clock KIA Rondo 2017 3.G Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2017, Model line: Rondo, Model: KIA Rondo 2017 3.GPages: 625, PDF Size: 19.69 MB

Page 489 of 625

What to do in an emergency

18

7

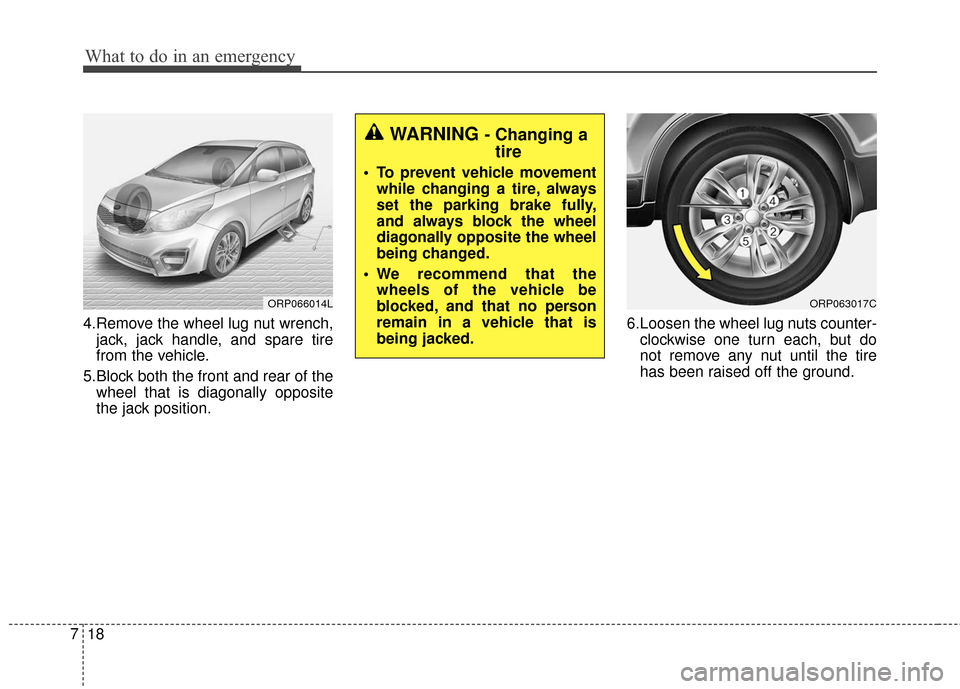

4.Remove the wheel lug nut wrench,

jack, jack handle, and spare tire

from the vehicle.

5.Block both the front and rear of the wheel that is diagonally opposite

the jack position. 6.Loosen the wheel lug nuts counter-

clockwise one turn each, but do

not remove any nut until the tire

has been raised off the ground.

ORP066014LORP063017C

WARNING - Changing atire

To prevent vehicle movement

while changing a tire, always

set the parking brake fully,

and always block the wheel

diagonally opposite the wheel

being changed.

We recommend that the wheels of the vehicle be

blocked, and that no person

remain in a vehicle that is

being jacked.

