ABS KIA SORENTO 2019 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2019, Model line: SORENTO, Model: KIA SORENTO 2019Pages: 573, PDF Size: 10.61 MB

Page 404 of 573

5127

Driving your vehicle

Hitches

It's important to have the correct

hitch equipment. Crosswinds, large

trucks going by, and rough roads are

a few reasons why you’ll need the

right hitch. Here are some rules to

follow:

Will you have to make any holes inthe body of your vehicle when you

install a trailer hitch? If you do, then

be sure to seal the holes later

when you remove the hitch.

If you don’t seal them, deadly car-

bon monoxide (CO) from your

exhaust can get into your vehicle,

as well as dirt and water.

The bumpers on your vehicle are not intended for hitches. Do not

attach rental hitches or other

bumper-type hitches to them. Use

only a frame-mounted hitch that

does not attach to the bumper.

Kia trailer hitch accessory is avail- able at an authorized Kia dealer.

Safety chains

You should always attach chains

between your vehicle and your trail-

er. Cross the safety chains under the

tongue of the trailer so that the

tongue will not drop to the road if it

becomes separated from the hitch.

Instructions about safety chains may

be provided by the hitch manufactur-

er or by the trailer manufacturer.

Follow the manufacturer’s recom-

mendation for attaching safety

chains. Always leave just enough

slack so you can turn with your trail-

er. And, never allow safety chains to

drag on the ground.

Trailer brakes

If your trailer is equipped with a brak-

ing system, make sure it conforms to

your state’s regulations and that it is

properly installed and operating cor-

rectly.

If your trailer weight exceeds the

maximum allowed weight without

trailer brakes, then the trailer will also

require its own brakes as well. Be

sure to read and follow the instruc-

tions for the trailer brakes so you’ll be

able to install, adjust and maintain

them properly.

Don’t tap into or modify your vehi-cle's brake system.

WARNING- Trailer brakes

Do not use a trailer with its own

brakes unless you are absolute-

ly certain that you have proper-

ly set up the brake system. This

is not a task for amateurs. Use

an experienced, competent

trailer shop for this work.

Page 407 of 573

Driving your vehicle

130

5

Towing up hill

When towing a trailer on steep

grades (in excess of 6%) pay close

attention to the engine coolant

temperature gauge to ensure the

engine does not overheat.

If the needle of the coolant temper-

ature gauge moves across the dial

towards “H” (HOT), pull over and

stop as soon as it is safe to do so,

and allow the engine to idle until it

cools down. You may proceed once

the engine has cooled sufficiently.

You must decide driving speed depending on trailer weight and

uphill grade to reduce the possibil-

ity of engine and transmission

overheating.

Parking on hills

Generally, if you have a trailer

attached to your vehicle, you should

not park your vehicle on a hill. People

can be seriously or fatally injured,

and both your vehicle and the trailer

can be damaged if they unexpected-

ly roll downhill.

However, if you ever have to park

your trailer on a hill, here's how to do

it:

1.Pull the vehicle into the parkingspace. Turn the steering wheel in

the direction of the curb (right if

headed downhill, left if headed up

hill).

2.If the vehicle has an automatic transmission, place the vehicle in P

(Park).

3.Set the parking brake and shut off the engine.

4.Place chocks under the trailer wheels on the down hill side of the

wheels. 5.Start the vehicle, hold the brakes,

shift to neutral, release the parking

brake and slowly release the

brakes until the trailer chocks

absorb the load.

6.Reapply the brakes, reapply the parking brake and shift the vehicle

to P (Park) for automatic transmis-

sion.

7.Shut off the vehicle and release the vehicle brakes but leave the park-

ing brake set.

