engine KIA STONIC 2018 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: STONIC, Model: KIA STONIC 2018Pages: 523, PDF Size: 24.99 MB

Page 445 of 523

SymbolFuse ratingCircuit Protected

40A Ignition Switch, PDM Relay Box (IG1 Relay, ACC Relay)

POWER

OUTLET40A Instrument Panel Junction Block (Power Outlet Relay)

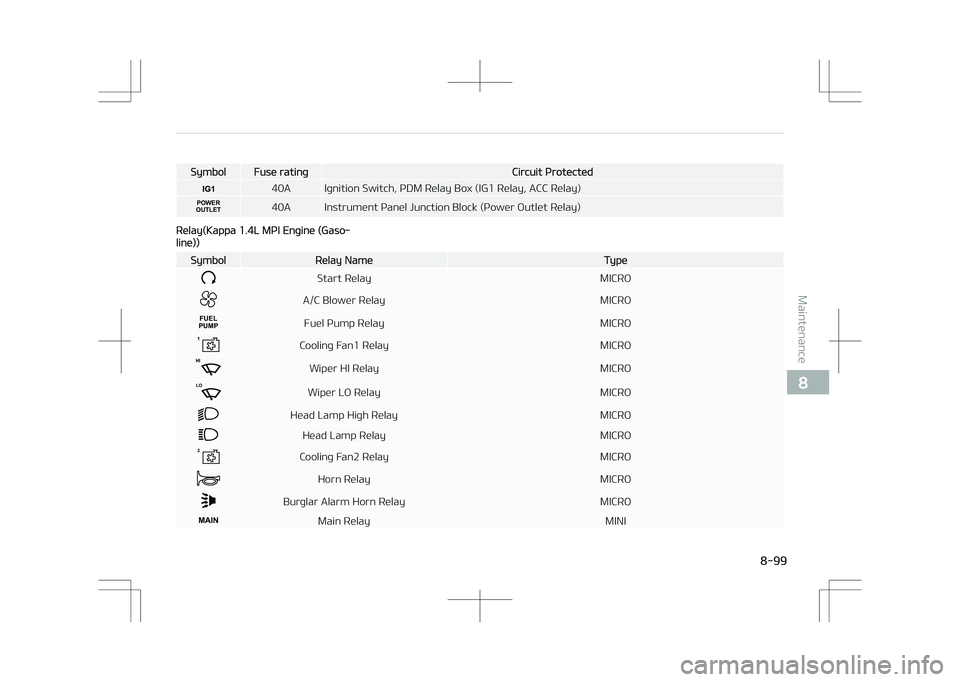

Relay(Kappa 1.4L MPI Engine (Gaso‐

line))

