cooling KIA PICANTO 2015 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2015, Model line: PICANTO, Model: KIA PICANTO 2015Pages: 846, PDF Size: 49.67 MB

Page 343 of 846

711

Maintenance

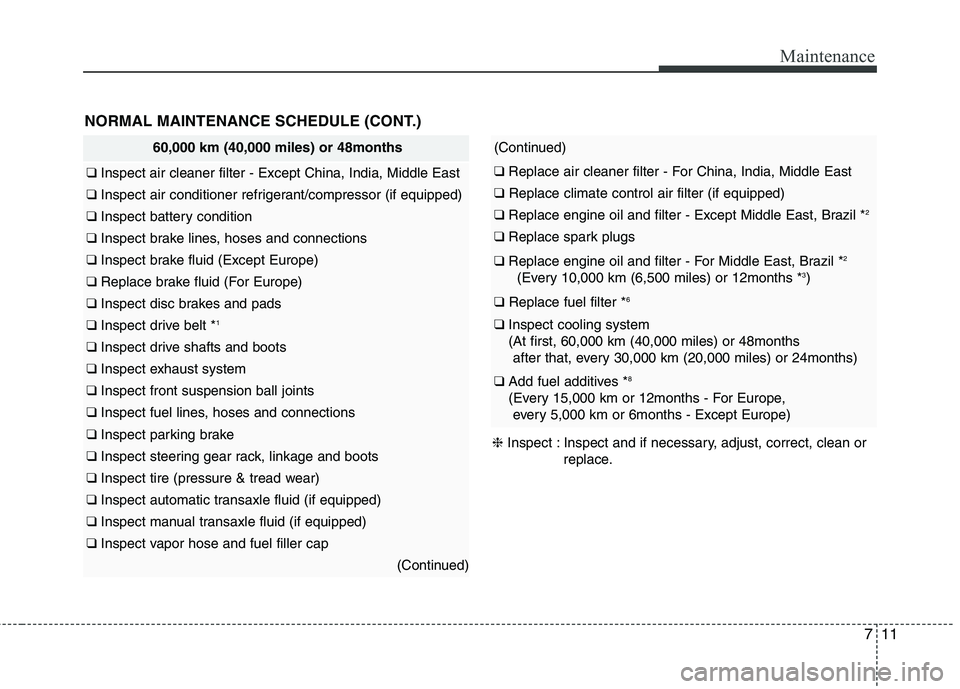

NORMAL MAINTENANCE SCHEDULE (CONT.)

60,000 km (40,000 miles) or 48months

❑ Inspect air cleaner filter - Except China, India, Middle East

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid (Except Europe)

❑ Replace brake fluid (For Europe)

❑ Inspect disc brakes and pads

❑ Inspect drive belt * 1

❑

Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel lines, hoses and connections

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tire (pressure & tread wear)

❑ Inspect automatic transaxle fluid (if equipped)

❑ Inspect manual transaxle fluid (if equipped)

❑ Inspect vapor hose and fuel filler cap

(Continued)

(Continued)

❑ Replace air cleaner filter - For China, India, Middle East

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter - Except Middle East, Brazil * 2

❑

Replace spark plugs

❑ Replace engine oil and filter - For Middle East, Brazil * 2

(Every 10,000 km (6,500 miles) or 12months * 3

)

❑ Replace fuel filter * 6

❑

Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

❑ Add fuel additives * 8

(Every 15,000 km or 12months - For Europe, every 5,000 km or 6months - Except Europe)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 345 of 846

