Oil KIA Rio 2008 2.G Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2008, Model line: Rio, Model: KIA Rio 2008 2.GPages: 219, PDF Size: 5.17 MB

Page 198 of 219

Maintenance

22 7

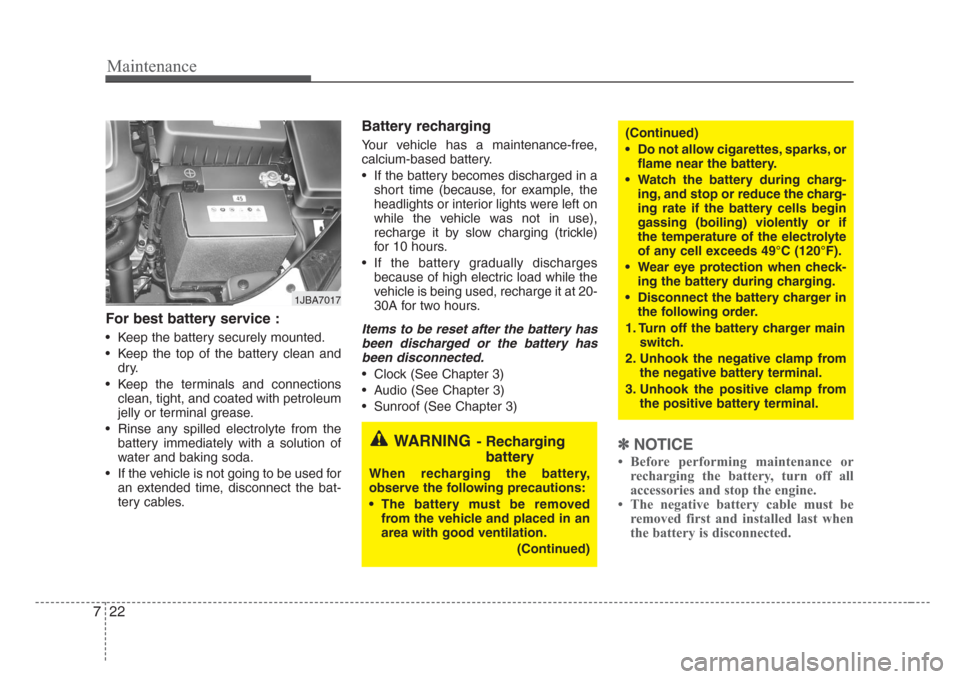

For best battery service :

• Keep the battery securely mounted.

• Keep the top of the battery clean and

dry.

• Keep the terminals and connections

clean, tight, and coated with petroleum

jelly or terminal grease.

• Rinse any spilled electrolyte from the

battery immediately with a solution of

water and baking soda.

• If the vehicle is not going to be used for

an extended time, disconnect the bat-

tery cables.

Battery recharging

Your vehicle has a maintenance-free,

calcium-based battery.

• If the battery becomes discharged in a

short time (because, for example, the

headlights or interior lights were left on

while the vehicle was not in use),

recharge it by slow charging (trickle)

for 10 hours.

• If the battery gradually discharges

because of high electric load while the

vehicle is being used, recharge it at 20-

30A for two hours.

Items to be reset after the battery has

been discharged or the battery has

been disconnected.

• Clock (See Chapter 3)

• Audio (See Chapter 3)

• Sunroof (See Chapter 3)

✽

NOTICE

• Before performing maintenance or

recharging the battery, turn off all

accessories and stop the engine.

• The negative battery cable must be

removed first and installed last when

the battery is disconnected.

1JBA7017

WARNING- Recharging

battery

When recharging the battery,

observe the following precautions:

• The battery must be removed

from the vehicle and placed in an

area with good ventilation.

(Continued)

(Continued)

• Do not allow cigarettes,sparks,or

flame near the battery.

• Watch the battery during charg-

ing, and stop or reduce the charg-

ing rate if the battery cells begin

gassing (boiling) violently or if

the temperature of the electrolyte

of any cell exceeds 49°C (120°F).