SymbolRelay NameType

Start Relay MICRO

A/C Blower Relay MICRO

FUEL

PUMPFuel Pump Relay MICRO

Cooling Fan1 Relay MICRO

Wiper HI RelayMICRO

LOWiper LO Relay MICRO

Head Lamp High Relay MICRO

Head Lamp RelayMICRO

2Cooling Fan2 Relay MICRO

Horn RelayMICRO

Burglar Alarm Horn Relay MICRO

MAINMain RelayMINI

8-99

8

Maintenance

Page 446 of 523

SymbolRelay NameType

A/C Blower RelayMICRO

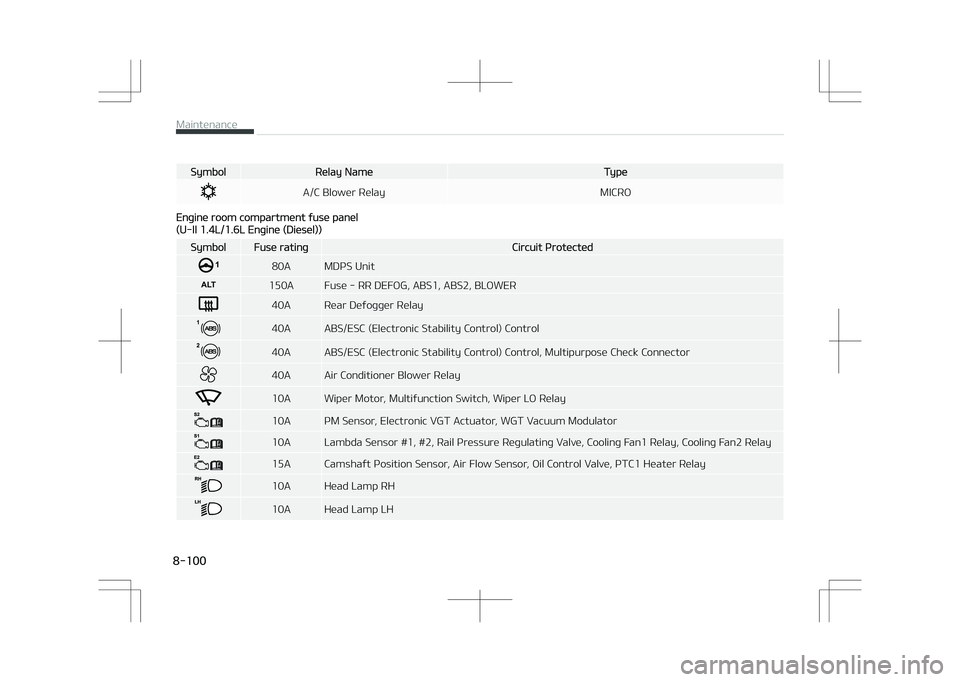

Engine room compartment fuse panel

(U-II 1.4L/1.6L Engine (Diesel))

SymbolFuse ratingCircuit Protected

80A MDPS Unit

ALT150A Fuse - RR DEFOG, ABS1, ABS2, BLOWER

40A Rear Defogger Relay

140A ABS/ESC (Electronic Stability Control) Control

40A ABS/ESC (Electronic Stability Control) Control, Multipurpose Check Connector

40A Air Conditioner Blower Relay

10A Wiper Motor, Multifunction Switch, Wiper LO Relay

10A PM Sensor, Electronic VGT Actuator, WGT Vacuum Modulator

10A Lambda Sensor #1, #2, Rail Pressure Regulating Valve, Cooling Fan1 Relay, Cooling Fan2 Relay

15A Camshaft Position Sensor, Air Flow Sensor, Oil Control Valve, PTC1 Heater Relay

10A Head Lamp RH

10A Head Lamp LH

Maintenance

8-100

Page 448 of 523

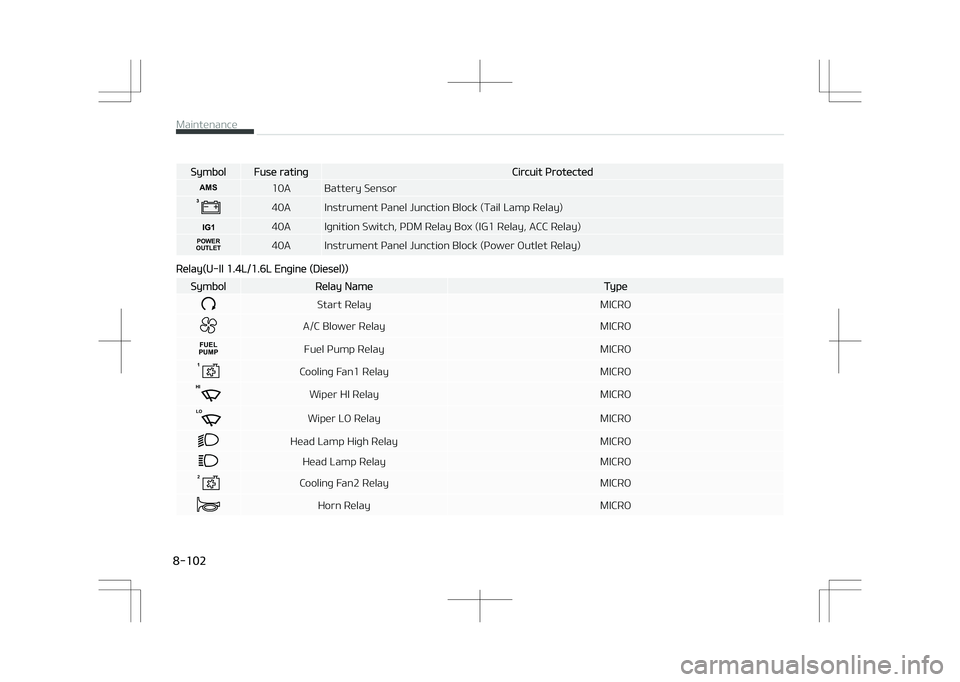

SymbolFuse ratingCircuit Protected

AMS10A Battery Sensor

40A Instrument Panel Junction Block (Tail Lamp Relay)

