fuel filter KIA SPORTAGE 2022 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2022, Model line: SPORTAGE, Model: KIA SPORTAGE 2022Pages: 630, PDF Size: 9.69 MB

Page 506 of 630

Maintenance

10

7

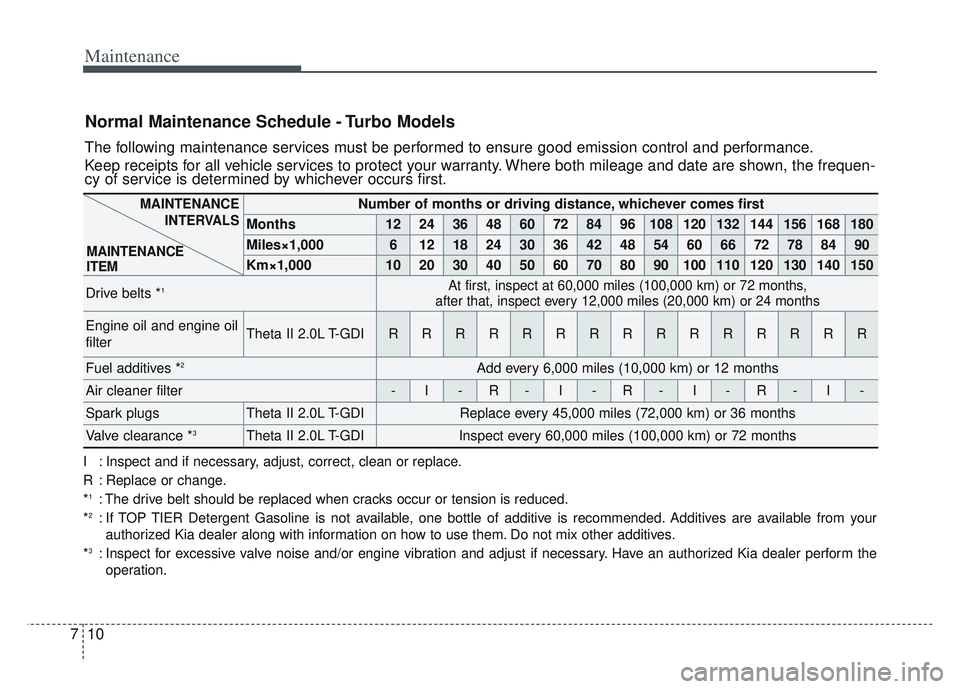

Normal Maintenance Schedule - Turbo Models

The following maintenance services must be performed to ensure good emission control and performance.

Keep receipts for all vehicle services to protect your warranty. Where both mileage and date are shown, the frequen-

cy of service is determined by whichever occurs first.

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,00061218243036424854606672788490

Km×1,000102030405060708090100110120130140150

Drive belts *1At first, inspect at 60,000 miles (100,000 km) or 72 months,

after that, inspect every 12,000 miles (20,000 km) or 24 months

Engine oil and engine oil

filterTheta II 2.0L T-GDIRRRRRRRRRRRRRRR

Fuel additives *2Add every 6,000 miles (10,000 km) or 12 months

Air cleaner filter-I-R-I-R-I-R-I-

Spark plugsTheta II 2.0L T-GDIReplace every 45,000 miles (72,000 km) or 36 months

Valve clearance *3Theta II 2.0L T-GDIInspect every 60,000 miles (100,000 km) or 72 months

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

1: The drive belt should be replaced when cracks occur or tension is reduced.

*2: If TOP TIER Detergent Gasoline is not available, one bottle of additive is recommended. Additives are available from your authorized Kia dealer along with information on how to use them. Do not mix other additives.

*

3: Inspect for excessive valve noise and/or engine vibration and adjust if necessary. Have an authorized Kia dealer perform the operation.