• Wear eye protection when check-

ing the battery during charging.

•Disconnect the battery charger in

the following order.

1. Turn off the battery charger main

switch.

2. Unhook the negative clamp from

the negative battery terminal.

3. Unhook the positive clamp from

the positive battery terminal.

Page 208 of 219

Maintenance

32 7

LUBRICANT SPECIFICATIONS

Recommended lubricants

To help achieve proper engine and powertrain performance and

durability, use only lubricants of the proper quality. The correct

lubricants also help promote engine efficiency that results in

improved fuel economy.

Engine oils labeled Energy Conserving Oil are now available.

Along with other additional benefits, they contribute to fuel

economy by reducing the amount of fuel necessary to over-

come engine friction. Often, these improvements are difficult to

measure in everyday driving, but in a year’s time, they can offer

significant cost and energy savings.

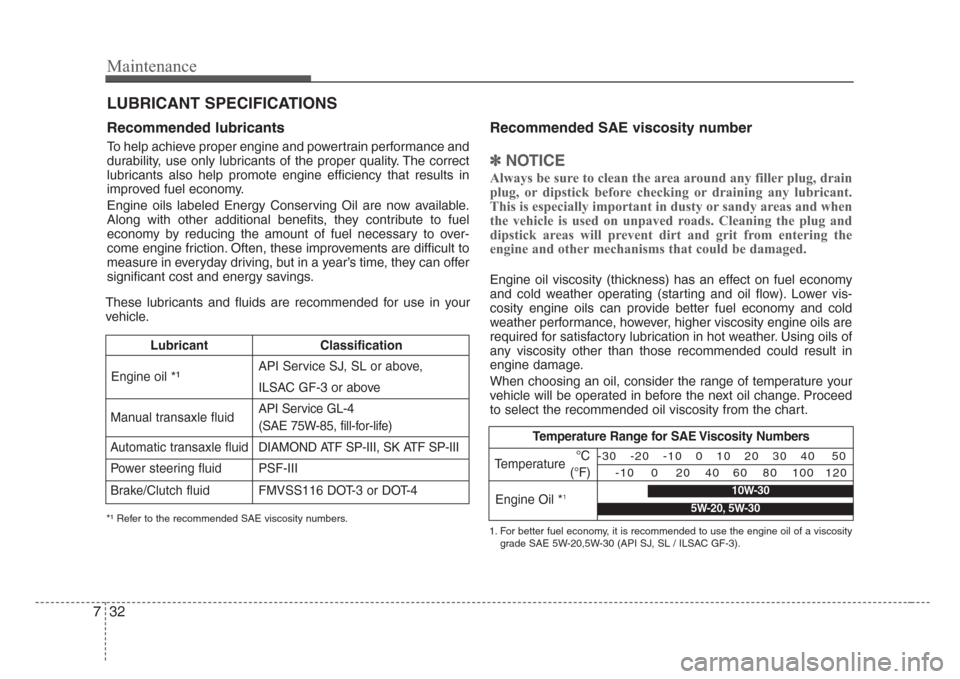

Recommended SAE viscosity number

✽

NOTICE

Always be sure to clean the area around any filler plug, drain

plug, or dipstick before checking or draining any lubricant.

This is especially important in dusty or sandy areas and when

the vehicle is used on unpaved roads. Cleaning the plug and

dipstick areas will prevent dirt and grit from entering the

engine and other mechanisms that could be damaged.

Engine oil viscosity (thickness) has an effect on fuel economy

and cold weather operating (starting and oil flow). Lower vis-

cosity engine oils can provide better fuel economy and cold

weather performance, however, higher viscosity engine oils are

required for satisfactory lubrication in hot weather. Using oils of

any viscosity other than those recommended could result in

engine damage.

When choosing an oil, consider the range of temperature your

vehicle will be operated in before the next oil change. Proceed

to select the recommended oil viscosity from the chart.

