light Lancia Flavia 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2012, Model line: Flavia, Model: Lancia Flavia 2012Pages: 233, PDF Size: 2.61 MB

Page 168 of 233

NOTE:

If the gas cap is lost or damaged, be

sure the replacement cap is for use

with this vehicle.CAUTION!

Damage to the fuel system oremission control system could r e-

sult from using an improper fuel

tank filler tube cap (gas cap).

A poorly fitting gas cap may cause

the “Malfunction Indicator Light

(MIL)” to turn on.

To avoid fuel spillage and overfill-

ing, do not “top off” the fuel tank

after filling. When the fuel nozzle

“clicks” or shuts off, the fuel tank

is full.WARNING!

Never have any smoking materi-als lit in or near the vehicle when

the gas cap is removed or the tank

is being filled.

(Continued)

WARNING!(Continued)

A fire may result if gasoline is

pumped into a portable container

that is inside of a vehicle. You

could be burned. Always place gas

containers on the ground while

filling.

NOTE:

Tighten the gas cap until you hear a “clicking” sound. This is

an indication that the gas cap is

tightened properly. The MIL in

the instrument cluster may turn

on if the gas cap is not secured

properly. Make sure that the gas

cap is tightened each time the

vehicle is refueled.

When the fuel nozzle “clicks” or shuts off, the fuel tank is full.

LOOSE FUEL FILLER CAP

MESSAGE

If the vehicle diagnostic system deter-

mines that the fuel filler cap is loose,

improperly installed, or damaged, a

“CHECK GAS CAP” message will be

displayed in the EVIC (Electronic Ve-

hicle Information Center). Refer to “Electronic Vehicle Information Cen-

ter” in “Understanding Your Instru-

ment Panel” for further information.

Tighten the fuel filler cap properly

and press the odometer reset button to

turn the message off. If the problem

continues, the message will appear

the next time the vehicle is started.

Refer to “Onboard Diagnostic Sys-

tem” in “Maintaining Your Vehicle”

for further information.

NOTE:

If the gas cap is lost or damaged, be

sure the replacement cap is for use

with this vehicle.

VEHICLE LOADING

VEHICLE CERTIFICATION

LABEL

Your vehicle has a certification label

attached to the rear of the

driver's

door.

The label contains the following infor -

mation:

Name of manufacturer

Month and year of manufacture

161

Page 180 of 233

PREPARATIONS FOR

JUMP-START

The battery in your vehicle is located

between the left front headlight as-

sembly and the left front wheel splash

shield. To allow jump-starting there

are remote battery posts located on

the left side of the engine compart-

ment.WARNING!

Take care to avoid the radiatorcooling fan whenever the hood is

raised. It can start anytime the

ignition switch is on. You can be

injured by moving fan blades.

(Continued)

WARNING!(Continued)

Remove any metal jewelry such as

watch bands or bracelets that

might make an inadvertent elec-

trical contact. You could be seri-

ously injured.

Batteries contain sulfuric acid

that can burn your skin or eyes

and generate hydrogen gas which

is flammable and explosive. Keep

open flames or sparks away from

the battery.

1. Set the parking brake, shift the

automatic transmission into PARK

and turn the ignition to LOCK.

2. Turn off the heater, radio, and all

unnecessary electrical accessories.

3. Remove the protective cover over

the remote positive (+)battery post.

To remove the cover, press the locking

tab and pull upward on the cover. 4. If using another vehicle to jump-

start the battery, park the vehicle

within the jumper cables reach, set

the parking brake and make sure the

ignition is OFF.

WARNING!

Do not allow vehicles to touch each

other as this could establish a

ground connection and personal in-

jury could result.

JUMP-STARTING

PROCEDUREWARNING!

Failure to follow this procedure

could result in personal injury or

property damage due to battery ex-

plosion.