Page 490 of 625

719

What to do in an emergency

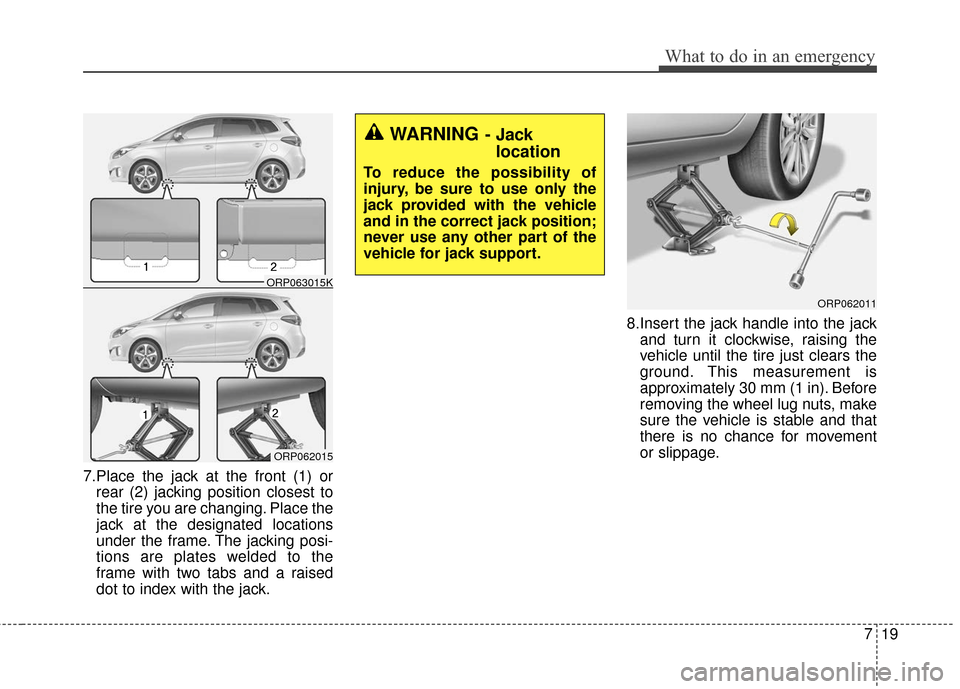

7.Place the jack at the front (1) orrear (2) jacking position closest to

the tire you are changing. Place the

jack at the designated locations

under the frame. The jacking posi-

tions are plates welded to the

frame with two tabs and a raised

dot to index with the jack. 8.Insert the jack handle into the jack

and turn it clockwise, raising the

vehicle until the tire just clears the

ground. This measurement is

approximately 30 mm (1 in). Before

removing the wheel lug nuts, make

sure the vehicle is stable and that

there is no chance for movement

or slippage.

ORP062011

WARNING- Jack location

To reduce the possibility of

injury, be sure to use only the

jack provided with the vehicle

and in the correct jack position;

never use any other part of the

vehicle for jack support.

ORP062015

ORP063015K

Page 491 of 625

What to do in an emergency

20

7

9.Loosen the wheel nuts and remove

them with your fingers. Slide the

wheel off the studs and lay it flat so

it cannot roll away. To put the

wheel on the hub, pick up the

spare tire, line up the holes with

the studs and slide the wheel onto

them. If this is difficult, tip the wheel

slightly and get the top hole in the

wheel lined up with the top stud.

Then jiggle the wheel back and

forth until the wheel can be slid

over the other studs. 10. To install the wheel, hold it on the

studs, put the wheel nuts on the

studs and tighten them finger

tight. Jiggle the tire to be sure it is

completely seated, then tighten

the nuts as much as possible

with your fingers again.

11. Lower the vehicle to the ground by turning the wheel nut wrench

counterclockwise.

WARNING

Wheels may have sharp edges.

Handle them carefully to avoid

possible severe injury. Before

putting the wheel into place, be

sure that there is nothing on the

hub or wheel (such as mud, tar,

gravel, etc.) that prevents the

wheel from fitting solidly

against the hub.

If there is, remove it. If the con-

tact of the mounting surface

between the wheel and hub is

not good, the wheel nuts could

come loose and cause the loss

of a wheel. Loss of a wheel may

result in loss of control of the

vehicle. This may cause serious

injury or death.