Page 436 of 573

What to do in an emergency

20

6

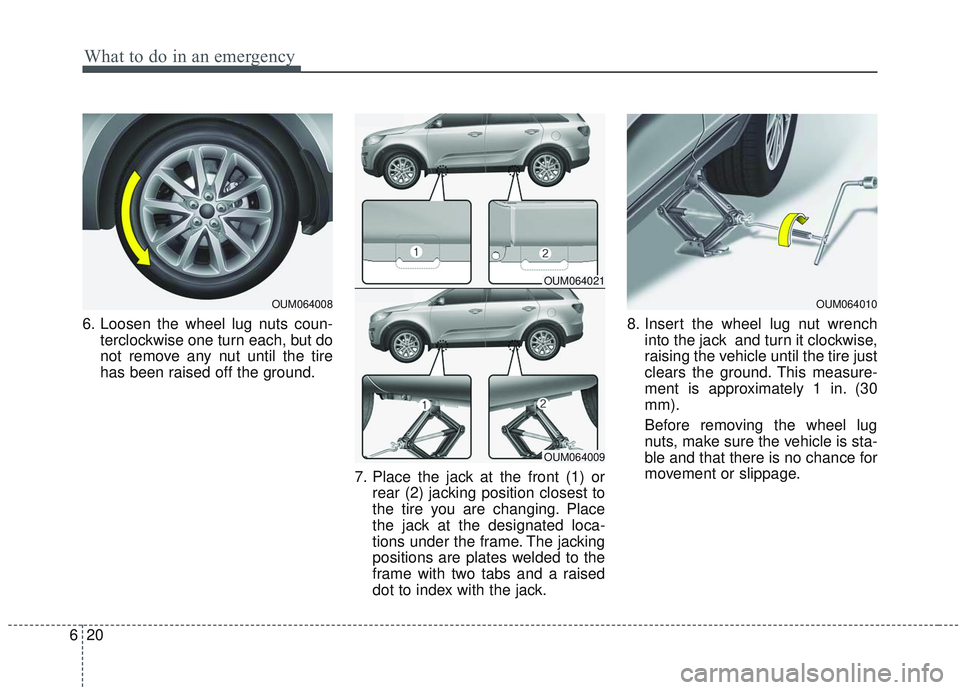

6. Loosen the wheel lug nuts coun-

terclockwise one turn each, but do

not remove any nut until the tire

has been raised off the ground.

7. Place the jack at the front (1) orrear (2) jacking position closest to

the tire you are changing. Place

the jack at the designated loca-

tions under the frame. The jacking

positions are plates welded to the

frame with two tabs and a raised

dot to index with the jack. 8. Insert the wheel lug nut wrench

into the jack and turn it clockwise,

raising the vehicle until the tire just

clears the ground. This measure-

ment is approximately 1 in. (30

mm).

Before removing the wheel lug

nuts, make sure the vehicle is sta-

ble and that there is no chance for

movement or slippage.

OUM064008

OUM064021

OUM064009

OUM064010

Page 484 of 573

741

Maintenance

Tire replacement

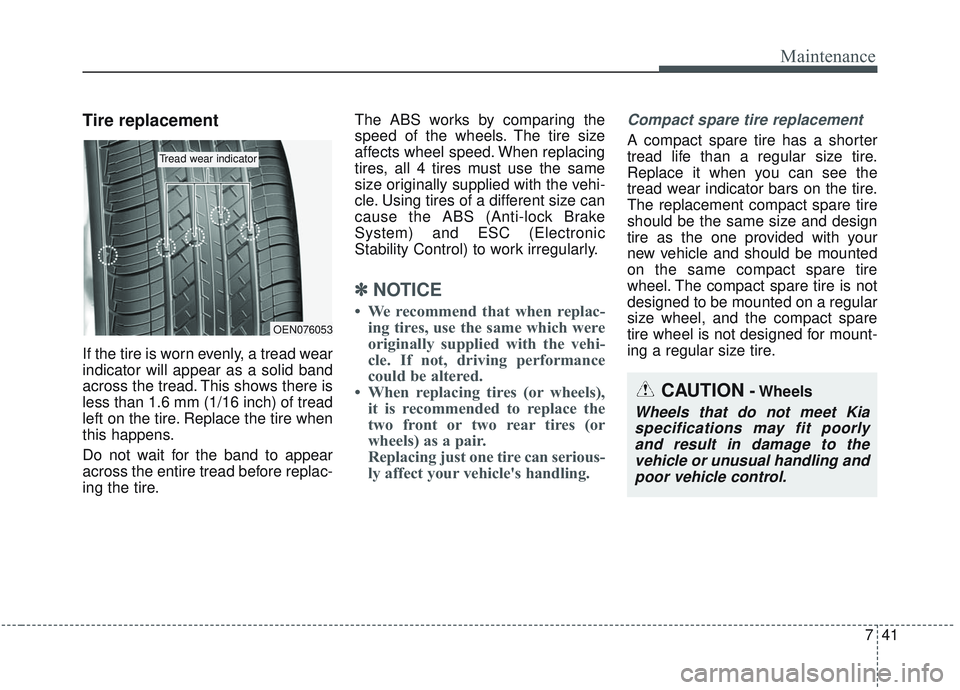

If the tire is worn evenly, a tread wear

indicator will appear as a solid band

across the tread. This shows there is

less than 1.6 mm (1/16 inch) of tread

left on the tire. Replace the tire when

this happens.

