oil KIA Sportage 2013 SL / 3.G Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2013, Model line: Sportage, Model: KIA Sportage 2013 SL / 3.GPages: 387, PDF Size: 8.44 MB

Page 329 of 387

711

Maintenance

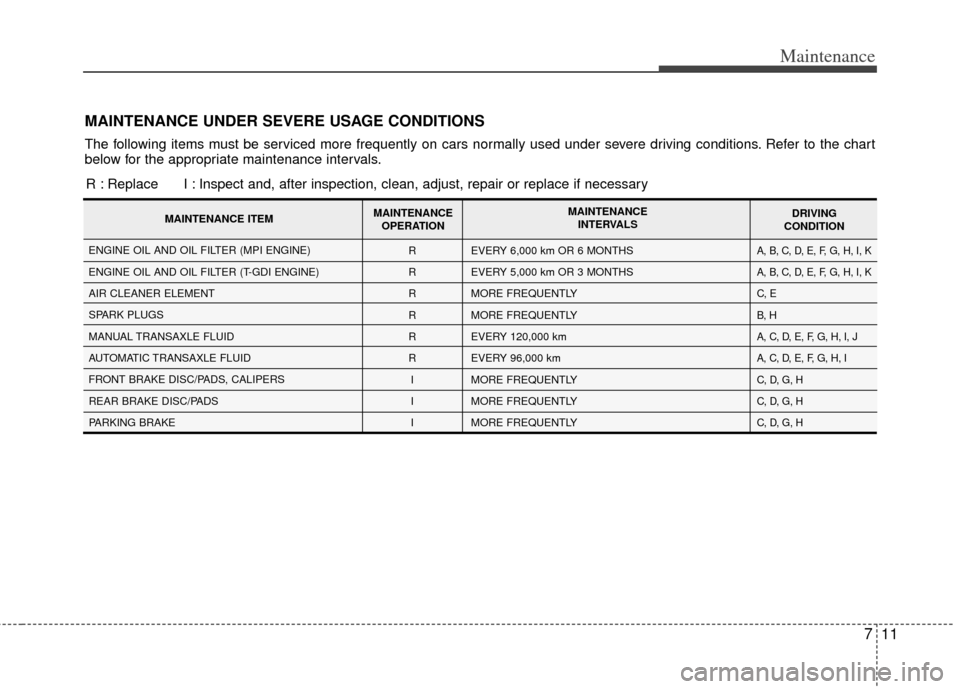

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart

below for the appropriate maintenance intervals.R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if neces\

sary

R

R

R

R

R

R

I

I

I EVERY 6,000 km OR 6 MONTHS

EVERY 5,000 km OR 3 MONTHS

MORE FREQUENTLY

MORE FREQUENTLY

EVERY 120,000 km

EVERY 96,000 km

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLYA, B, C, D, E, F, G, H, I, K

A, B, C, D, E, F, G, H, I, K

C, E

B, H

A, C, D, E, F, G, H, I, J

A, C, D, E, F, G, H, I

C, D, G, H

C, D, G, H

C, D, G, H ENGINE OIL AND OIL FILTER (MPI ENGINE)

ENGINE OIL AND OIL FILTER (T-GDI ENGINE)