Remote Battery Posts

1 — Remote Positive (+) Post (cov-

ered with protective cap)

2 — Remote Negative (-) Post

Locking Tab

173

Page 189 of 233

ONBOARD DIAGNOSTIC

SYSTEM — OBD II

Your vehicle is equipped with a so-

phisticated onboard diagnostic sys-

tem called OBD II. This system moni-

tors the performance of the emissions,

engine, and automatic transmission

control systems. When these systems

are operating properly, your vehicle

will provide excellent performance

and fuel economy, as well as engine

emissions well within current govern-

ment regulations.

If any of these systems require service,

the OBD II system will turn on the

“Malfunction Indicator Light.” It will

also store diagnostic codes and other

information to assist your service

technician in making repairs. Al-

though your vehicle will usually be

drivable and not need towing, see

your dealer for service as soon as pos-

sible.

CAUTION!

Prolonged driving with the “Mal-function Indicator Light” on

could cause further damage to the

emission control system. It could

also affect fuel economy and

driveability. The vehicle must be

serviced before any emissions

tests can be performed.

If the “Malfunction Indicator

Light” is flashing while the engine

is running, severe catalytic con-

verter damage and power loss will

soon occur. Immediate service is

required.

REPLACEMENT PARTS

Use of genuine parts for normal/

scheduled maintenance and repairs is

highly recommended to ensure the de-

signed performance.

Damage or failures caused by the use

of parts which are not quality-

equivalent to genuine parts for main-

tenance and repairs will not be cov-

ered by the manufacturer’s warranty. MAINTENANCE

PROCEDURES

The pages that follow contain the

re-

quired maintenance services deter-

mined by the engineers who designed

your vehicle.

Besides those maintenance items

specified in the fixed maintenance

schedule, there are other components

which may require servicing or re-

placement in the future.

CAUTION!

Failure to properly maintain your vehicle or perform repairs and

service when necessary could re-

sult in more costly repairs, dam-

age to other components or nega-

tively impact vehicle

performance. Immediately have

potential malfunctions examined

by an authorized dealership or

qualified repair center.

(Continued)

182

Page 194 of 233

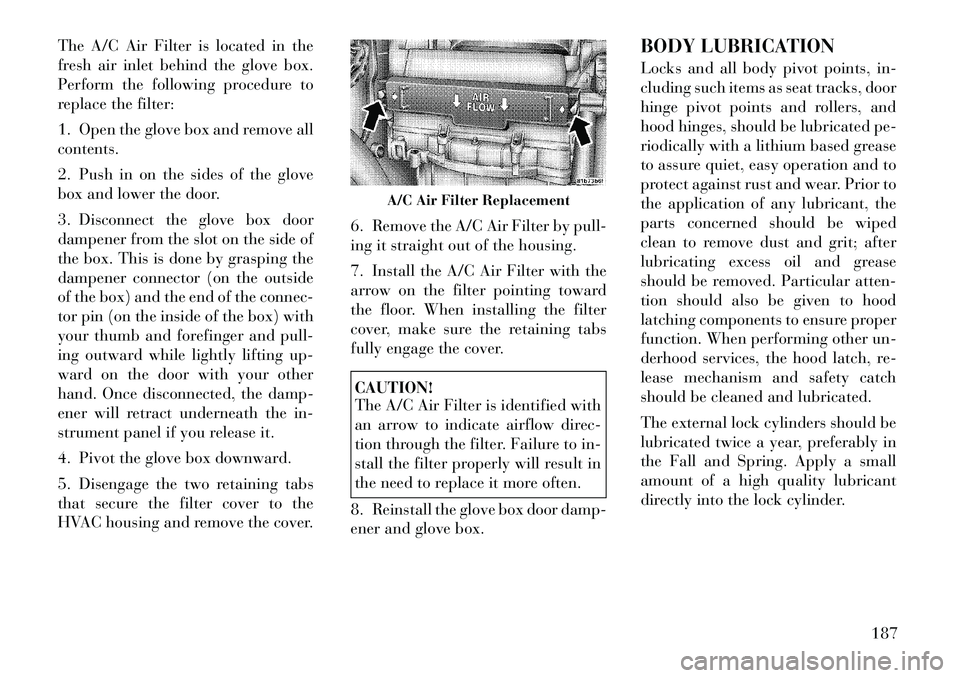

The A/C Air Filter is located in the

fresh air inlet behind the glove box.