713

Maintenance

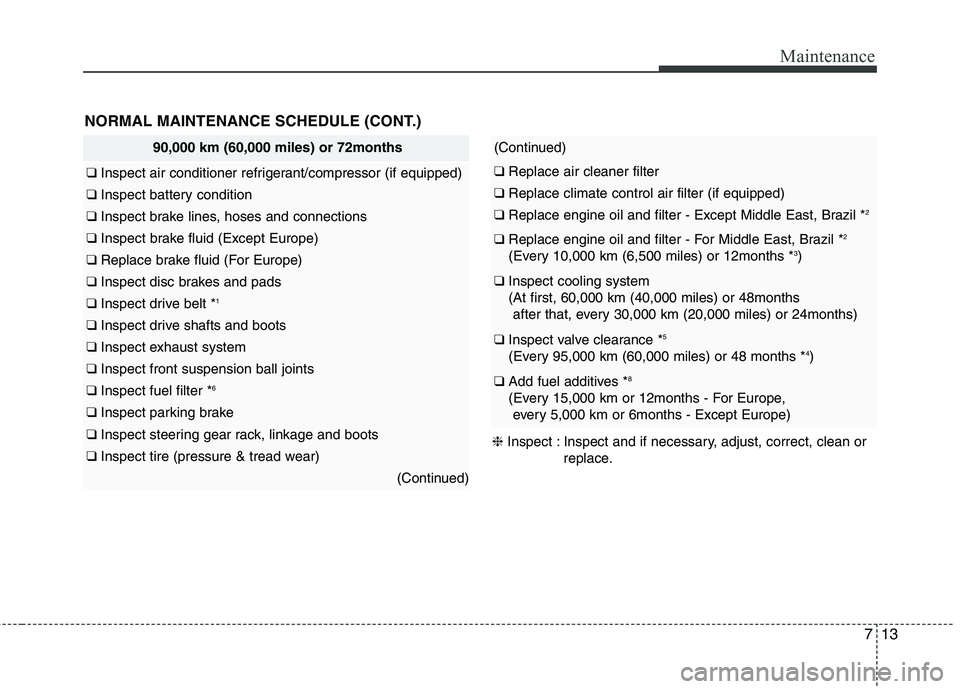

NORMAL MAINTENANCE SCHEDULE (CONT.)

90,000 km (60,000 miles) or 72months

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid (Except Europe)

❑ Replace brake fluid (For Europe)

❑ Inspect disc brakes and pads

❑ Inspect drive belt * 1

❑

Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filter * 6

❑

Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tire (pressure & tread wear)

(Continued)

(Continued)

❑ Replace air cleaner filter

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter - Except Middle East, Brazil * 2

❑

Replace engine oil and filter - For Middle East, Brazil * 2

(Every 10,000 km (6,500 miles) or 12months * 3

)

❑ Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

❑ Inspect valve clearance * 5

(Every 95,000 km (60,000 miles) or 48 months * 4

)

❑ Add fuel additives * 8

(Every 15,000 km or 12months - For Europe, every 5,000 km or 6months - Except Europe)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 347 of 846

715

Maintenance

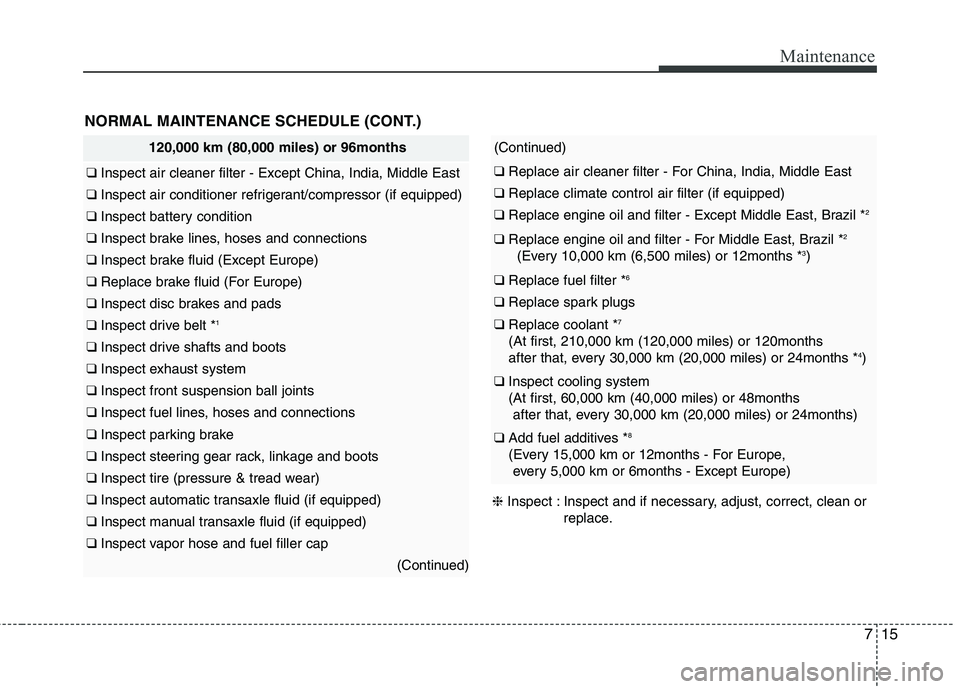

NORMAL MAINTENANCE SCHEDULE (CONT.)