*¹ Refer to the recommended SAE viscosity numbers.

These lubricants and fluids are recommended for use in your

vehicle.

Lubricant Classification

API Service SJ, SL or above,

ILSAC GF-3 or above

Manual transaxle fluidAPI Service GL-4

(SAE 75W-85, fill-for-life)

DIAMOND ATF SP-III, SK ATF SP-III

Power steering fluid PSF-III

Brake/Clutch fluid FMVSS116 DOT-3 or DOT-4

Engine oil *¹

Automatic transaxle fluidTemperature Range for SAE Viscosity Numbers

Temperature

Engine Oil *

1

°C

(°F)-30 -20 -10 0 10 20 30 40 50

-10 0 20 40 60 80 100 120

1. For better fuel economy, it is recommended to use the engine oil of a viscosity

grade SAE 5W-20,5W-30 (API SJ, SL / ILSAC GF-3).

10W-30

5W-20, 5W-30

Page 210 of 219

Maintenance

34 7

Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.

✽

NOTICE

• Wiping dust or dirt off the body with

a dry cloth will scratch the finish.

• Do not use steel wool, abrasive clean-

ers, or strong detergents containing

highly alkaline or caustic agents on

chrome-plated or anodized aluminum

parts. This may result in damage to

the protective coating and cause dis-

coloration or paint deterioration.

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust

and may develop into a major repair

expense.

✽

NOTICE

If your vehicle is damaged and requires

any metal repair or replacement, be sure

the body shop applies anti-corrosion

materials to the parts repaired or

replaced.

Bright-metal maintenance

• To remove road tar and insects, use a

tar remover, not a scraper or other

sharp object.

• To protect the surfaces of bright-metal

parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

• During winter weather or in coastal

areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on underbody parts such as the

fuel lines, frame, floor pan and exhaust

system, even though they have been

treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month, after off-road

driving and at the end of each winter. Pay

special attention to these areas because

it is difficult to see all the mud and dirt. It

will do more harm than good to wet down

the road grime without removing it. The

lower edges of doors, rocker panels, and

frame members have drain holes that

should not be allowed to clog with dirt;

trapped water in these areas can cause

rusting.

WARNING

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

Page 211 of 219

735

Maintenance

Aluminum wheel maintenance

The aluminum wheels are coated with a

clear protective finish.

• Do not use any abrasive cleaner, pol-

ishing compound, solvent, or wire

brushes on aluminum wheels. They

may scratch or damage the finish.

• Use only a mild soap or neutral deter-

gent, and rinse thoroughly with water.

Also, be sure to clean the wheels after

driving on salted roads. This helps pre-

vent corrosion.

• Avoid washing the wheels with high-

speed car wash brushes.

• Do not use any acid detergent. It may

damage and corrode the aluminum

wheels coated with a clear protective

finish.

INTERIOR CARE

Interior general precautions

Prevent caustic solutions such as per-

fume and cosmetic oil from contacting

the dashboard because they may cause

damage or discoloration. If they do con-

tact the dashboard, wipe them off imme-

diately. See the instructions that follow for

the proper way to clean vinyl.

✽

NOTICE

Never allow water or other liquids to

come in contact with electrical/electron-

ic components inside the vehicle as this

may damage them.

Cleaning the upholstery and inte-

rior trim

Vinyl

Remove dust and loose dirt from vinyl

with a whisk broom or vacuum cleaner.

Clean vinyl surfaces with a vinyl cleaner.

Fabric

Remove dust and loose dirt from fabric

with a whisk broom or vacuum cleaner.

Clean with a mild soap solution recom-

mended for upholstery or carpets.

Remove fresh spots immediately with a

fabric spot cleaner. If fresh spots do not

receive immediate attention, the fabric

can be stained and its color can be

affected. Also, its fire-resistant properties

can be reduced if the material is not

properly maintained.

✽

NOTICE

Using anything but recommended

cleaners and procedures may affect the

fabric’s appearance and fire-resistant

properties.