Do not wait for the band to appear

across the entire tread before replac-

ing the tire.The ABS works by comparing the

speed of the wheels. The tire size

affects wheel speed. When replacing

tires, all 4 tires must use the same

size originally supplied with the vehi-

cle. Using tires of a different size can

cause the ABS (Anti-lock Brake

System) and ESC (Electronic

Stability Control) to work irregularly.

✽ ✽

NOTICE

• We recommend that when replac-

ing tires, use the same which were

originally supplied with the vehi-

cle. If not, driving performance

could be altered.

• When replacing tires (or wheels), it is recommended to replace the

two front or two rear tires (or

wheels) as a pair.

Replacing just one tire can serious-

ly affect your vehicle's handling.

Compact spare tire replacement

A compact spare tire has a shorter

tread life than a regular size tire.

Replace it when you can see the

tread wear indicator bars on the tire.

The replacement compact spare tire

should be the same size and design

tire as the one provided with your

new vehicle and should be mounted

on the same compact spare tire

wheel. The compact spare tire is not

designed to be mounted on a regular

size wheel, and the compact spare

tire wheel is not designed for mount-

ing a regular size tire.

OEN076053

Tread wear indicator

CAUTION-Wheels

Wheels that do not meet Kia

specifications may fit poorlyand result in damage to thevehicle or unusual handling andpoor vehicle control.

Page 503 of 573

Maintenance

60

7

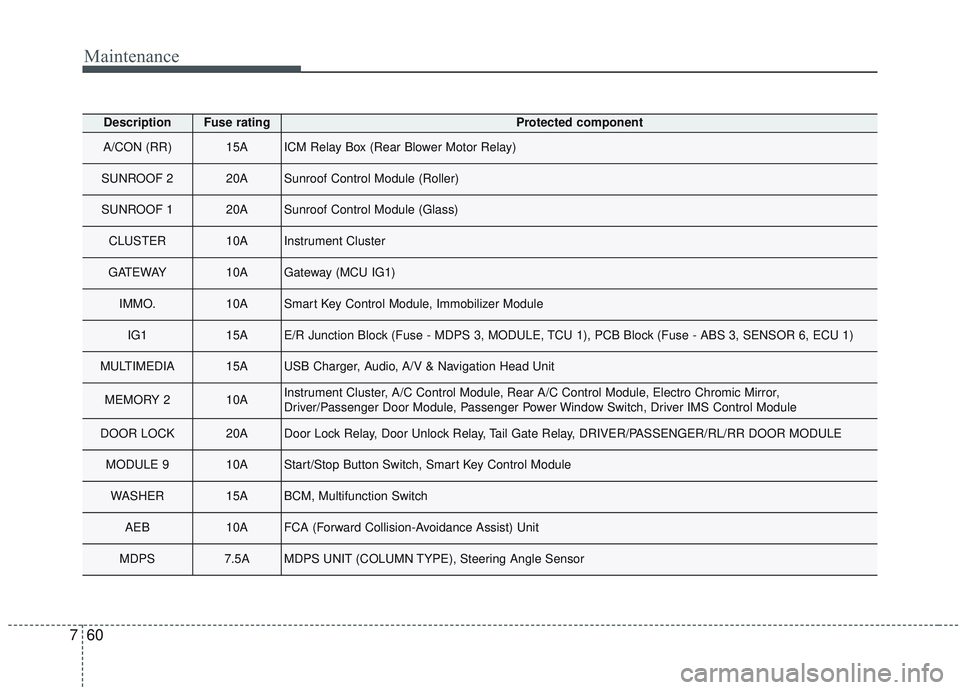

DescriptionFuse ratingProtected component

A/CON (RR) 15AICM Relay Box (Rear Blower Motor Relay)

SUNROOF 2 20ASunroof Control Module (Roller)

SUNROOF 1 20ASunroof Control Module (Glass)

CLUSTER 10AInstrument Cluster

GATEWAY10AGateway (MCU IG1)