120,000 km (80,000 miles) or 96months

❑ Inspect air cleaner filter - Except China, India, Middle East

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid (Except Europe)

❑ Replace brake fluid (For Europe)

❑ Inspect disc brakes and pads

❑ Inspect drive belt * 1

❑

Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel lines, hoses and connections

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tire (pressure & tread wear)

❑ Inspect automatic transaxle fluid (if equipped)

❑ Inspect manual transaxle fluid (if equipped)

❑ Inspect vapor hose and fuel filler cap

(Continued)

(Continued)

❑ Replace air cleaner filter - For China, India, Middle East

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter - Except Middle East, Brazil * 2

❑

Replace engine oil and filter - For Middle East, Brazil * 2

(Every 10,000 km (6,500 miles) or 12months * 3

)

❑ Replace fuel filter * 6

❑

Replace spark plugs

❑ Replace coolant * 7

(At first, 210,000 km (120,000 miles) or 120months

after that, every 30,000 km (20,000 miles) or 24months * 4

)

❑ Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

❑ Add fuel additives * 8

(Every 15,000 km or 12months - For Europe, every 5,000 km or 6months - Except Europe)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 351 of 846

719

Maintenance

Spark plugs

Make sure to install new spark plugs of

the correct heat range.

Valve clearance

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

We recommend that the system be serv-

iced by an authorized Kia dealer. Cooling system

Check cooling system components, such

as radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Automatic transaxle fluid (if equipped)

The fluid level should be in the "HOT"

range of the dipstick, after the engine

and transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine run-

ning and the transaxle in neutral, with the

parking brake properly applied.

Page 355 of 846

723

Maintenance

ENGINE COOLANT

The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the fac-

tory.

Check the antifreeze protection and

coolant level at least once a year, at thebeginning of the winter season, and

before traveling to a colder climate. Checking the coolant level

WARNING

Removingradiator cap

Never attempt to remove the radi- ator cap while the engine is oper-

ating or hot. Doing so might leadto cooling system and engine

damage and could result in seri-

ous personal injury from escap-ing hot coolant or steam.

Turn the engine off and wait until it cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the cool-

ing system. When you are sure allthe pressure has been released,

press down on the cap, using a

thick towel, and continue turning

counterclockwise to remove it.

(Continued)

(Continued)

Even if the engine is not operat-ing, do not remove the radiator cap or the drain plug while the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

WARNING

The electric motor (cool-ing fan) is

controlled byenginecoolant tem-

perature, refrigerant pressure and

vehicle speed. It may sometimes

operate even when the engine is

not running. Use extreme caution

when working near the blades of

the cooling fan so that you are not

injured by a rotating fan blades. Asthe engine coolant temperature

decreases, the electric motor will

automatically shut off. This is a nor-mal condition.

CAUTION

When the engine overheats from

low engine coolant, suddenly

adding engine coolant may causecracks in the engine. To preventdamage, add engine coolant slowly in small quantities.

Do not drive with no engine coolant. It may cause water pumpfailure and engine seizure, etc.