Perform the following procedure to

replace the filter:

1. Open the glove box and remove all

contents.

2. Push in on the sides of the glove

box and lower the door.

3. Disconnect the glove box door

dampener from the slot on the side of

the box. This is done by grasping the

dampener connector (on the outside

of the box) and the end of the connec-

tor pin (on the inside of the box) with

your thumb and forefinger and pull-

ing outward while lightly lifting up-

ward on the door with your other

hand. Once disconnected, the damp-

ener will retract underneath the in-

strument panel if you release it.

4. Pivot the glove box downward.

5. Disengage the two retaining tabs

that secure the filter cover to the

HVAC housing and remove the cover.6. Remove the A/C Air Filter by pull-

ing it straight out of the housing.

7. Install the A/C Air Filter with the

arrow on the filter pointing toward

the floor. When installing the filter

cover, make sure the retaining tabs

fully engage the cover.

CAUTION!

The A/C Air Filter is identified with

an arrow to indicate airflow direc-

tion through the filter. Failure to in-

stall the filter properly will result in

the need to replace it more often.

8. Reinstall the glove box door damp-

ener and glove box. BODY LUBRICATION

Locks and all body pivot points, in-

cluding such items as seat tracks, door

hinge pivot points and rollers, and

hood hinges, should be lubricated pe-

riodically with a lithium based grease

to assure quiet, easy operation and to

protect against rust and wear. Prior to

the application of any lubricant, the

parts concerned should be wiped

clean to remove dust and grit; after

lubricating excess oil and grease

should be removed. Particular atten-

tion should also be given to hood

latching components to ensure proper

function. When performing other un-

derhood services, the hood latch, re-

lease mechanism and safety catch

should be cleaned and lubricated.

The external lock cylinders should be

lubricated twice a year, preferably in

the Fall and Spring. Apply a small

amount of a high quality lubricant

directly into the lock cylinder.

A/C Air Filter Replacement

187

Page 201 of 233

Master Cylinder – Brake Fluid

Level Check

Check the fluid level in the master

cylinder immediately if the brake sys-

tem warning light indicates system

failure.

Check the fluid level in the master

cylinder when performing underhood

services.

Clean the top of the master cylinder

area before removing the cap. If nec-

essary, add fluid to bring the fluid

level up to the requirements described

on the brake fluid reservoir.

Overfilling of fluid is not recom-

mended because it may cause leaking

in the system.

Fluid level can be expected to fall as

the brake pads wear. Brake fluid level

should be checked when pads are re-

placed. However, low fluid level may

be caused by a leak and a checkup

may be needed.

Use only manufacturer's recom-

mended brake fluid. Refer to “Fluids,

Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for fur-

ther information.

WARNING!

Use the manufacturer’s recom- mended brake fluid or a quality-

equivalent product. Refer to “Flu-

ids, Lubricants, and Genuine

Parts” in “Maintaining Your Ve-

hicle” for further information. Us-

ing the wrong type of brake fluid

can severely damage your brake

system and/or impair its perfor-

mance.

To avoid contamination from for-

eign matter or moisture, use only

new brake fluid or fluid that has

been in a tightly closed container.

Keep the master cylinder reservoir

cap secured at all times. Brake

fluid in a open container absorbs

moisture from the air resulting in

a lower boiling point. This may

cause it to boil unexpectedly dur-

ing hard or prolonged braking,

resulting in sudden brake failure.

This could result in a collision.

(Continued)

WARNING!(Continued)

Overfilling the brake fluid reser-

voir can result in spilling brake

fluid on hot engine parts, causing

the brake fluid to catch fire. Brake

fluid can also damage painted and

vinyl surfaces, care should be

taken to avoid its contact with

these surfaces.

Do not allow petroleum based

fluid to contaminate the brake

fluid. Brake seal components

could be damaged, causing partial

or complete brake failure. This

could result in a collision.

AUTOMATIC

TRANSMISSION

The automatic transmission and dif-

ferential assembly are contained

within a single housing.