40A Ignition Switch, PDM Relay Box (IG1 Relay, ACC Relay)

POWER

OUTLET40A Instrument Panel Junction Block (Power Outlet Relay)

Relay(U-II 1.4L/1.6L Engine (Diesel))

SymbolRelay NameType

Start Relay MICRO

A/C Blower Relay MICRO

FUEL

PUMPFuel Pump Relay MICRO

Cooling Fan1 Relay MICRO

Wiper HI RelayMICRO

LOWiper LO Relay MICRO

Head Lamp High Relay MICRO

Head Lamp RelayMICRO

2Cooling Fan2 Relay MICRO

Horn RelayMICRO

Maintenance

8-102

Page 449 of 523

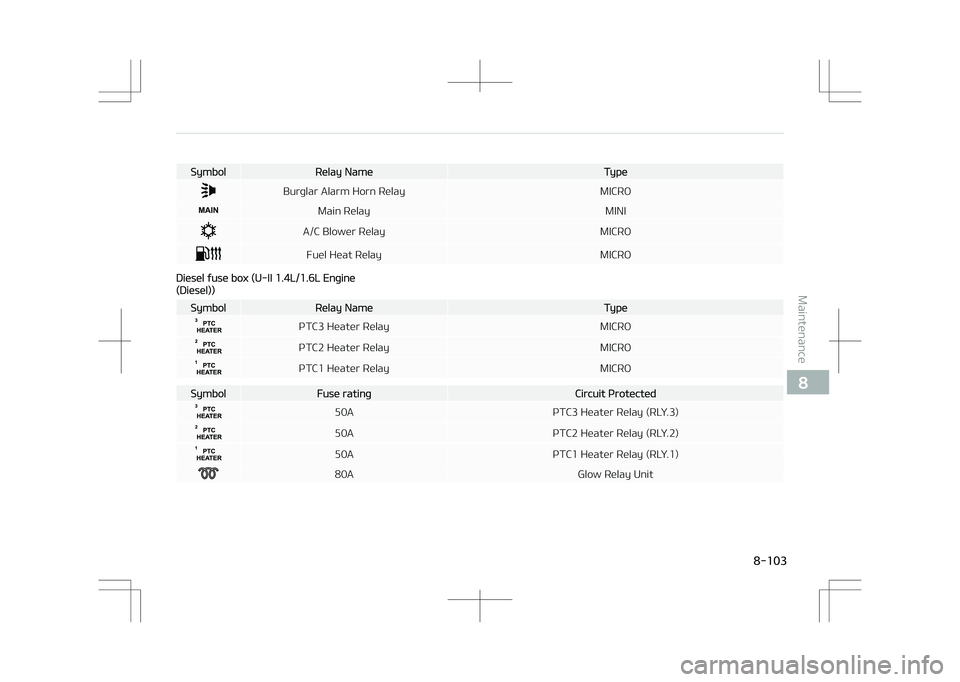

SymbolRelay NameType

Burglar Alarm Horn RelayMICRO

MAINMain RelayMINI

A/C Blower Relay MICRO

Fuel Heat RelayMICRO

Diesel fuse box (U-II 1.4L/1.6L Engine

(Diesel))

SymbolRelay NameType

PTC3 Heater Relay MICRO

PTC2 Heater RelayMICRO

PTC1 Heater RelayMICRO

SymbolFuse ratingCircuit Protected

50APTC3 Heater Relay (RLY.3)

50APTC2 Heater Relay (RLY.2)

50APTC1 Heater Relay (RLY.1)

80A Glow Relay Unit

8-103

8

Maintenance

Page 475 of 523

CAUTION

•Water washing in the engine com‐partment including high pressurewater washing may cause the fail‐ure of electrical circuits located inthe engine compartment.

•Never allow water or other liquidsto come in contact with electrical/electronic components inside thevehicle as this may damage them.

Waxing

Wax the vehicle when water will no lon‐

ger bead on the paint. Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufactur‐

er’s instructions. Wax all metal trim to protect it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip

the wax from the finish. Be sure to re- wax these areas even if the rest of the

vehicle does not yet need waxing.

