ESP switch.

After dynamometer testing is com- pleted, turn the ESP system back on

by pressing the ESP switch again.

G270100AUN

1. Crankcase emission control system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valveinto the induction system.

G270200AUN

2. Evaporative emission control system

The Evaporative Emission Control

System is designed to prevent fuel vapors

from escaping into the atmosphere. G270201AUN

Canister

Fuel vapors generated inside the fuel tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.

G270202AUN

Purge Control Solenoid Valve (PCSV)

The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant temper-

ature is low during idling, the PCSV clos-

es so that evaporated fuel is not taken

into the engine. After the engine warms-

up during ordinary driving, the PCSV

opens to introduce evaporated fuel to the

engine.

G270300AUN

3. Exhaust emission control

system

The Exhaust Emission Control System is

a highly effective system which controls

exhaust emissions while maintaining

good vehicle performance.