air suspension KIA SORENTO 2010 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2010, Model line: SORENTO, Model: KIA SORENTO 2010Pages: 399, PDF Size: 40.44 MB

Page 318 of 399

Maintenance

12

7

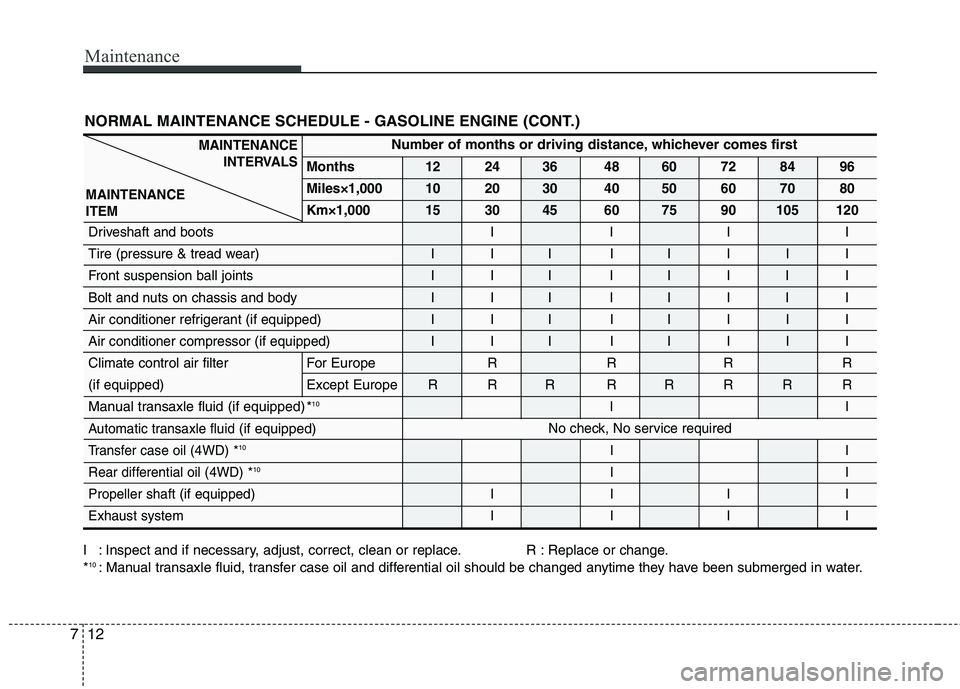

NORMAL MAINTENANCE SCHEDULE - GASOLINE ENGINE (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace. R : Replace or change. * 10

: Manual transaxle fluid, transfer case oil and differential oil should be changed anytime they have been submerged in water.

Number of months or driving distance, whichever comes first

Months 12 24 36 48 60 72 84 96

Miles×1,000 10 20 30 40 50 60 70 80

Km×1,000 15 30 45 60 75 90 105 120

Driveshaft and boots I I I I

Tire (pressure & tread wear) I I I I I I I I

Front suspension ball joints I I I I I I I I

Bolt and nuts on chassis and body I I I I I I I I

Air conditioner refrigerant (if equipped) I I I I I I I I

Air conditioner compressor (if equipped) I I I I I I I IClimate control air filter

For EuropeRRRR

(if equipped)

Except EuropeRRR RRRRR

Manual transaxle fluid (if equipped) * 10

II

Automatic transaxle fluid(if equipped)