MAINTENANCE INTERVALS

MAINTENANCE

ITEM

Page 508 of 630

Maintenance

12

7

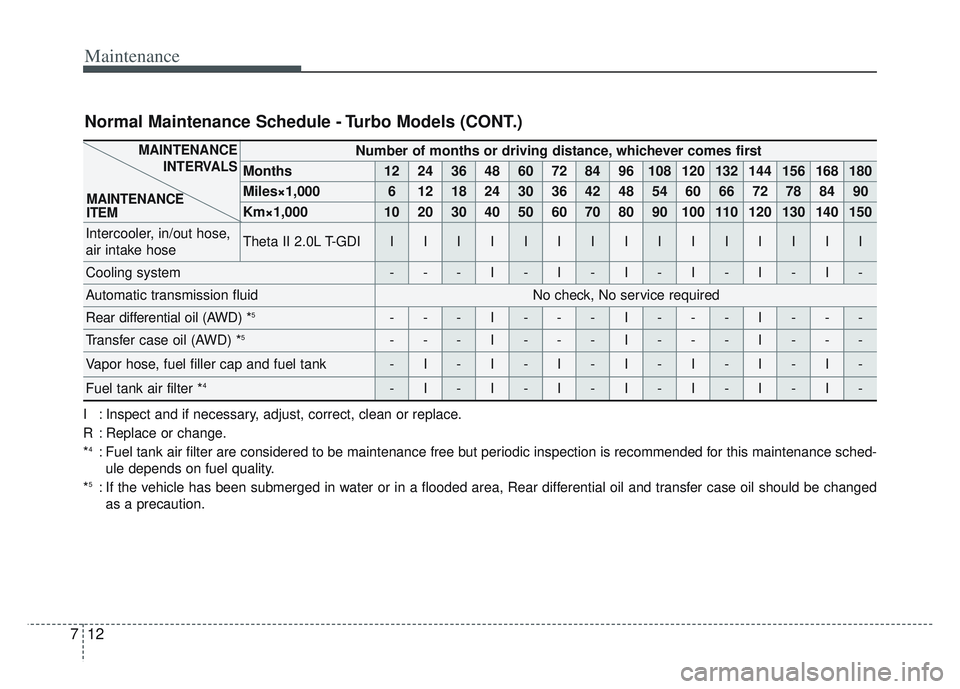

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,00061218243036424854606672788490

Km×1,000102030405060708090100110120130140150

Intercooler, in/out hose,

air intake hoseTheta II 2.0L T-GDIIIIIIIIIIIIIIII

Cooling system---I-I-I-I-I-I-

Automatic transmission fluidNo check, No service required

Rear differential oil (AWD) *5---I---I---I---

Transfer case oil (AWD) *5---I---I---I---

Vapor hose, fuel filler cap and fuel tank-I-I-I-I-I-I-I-

Fuel tank air filter *4-I-I-I-I-I-I-I-

Normal Maintenance Schedule - Turbo Models (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

4: Fuel tank air filter are considered to be maintenance free but periodic inspection is recommended for this maintenance sched-

ule depends on fuel quality.

*

5: If the vehicle has been submerged in water or in a flooded area, Rear differential oil and transfer case oil should be changed as a precaution.