The fluid level in the automatic trans-

mission should be checked whenever

the vehicle is serviced. Operation with

an improper fluid level will greatly

reduce the life of the transmission and

the fluid.

194

Page 204 of 233

If you carry special cargo such aschemicals, fertilizers, de-icer salt,

etc., be sure that such materials are

well packaged and sealed.

If a lot of driving is done on gravel roads, consider mud or stone

shields behind each wheel.

Use Touch Up Paint or equivalent on scratches as soon as possible.

Your authorized dealer has touch

up paint to match the color of your

vehicle.

Wheel And Wheel Trim Care

All wheels and wheel trim, especially

aluminum and chrome-plated wheels

should be cleaned regularly with a

mild soap and water to prevent corro-

sion. To remove heavy soil and/or ex-

cessive brake dust, use a nonabrasive,

non-acidic cleaner. Do not use scour-

ing pads, steel wool, a bristle brush, or

metal polishes. Do not use oven

cleaner. Avoid automatic car washes

that use acidic solutions or harsh

brushes that may damage the wheels’

protective finish. Interior Care

Interior trim should be cleaned start-

ing with a damp cloth. Do not use

harsh cleaners.

Your leather upholstery can be best

preserved by regular cleaning with a

damp soft cloth. Small particles of

dirt can act as an abrasive and dam-

age the leather upholstery and should

be removed promptly with a damp

cloth. Stubborn soils can be removed

easily with a soft cloth and appropri-

ate products. Care should be taken to

avoid soaking your leather upholstery

with any liquid. Please do not use

polishes, oils, cleaning fluids, sol-

vents, detergents, or ammonia-based

cleaners to clean your leather uphol-

stery. Application of a leather condi-

tioner is not required to maintain the

original condition.

WARNING!

Do not use volatile solvents for

cleaning purposes. Many are poten-

tially flammable, and if used in

closed areas they may cause respira-

tory harm.Cleaning Headlights

Your vehicle has plastic headlights

that are lighter and less susceptible to

stone breakage than glass headlights.

Plastic is not as scratch resistant as

glass and therefore different lens clean-

ing procedures must be followed.To minimize the possibility of scratch-

ing the lenses and reducing light out-

put, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild

soap solution followed by rinsing.

Do not use abrasive cleaning compo-

nents, solvents, steel wool or other

aggressive material to clean the

lenses.

Glass Surfaces

All glass surfaces should be cleaned

on a regular basis with any commer-

cial household-type glass cleaner.

Never use an abrasive type cleaner.

Use caution when cleaning the inside

rear window equipped with electric

defrosters or the right rear quarter

window equipped with the radio an-

tenna. Do not use scrapers or other

sharp instrument that may scratch

the elements.

197

Page 207 of 233

WEATHER STRIP CARE –

SOFT AND HARD TOP

Lubricate all top and door glass

weather strips periodically with a

weather strip lubricant to keep them

soft and pliable.FUSES

INTEGRATED POWER

MODULE

The Integrated Power Module is lo-

cated in the engine compartment near

the air cleaner assembly. This center

contains cartridge fuses and mini

fuses. A label that identifies each

component may be printed on the in-

side of the cover. Refer to the graphic

below for FUSES/TIPM location.

Cavity

Cartridge Fuse Mini Fuse Description

1 40 Amp Green —Power Top Module

2 —20 Amp Yellow Brake Vacuum Pump

3 —10 Amp RedCenter High Mounted Stop Light (CHMSL)/

Brake Switch

4 —10 Amp Red Ignition Switch

5 —20 Amp Yellow Trailer Tow (when present)

6 —10 Amp Red Power Mirror Switch/Climate Controls

7 —30 Amp Green Ignition Off Draw (IOD) Sense 1

8 —30 Amp Green Ignition Off Draw (IOD) Sense 2

9 40 Amp Green Battery Feed – Power Seats (for versions/

markets, where provided)

10 —20 Amp Yellow Instrument Panel/Power Locks/Interior

Lights

11 —15 Amp Lt Blue Selectable Power Outlet (Inside Center Arm

Rest)

12 —20 Amp Yellow —

13 —20 Amp Yellow Ignition/Cigar Lighter

Integrated Power Module

200

Page 210 of 233

VEHICLE STORAGE

If you will not be using your vehicle

for more than 21 days, you may want

to take steps to preserve your battery.

