belt KIA Rio 2014 3.G Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2014, Model line: Rio, Model: KIA Rio 2014 3.GPages: 397, PDF Size: 7.56 MB

Page 326 of 397

Maintenance

16

7

NORMAL MAINTENANCE SCHEDULE (CONT.)

192,000 km or 96 months

❑ Inspect air conditioning compressor, air conditioner refrigerant and

performance (if equipped)

❑ Inspect cooling system *1

❑Inspect drive belt *4

(First 96,000 km or 72 months after

every 24,000 km or 24 months)

❑ Inspect drive shaft and boots

❑ Inspect fuel filter *2

❑Inspect fuel line, hoses and connection

❑Inspect fuel tank air filter *2

❑Inspect valve clearance *3

❑Inspect vapor hose and fuel filler cap

❑Inspect visually the following items

1) Battery condition

2) Brake fluid / clutch (if equipped) fluid

3) Brake lines, hoses and connections

4) Brake pedal and operation

5) Chassis/body nuts and bolts

6) Drum brake and linings (if equipped)

7) Disc brakes and pads (if equipped)

8) Exhaust pipe and muffler

9) Front suspension ball joints

10) Fuel tank, cap, lines and hoses

11) Lubricate all locks and hinges

12) Parking brakes

13) Steering operation and linkage

14) Suspension mounting bolts

(Continued)

(Continued)

❑ Replace air cleaner filter

❑Replace climate control air filter (if equipped)

❑Replace engine coolant*5

(First, 192,000 km or 120 months

after every 48,000 km or 24 months)

❑ Replace engine oil and filter

(Every 12,000 km or 12 months)

❑ Add fuel additive *A (Every 12,000 km or 12 months)

❑Rotate tires - including tire pressure and tread wear

(Every 12,000 km or 12 months)

*1lnspect "Water Pump" when replacing the drive belt or timing belt.

*2Fuel filter & Fuel tank air filter are considered to be maintenance free\

but

periodic inspection is recommended for this maintenance schedule

depends on fuel quality. If there are some important safety matters like

fuel flow restriction, surging, loss of power, hard starting problem etc,

replace the fuel filter immediately regardless of maintenance schedule

and consult an authorized Kia dealer for details.

*

3Inspect for excessive tappet noise and/or engine vibration and adjust if

necessary.

*

4The drive belt should be replaced when cracks occur or tension is reduced excessively.

*

5When replacing coolant, use only a qualified coolant additive for your vehicle and never mix hard water in the coolant filled at the factory.

An improper coolant mixture can result in serious malfunction or engine

damage.

*

AIf TOP TIER Detergent Gasoline is not available, one bottle of additive is

recommended. Additives are available from your authorized Kia dealer

along with information on how to use them. Do not mix other additives.

❈ Inspect : Inspect and if necessary, adjust, correct, clean or replace.

Page 327 of 397

717

Maintenance

NORMAL MAINTENANCE SCHEDULE (CONT.)

216,000 km or 108 months

❑Inspect air cleaner filter

❑Inspect air conditioning compressor, air conditioner refrigerant and

performance (if equipped)

❑ Inspect cooling system *1

❑Inspect drive belt *4

(First 96,000 km or 72 months after

every 24,000 km or 24 months)

❑ Inspect drive shaft and boots

❑ Inspect visually the following items

1) Battery condition

2) Brake fluid / clutch (if equipped) fluid

3) Brake lines, hoses and connections

4) Brake pedal and operation

5) Chassis/body nuts and bolts

6) Drum brake and linings (if equipped)

7) Disc brakes and pads (if equipped)

8) Exhaust pipe and muffler

9) Front suspension ball joints

10) Fuel tank, cap, lines and hoses

11) Lubricate all locks and hinges

12) Parking brakes

13) Steering operation and linkage

14) Suspension mounting bolts

(Continued)

(Continued)

❑ Replace climate control air filter (if equipped)

❑Replace engine oil and filter

(Every 12,000 km or 12 months)

❑Add fuel additive *A

(Every 12,000 km or 12 months)

❑Rotate tires - including tire pressure and tread wear

(Every 12,000 km or 12 months)

*

1lnspect "Water Pump" when replacing the drive belt or timing belt.

*4The drive belt should be replaced when cracks occur or tension is reduced excessively.

*

AIf TOP TIER Detergent Gasoline is not available, one bottle of addi-

tive is recommended. Additives are available from your authorized

Kia dealer along with information on how to use them. Do not mix

other additives.

❈ Inspect : Inspect and if necessary, adjust, correct, clean or replace.