MAINTENANCE INTERVALS

MAINTENANCE

ITEM

Page 512 of 630

Maintenance

16

7

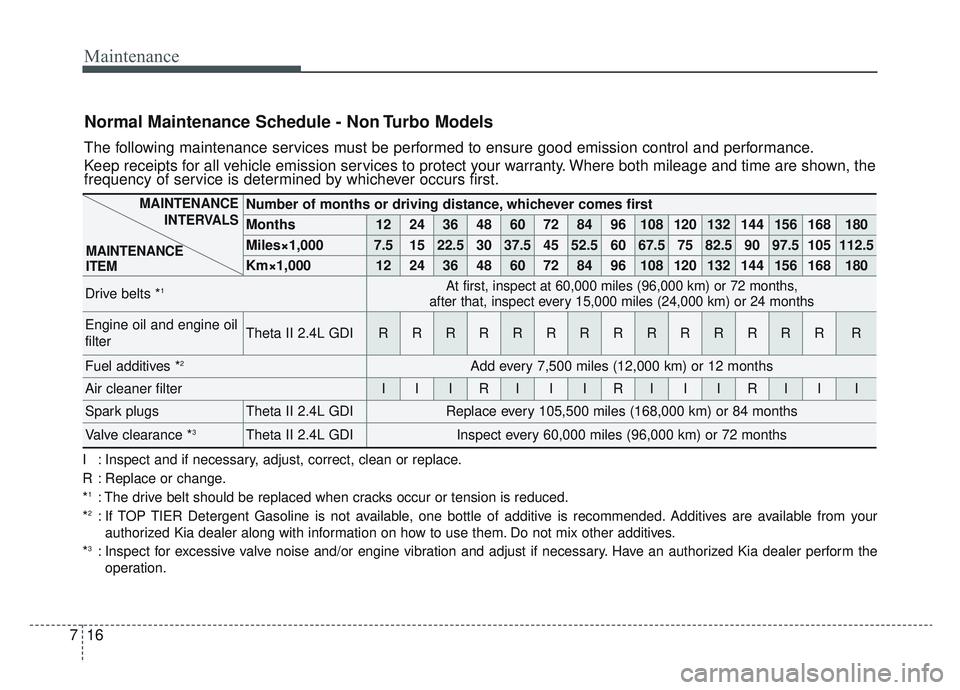

Normal Maintenance Schedule - Non Turbo Models

The following maintenance services must be performed to ensure good emission control and performance.

Keep receipts for all vehicle emission services to protect your warranty. Where both mileage and time are shown, the

frequency of service is determined by whichever occurs first.

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,0007.51522.530 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5

Km×1,00012 24 36 48 60 72 84 96 108 120 132 144 156 168 180

Drive belts *1At first, inspect at 60,000 miles (96,000 km) or 72 months,

after that, inspect every 15,000 miles (24,000 km) or 24 months

Engine oil and engine oil

filterTheta II 2.4L GDIRRRRRRRRRRRRRRR

Fuel additives *2Add every 7,500 miles (12,000 km) or 12 months

Air cleaner filterIIIRIIIRIIIRIII

Spark plugsTheta II 2.4L GDIReplace every 105,500 miles (168,000 km) or 84 months

Valve clearance *3Theta II 2.4L GDIInspect every 60,000 miles (96,000 km) or 72 months

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

1: The drive belt should be replaced when cracks occur or tension is reduced.

*2: If TOP TIER Detergent Gasoline is not available, one bottle of additive is recommended. Additives are available from your authorized Kia dealer along with information on how to use them. Do not mix other additives.

*

3: Inspect for excessive valve noise and/or engine vibration and adjust if necessary. Have an authorized Kia dealer perform the operation.