Page 212 of 219

Maintenance

36 7

Cleaning the lap/shoulder belt

webbing

Clean the belt webbing with any mild

soap solution recommended for cleaning

upholstery or carpet. Follow the instruc-

tions provided with the soap. Do not

bleach or re-dye the webbing because

this may weaken it.

Cleaning the interior window

glass

If the interior glass surfaces of the vehi-

cle become fogged (that is, covered with

an oily, greasy or waxy film), they should

be cleaned with glass cleaner. Follow the

directions on the glass cleaner container.

✽

NOTICE

Do not scrape or scratch the inside of

the rear window. This may result in

damage to the rear window defroster

grid.

Page 216 of 219

Specifications

4 8

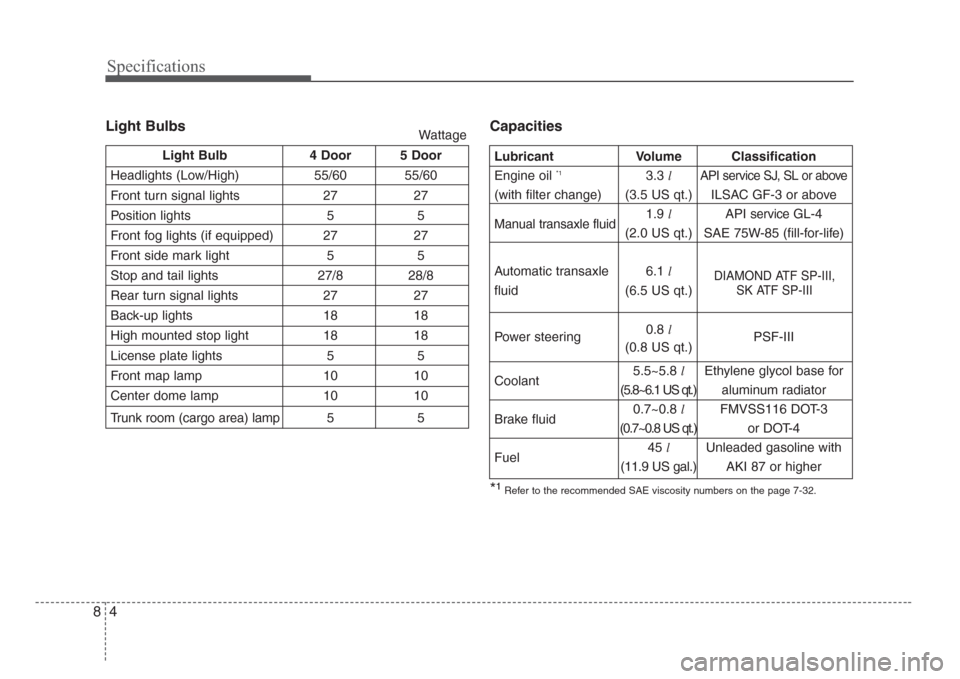

Light BulbsCapacities

Light Bulb 4 Door 5 Door

Headlights (Low/High) 55/60 55/60

Front turn signal lights 27 27

Position lights 5 5

Front fog lights (if equipped) 27 27

Front side mark light 5 5

Stop and tail lights 27/8 28/8

Rear turn signal lights 27 27

Back-up lights 18 18

High mounted stop light 18 18

License plate lights 5 5

Front map lamp 10 10

Center dome lamp 10 10

Trunk room (cargo area) lamp 5 5

Wattage

Lubricant Volume Classification

Engine oil

*13.3lAPI service SJ, SL or above

(with filter change) (3.5 US qt.) ILSAC GF-3 or above

Manual transaxle fluid1.9lAPIserviceGL-4

(2.0 US qt.) SAE 75W-85 (fill-for-life)

Automatic transaxle 6.1 l

fluid (6.5 US qt.)

Power steering0.8l

PSF-III

(0.8 US qt.)