Disengage the mini-fuse in thePower Distribution Center labeled

IOD (Ignition Off-Draw).

Or disconnect the negative cable from the battery. Refer to “Prepa-

ration for Jump Start” in “Jump-

Starting” to identify the location of

the negative post.

Anytime you store your vehicle, or keep it out of service (i.e., vacation)

for two weeks or more, run the air

conditioning system at idle for

about five minutes in the fresh air

and high blower setting. This will

ensure adequate system lubrication

to minimize the possibility of com-

pressor damage when the system is

started again.

REPLACEMENT BULBS

All the inside bulbs are brass or glass

wedge base. Aluminum base bulbs are

not approved and should not be used

for replacement. LIGHT BULBS – Interior Bulb No.

Front Courtesy/Reading

Lamp . . . . . . . . . . . . . . 578/W5W

Center Courtesy/Reading

Lamp . . . . . . . . . . . . . . 578/W5W

Glove Box Lamp . . . . . . . . . . . 194

Shift Indicator Lamp . . IKLE14140

Rear Compartment (Trunk)

Lamp . . . . . . . . . . . . . . . . . . . 579

NOTE:

For lighted switches, see your au-

thorized dealer for replacement.

LIGHT BULBS – Exterior Bulb No.

Bi-Halogen Headlamp . . . . . . HIR2

Front Turn Signal Lamp . . 3157NAKFront Park Lamp . . . . . . . . . . LED

(Serviced at Authorized Dealer)

Side Repeater Lamp . . . . . . WY5W

Front Fog Lamp . . . . . . . . . . . H11

Center High Mounted Stop

(CHMSL) Lamp . . . . . . . . . . LED

(Serviced at Authorized Dealer)

Rear Tail/Stop Lamp . . . . . . . LED

(Serviced at Authorized Dealer)

Rear Turn Signal Lamp . . . . W16W

Rear Fog Lamp . . . . . . . . . . . LED

(Serviced at Authorized Dealer)

Backup Lamp . . . . . . . . . . . W16W

License Lamp. . . . . . . . . . . . W5W BULB REPLACEMENT

HEADLAMP

CAUTION!

Where possible, it is advisable to

have bulbs changed at a LANCIA

Dealership. Proper operation and

orientation of the external lights are

essential for driving safety and com-

plying with the law.

1. Raise and prop open the hood. Lo-

cate the connector behind the head-

lamp.

NOTE:

It may be necessary to remove the

air cleaner filter housing and po-

sition the totally integrated power

module aside prior to replacing

the low beam headlamp on the

driver's side of the vehicle.

203

Page 212 of 233

REAR TURN SIGNAL

LAMPS

1. Open the trunk and gently pull

back the trunk liner behind the tail

lamp (requires removal of a push pin

holding the trunk trim in place near

the tail lamp).

2. Remove the two plastic wing nuts

from the tail lamp housing.

NOTE:

Placing a small flat head screw-

driver or similar tool between the

lamp outboard ball stud and plas-

tic grommet from inside the trunk

can help to disengage the outboard

edge of the tail lamp.

3. Grasp the tail lamp by both the

outboard and inboard sides, and pull

firmly to disengage the tail lamp from

the vehicle.NOTE:

It is normal to hear a loud sound

when the lower tail lamp area un-

snaps from the vehicle mounting

bracket during tail lamp removal.

4. Twist and remove socket from

lamp.

5. Remove bulb from socket and re-

place.

6. Reinstall the tail lamp, fasteners,

and trunk liner.

BACKUP LAMP

1. Remove four push pins from the

bottom of the lower valance (from left

to right: 1st, 3rd, 6th & 8th) and two

push pins from the rear of the bracket.

2. Remove bracket by pulling for-

ward of vehicle.

3. Remove socket from housing with

a counter-clockwise

1�4turn.