AIR CLEANER ELEMENT

SPARK PLUGS

MANUAL TRANSAXLE FLUID

AUTOMATIC TRANSAXLE FLUID

FRONT BRAKE DISC/PADS, CALIPERS

REAR BRAKE DISC/PADS

PARKING BRAKE

MAINTENANCE ITEM

MAINTENANCE

OPERATION MAINTENANCE

INTERVALS DRIVING

CONDITION

Page 330 of 387

Maintenance

12

7

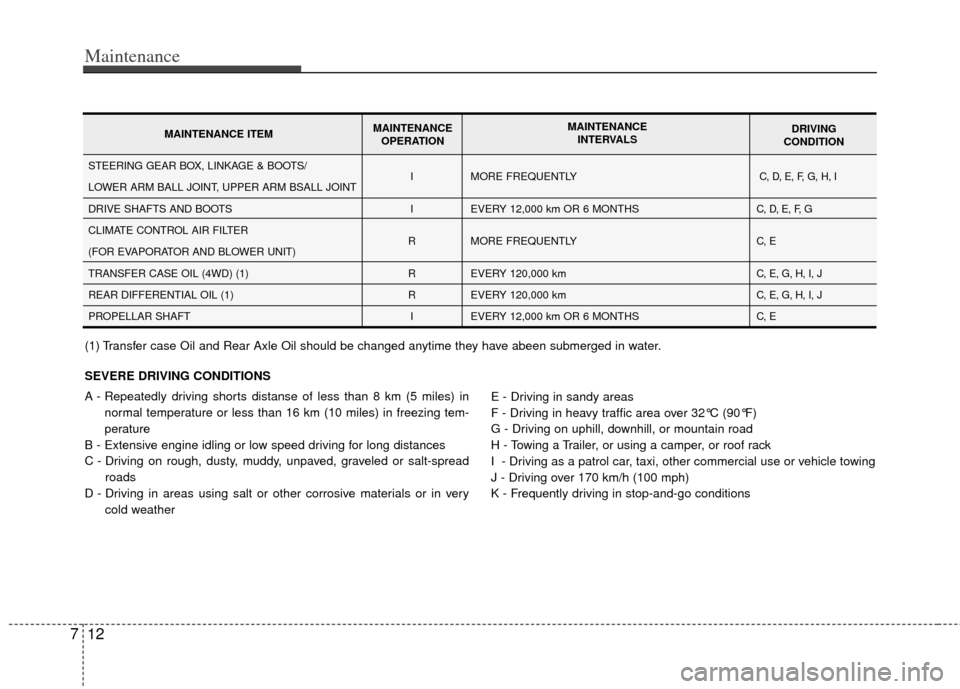

SEVERE DRIVING CONDITIONS

A - Repeatedly driving shorts distanse of less than 8 km (5 miles) in

normal temperature or less than 16 km (10 miles) in freezing tem-

perature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt-spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather E - Driving in sandy areas

F - Driving in heavy traffic area over 32°C (90°F)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle towing

J - Driving over 170 km/h (100 mph)

K - Frequently driving in stop-and-go conditions

I

I

R

R

R I MORE FREQUENTLY

EVERY 12,000 km OR 6 MONTHS

MORE FREQUENTLY

EVERY 120,000 km

EVERY 120,000 km

EVERY 12,000 km OR 6 MONTHSC, D, E, F, G, H, I

C, D, E, F, G

C, E

C, E, G, H, I, J

C, E, G, H, I, J

C, ESTEERING GEAR BOX, LINKAGE & BOOTS/

LOWER ARM BALL JOINT, UPPER ARM BSALL JOINT

DRIVE SHAFTS AND BOOTS

CLIMATE CONTROL AIR FILTER

(FOR EVAPORATOR AND BLOWER UNIT)

TRANSFER CASE OIL (4WD) (1)

REAR DIFFERENTIAL OIL (1)

PROPELLAR SHAFT

MAINTENANCE ITEM MAINTENANCE

OPERATION MAINTENANCE

INTERVALS DRIVING

CONDITION

(1) Transfer case Oil and Rear Axle Oil should be changed anytime they have abeen submerged in water.

Page 331 of 387

713

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

G050100AHM

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the vehicle is

being driven in severe conditions, more

frequent oil and filter changes are

required.

G050200AUN

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically for

proper tension and adjusted as neces-

sary.

G050300AUN

Fuel filter (cartridge)

A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by an authorized Kia dealer.

G050400AUN-EU

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

an authorized Kia dealer replace any

damaged or leaking parts immediately.

G050600AUN

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap is

correctly replaced.

G050700AUN

Vacuum crankcase ventilation

hoses

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or moving

component which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

G050800AUN

Air cleaner filter

A Genuine Kia air cleaner filter is recom-

mended when the filter is replaced.