■ Type B■Type A

■ Type B■Type A

Page 356 of 846

Maintenance

24

7

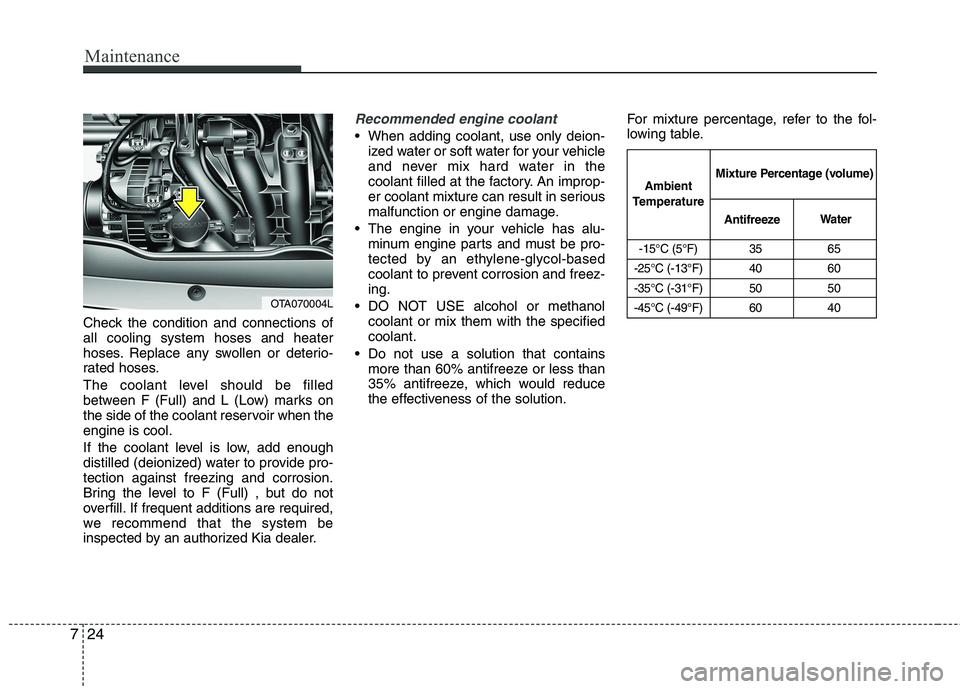

Check the condition and connections of all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F (Full) and L (Low) marks on

the side of the coolant reservoir when theengine is cool.

If the coolant level is low, add enough

distilled (deionized) water to provide pro-tection against freezing and corrosion.

Bring the level to F (Full) , but do not

overfill. If frequent additions are required,

we recommend that the system be

inspected by an authorized Kia dealer.

Recommended engine coolant

When adding coolant, use only deion- ized water or soft water for your vehicle

and never mix hard water in the

coolant filled at the factory. An improp-

er coolant mixture can result in serious

malfunction or engine damage.

The engine in your vehicle has alu- minum engine parts and must be pro-

tected by an ethylene-glycol-based

coolant to prevent corrosion and freez-ing.

DO NOT USE alcohol or methanol coolant or mix them with the specifiedcoolant.

Do not use a solution that contains more than 60% antifreeze or less than

35% antifreeze, which would reduce

the effectiveness of the solution. For mixture percentage, refer to the fol-

lowing table.

-15°C (5°F) 35 65

-25°C (-13°F) 40 60

-35°C (-31°F) 50 50

-45°C (-49°F) 60 40

Ambient

Temperature Mixture Percentage (volume)