4. Remove bulb from socket by pull-

ing directly out (do not turn/twist)

and install replacement bulb.

5. Insert socket back into the housing

with a clockwise

1�4turn.

6. Return bracket into position.

7. Snap the six (6) push pins back

into place.

LICENSE PLATE LAMP

1. Using a small screwdriver, press

inward the locking tab on the side of

the lamp assembly and pull down on

the lamp assembly for removal.

2. Remove bulb socket by twisting

out of lamp assembly.

3. Pull bulb from socket, replace, and

reinstall the bulb socket into lamp

assembly.

4. Install lamp assembly to lightbar

ensuring the locking tab is secure.

205

Page 220 of 233

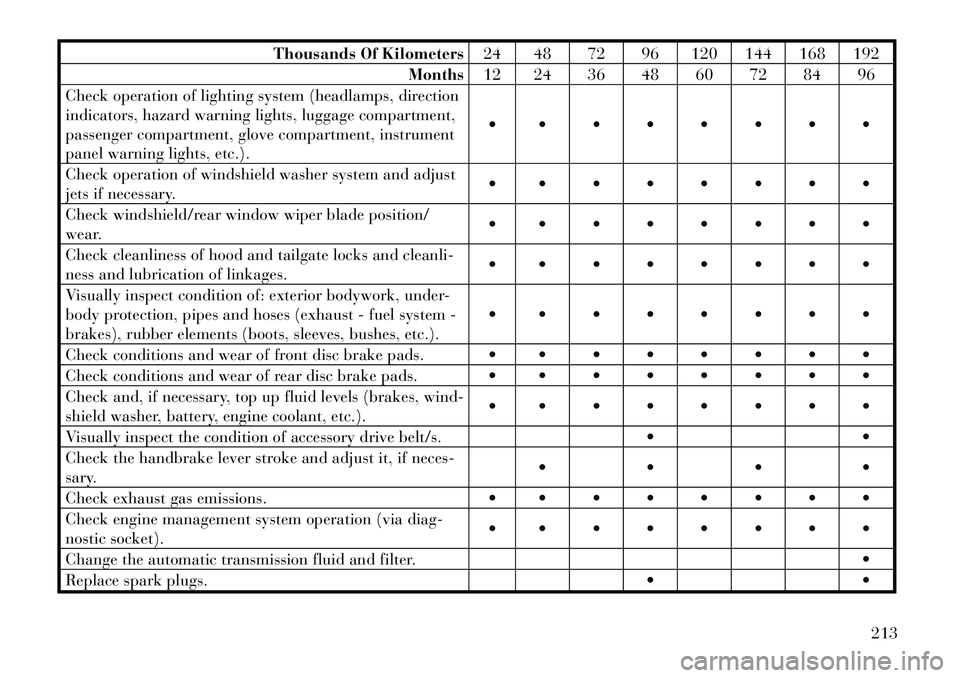

Thousands Of Kilometers24 48 72 96 120 144 168 192

Months 12 24 36 48 60 72 84 96

Check operation of lighting system (headlamps, direction

indicators, hazard warning lights, luggage compartment,

passenger compartment, glove compartment, instrument

panel warning lights, etc.).

Check operation of windshield washer system and adjust

jets if necessary.

Check windshield/rear window wiper blade position/

wear.

Check cleanliness of hood and tailgate locks and cleanli-

ness and lubrication of linkages.

Visually inspect condition of: exterior bodywork, under-

body protection, pipes and hoses (exhaust - fuel system -

brakes), rubber elements (boots, sleeves, bushes, etc.).

Check conditions and wear of front disc brake pads.

Check conditions and wear of rear disc brake pads.

Check and, if necessary, top up fluid levels (brakes, wind-

shield washer, battery, engine coolant, etc.).

Visually inspect the condition of accessory drive belt/s.

Check the handbrake lever stroke and adjust it, if neces-

sary.

Check exhaust gas emissions.

Check engine management system operation (via diag-

nostic socket).

Change the automatic transmission fluid and filter.

Replace spark plugs.

213