Page 334 of 387

Maintenance

16

7

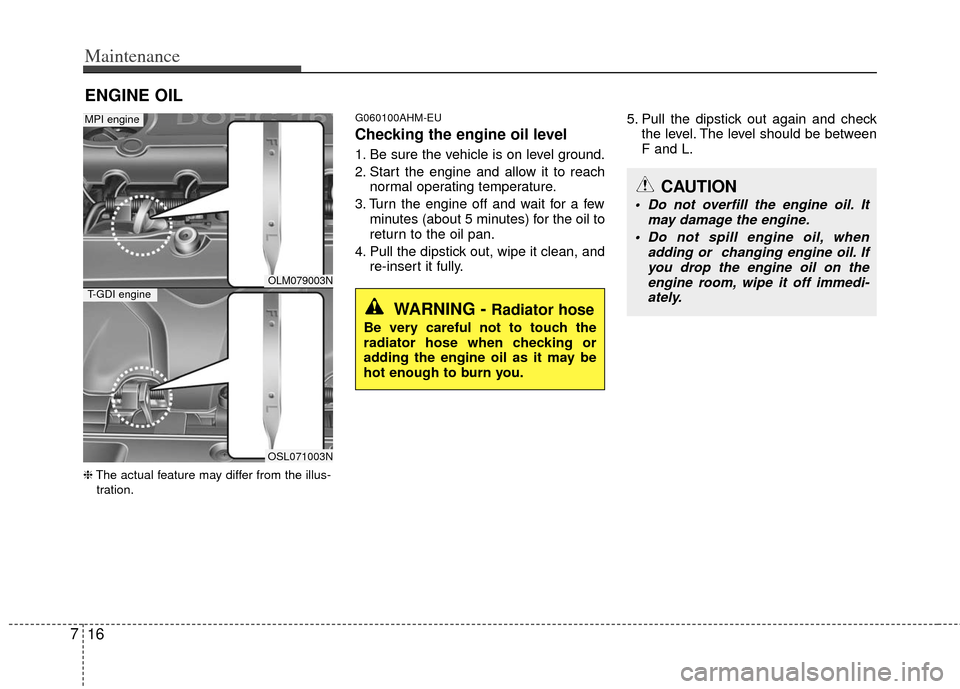

ENGINE OIL

❈ The actual feature may differ from the illus-

tration.

G060100AHM-EU

Checking the engine oil level

1. Be sure the vehicle is on level ground.

2. Start the engine and allow it to reach normal operating temperature.

3. Turn the engine off and wait for a few minutes (about 5 minutes) for the oil to

return to the oil pan.

4. Pull the dipstick out, wipe it clean, and re-insert it fully. 5. Pull the dipstick out again and check

the level. The level should be between

F and L.

WARNING - Radiator hose

Be very careful not to touch the

radiator hose when checking or

adding the engine oil as it may be

hot enough to burn you.

CAUTION

Do not overfill the engine oil. It may damage the engine.

Do not spill engine oil, when adding or changing engine oil. Ifyou drop the engine oil on theengine room, wipe it off immedi-ately.