IMMO.10ASmart Key Control Module, Immobilizer Module

IG1 15AE/R Junction Block (Fuse - MDPS 3, MODULE, TCU 1), PCB Block (Fuse - ABS 3, SENSOR 6, ECU 1)

MULTIMEDIA 15AUSB Charger, Audio, A/V & Navigation Head Unit

MEMORY 2 10AInstrument Cluster, A/C Control Module, Rear A/C Control Module, Electro Chromic Mirror,

Driver/Passenger Door Module, Passenger Power Window Switch, Driver IMS Control Module

DOOR LOCK 20ADoor Lock Relay, Door Unlock Relay, Tail Gate Relay, DRIVER/PASSENGER/RL/RR DOOR MODULE

MODULE 910AStart/Stop Button Switch, Smart Key Control Module

WASHER 15ABCM, Multifunction Switch

AEB10AFCA (Forward Collision-Avoidance Assist) Unit

MDPS 7.5AMDPS UNIT (COLUMN TYPE), Steering Angle Sensor

Page 507 of 573

Maintenance

64

7

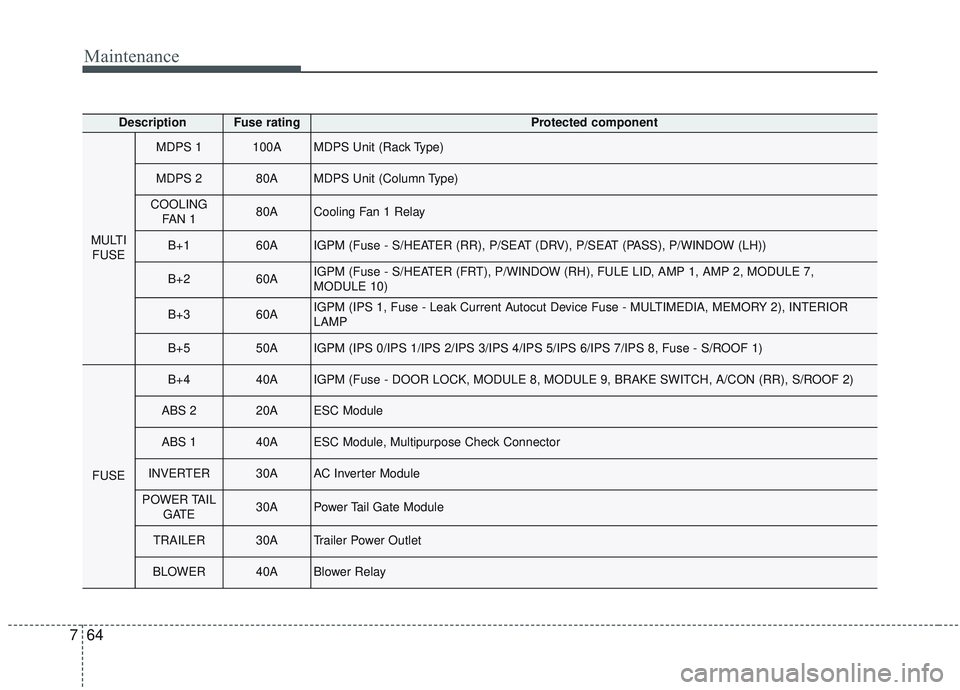

DescriptionFuse ratingProtected component

MULTI

FUSE

MDPS 1100AMDPS Unit (Rack Type)

MDPS 280AMDPS Unit (Column Type)

COOLING FAN 180ACooling Fan 1 Relay

B+160AIGPM (Fuse - S/HEATER (RR), P/SEAT (DRV), P/SEAT (PASS), P/WINDOW (LH))

B+260AIGPM (Fuse - S/HEATER (FRT), P/WINDOW (RH), FULE LID, AMP 1, AMP 2, MODULE 7,

MODULE 10)

B+360AIGPM (IPS 1, Fuse - Leak Current Autocut Device Fuse - MULTIMEDIA, MEMORY 2), INTERIOR

LAMP

B+550AIGPM (IPS 0/IPS 1/IPS 2/IPS 3/IPS 4/IPS 5/IPS 6/IPS 7/IPS 8, Fuse - S/R\

OOF 1)

FUSE

B+440AIGPM (Fuse - DOOR LOCK, MODULE 8, MODULE 9, BRAKE SWITCH, A/CON (RR),\

S/ROOF 2)