Antifreeze Water

OTA070004L

Page 390 of 846

Maintenance

58

7

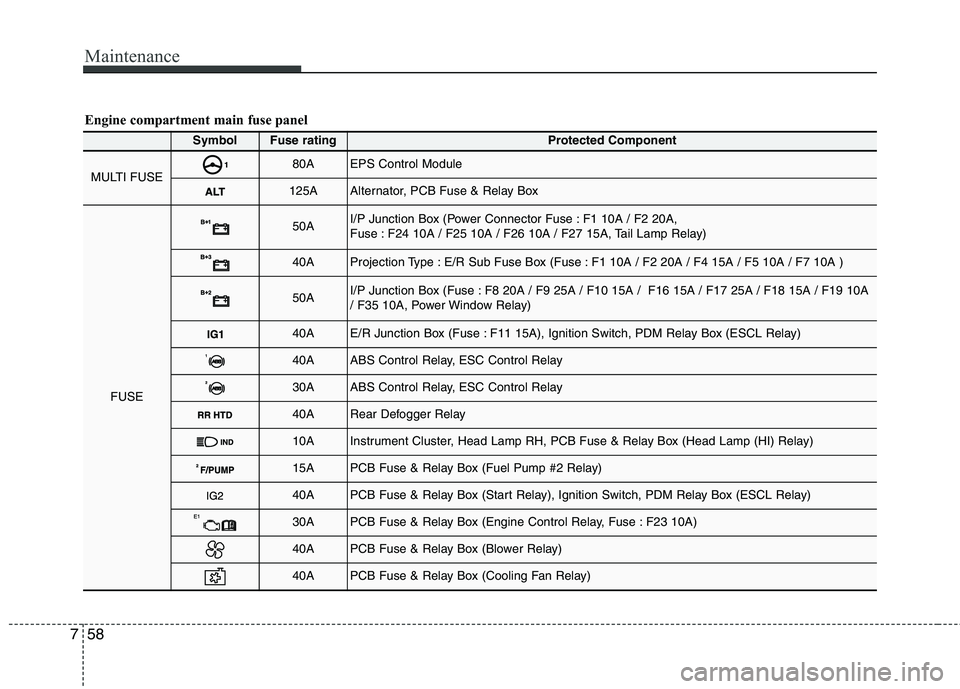

SymbolFuse ratingProtected Component

MULTI FUSE80AEPS Control Module

125AAlternator, PCB Fuse & Relay Box

FUSE

50AI/P Junction Box (Power Connector Fuse : F1 10A / F2 20A,

Fuse : F24 10A / F25 10A / F26 10A / F27 15A, Tail Lamp Relay)

40AProjection Type : E/R Sub Fuse Box (Fuse : F1 10A / F2 20A / F4 15A / F5 10A / F7 10A )

50AI/P Junction Box (Fuse : F8 20A / F9 25A / F10 15A / F16 15A / F17 25A / F18 15A / F19 10A

/ F35 10A, Power Window Relay)

40AE/R Junction Box (Fuse : F11 15A), Ignition Switch, PDM Relay Box (ESCL Relay)

40AABS Control Relay, ESC Control Relay

30AABS Control Relay, ESC Control Relay

40ARear Defogger Relay

10AInstrument Cluster, Head Lamp RH, PCB Fuse & Relay Box (Head Lamp (HI) Relay)

15APCB Fuse & Relay Box (Fuel Pump #2 Relay)

40APCB Fuse & Relay Box (Start Relay), Ignition Switch, PDM Relay Box (ESCL Relay)

30APCB Fuse & Relay Box (Engine Control Relay, Fuse : F23 10A)

40APCB Fuse & Relay Box (Blower Relay)

40APCB Fuse & Relay Box (Cooling Fan Relay)