OLM079003N

OSL071003N

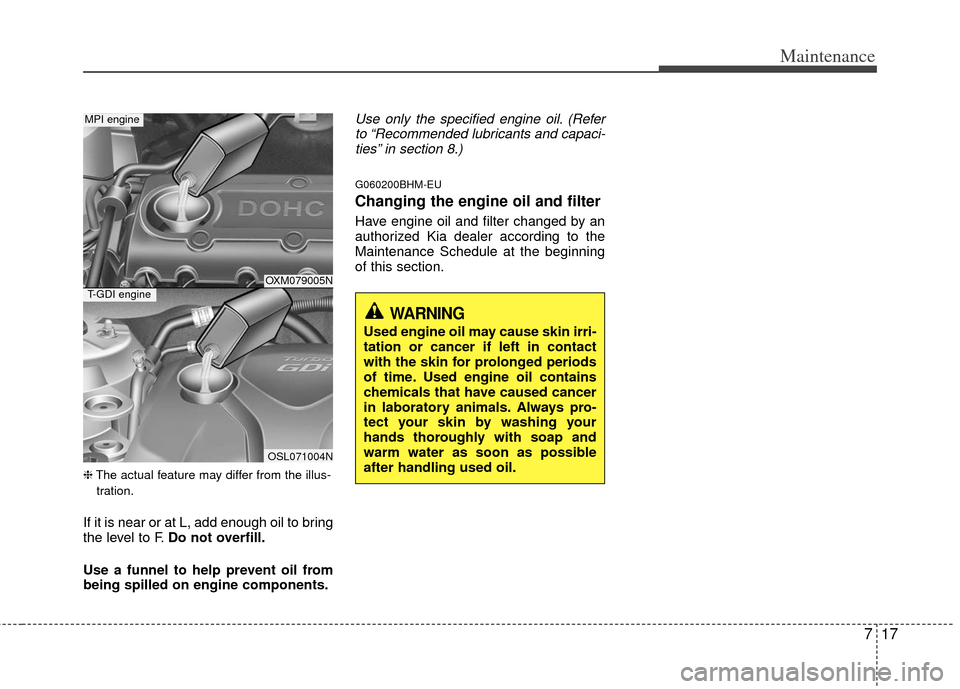

MPI engine

T-GDI engine

Page 335 of 387

717

Maintenance

❈The actual feature may differ from the illus-

tration.

If it is near or at L, add enough oil to bring

the level to F. Do not overfill.

Use a funnel to help prevent oil from

being spilled on engine components.

Use only the specified engine oil. (Refer to “Recommended lubricants and capaci-ties” in section 8.)

G060200BHM-EU

Changing the engine oil and filter

Have engine oil and filter changed by an

authorized Kia dealer according to the

Maintenance Schedule at the beginning

of this section.

OXM079005N

OSL071004N

MPI engine

T-GDI engine

WARNING

Used engine oil may cause skin irri-

tation or cancer if left in contact

with the skin for prolonged periods

of time. Used engine oil contains

chemicals that have caused cancer

in laboratory animals. Always pro-

tect your skin by washing your

hands thoroughly with soap and

warm water as soon as possible

after handling used oil.

Page 339 of 387

721

Maintenance

BRAKE/CLUTCH (IF EQUIPPED) FLUID

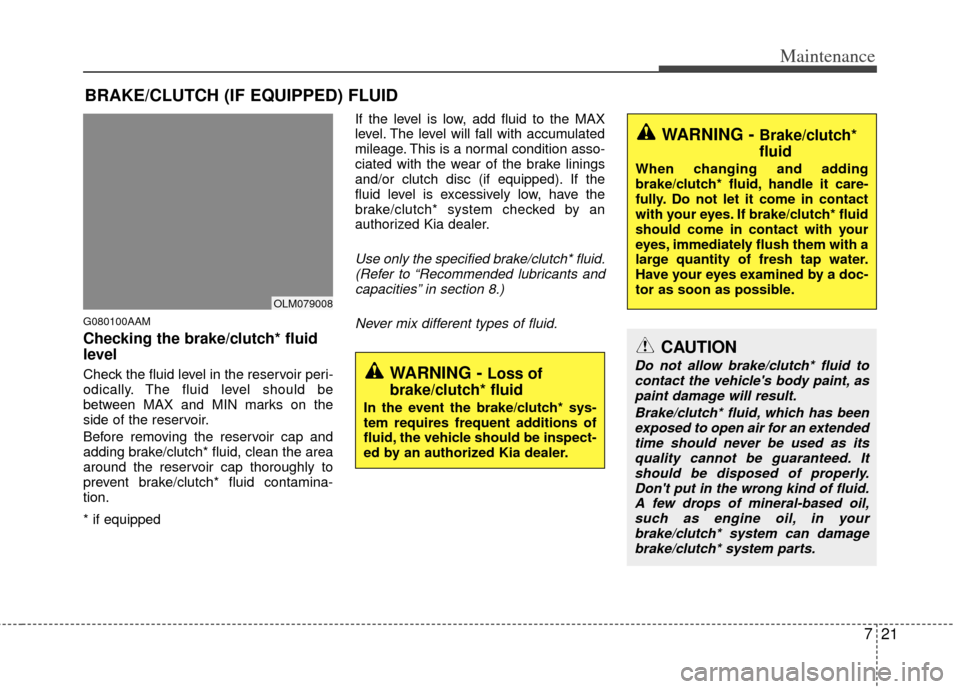

G080100AAM

Checking the brake/clutch* fluid

level

Check the fluid level in the reservoir peri-

odically. The fluid level should be

between MAX and MIN marks on the

side of the reservoir.