Page 514 of 630

Maintenance

18

7

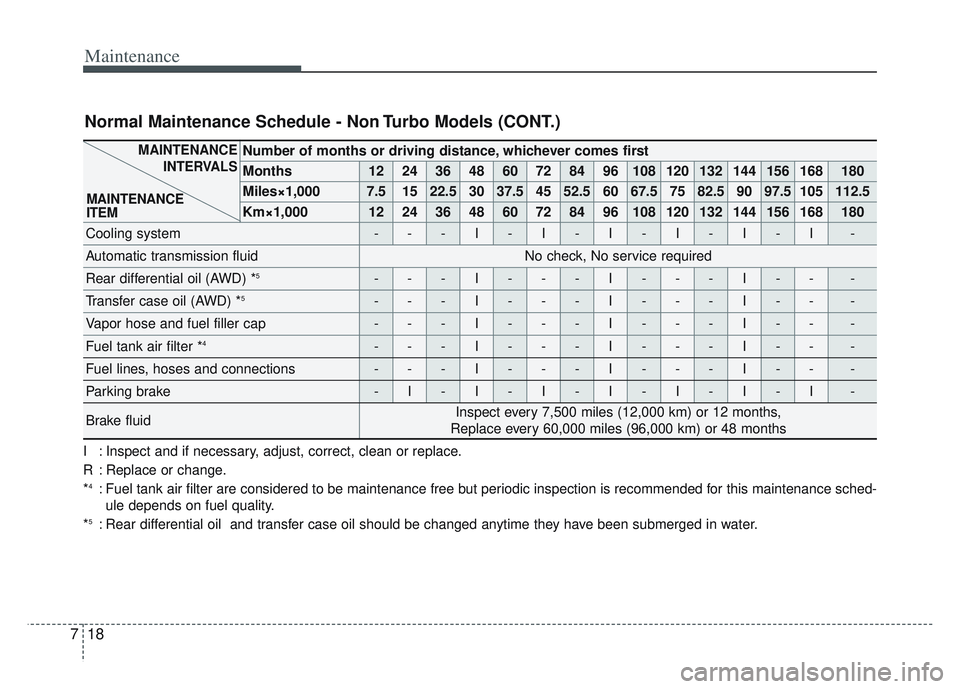

Number of months or driving distance, whichever comes first

Months1224364860728496108120132144156168180

Miles×1,0007.51522.530 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5

Km×1,00012 24 36 48 60 72 84 96 108 120 132 144 156 168 180

Cooling system---I-I-I-I-I-I-

Automatic transmission fluidNo check, No service required

Rear differential oil (AWD) *5---I---I---I---

Transfer case oil (AWD) *5---I---I---I---

Vapor hose and fuel filler cap---I---I---I---

Fuel tank air filter *4---I---I---I---

Fuel lines, hoses and connections---I---I---I---

Parking brake-I-I-I-I-I-I-I-

Brake fluidInspect every 7,500 miles (12,000 km) or 12 months,

Replace every 60,000 miles (96,000 km) or 48 months

MAINTENANCE INTERVALS

MAINTENANCE

ITEM

Normal Maintenance Schedule - Non Turbo Models (CONT.)

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

4: Fuel tank air filter are considered to be maintenance free but periodic inspection is recommended for this maintenance sched- ule depends on fuel quality.

*

5: Rear differential oil and transfer case oil should be changed anytime they have been submerged in water.

Page 517 of 630

721

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the

vehicle is being driven in severe con-

ditions, more frequent oil and filter

changes are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel filter (for gasoline)

Kia gasoline vehicle is equipped a

lifetime fuel filter that integrated with

the fuel tank. Regular maintenance

or replacement is not needed but

depends on fuel quality. If there are

some important safety matters like

fuel flow restriction, surging, loss of

power, hard starting problem etc, fuel

filter inspection or replace is needed.

The fuel filter should be inspected or

replaced by an authorized Kia dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized Kia dealer

replace any damaged or leaking

parts immediately.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-

rectly replaced.

Page 598 of 630

Maintenance

102

7

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the

Warranty & Consumer Information

manual in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

applicable emission regulations.

There are three emission control

systems, as follows.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control system

In order to assure the proper function

of the emission control systems, it is

recommended that you have your

vehicle inspected and maintained by

an authorized Kia dealer in accor-

dance with the maintenance sched-

ule in this manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from mis-

firing during dynamometer test-

ing, turn the Electronic Stability

Control (ESC) system off by

selecting the LCD display.

After dynamometer testing is completed, turn the ESC system

back on by selecting the LCD

display again.1. Crankcase emission control system

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.

This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative emission con-trol (including ORVR:

Onboard Refueling Vapor

Recovery)

system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

(The ORVR system is designed to

allow the vapors from the fuel tank to

be loaded into a canister while refu-

eling at the gas station, preventing

the escape of fuel vapors into the

atmosphere.)