Transfer case oil (4WD) *10

II

Rear differential oil (4WD) * 10

II

Propeller shaft

(if equipped)IIII

Exhaust system I I I I

MAINTENANCE

INTERVALS

MAINTENANCE ITEM

No check, No service required

Page 319 of 399

713

Maintenance

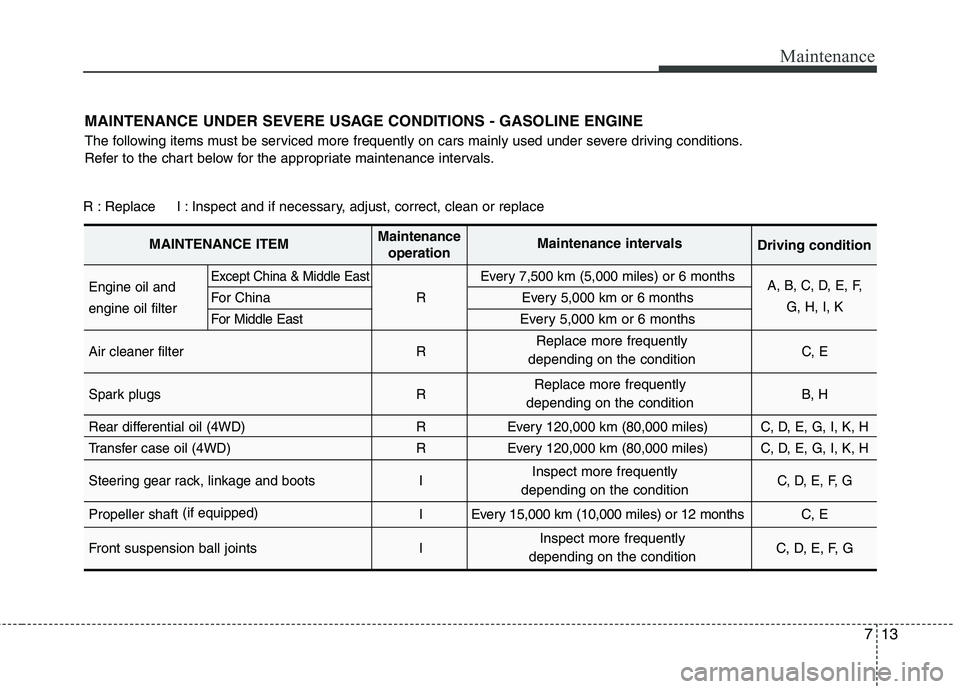

MAINTENANCE UNDER SEVERE USAGE CONDITIONS - GASOLINE ENGINE

The following items must be serviced more frequently on cars mainly used under severe driving conditions.

Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and if necessary, adjust, correct, clean or replace

Except China & Middle EastEvery 7,500 km (5,000 miles) or 6 monthsA, B, C, D, E, F,

Engine oil and

For China R Every 5,000 km or 6 months G, H, I, K

engine oil filter

For Middle East

Every 5,000 km or 6 months

Air cleaner filter R C, E

Spark plugs R B, H

Rear differential oil (4WD) R Every 120,000 km (80,000 miles) C, D, E, G, I, K, H