Before removing the reservoir cap and

adding brake/clutch* fluid, clean the area

around the reservoir cap thoroughly to

prevent brake/clutch* fluid contamina-

tion.

* if equippedIf the level is low, add fluid to the MAX

level. The level will fall with accumulated

mileage. This is a normal condition asso-

ciated with the wear of the brake linings

and/or clutch disc (if equipped). If the

fluid level is excessively low, have the

brake/clutch* system checked by an

authorized Kia dealer.

Use only the specified brake/clutch* fluid.

(Refer to “Recommended lubricants andcapacities” in section 8.)

Never mix different types of fluid.

WARNING - Loss of

brake/clutch* fluid

In the event the brake/clutch* sys-

tem requires frequent additions of

fluid, the vehicle should be inspect-

ed by an authorized Kia dealer.

OLM079008

WARNING - Brake/clutch*

fluid

When changing and adding

brake/clutch* fluid, handle it care-

fully. Do not let it come in contact

with your eyes. If brake/clutch* fluid

should come in contact with your

eyes, immediately flush them with a

large quantity of fresh tap water.

Have your eyes examined by a doc-

tor as soon as possible.

CAUTION

Do not allow brake/clutch* fluid to

contact the vehicle's body paint, aspaint damage will result.

Brake/clutch* fluid, which has beenexposed to open air for an extendedtime should never be used as its quality cannot be guaranteed. Itshould be disposed of properly. Don't put in the wrong kind of fluid.A few drops of mineral-based oil, such as engine oil, in yourbrake/clutch* system can damagebrake/clutch* system parts.

Page 347 of 387

729

Maintenance

G190200AUN

Battery recharging

Your vehicle has a maintenance-free,

calcium-based battery.

If the battery becomes discharged in ashort time (because, for example, the

headlights or interior lights were left on

while the vehicle was not in use),

recharge it by slow charging (trickle)

for 10 hours.

If the battery gradually discharges because of high electric load while the

vehicle is being used, recharge it at 20-

30A for two hours.

(Continued)

The electrical ignition systemworks with high voltage. Never

touch these components with the

engine running or the ignition

switched on.

Failure to follow the above warn-

ings can result in serious bodily

injury or death.WARNING- Recharging battery

When recharging the battery,

observe the following precautions:

The battery must be removed

from the vehicle and placed in an

area with good ventilation.

Do not allow cigarettes, sparks, or flame near the battery.

Watch the battery during charg- ing, and stop or reduce the charg-

ing rate if the battery cells begin

gassing (boiling) violently or if

the temperature of the electrolyte

of any cell exceeds 49°C (120°F).

Wear eye protection when check- ing the battery during charging.

Disconnect the battery charger in the following order.

1. Turn off the battery charger main switch.

2. Unhook the negative clamp from the negative battery terminal.

3. Unhook the positive clamp from the positive battery terminal.

CAUTION

If you connect unauthorized elec-tronic devices to the battery, thebattery may be discharged. Never use unauthorized devices.

Page 359 of 387

741

Maintenance

G201100AAM

Tire terminology and definitions

Air Pressure: The amount of air

inside the tire pressing outward on

the tire. Air pressure is expressed in

kilopascal (kPa) or pounds per

square inch (psi).

Accessory Weight: This means the

combined weight of optional acces-

sories. Some examples of optional

accessories are, automatic

transaxle, power seats, and air con-

ditioning.

Aspect Ratio : The relationship of a

tire's height to its width.

Belt: A rubber coated layer of cords

that is located between the plies and

the tread. Cords may be made from

steel or other reinforcing materials.

Bead: The tire bead contains steel

wires wrapped by steel cords that

hold the tire onto the rim.

Bias Ply Tire : A pneumatic tire in

which the plies are laid at alternate

angles less than 90 degrees to the

centerline of the tread. Cold Tire Pressure: The amount of

air pressure in a tire, measured in

kilopascals (kPa) or pounds per

square inch (psi) before a tire has

built up heat from driving.

Curb Weight: This means the weight

of a motor vehicle with standard and

optional equipment including the

maximum capacity of fuel, oil and

coolant, but without passengers and

cargo.