Page 622 of 630

Index

4I

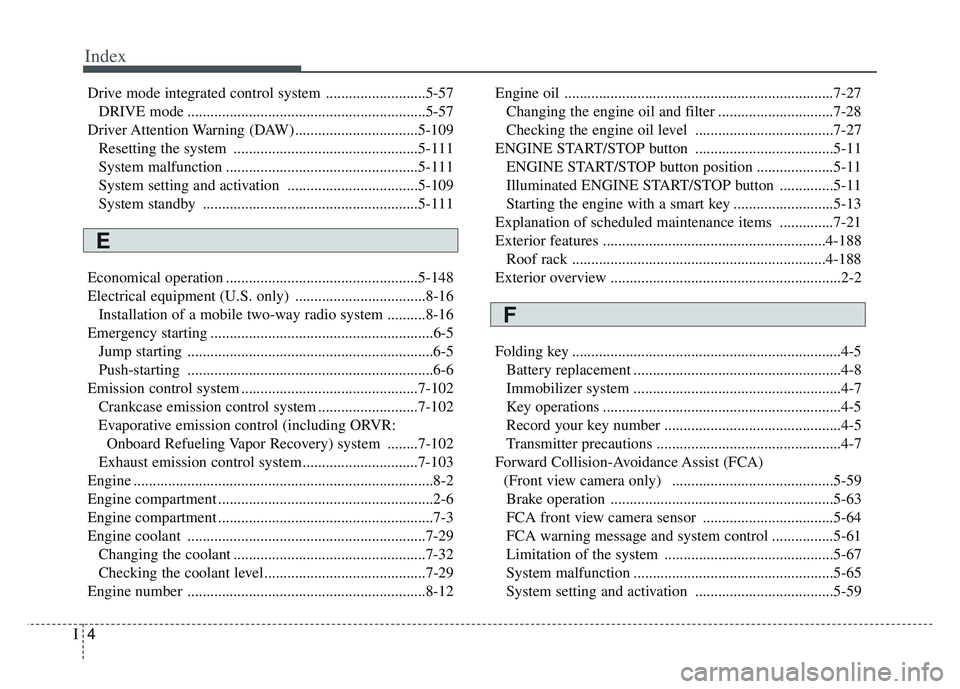

Drive mode integrated control system ..........................5-57DRIVE mode ..............................................................5-57

Driver Attention Warning (DAW)................................5-109 Resetting the system ................................................5-111

System malfunction ..................................................5-111

System setting and activation ..................................5-109

System standby ........................................................5-111

Economical operation ..................................................5-148

Electrical equipment (U.S. only) ..................................8-16 Installation of a mobile two-way radio system ..........8-16

Emergency starting ..........................................................6-5 Jump starting ................................................................6-5

Push-starting ................................................................6-6

Emission control system ..............................................7-102 Crankcase emission control system ..........................7-102

Evaporative emission control (including ORVR: Onboard Refueling Vapor Recovery) system ........7-102

Exhaust emission control system ..............................7-103

Engine ........................................................................\

......8-2

Engine compartment ........................................................2-6

Engine compartment ........................................................7-3

Engine coolant ..............................................................7-29 Changing the coolant ..................................................7-32

Checking the coolant level..........................................7-29

Engine number ..............................................................8-12 Engine oil ......................................................................7-\

27

Changing the engine oil and filter ..............................7-28

Checking the engine oil level ....................................7-27

ENGINE START/STOP button ....................................5-11 ENGINE START/STOP button position ....................5-11

Illuminated ENGINE START/STOP button ..............5-11

Starting the engine with a smart key ..........................5-13

Explanation of scheduled maintenance items ..............7-21

Exterior features ..........................................................4-188 Roof rack ..................................................................4-188

Exterior overview ............................................................2-2

Folding key ......................................................................4-\

5 Battery replacement ......................................................4-8

Immobilizer system ......................................................4-7

Key operations ..............................................................4-5

Record your key number ..............................................4-5

Transmitter precautions ................................................4-7

Forward Collision-Avoidance Assist (FCA) (Front view camera only) ..........................................5-59Brake operation ..........................................................5-63

FCA front view camera sensor ..................................5-64

FCA warning message and system control ................5-61

Limitation of the system ............................................5-67

System malfunction ....................................................5-65

System setting and activation ....................................5-59

E

F