Page 497 of 625

What to do in an emergency

26

7

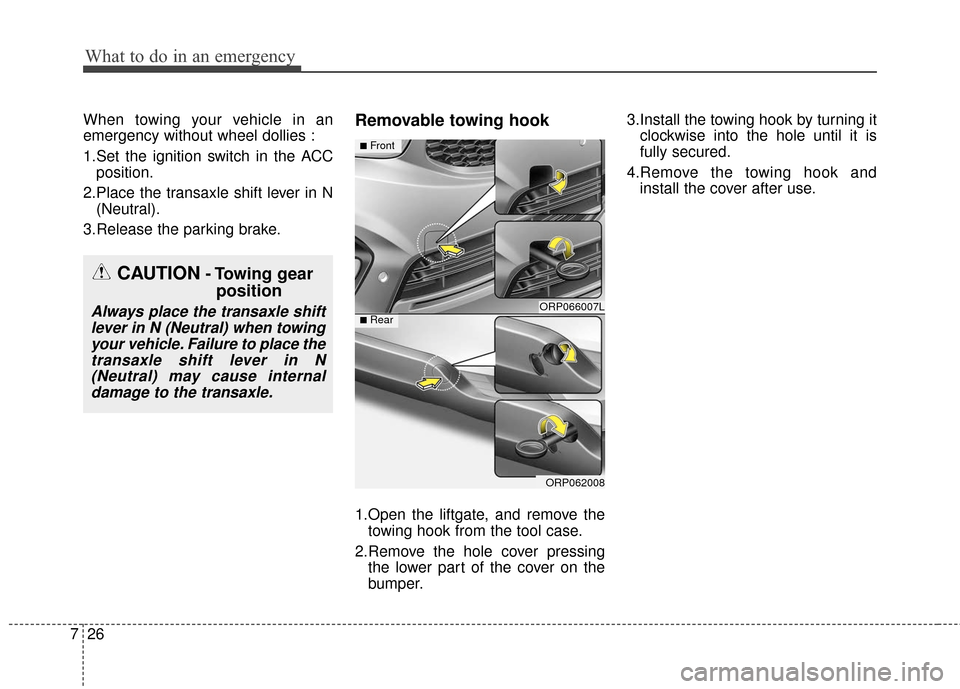

When towing your vehicle in an

emergency without wheel dollies :

1.Set the ignition switch in the ACC

position.

2.Place the transaxle shift lever in N (Neutral).

3.Release the parking brake.Removable towing hook

1.Open the liftgate, and remove the towing hook from the tool case.

2.Remove the hole cover pressing the lower part of the cover on the

bumper. 3.Install the towing hook by turning it

clockwise into the hole until it is

fully secured.

4.Remove the towing hook and install the cover after use.

CAUTION- Towing gear position

Always place the transaxle shift

lever in N (Neutral) when towingyour vehicle. Failure to place thetransaxle shift lever in N(Neutral) may cause internaldamage to the transaxle.ORP066007L

ORP062008

■Front

■Rear

Page 531 of 625

831

Maintenance

ENGINE COOLANT

The high-pressure cooling system

has a reservoir filled with year-round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level at least once a year, at

the beginning of the winter season,

and before traveling to a colder cli-

mate.Checking the coolant level

WARNING

Removing radiatorcap

Never attempt to remove the

radiator cap while the engine

is operating or hot. Doing so

might lead to cooling system

and engine damage. Also, hot

coolant or steam could cause

serious personal injury.

Turn the engine off and wait until it cools down. Use

extreme care when removing

the radiator cap. Wrap a thick

towel around it, and turn it

counterclockwise slowly to

the first stop. Step back while

the pressure is released from

the cooling system.

(Continued)

(Continued)When you are sure all the

pressure has been released,

press down on the cap, using

a thick towel, and continue

turning counterclockwise to

remove it.

Even if the engine is not oper- ating, do not remove the radi-

ator cap or the drain plug

while the engine and radiator

are hot. Hot coolant and

steam may still blow out

under pressure, causing seri-

ous injury.

Page 569 of 625

869

Maintenance

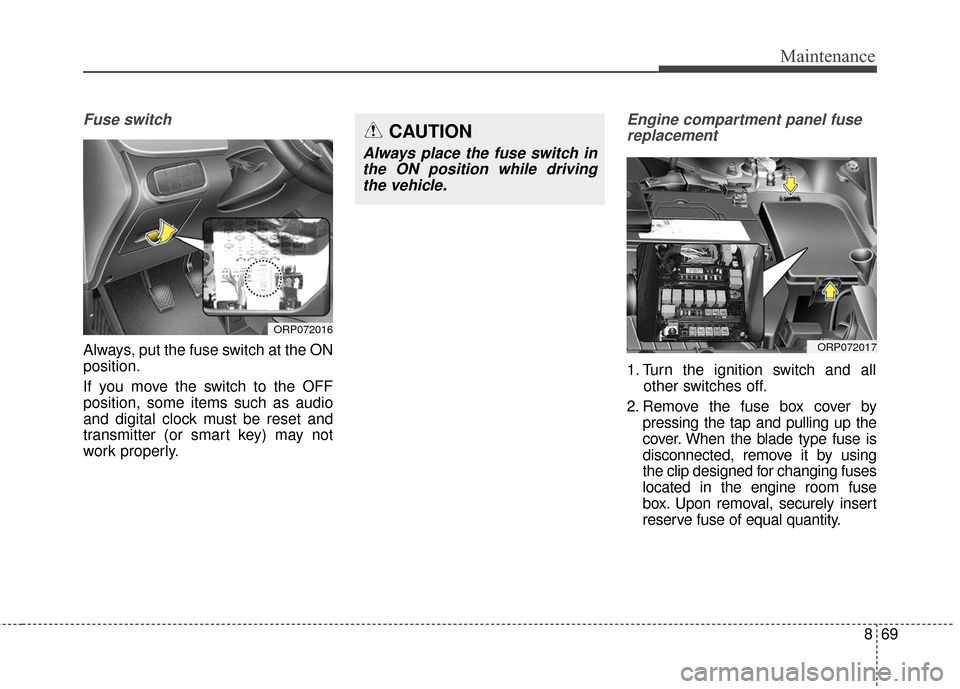

Fuse switch

Always, put the fuse switch at the ON

position.