Engine compartment main fuse panel

Page 391 of 846

759

Maintenance

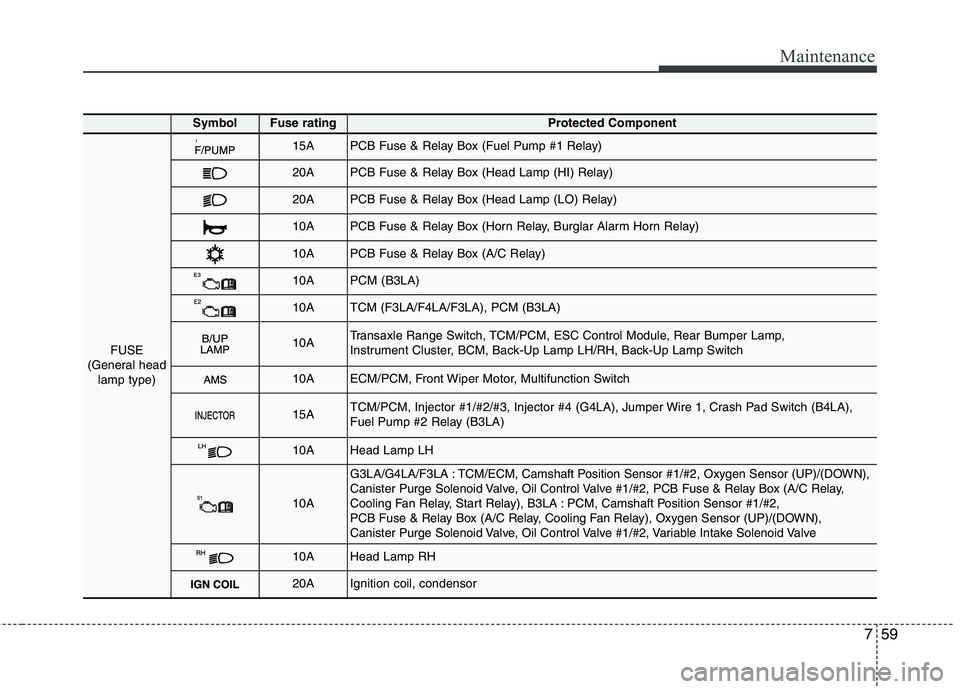

SymbolFuse ratingProtected Component

FUSE

(General head lamp type)

15APCB Fuse & Relay Box (Fuel Pump #1 Relay)

20APCB Fuse & Relay Box (Head Lamp (HI) Relay)

20APCB Fuse & Relay Box (Head Lamp (LO) Relay)

10APCB Fuse & Relay Box (Horn Relay, Burglar Alarm Horn Relay)

10APCB Fuse & Relay Box (A/C Relay)

10APCM (B3LA)

10ATCM (F3LA/F4LA/F3LA), PCM (B3LA)

10ATransaxle Range Switch, TCM/PCM, ESC Control Module, Rear Bumper Lamp,

Instrument Cluster, BCM, Back-Up Lamp LH/RH, Back-Up Lamp Switch

10AECM/PCM, Front Wiper Motor, Multifunction Switch

15ATCM/PCM, Injector #1/#2/#3, Injector #4 (G4LA), Jumper Wire 1, Crash Pad Switch (B4LA),

Fuel Pump #2 Relay (B3LA)

10AHead Lamp LH

10A

G3LA/G4LA/F3LA : TCM/ECM, Camshaft Position Sensor #1/#2, Oxygen Sensor (UP)/(DOWN),

Canister Purge Solenoid Valve, Oil Control Valve #1/#2, PCB Fuse & Relay Box (A/C Relay,

Cooling Fan Relay, Start Relay), B3LA : PCM, Camshaft Position Sensor #1/#2,

PCB Fuse & Relay Box (A/C Relay, Cooling Fan Relay), Oxygen Sensor (UP)/(DOWN),

Canister Purge Solenoid Valve, Oil Control Valve #1/#2, Variable Intake Solenoid Valve

10AHead Lamp RH

20AIgnition coil, condensor

Page 392 of 846

Maintenance

60

7

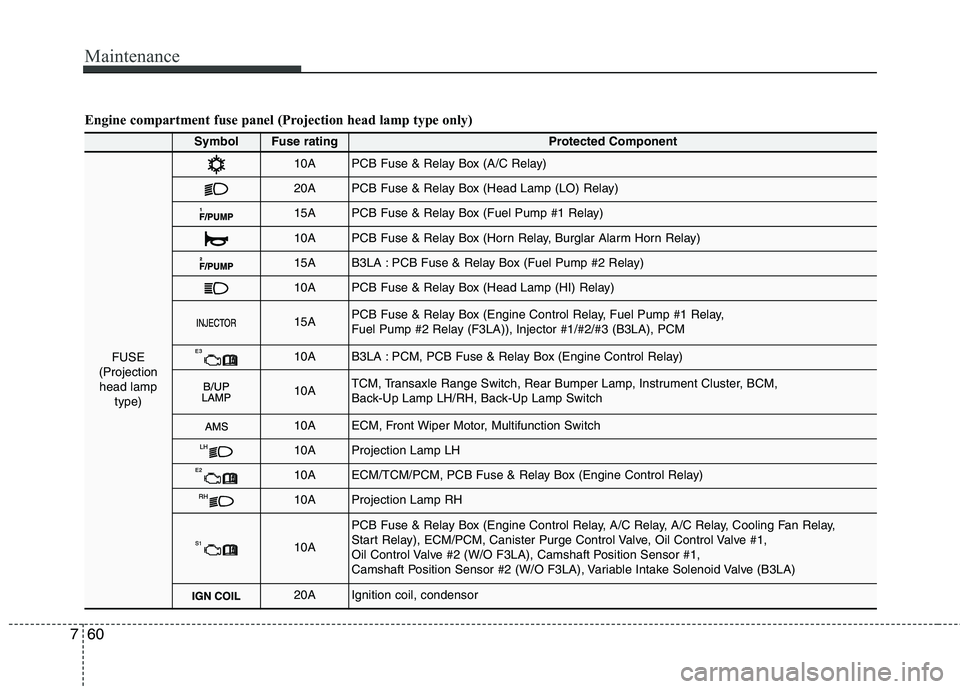

Engine compartment fuse panel (Projection head lamp type only)