Transfer case oil (4WD) R Every 120,000 km (80,000 miles) C, D, E, G, I, K, H

Steering gear rack, linkage and boots I C, D, E, F, G

Propeller shaft (if equipped)I Every 15,000 km (10,000 miles) or 12 months C, E

Front suspension ball joints I C, D, E, F, G

MAINTENANCE ITEMMaintenance

operation Maintenance intervals

Driving condition

Replace more frequently

depending on the condition

Inspect more frequently

depending on the condition Replace more frequently

depending on the condition

Inspect more frequently

depending on the condition

Page 324 of 399

Maintenance

18

7

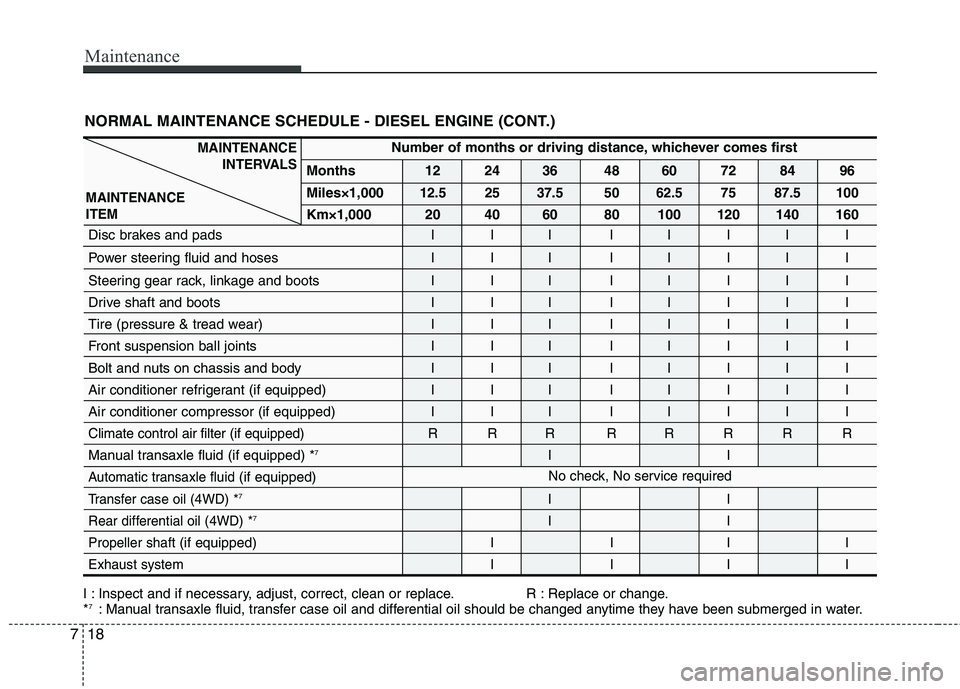

NORMAL MAINTENANCE SCHEDULE - DIESEL ENGINE (CONT.)

Number of months or driving distance, whichever comes first

Months 12 24 36 48 60 72 84 96 Miles×1,000

12.5 25 37.5 50 62.5 75 87.5 100

Km×1,000 20 40 60 80 100 120 140 160

Disc brakes and pads I I I I I I I I

Power steering fluid and hoses I I I I I I I I

Steering gear rack, linkage and boots I I I I I I I I

Drive shaft and boots I I I I I I I I

Tire (pressure & tread wear) I I I I I I I I

Front suspension ball joints I I I I I I I I

Bolt and nuts on chassis and body I I I I I I I I

Air conditioner refrigerant (if equipped) I I I I I I I I

Air conditioner compressor (if equipped) I I I I I I I I

Climate control air filter (if equipped) R R R R R R R R

Manual transaxle fluid (if equipped) * 7

II

Automatic transaxle fluid(if equipped)

Transfer case oil (4WD) *7

II

Rear differential oil (4WD) * 7

II

Propeller shaft

(if equipped) IIII

Exhaust system I I I I

I : Inspect and if necessary, adjust, correct, clean or replace. R : Replace or change. *7

: Manual transaxle fluid, transfer case oil and differential oil should be changed anytime they have been submerged in water.