Page 328 of 397

Maintenance

18

7

240,000 km or 120 months

❑ Inspect air conditioning compressor, air conditioner refrigerant and

performance (if equipped)

❑ Inspect cooling system *1

❑Inspect drive belt *4

(First 96,000 km or 72 months after

every 24,000 km or 24 months)

❑ Inspect drive shaft and boots

❑ Inspect fuel filter *2

❑Inspect fuel line, hoses and connection

❑Inspect fuel tank air filter *2

❑Inspect manual transaxle fluid (if equipped)

(Every 60,000 km or 48 months)

❑ Inspect vapor hose and fuel filler cap

❑Inspect visually the following items

1) Battery condition

2) Brake fluid / clutch (if equipped) fluid

3) Brake lines, hoses and connections

4) Brake pedal and operation

5) Chassis/body nuts and bolts

6) Drum brake and linings (if equipped)

7) Disc brakes and pads (if equipped)

8) Exhaust pipe and muffler

9) Front suspension ball joints

10) Fuel tank, cap, lines and hoses

11) Lubricate all locks and hinges

12) Parking brakes

(Continued)

(Continued)

13) Steering operation and linkage

14) Suspension mounting bolts

❑ Replace air cleaner filter

❑Replace climate control air filter (if equipped)

❑Replace engine coolant *5

(First 192,000 km or 120 months

after every 48,000 km or 24 months)

❑ Replace engine oil and filter

(Every 12,000 km or 12 months)

❑Add fuel additive *A

(Every 12,000 km or 12 months)

❑Rotate tires - including tire pressure and tread wear

(Every 12,000 km or 12 months)

NORMAL MAINTENANCE SCHEDULE (CONT.)

*1lnspect "Water Pump" when replacing the drive belt or timing belt.

*2Fuel filter & Fuel tank air filter are considered to be maintenance free\

but

periodic inspection is recommended for this maintenance schedule

depends on fuel quality. If there are some important safety matters like

fuel flow restriction, surging, loss of power, hard starting problem etc,

replace the fuel filter immediately regardless of maintenance schedule

and consult an authorized Kia dealer for details.

*

4The drive belt should be replaced when cracks occur or tension is reduced excessively.

*

5When replacing coolant, use only a qualified coolant additive for your vehicle and never mix hard water in the coolant filled at the factory.

An improper coolant mixture can result in serious malfunction or engine

damage.

*

AIf TOP TIER Detergent Gasoline is not available, one bottle of additive is

recommended. Additives are available from your authorized Kia dealer

along with information on how to use them. Do not mix other additives.

❈ Inspect : Inspect and if necessary, adjust, correct, clean or replace.

Page 332 of 397

Maintenance

22

7

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the vehicle is

being driven in severe conditions, more

frequent oil and filter changes are

required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically for

proper tension and adjusted as neces-

sary.

Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by an authorized Kia dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

an authorized Kia dealer replace any

damaged or leaking parts immediately.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap is

correctly replaced.