ABS 220AESC Module

ABS 140AESC Module, Multipurpose Check Connector

INVERTER30AAC Inverter Module

POWER TAIL GATE 30APower Tail Gate Module

TRAILER30ATrailer Power Outlet

BLOWER40ABlower Relay

Page 509 of 573

Maintenance

66

7

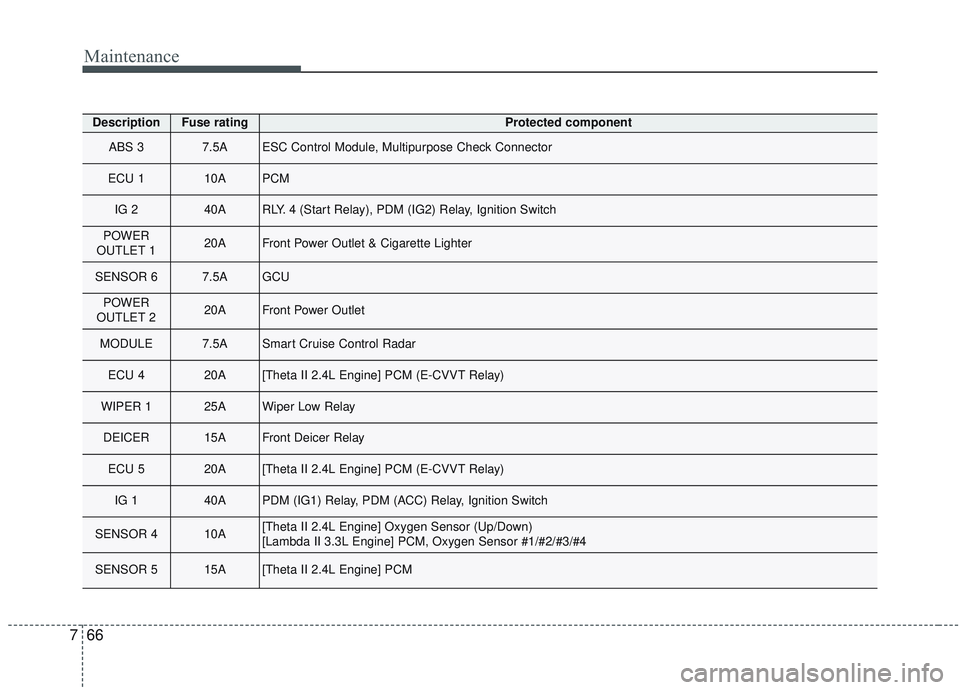

DescriptionFuse ratingProtected component

ABS 3 7.5AESC Control Module, Multipurpose Check Connector

ECU 1 10APCM

IG 2 40ARLY. 4 (Start Relay), PDM (IG2) Relay, Ignition Switch

POWER

OUTLET 1 20AFront Power Outlet & Cigarette Lighter

SENSOR 6 7.5AGCU

POWER

OUTLET 2 20AFront Power Outlet

MODULE7.5ASmart Cruise Control Radar

ECU 4 20A[Theta II 2.4L Engine] PCM (E-CVVT Relay)

WIPER 125AWiper Low Relay

DEICER 15AFront Deicer Relay

ECU 5 20A[Theta II 2.4L Engine] PCM (E-CVVT Relay)

IG 1 40APDM (IG1) Relay, PDM (ACC) Relay, Ignition Switch

SENSOR 4 10A[Theta II 2.4L Engine] Oxygen Sensor (Up/Down)