MAINTENANCE

INTERVALS

MAINTENANCE ITEM

No check, No service required

Page 326 of 399

Maintenance

20

7

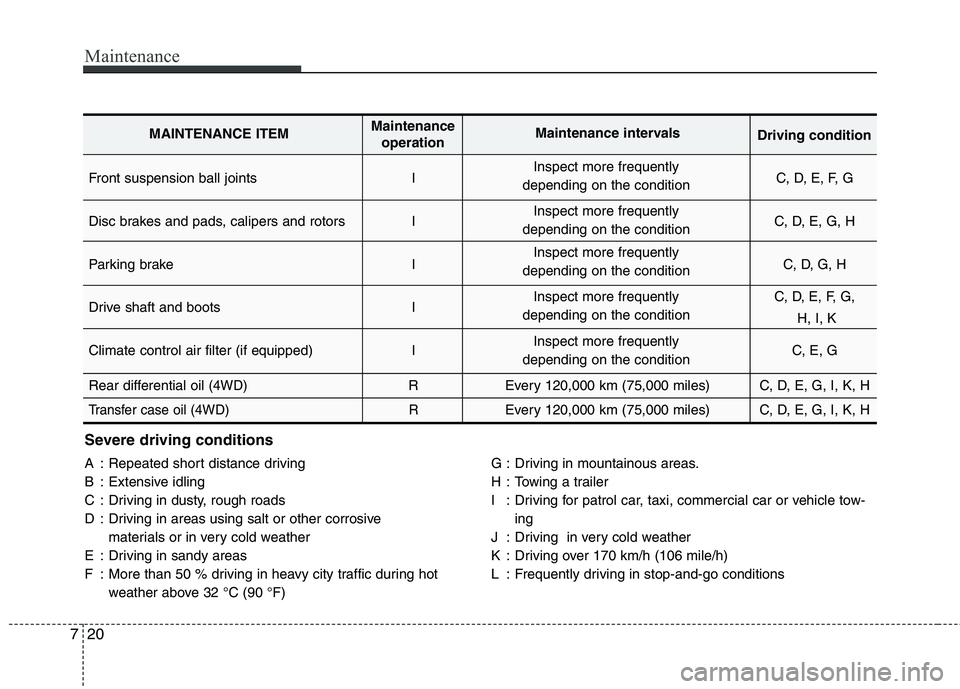

Severe driving conditions

A : Repeated short distance driving

B : Extensive idling

C : Driving in dusty, rough roads

D : Driving in areas using salt or other corrosive

materials or in very cold weather

E : Driving in sandy areas

F : More than 50 % driving in heavy city traffic during hot weather above 32 °C (90 °F) G : Driving in mountainous areas.

H : Towing a trailer

I : Driving for patrol car, taxi, commercial car or vehicle tow-

ing

J : Driving in very cold weather

K : Driving over 170 km/h (106 mile/h)

L : Frequently driving in stop-and-go conditions

Front suspension ball joints I C, D, E, F, G

Disc brakes and pads, calipers and rotors I C, D, E, G, H

Parking brake I C, D, G, H

Drive shaft and boots I C, D, E, F, G,

H, I, K

Climate control air filter (if equipped) I C, E, G

Rear differential oil

(4WD)R Every 120,000 km (75,000 miles) C, D, E, G, I, K, H

Transfer case oil (4WD) REvery 120,000 km (75,000 miles) C, D, E, G, I, K, H

MAINTENANCE ITEM Maintenance

operation Maintenance intervals

Driving condition

Inspect more frequently

depending on the condition

Inspect more frequently

depending on the condition

Inspect more frequently

depending on the condition

Inspect more frequently

depending on the condition

Inspect more frequently

depending on the condition

Page 329 of 399

723

Maintenance

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately. Brake fluid

Check the brake fluid level in the brake

fluid reservoir. The level should be

between “MIN” and “MAX” marks on the

side of the reservoir. Use only hydraulic

brake fluid conforming to DOT 3 or DOT4 specification.

Parking brake

Inspect the parking brake system includ-

ing the parking brake pedal and cables.

Brake discs, pads, calipers and

rotors

Check the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage.Suspension mounting bolts

Check the suspension connections for

looseness or damage. Retighten to the

specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine off,

check for excessive free-play in the

steering wheel.

Check the linkage for bends or damage.

Check the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.

Power steering pump, belt and hoses

Check the power steering pump and

hoses for leakage and damage. Replace

any damaged or leaking parts immedi-

ately. Inspect the power steering belt (or

drive belt) for evidence of cuts, cracks,

excessive wear, oiliness and proper ten-

sion. Replace or adjust it if necessary.Drive shafts and boots

Check the drive shafts, boots and clamps

for cracks, deterioration, or damage.

Replace any damaged parts and, if nec-

essary, repack the grease.

Air conditioning refrigerant (if equipped)

Check the air conditioning lines and con-

nections for leakage and damage.