Do not apply wax on embossed unpain‐

ted unit, as it may tarnish the unit.

CAUTION

•Wiping dust or dirt off the bodywith a dry cloth will scratch thefinish.

•Do not use steel wool, abrasivecleaners, acid detergents or strongdetergents containing high alkalineor caustic agents on chrome-plat‐ed or anodized aluminum parts.This may result in damage to theprotective coating and cause dis‐coloration or paint deterioration.

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust and may develop into a major re‐

pair expense.

NOTICE

If your vehicle is damaged and re‐

quires any metal repair or replace‐

ment, be sure the body shop applies

anti-corrosion materials to the parts

repaired or replaced.

Bright-metal maintenance

• To remove road tar and insects, use a tar remover, not a scraper or other

sharp object.

• To protect the surfaces of bright metal parts from corrosion, apply a

coating of wax or chrome preserva‐

tive and rub to a high luster.

• During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.

8-129

8

Maintenance

Page 480 of 523

EMISSION CONTROL SYSTEM (IF EQUIPPED)

The emission control system of your vehicle is covered by a written limited

warranty. Please see the warranty in‐

formation contained in the Warranty & Maintenance book in your vehicle.

Your vehicle is equipped with an emis‐

sion control system to meet all applica‐

ble emission regulations.

There are three emission control sys‐ tems, as follows. 1. Crankcase emission control system

2. Evaporative emission control sys‐ tem

3. Exhaust emission control system

In order to assure the proper function

of the emission control systems, have

your vehicle inspected and maintained by a professional workshop in accord‐

ance with the maintenance schedule in

this manual. Kia recommends to visit an

authorized Kia dealer/service partner.

Caution for the Inspection and Mainte‐nance Test (With Electronic StabilityControl (ESC) system)

•To prevent the vehicle from misfiringduring dynamometer testing, turnthe Electronic Stability Control (ESC)system off by pressing the ESCswitch. •

After dynamometer testing is com‐pleted, turn the ESC system back onby pressing the ESC switch again.

1. Crankcase emission control

system

The positive crankcase ventilation sys‐

tem is employed to prevent air pollu‐ tion caused by blow-by gases being

emitted from the crankcase.

This system supplies fresh filtered air

to the crankcase through the air intake hose. Inside the crankcase, the fresh air

mixes with blow-by gases, which then

pass through the PCV valve into the in‐ duction system.

2. Evaporative emission control

system

The Evaporative Emission Control Sys‐

tem is designed to prevent fuel vapors from escaping into the atmosphere.

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the on‐ board canister. When the engine is run‐

ning, the fuel vapors absorbed in the

canister are drawn into the surge tank through the purge control solenoid

valve.

Purge Control Solenoid Valve (PCSV)

The purge control solenoid valve is con‐

trolled by the Engine Control Module (ECM); when the engine coolant tem‐

perature is low during idling, the PCSV

closes so that evaporated fuel is not taken into the engine. After the engine

warms up during ordinary driving, the

PCSV opens to introduce evaporated fuel to the engine.

3. Exhaust emission control

system

The Exhaust Emission Control System

is a highly effective system which con‐

trols exhaust emissions while maintain‐

ing good vehicle performance.

Vehicle modifications

This vehicle should not be modified.

Modification of your vehicle could affect

its performance, safety or durability and may even violate governmental

safety and emissions regulations.

In addition, damage or performance

problems resulting from any modifica‐ tion may not be covered under warran‐

ty.

Maintenance

8-134

Page 481 of 523

• If you use unauthorized electronicdevices, it may cause the vehicle to

operate abnormally, wire damage, battery discharge and fire. For your

safety, do not use unauthorized elec‐

tronic devices.

Engine exhaust gas precautions

(carbon monoxide)

• Carbon monoxide can be present with other exhaust fumes. Therefore, if

you smell exhaust fumes of any kind inside your vehicle, have it inspected

and repaired immediately. If you ever

suspect exhaust fumes are coming

into your vehicle, drive it only with all

the windows fully open. Have your vehicle checked and repaired immedi‐

ately.

WARNING

nExhaust

Engine exhaust gases contain carbonmonoxide (CO). Though colorless andodorless, it is dangerous and couldbe lethal if inhaled. Follow the in‐structions on this page to avoid COpoisoning.