Coolant5.5~5.8lEthylene glycol base for

(5.8~6.1 US qt.)aluminum radiator

Brake fluid0.7~0.8lFMVSS116 DOT-3

(0.7~0.8 US qt.) o r D OT- 4

Fuel45lUnleaded gasoline with

(11.9 US gal.)AKI 87 or higher

*¹Refer to the recommended SAE viscosity numbers on the page 7-32.

DIAMOND ATF SP-III,

SK ATF SP-III

Page 218 of 219

Index

2 9

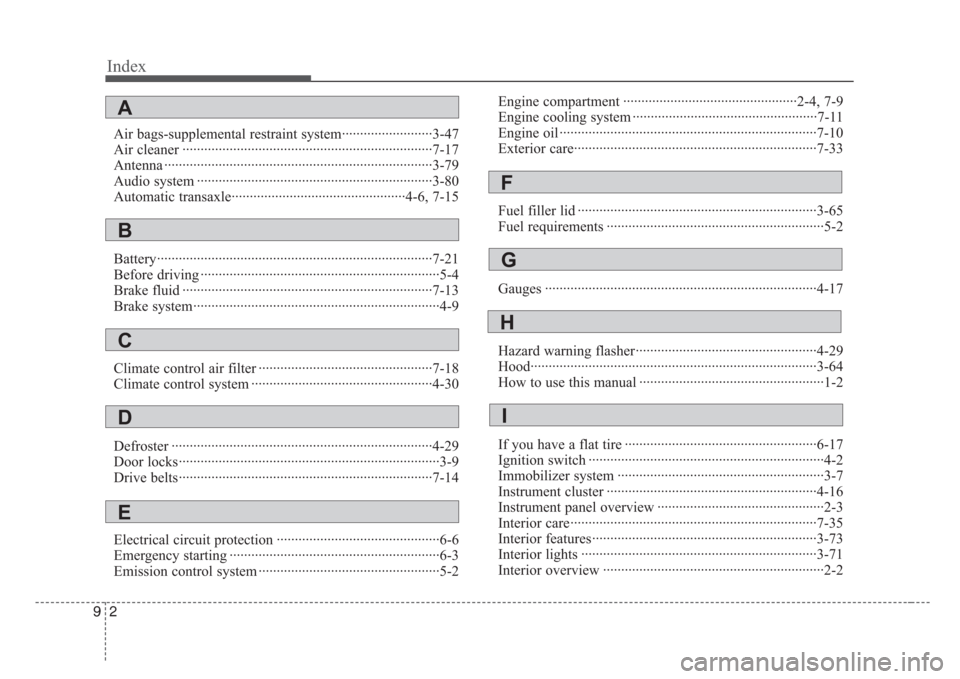

Air bags-supplemental restraint system·························3-47

Air cleaner ·····································································7-17

Antenna ··········································································3-79

Audio system ·································································3-80

Automatic transaxle················································4-6, 7-15

Battery············································································7-21

Before driving ··································································5-4

Brake fluid ·····································································7-13

Brake system····································································4-9

Climate control air filter ················································7-18

Climate control system ··················································4-30

Defroster ········································································4-29

Door locks········································································3-9

Drive belts······································································7-14

Electrical circuit protection ·············································6-6

Emergency starting ··························································6-3

Emission control system ··················································5-2Engine compartment ················································2-4, 7-9

Engine cooling system ···················································7-11

Engine oil ·······································································7-10

Exterior care···································································7-33

Fuel filler lid ··································································3-65

Fuel requirements ····························································5-2

Gauges ···········································································4-17

Hazard warning flasher··················································4-29

Hood···············································································3-64

How to use this manual ···················································1-2

If you have a flat tire ·····················································6-17

Ignition switch ·································································4-2

Immobilizer system ·························································3-7

Instrument cluster ··························································4-16

Instrument panel overview ··············································2-3

Interior care····································································7-35

Interior features······························································3-73

Interior lights ·································································3-71

Interior overview ·····························································2-2

A

B

C

E

D

F

G

H

I