If you move the switch to the OFF

position, some items such as audio

and digital clock must be reset and

transmitter (or smart key) may not

work properly.

Engine compartment panel fusereplacement

1. Turn the ignition switch and all other switches off.

2. Remove the fuse box cover by pressing the tap and pulling up the

cover. When the blade type fuse is

disconnected, remove it by using

the clip designed for changing fuses

located in the engine room fuse

box. Upon removal, securely insert

reserve fuse of equal quantity.

ORP072016

CAUTION

Always place the fuse switch inthe ON position while drivingthe vehicle.

ORP072017

Page 575 of 625

875

Maintenance

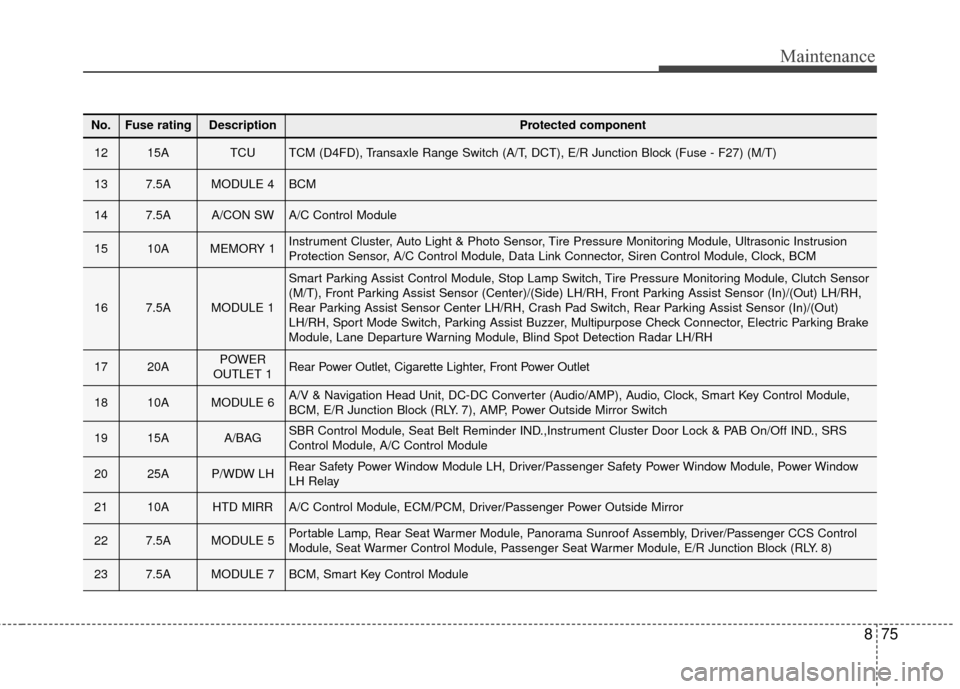

No.Fuse ratingDescriptionProtected component

1215ATCUTCM (D4FD), Transaxle Range Switch (A/T, DCT), E/R Junction Block (Fuse - F27) (M/T)

137.5AMODULE 4BCM

147.5AA/CON SWA/C Control Module

1510AMEMORY 1Instrument Cluster, Auto Light & Photo Sensor, Tire Pressure Monitoring Module, Ultrasonic Instrusion

Protection Sensor, A/C Control Module, Data Link Connector, Siren Control Module, Clock, BCM

167.5AMODULE 1

Smart Parking Assist Control Module, Stop Lamp Switch, Tire Pressure Monitoring Module, Clutch Sensor

(M/T), Front Parking Assist Sensor (Center)/(Side) LH/RH, Front Parking Assist Sensor (In)/(Out) LH/RH,

Rear Parking Assist Sensor Center LH/RH, Crash Pad Switch, Rear Parking Assist Sensor (In)/(Out)

LH/RH, Sport Mode Switch, Parking Assist Buzzer, Multipurpose Check Connector, Electric Parking Brake

Module, Lane Departure Warning Module, Blind Spot Detection Radar LH/RH

1720APOWER

OUTLET 1Rear Power Outlet, Cigarette Lighter, Front Power Outlet

1810AMODULE 6A/V & Navigation Head Unit, DC-DC Converter (Audio/AMP), Audio, Clock, Smart Key Control Module,