[Lambda II 3.3L Engine] PCM, Oxygen Sensor #1/#2/#3/#4

SENSOR 5 15A[Theta II 2.4L Engine] PCM

Page 516 of 573

773

Maintenance

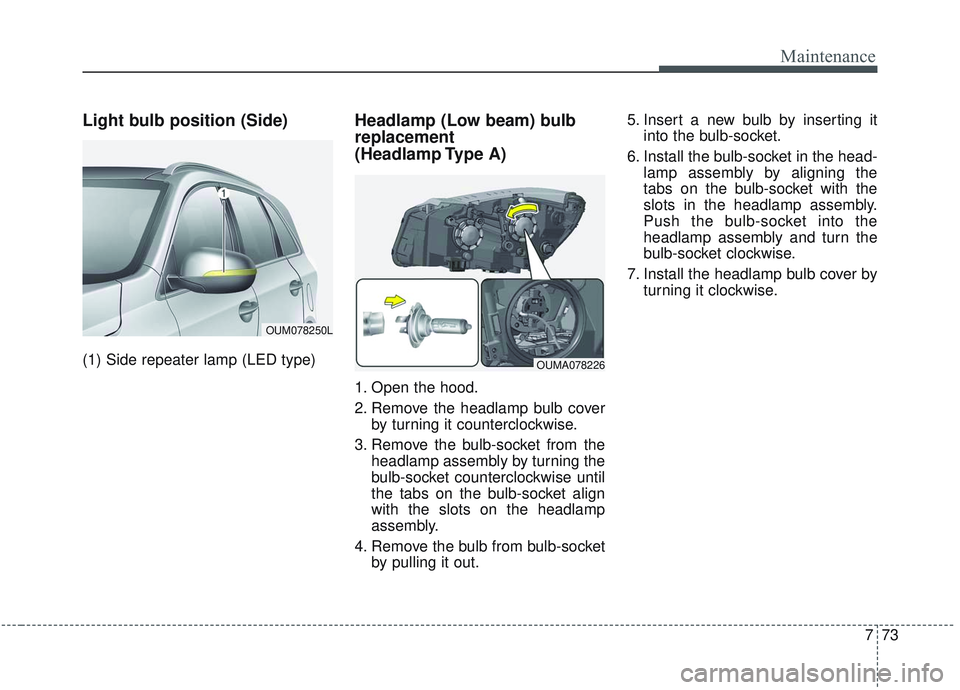

Light bulb position (Side)

(1) Side repeater lamp (LED type)

Headlamp (Low beam) bulb

replacement

(Headlamp Type A)

1. Open the hood.

2. Remove the headlamp bulb coverby turning it counterclockwise.

3. Remove the bulb-socket from the headlamp assembly by turning the

bulb-socket counterclockwise until

the tabs on the bulb-socket align

with the slots on the headlamp

assembly.

4. Remove the bulb from bulb-socket by pulling it out. 5. Insert a new bulb by inserting it

into the bulb-socket.

6. Install the bulb-socket in the head- lamp assembly by aligning the

tabs on the bulb-socket with the

slots in the headlamp assembly.

Push the bulb-socket into the

headlamp assembly and turn the

bulb-socket clockwise.

7. Install the headlamp bulb cover by turning it clockwise.

OUM078250L

OUMA078226

Page 517 of 573

Maintenance

74

7

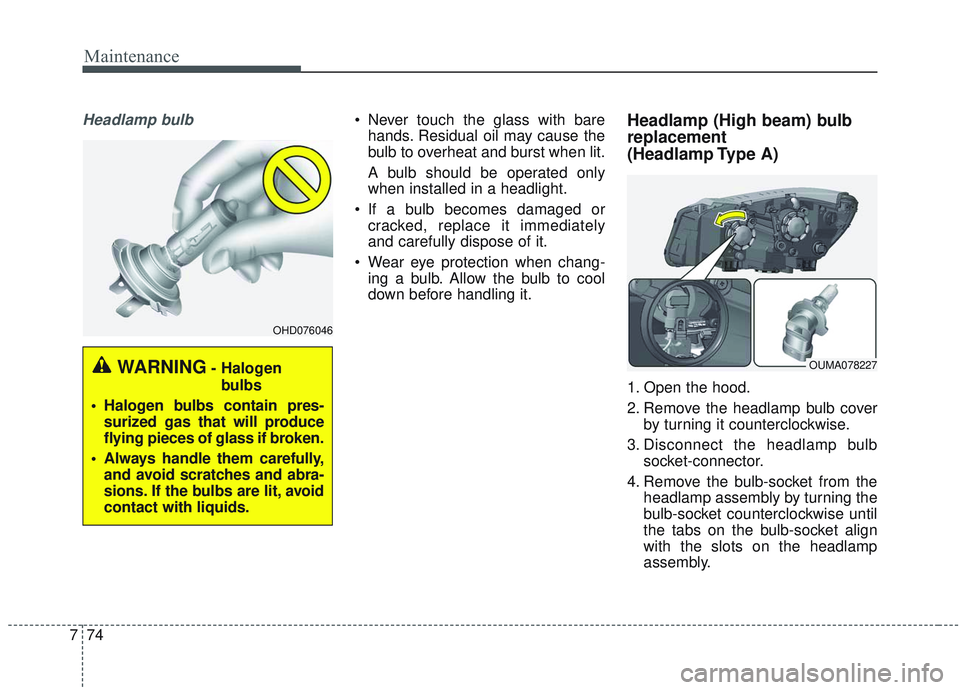

Headlamp bulb Never touch the glass with bare

hands. Residual oil may cause the

bulb to overheat and burst when lit.