• Do not operate the engine in confined or closed areas (such as garages) any

more than what is necessary to move the vehicle in or out of the area.

• When the vehicle is stopped in an open area for more than a short time

with the engine running, adjust the

ventilation system (as needed) to

draw outside air into the vehicle.

• Never sit in a parked or stopped vehi‐ cle for any extended time with the

engine running.

• When the engine stalls or fails to start, excessive attempts to restart

the engine may cause damage to the

emission control system.

Operating precautions for catalytic

converters (if equipped)

WARNING

nFire

(Continued)

(Continued)

•A hot exhaust system can igniteflammable items under your vehi‐cle. Do not park the vehicle over ornear flammable objects, such asgrass, vegetation, paper, leaves,etc.

•The exhaust system and catalyticsystem are very hot while the en‐gine is running or immediately af‐ter the engine is turned off. Keepaway from the exhaust systemand catalytic, you may get burned.Also, do not remove the heat sinkaround the exhaust system, donot seal the bottom of the vehicleor do not coat the vehicle for cor‐rosion control. It may present afire risk under certain conditions.

Your vehicle is equipped with a catalytic

converter emission control device.

Therefore, the following precautions must be observed: • Make sure to refuel your vehicle ac‐ cording to the L

Page 482 of 523

• Do not misuse or abuse the engine.Examples of misuse are coasting with

the ignition off and descending steep grades in gear with the ignition off.

• Do not operate the engine at high idle speed for extended periods (5 mi‐

nutes or more).

• Do not modify or tamper with any part of the engine or emission control

system. All inspections and adjust‐ ments must be made by a professio‐

nal workshop. Kia recommends to

visit an authorized Kia dealer/service

center.

• Avoid driving with an extremely low fuel level. Running out of fuel couldcause the engine to misfire, damag‐

ing the catalytic converter.

Failure to observe these precautions

could result in damage to the catalytic converter and to your vehicle.

Additionally, such actions could void

your warranties.

Diesel particulate filter (if

equipped)

The Diesel Particulate Filter (DPF) sys‐

tem removes the soot in the exhaust gas. Unlike a disposable air filter, the DPF

system automatically burns (oxidizes)

and removes the accumulated soot ac‐ cording to the driving condition. In other

words, the active burning by engine

control system and high exhaust gas temperature caused by normal/high

driving condition burns and removes

the accumulated soot.

However, if the vehicle continues to be driven at repeated short distance or

driven at low speed for a long time, the

accumulated soot may not be auto‐ matically removed because of low ex‐

haust gas temperature. More than a

certain amount of soot deposited, the malfunction indicator light (

) illumi‐

nates.

When the malfunction indicator light

blinks, it may stop blinking by driving

the vehicle at more than 60 km/h (37 mph) or at more than second gear

with 1500 ~ 2500 engine rpm for a cer‐

tain time (for about 25 minutes).

If the malfunction indicator light (

)

continues to be blinked or the warning

massage "Check exhaust system" illu‐ minates in spite of the procedure, visit

a professional workshop and check the

DPF system. Kia recommends to visit an authorized Kia dealer/service part‐

ner. If you continue to drive with the mal‐

function indicator light blinking for a long time, the DPF system can be dam‐

aged and fuel consumption can be wor‐

sen.

CAUTION

Diesel Fuel (if equipped with DPF)It is recommended to use the regula‐ted automotive diesel fuel for dieselvehicle equipped with the DPF sys‐tem.If you use diesel fuel including highsulfur (more than 50 ppm sulfur)and unspecified additives, it cancause the DPF system to be dam‐aged and white smoke can be emit‐ted.

Lean NOx trap (if equipped)

The Lean NOx Trap (LNT) system re‐

moves the nitrogen oxide in the ex‐ haust gas. The smell can occur in the

exhaust gas depending on the quality

of the fuel and it can degrade NOx re‐ duction performance, please use the

regulated automotive diesel fuel.