SymbolFuse ratingProtected Component

FUSE

(Projection head lamp type)

10APCB Fuse & Relay Box (A/C Relay)

20APCB Fuse & Relay Box (Head Lamp (LO) Relay)

15APCB Fuse & Relay Box (Fuel Pump #1 Relay)

10APCB Fuse & Relay Box (Horn Relay, Burglar Alarm Horn Relay)

15AB3LA : PCB Fuse & Relay Box (Fuel Pump #2 Relay)

10APCB Fuse & Relay Box (Head Lamp (HI) Relay)

15APCB Fuse & Relay Box (Engine Control Relay, Fuel Pump #1 Relay,

Fuel Pump #2 Relay (F3LA)), Injector #1/#2/#3 (B3LA), PCM

10AB3LA : PCM, PCB Fuse & Relay Box (Engine Control Relay)

10ATCM, Transaxle Range Switch, Rear Bumper Lamp, Instrument Cluster, BCM,

Back-Up Lamp LH/RH, Back-Up Lamp Switch

10AECM, Front Wiper Motor, Multifunction Switch

10AProjection Lamp LH

10AECM/TCM/PCM, PCB Fuse & Relay Box (Engine Control Relay)

10AProjection Lamp RH

10A

PCB Fuse & Relay Box (Engine Control Relay, A/C Relay, A/C Relay, Cooling Fan Relay,

Start Relay), ECM/PCM, Canister Purge Control Valve, Oil Control Valve #1,

Oil Control Valve #2 (W/O F3LA), Camshaft Position Sensor #1,

Camshaft Position Sensor #2 (W/O F3LA), Variable Intake Solenoid Valve (B3LA)

20AIgnition coil, condensor

Page 420 of 846

I3

Index

Cargo weight ..................................................................5-56

Central door lock switch ................................................4-17

Changing tires ..................................................................6-9Chains

Tire chains ................................................................5-45

Checking tire inflation pressure ......................................7-41

Child restraint system ....................................................3-28 Lap belt......................................................................3-31

Lap/shoulder belt ......................................................3-30

Child-protector rear door lock ........................................4-18

Climate control system (Automatic) ..............................4-92 Air conditioning ........................................................4-97

Automatic heating and air conditioning....................4-93

Manual heating and air conditioning ........................4-94

Climate control system (Manual) ..................................4-83 Air conditioning ........................................................4-88

Climate control air filter............................................4-90

Heating and air conditioning ....................................4-84

Cigarette lighter ............................................................4-103

Climate control air filter ........................................4-90, 7-32

Clock (Digital) ..............................................................4-106

Clothes hanger ..............................................................4-108

Combined instrument, see instrument cluster ................4-42

Coolant ............................................................................7-23

Cooling fluid, see engine coolant ..................................7-23

Crankcase emission control system ................................7-75

Cup holder ....................................................................4-104

Curtain air bag ................................................................3-52 Dashboard, see instrument cluster ..................................4-42

Daytime running light ....................................................4-69

Declaration of conformity ................................................8-8

Defogging (Windshield) ................................................4-99

Defogging logic (Windshield) ......................................4-101

Defroster (Rear window) ................................................4-82

Defrosting (Windshield) ................................................4-99

Digital clock..................................................................4-106

Dimensions ......................................................................8-2

Displays, see instrument cluster ....................................4-42

Door locks ......................................................................4-15

Central door lock switch ..........................................4-17

Child-protector rear door lock ..................................4-18

Drink holders, see cup holders ....................................4-104

Driver's air bag ................................................................3-46

Driving at night ..............................................................5-41

Driving in flooded areas ................................................5-43

Driving in the rain ..........................................................5-42D