A bulb should be operated only

when installed in a headlight.

If a bulb becomes damaged or cracked, replace it immediately

and carefully dispose of it.

Wear eye protection when chang- ing a bulb. Allow the bulb to cool

down before handling it.Headlamp (High beam) bulb

replacement

(Headlamp Type A)

1. Open the hood.

2. Remove the headlamp bulb cover by turning it counterclockwise.

3. Disconnect the headlamp bulb socket-connector.

4. Remove the bulb-socket from the headlamp assembly by turning the

bulb-socket counterclockwise until

the tabs on the bulb-socket align

with the slots on the headlamp

assembly.

WARNING- Halogen

bulbs

Halogen bulbs contain pres- surized gas that will produce

flying pieces of glass if broken.

Always handle them carefully, and avoid scratches and abra-

sions. If the bulbs are lit, avoid

contact with liquids.

OHD076046

OUMA078227

Page 518 of 573

775

Maintenance

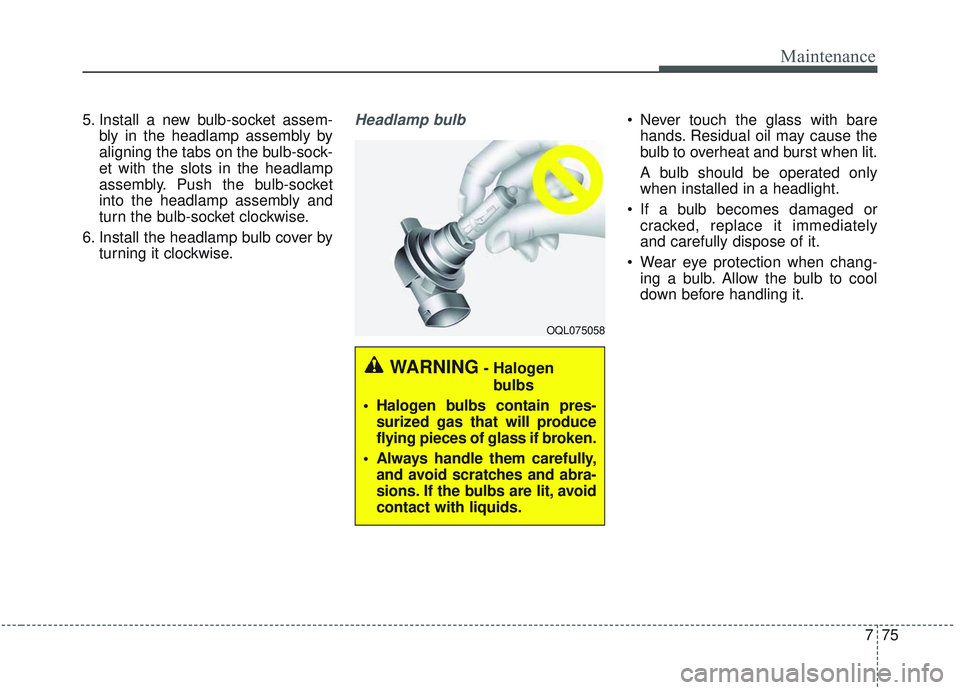

5. Install a new bulb-socket assem-bly in the headlamp assembly by

aligning the tabs on the bulb-sock-

et with the slots in the headlamp

assembly. Push the bulb-socket

into the headlamp assembly and

turn the bulb-socket clockwise.

6. Install the headlamp bulb cover by turning it clockwise.Headlamp bulb Never touch the glass with barehands. Residual oil may cause the

bulb to overheat and burst when lit.

A bulb should be operated only

when installed in a headlight.

If a bulb becomes damaged or cracked, replace it immediately

and carefully dispose of it.

Wear eye protection when chang- ing a bulb. Allow the bulb to cool

down before handling it.

WARNING- Halogen

bulbs

Halogen bulbs contain pres- surized gas that will produce

flying pieces of glass if broken.

Always handle them carefully, and avoid scratches and abra-

sions. If the bulbs are lit, avoid

contact with liquids.

OQL075058