DOT Markings: The DOT code

includes the Tire Identification

Number (TIN), an alphanumeric des-

ignator which can also identify the

tire manufacturer, production plant,

brand and date of production.

GVWR: Gross Vehicle Weight Rating

GAWR FRT: Gross Axle Weight

Rating for the Front Axle.

GAWR RR: Gross Axle Weight

Rating for the Rear axle.

Intended Outboard Sidewall

: The

side of an asymmetrical tire, that

must always face outward when

mounted on a vehicle.

Kilopascal (kPa): The metric unit for

air pressure.

Load Index: An assigned number

ranging from 1 to 279 that corre-

sponds to the load carrying capacity

of a tire.

Maximum Inflation Pressure : The

maximum air pressure to which a

cold tire may be inflated. The maxi-

mum air pressure is molded onto the

sidewall.

Maximum Load Rating : The load

rating for a tire at the maximum per-

missible inflation pressure for that

tire.

Maximum Loaded Vehicle Weight:

The sum of curb weight; accessory

weight; vehicle capacity weight; and

production options weight.

Normal Occupant Weight: The

number of occupants a vehicle is

designed to seat multiplied by 68 kg

(150 pounds).

Page 362 of 387

Maintenance

44

7

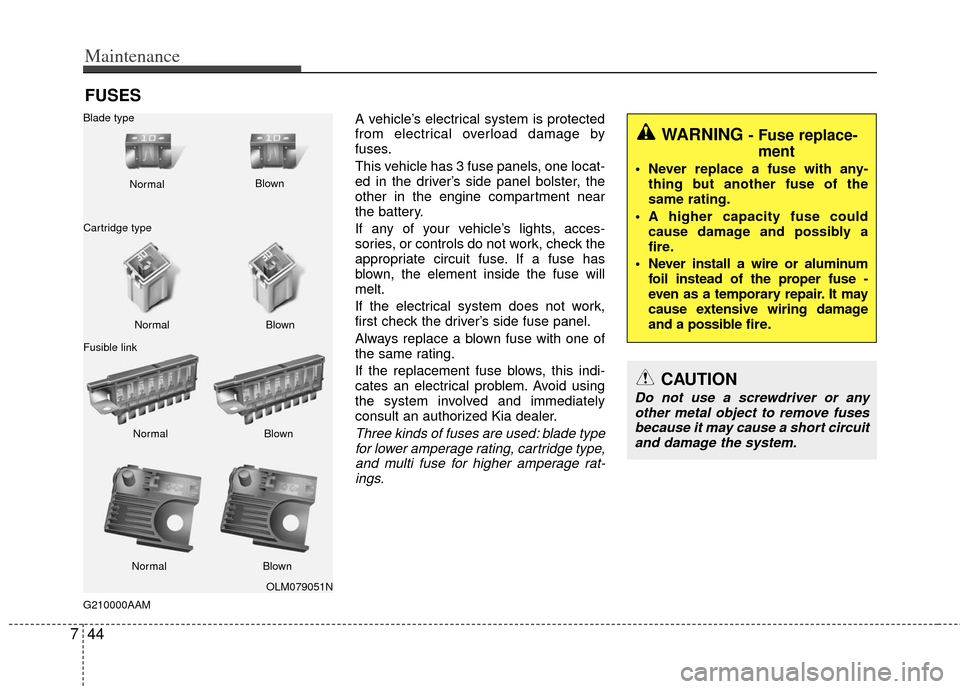

FUSES

G210000AAM

A vehicle’s electrical system is protected

from electrical overload damage by

fuses.

This vehicle has 3 fuse panels, one locat-

ed in the driver’s side panel bolster, the

other in the engine compartment near

the battery.

If any of your vehicle’s lights, acces-

sories, or controls do not work, check the

appropriate circuit fuse. If a fuse has

blown, the element inside the fuse will

melt.

If the electrical system does not work,

first check the driver’s side fuse panel.

Always replace a blown fuse with one of

the same rating.

If the replacement fuse blows, this indi-

cates an electrical problem. Avoid using

the system involved and immediately

consult an authorized Kia dealer.