Maintenance

8-136

Page 483 of 523

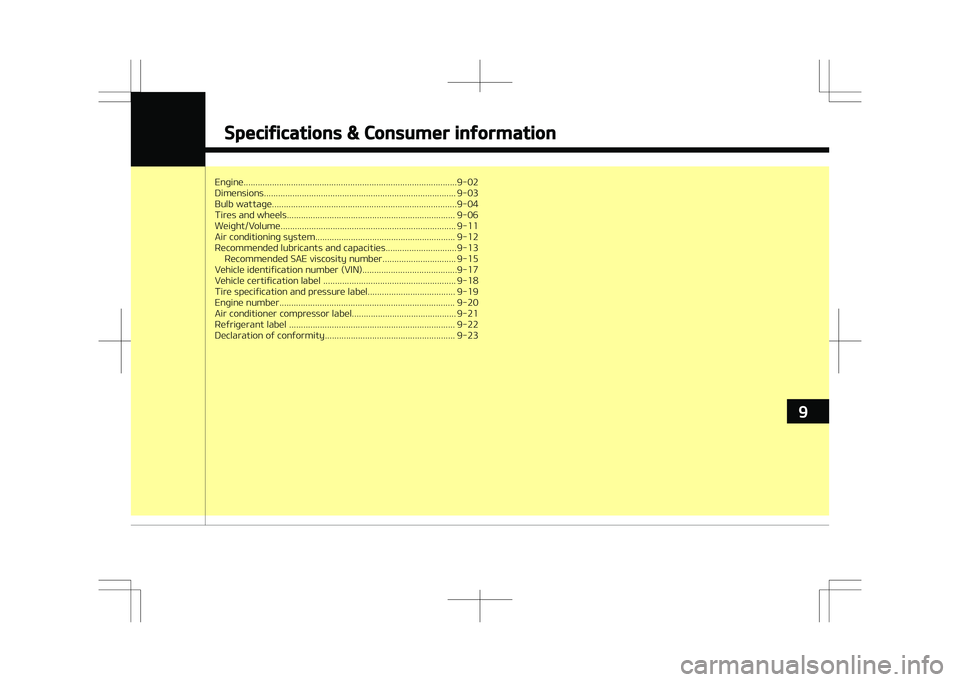

Engine..........................................................................................9-02

Dimensions................................................................................. 9-03

Bulb wattage..............................................................................9-04

Tires and wheels....................................................................... 9-06

Weight/Volume.......................................................................... 9-11

Air conditioning system........................................................... 9-12

Recommended lubricants and capacities.............................. 9-13Recommended SAE viscosity number............................... 9-15

Vehicle identification number (VIN)........................................9-17

Vehicle certification label ........................................................ 9-18

Tire specification and pressure label..................................... 9-19

Engine number.......................................................................... 9-20

Air conditioner compressor label............................................ 9-21

Refrigerant label ...................................................................... 9-22

Declaration of conformity....................................................... 9-23

Specifications & Consumer information

9

Page 484 of 523

![KIA STONIC 2018 Owners Manual ENGINE

ItemGasoline 1.0Gasoline 1.2Gasoline 1.4Diesel 1.4Diesel 1.6

Displacement 998 (60.9) 1,248 (76.2) 1,368 (83.48) 1,396 (85.12) 1,582 (96.53)

[cc (cu.in)]

Bore x Stroke 71 x 84 (2.8 x

3.3) 71 x 7 KIA STONIC 2018 Owners Manual ENGINE

ItemGasoline 1.0Gasoline 1.2Gasoline 1.4Diesel 1.4Diesel 1.6

Displacement 998 (60.9) 1,248 (76.2) 1,368 (83.48) 1,396 (85.12) 1,582 (96.53)

[cc (cu.in)]

Bore x Stroke 71 x 84 (2.8 x

3.3) 71 x 7](/img/2/40480/w960_40480-483.png)

ENGINE

ItemGasoline 1.0Gasoline 1.2Gasoline 1.4Diesel 1.4Diesel 1.6

Displacement 998 (60.9) 1,248 (76.2) 1,368 (83.48) 1,396 (85.12) 1,582 (96.53)

[cc (cu.in)]

Bore x Stroke 71 x 84 (2.8 x

3.3) 71 x 78.8 (2.80

x 3.10) 72 x 84 (2.83 x

3.30) 75 x 79 (2.95 x

3.11) 77.2 x 84.5

(3.03 x 3.32)

[mm (in)]

Firing order 1-2-3 1-3-4-2 1-3-4-2 1-3-4-2 1-3-4-2

No. of cylinders 3 4, In-line 4, In-line 4, In-line 4, In-line

Specifications & Consumer information

9-02