BCM, E/R Junction Block (RLY. 7), AMP, Power Outside Mirror Switch

1915AA/BAGSBR Control Module, Seat Belt Reminder IND.,Instrument Cluster Door Lock & PAB On/Off IND., SRS

Control Module, A/C Control Module

2025AP/WDW LHRear Safety Power Window Module LH, Driver/Passenger Safety Power Window Module, Power Window

LH Relay

2110AHTD MIRRA/C Control Module, ECM/PCM, Driver/Passenger Power Outside Mirror

227.5AMODULE 5Portable Lamp, Rear Seat Warmer Module, Panorama Sunroof Assembly, Driver/Passenger CCS Control

Module, Seat Warmer Control Module, Passenger Seat Warmer Module, E/R Junction Block (RLY. 8)

237.5AMODULE 7BCM, Smart Key Control Module

Page 582 of 625

Maintenance

82

8

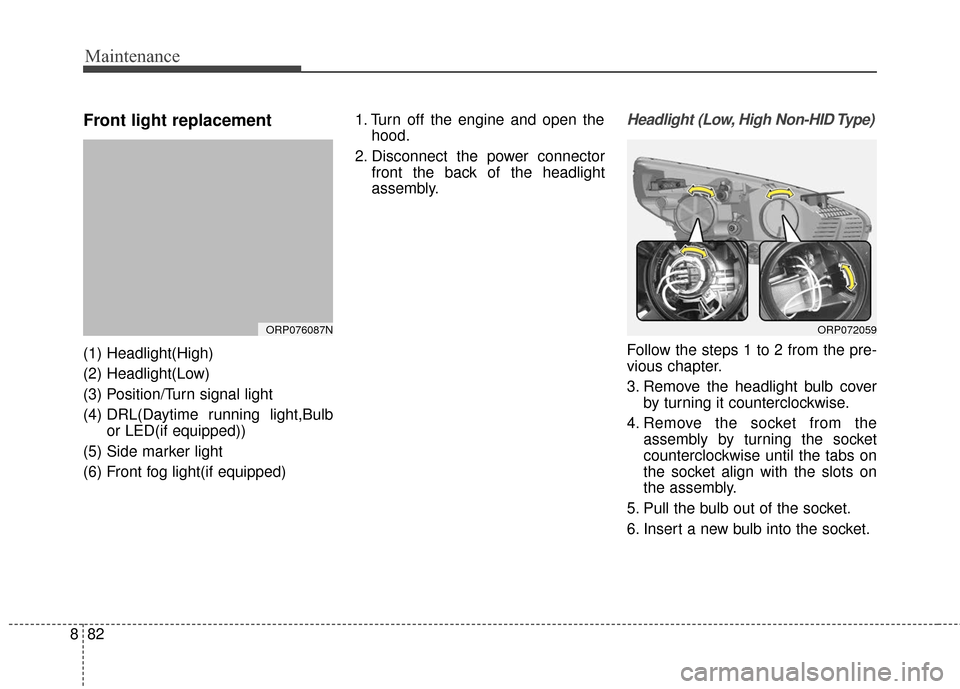

Front light replacement

(1) Headlight(High)

(2) Headlight(Low)

(3) Position/Turn signal light

(4) DRL(Daytime running light,Bulb

or LED(if equipped))

(5) Side marker light

(6) Front fog light(if equipped) 1. Turn off the engine and open the

hood.

2. Disconnect the power connector front the back of the headlight

assembly.

Headlight (Low, High Non-HID Type)

Follow the steps 1 to 2 from the pre-

vious chapter.

3. Remove the headlight bulb coverby turning it counterclockwise.

4. Remove the socket from the assembly by turning the socket

counterclockwise until the tabs on

the socket align with the slots on

the assembly.

5. Pull the bulb out of the socket.

6. Insert a new bulb into the socket.

ORP076087NORP072059

Page 583 of 625

883

Maintenance

7. Install the socket in the assemblyby aligning the tabs on the socket

with the slots in the assembly.

Push the socket into the assembly

and turn the socket clockwise.

8. Install the headlight bulb cover by turning it clockwise.

9. Connect the power connector to the back of the headlight assem-

bly.

✽ ✽NOTICE

If the headlight aiming adjustment

is necessary after the headlight

assembly is reinstalled, have the

vehicle checked by an authorized

Kia dealer.