Three kinds of fuses are used: blade type

for lower amperage rating, cartridge type,and multi fuse for higher amperage rat-ings.

WARNING - Fuse replace- ment

Never replace a fuse with any-

thing but another fuse of the

same rating.

A higher capacity fuse could cause damage and possibly a

fire.

Never install a wire or aluminum foil instead of the proper fuse -

even as a temporary repair. It may

cause extensive wiring damage

and a possible fire.

CAUTION

Do not use a screwdriver or anyother metal object to remove fusesbecause it may cause a short circuitand damage the system.

OLM079051N

Normal

Normal

Blade type

Cartridge type

Fusible link Blown

Blown

Normal Blown

Normal Blown

Page 370 of 387

Maintenance

52

7

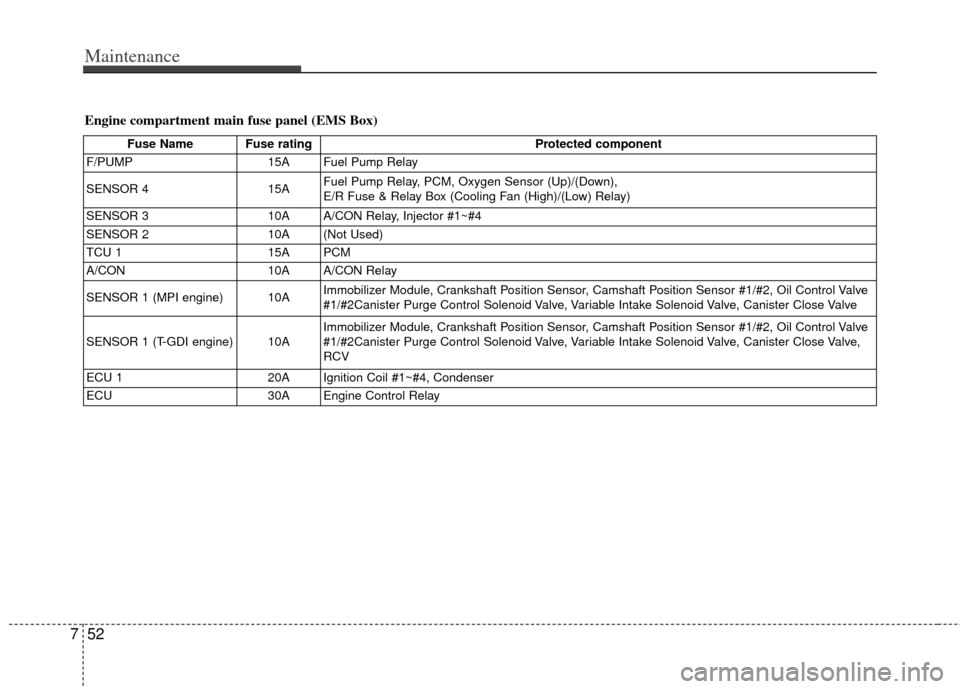

Fuse Name Fuse rating Protected component

F/PUMP 15A Fuel Pump Relay

SENSOR 4 15AFuel Pump Relay, PCM, Oxygen Sensor (Up)/(Down),

E/R Fuse & Relay Box (Cooling Fan (High)/(Low) Relay)

SENSOR 3 10A A/CON Relay, Injector #1~#4

SENSOR 2 10A (Not Used)

TCU 1 15A PCM

A/CON 10A A/CON Relay

SENSOR 1 (MPI engine) 10A Immobilizer Module, Crankshaft Position Sensor, Camshaft Position Sensor #1/#2, Oil Control Valve

#1/#2Canister Purge Control Solenoid Valve, Variable Intake Solenoid Valve, Canister Close Valve

SENSOR 1 (T-GDI engine) 10A Immobilizer Module, Crankshaft Position Sensor, Camshaft Position Sensor #1/#2, Oil Control Valve

#1/#2Canister Purge Control Solenoid Valve, Variable Intake Solenoid Valve, Canister Close Valve,

RCV

ECU 1 20A Ignition Coil #1~#4, Condenser

ECU 30A Engine Control Relay

Engine compartment main fuse panel (EMS Box)