Vacuum crankcase ventilation

hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or moving

component which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

Page 353 of 397

743

Maintenance

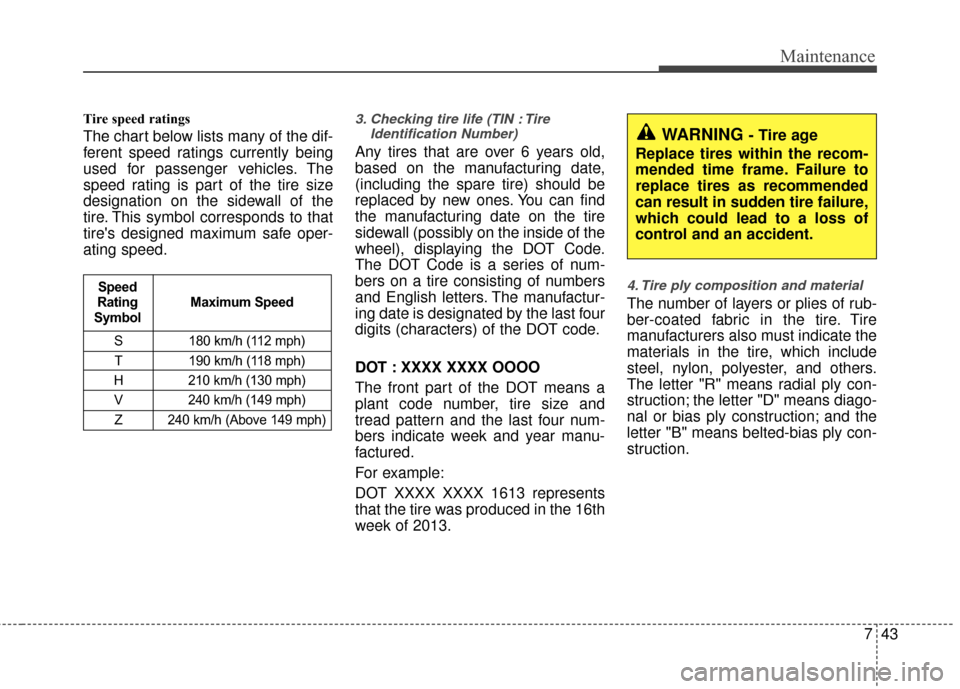

Tire speed ratings

The chart below lists many of the dif-

ferent speed ratings currently being

used for passenger vehicles. The

speed rating is part of the tire size

designation on the sidewall of the

tire. This symbol corresponds to that

tire's designed maximum safe oper-

ating speed.

3. Checking tire life (TIN : TireIdentification Number)

Any tires that are over 6 years old,

based on the manufacturing date,

(including the spare tire) should be

replaced by new ones. You can find

the manufacturing date on the tire

sidewall (possibly on the inside of the

wheel), displaying the DOT Code.

The DOT Code is a series of num-

bers on a tire consisting of numbers

and English letters. The manufactur-

ing date is designated by the last four

digits (characters) of the DOT code.

DOT : XXXX XXXX OOOO

The front part of the DOT means a

plant code number, tire size and

tread pattern and the last four num-

bers indicate week and year manu-

factured.

For example:

DOT XXXX XXXX 1613 represents

that the tire was produced in the 16th

week of 2013.

4. Tire ply composition and material

The number of layers or plies of rub-

ber-coated fabric in the tire. Tire

manufacturers also must indicate the

materials in the tire, which include

steel, nylon, polyester, and others.

The letter "R" means radial ply con-

struction; the letter "D" means diago-

nal or bias ply construction; and the

letter "B" means belted-bias ply con-

struction.

S 180 km/h (112 mph)

T 190 km/h (118 mph)

H 210 km/h (130 mph) V 240 km/h (149 mph)Z 240 km/h (Above 149 mph)

Maximum Speed

Speed

Rating

Symbol

WARNING - Tire age

Replace tires within the recom-

mended time frame. Failure to

replace tires as recommended

can result in sudden tire failure,

which could lead to a loss of

control and an accident.

Page 355 of 397

745

Maintenance

Temperature -A, B & C

The temperature grades are A (the

highest), B and C representing the

tire’s resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled condi-

tions on a specified indoor laboratory

test wheel.

Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. Grades B and A

represent higher levels of perform-

ance on the laboratory test wheel

than the minimum required by law.Tire terminology and definitions

Air Pressure: The amount of air

inside the tire pressing outward on

the tire. Air pressure is expressed in

kilopascal (kPa) or pounds per

square inch (psi).

Accessory Weight

: This means the

combined weight of optional acces-

sories. Some examples of optional

accessories are, automatic

transaxle, power seats, and air con-

ditioning.

Aspect Ratio : The relationship of a

tire's height to its width.

Belt: A rubber coated layer of cords

that is located between the plies and

the tread. Cords may be made from

steel or other reinforcing materials.

Bead: The tire bead contains steel

wires wrapped by steel cords that

hold the tire onto the rim.

Bias Ply Tire : A pneumatic tire in

which the plies are laid at alternate

angles less than 90 degrees to the

centerline of the tread. Cold Tire Pressure: The amount of

air pressure in a tire, measured in

kilopascals (kPa) or pounds per

square inch (psi) before a tire has

built up heat from driving.

Curb Weight: This means the weight

of a motor vehicle with standard and

optional equipment including the

maximum capacity of fuel, oil and

coolant, but without passengers and

cargo.

DOT Markings: The DOT code

includes the Tire Identification

Number (TIN), an alphanumeric des-

ignator which can also identify the

tire manufacturer, production plant,

brand and date of production.

GVWR: Gross Vehicle Weight Rating

GAWR FRT: Gross Axle Weight

Rating for the Front Axle.

GAWR RR: Gross Axle Weight

Rating for the Rear axle.

Page 357 of 397

747

Maintenance

Vehicle Maximum Load on the

Tire: Load on an individual tire due to

curb and accessory weight plus

maximum occupant and cargo

weight.

Vehicle Normal Load on the Tire:

Load on an individual tire that is

determined by distributing to each

axle its share of the curb weight,

accessory weight, and normal occu-

pant weight and driving by 2.

Vehicle Placard: A label permanent-

ly attached to a vehicle showing the

original equipment tire size and rec-

ommended inflation pressure.