Headlight (Low, HID type),

DRL (LED type)

If the DRL lamp (LED) does not

operate, have the vehicle checked by

an authorized Kia dealer.

LED lamps do not have replaceable

bulbs.

A skilled technician should check or

repair the Headlight low (HID) and

DRL lamp(LED), for it may damage

related parts of the vehicle.

✽ ✽ NOTICE

HID lamps have superior perform-

ance vs. halogen bulbs. HID lamps

are estimated by the manufacturer to

last twice as long or longer than halo-

gen bulbs depending on their fre-

quency of use. They will probably

require replacement at some point in

the life of the vehicle. Cycling the

headlamps on and off more than typ-

ical use will shorten HID lamps life.

HID lamps do not fail in the same

manner as halogen incandescent

lamps. If a headlamp goes out after a

period of operation but will immedi-

ately relight when the headlamp

switch is cycled it is likely the HID

lamp needs to be replaced. HID light-

ing components are more complex

than conventional halogen bulbs thus

have higher replacement cost.

WARNING - HID

Headlight low beam

(if equipped)

Do not attempt to replace or

inspect the low beam (XENON

bulb) due to electric shock dan-

ger. If the low beam (XENON

bulb) is not working, have the

vehicle checked by an author-

ized Kia dealer.

Page 584 of 625

Maintenance

84

8

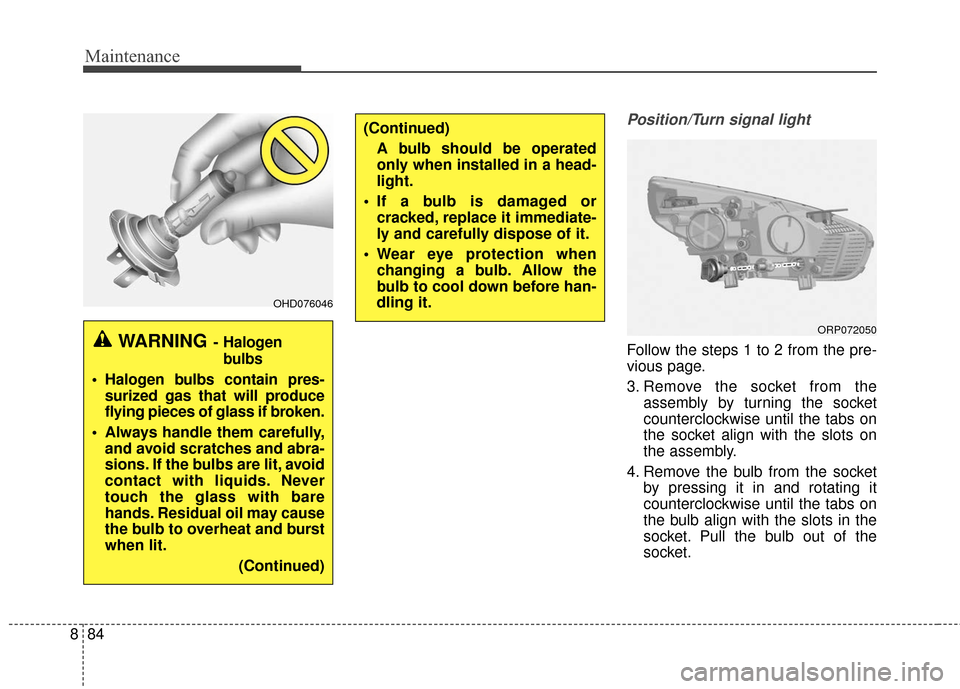

Position/Turn signal light

Follow the steps 1 to 2 from the pre-

vious page.

3. Remove the socket from the

assembly by turning the socket

counterclockwise until the tabs on

the socket align with the slots on

the assembly.

4. Remove the bulb from the socket by pressing it in and rotating it

counterclockwise until the tabs on

the bulb align with the slots in the

socket. Pull the bulb out of the

socket.

OHD076046

WARNING- Halogen

bulbs

Halogen bulbs contain pres-surized gas that will produce

flying pieces of glass if broken.

Always handle them carefully, and avoid scratches and abra-

sions. If the bulbs are lit, avoid

contact with liquids. Never

touch the glass with bare

hands. Residual oil may cause

the bulb to overheat and burst

when lit.

(Continued)

(Continued)A bulb should be operated

only when installed in a head-

light.

If a bulb is damaged or cracked, replace it immediate-

ly and carefully dispose of it.

Wear eye protection when changing a bulb. Allow the

bulb to cool down before han-

dling it.

ORP072050