All season tires

Kia specifies all season tires on

some models to provide good per-

formance for use all year round,

including snowy and icy road condi-

tions. All season tires are identified

by ALL SEASON and/or M+S (Mud

and Snow) on the tire sidewall. Snow

tires have better snow traction than

all season tires and may be more

appropriate in some areas.Summer tires

Kia specifies summer tires on some

models to provide superior perform-

ance on dry roads. Summer tire per-

formance is substantially reduced in

snow and ice. Summer tires do not

have the tire traction rating M+S

(Mud and Snow) on the tire side wall.

If you plan to operate your vehicle in

snowy or icy conditions, Kia recom-

mends the use of snow tires or all

season tires on all four wheels.

Snow tires

If you equip your car with snow tires,

they should be the same size and

have the same load capacity as the

original tires. Snow tires should be

installed on all four wheels; other-

wise, poor handling may result.

Snow tires should carry 28 kPa (4

psi) more air pressure than the pres-

sure recommended for the standard

tires on the tire label on the driver's

side of the center pillar, or up to the

maximum pressure shown on the tire

sidewall, whichever is less.

Do not drive faster than 120 km/h (75

mph) when your vehicle is equipped

with snow tires.Radial-ply tires

Radial-ply tires provide improved

tread life, road hazard resistance and

smoother high speed ride. The radi-

al-ply tires used on this vehicle are of

belted construction, and are selected

to complement the ride and handling

characteristics of your vehicle.

Radial-ply tires have the same load

carrying capacity as bias-ply or bias

belted tires of the same size and use

the same recommended inflation

pressure. Mixing of radial-ply tires

with bias-ply or bias belted tires is

not recommended. Any combina-

tions of radial-ply and bias-ply or bias

belted tires when used on the same

vehicle will seriously deteriorate

vehicle handling. The best rule to fol-

low is: Identical radial-ply tires should

always be used as a set of four.

Longer wearing tires can be more

susceptible to irregular tread wear. It

is very important to follow the tire

rotation interval shown in this section

to achieve the tread life potential of

these tires. Cuts and punctures in

radial-ply tires are repairable only in

the tread area, because of sidewall

flexing. Consult your tire dealer for

radial-ply tire repairs.

Page 375 of 397

765

Maintenance

Cleaning the upholstery and interiortrim

Vinyl

Remove dust and loose dirt from vinyl

with a whisk broom or vacuum cleaner.

Clean vinyl surfaces with a vinyl cleaner.

Fabric

Remove dust and loose dirt from fabric

with a whisk broom or vacuum cleaner.

Clean with a mild soap solution recom-

mended for upholstery or carpets.

Remove fresh spots immediately with a

fabric spot cleaner. If fresh spots do not

receive immediate attention, the fabric

can be stained and its color can be

affected. Also, its fire-resistant properties

can be reduced if the material is not

properly maintained.

Using anything but recommended clean-

ers and procedures may affect the fab-

ric’s appearance and fire-resistant prop-

erties.

Cleaning the lap/shoulder belt web-bing

Clean the belt webbing with any mild

soap solution recommended for cleaning

upholstery or carpet. Follow the instruc-

tions provided with the soap. Do not

bleach or re-dye the webbing because

this may weaken it.

Cleaning the interior window glass

If the interior glass surfaces of the vehi-

cle become fogged (that is, covered with

an oily, greasy or waxy film), they should

be cleaned with glass cleaner. Follow the

directions on the glass cleaner container.

CAUTION - Rear windows

Do not scrape or scratch the insideof the rear window. This may resultin damage to the rear windowdefroster grid.

Page 390 of 397

I3

Index

Cargo capacity ··················\

··················\

··················\

·········5-52

Cargo weight ··················\

··················\

··················\

············5-56

Center console storage ··················\

··················\

···············4-92

Central door lock switch··················\

··················\

············4-16

Certification label ··················\

··················\

···············5-54, 8-8

Changing tires ··················\

··················\

··················\

··········6-14

Checking tire inflation pressure··················\

··················\

·7-38

Child restraint system ··················\

··················\

················3-22Lower anchor ··················\

··················\

··················\

·········3-28

Seat belt ··················\

··················\

··················\

·················3-24\

Tether anchor system ··················\

··················\

···············3-26

Child-protector rear door lock ··················\

··················\

···4-18

Cigarette lighter ··················\

··················\

··················\

·······4-96

Climate control air filter ··················\

··················\

···4-81, 7-32

Clock (Digital) ··················\

··················\

··················\

·········4-99

Clothes hanger ··················\

··················\

··················\

·······4-100

Combined instrument, see instrument cluster ···············4-41

Compact spare tire ··················\

··················\

··················\

···6-19

Compact spare tire replacement ··················\

··················\

7-41

Coolant ··················\

··················\

··················\

··················\

···7-26

Cooling fluid, see engine coolant ··················\

················7-26

Crankcase emission control system ··················\

·············7-66

Cruise control system ··················\

··················\

················5-32

Cup holder ··················\

··················\

··················\

···············4-97

Curtain air bag ··················\

··················\

··················\

·········3-45 Dashboard illumination, see instrument panel

illumination··················\

··················\

··················\

············4-42

Dashboard, see instrument cluster ··················\

···············4-41

Defogging (Windshield) ··················\

··················\

············4-90

Defogging logic (Windshield) ··················\

··················\

···4-91

Defroster (Rear window) ··················\

··················\

···········4-80

Defrosting (Windshield) ··················\

··················\

············4-90

Digital clock··················\

··················\

··················\

·············4-99

Dimensions ··················\

··················\

··················\

················8-2

Display illumination, see instrument panel illumination··················\

··················\

··················\

············4-42

Displays, see instrument cluster ··················\

··················\

4-41

Door locks··················\

··················\

··················\

················4-15 Central door lock switch ··················\

··················\

·········4-17

Child-protector rear door lock ··················\

··················\

·4-18

Drinks holders, see cup holders··················\

··················\

·4-97

Driver's 3-point seat belt ··················\

··················\

············3-14

Driver's and passenger's front air bag ··················\

··········3-41

Driving at night ··················\

··················\

··················\

········5-45

Driving in flooded areas ··················\

··················\

············5-46

Driving in the rain··················\

··················\

··················\

····5-46D

Page 391 of 397

Index

4I

Economical operation ··················\

··················\

················5-42

Electric power steering ··················\

··················\

··············4-35

Electronic stability program (ESC) ··················\

·············5-25

Emergency starting ··················\

··················\

··················\

····6-4Jump starting ··················\

··················\

··················\

···········6-4

Push starting ··················\

··················\

··················\

············6-6

Emergency while driving ··················\

··················\

·············6-2

Emission control system ··················\

··················\

············7-66 Crankcase emission control system··················\

···········7-66

Evaporative emission control System ··················\

·······7-66

Exhaust emission control system ··················\

··············7-66

Engine ··················\

··················\

··················\

··················\

······8-2

Engine compartment ··················\

··················\

··················\

··2-4

Engine compartment panel fuse ··················\

··················\

7-58

Engine coolant ··················\

··················\

··················\

·········7-26

Engine coolcant temperature gauge··················\

·············4-43

Engine number ··················\

··················\

··················\

···········8-9

Engine oil ··················\

··················\

··················\

·················7-25\

Engine overheats ··················\

··················\

··················\

········6-7

Engine start/stop button ··················\

··················\

···············5-6

Engine will not start··················\

··················\

··················\

···6-3

Evaporative emission control System ··················\

··········7-66

Exhaust emission control system··················\

·················7-66\

Explanation of scheduled maintenance items ···············7-22

Exterior care··················\

··················\

··················\

·············7-60 Flat tire (with spare tire) ··················\

··················\

············6-13

Jack and tools ··················\

··················\

··················\

········6-13

Changing tires··················\

··················\

··················\

········6-14

Compact spare tire ··················\

··················\

··················\

·6-19

Removing and storing the spare tire···········\

·················6-14\

Flat tire (with tire mobility kit) ··················\

··················\

·6-21

Floor mat anchor(s) ··················\

··················\

·················4-10\

1

Fluid Automatic transaxle fluid ··················\

··················\

········7-30

Brakes/clutch fluid··················\

··················\

··················\

·7-29

Washer fluid··················\

··················\

··················\

···········7-30

Folding the outside rearviwe mirror ··················\

············4-40

Folding the rear seat ··················\

··················\

··················\

3-10

Front passenger and rear seat belt ··················\

···············3-16

Front seat adjustment ··················\

··················\

··················\

·3-4

Fuel filler lid ··················\

··················\

··················\

············4-28

Fuel gauge··················\

··················\

··················\

················4-43

Fuel requirements ··················\

··················\

··················\

······1-3

Fuses ··················\

··················\

··················\

··················\

······7-49 Engine compartment panel fuse ··················\

················7-51

Fuse/relay panel description ··················\

··················\

····7-52

Instrument panel fuse ··················\

··················\

··············7-50

Memory fuse··················\

··················\

··················\

··········7-51

Multi fuse ··················\

··················\

··················\

··············7-52

FE