brake fluid Lancia Flavia 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2012, Model line: Flavia, Model: Lancia Flavia 2012Pages: 233, PDF Size: 2.61 MB

Page 54 of 233

Periodic Safety Checks You

Should Make Outside The

Vehicle

Tires

Examine tires for excessive tread wear

and uneven wear patterns. Check for

stones, nails, glass, or other objects

lodged in the tread or sidewall. In-

spect the tread for cuts and cracks.

Inspect sidewalls for cuts, cracks and

bulges. Check the wheel nuts for

tightness. Check the tires (including

spare) for proper cold inflation pres-

sure.Lights

Have someone observe the operation

of exterior lights while you work the

controls. Check turn signal and high

beam indicator lights on the instru-

ment panel.

Door Latches

Check for positive closing, latching,

and locking.

Fluid Leaks

Check area under vehicle after over-

night parking for fuel, engine coolant,

oil, or other fluid leaks. Also, if gaso-

line fumes are detected or if fuel,

power steering fluid, or brake fluid

leaks are suspected, the cause should

be located and corrected immediately.

47

Page 115 of 233

7. Air Bag Warning LightThis light will turn on for

four to eight seconds as a

bulb check when the igni-

tion switch is first turned to

ON/RUN. If the light is either not on

during starting, stays on, or turns on

while driving, have the system in-

spected at an authorized dealer as

soon as possible. Refer to “Occupant

Restraints” in “Things To Know Be-

fore Starting Your Vehicle” for further

information.

8. Seat Belt Reminder Light

When the ignition switch is first

turned to ON/RUN, this light

will turn on for four to eight

seconds as a bulb check. During the

bulb check, if the driver's seat belt is

unbuckled, a chime will sound. After

the bulb check or when driving, if the

driver seat belt remains unbuckled,

the Seat Belt Warning Light will flash

or remain on continuously. Refer to

“Occupant Restraints” in “Things To

Know Before Starting Your Vehicle”

for further information. 9. Oil Pressure Warning Light

This light indicates low engine

oil pressure. The light will

come on and remain on when the ig-

nition switch is turned from the OFF

to the ON/RUN position, and the light

will turn off after the engine is started.

If the bulb does not come on during

starting, have the system checked by

an authorized dealer.

If the light comes on and remains on

while driving, stop the vehicle and

shut off the engine. DO NOT OPER-

ATE THE VEHICLE UNTIL THE

CAUSE IS CORRECTED.

The light does not show the quantity

of oil in the engine. This can be deter-

mined using the procedure shown in

“Maintaining Your Vehicle”.

10. Engine Temperature Warning

Light This light warns of an over-

heated engine condition. As

engine coolant temperature

rise and the gauge approaches H, the

light will illuminate and a single

chime will sound after reaching a set

threshold. Further overheating will cause a continuous chime sound for

4 minutes or until the engine is al-

lowed to cool.

If the light turns on while driving,

safely pull over and stop the vehicle. If

the A/C system is on, turn it off. Also,

shift the transmission into NEUTRAL

and idle the vehicle. If the tempera-

ture reading does not return to nor-

mal, turn the engine off immediately

and call for service. Refer to “If Your

Engine Overheats” in “What To Do In

Emergencies” for further informa-

tion.

11. Brake Warning Light

This light monitors various

brake functions, including

brake fluid level and parking

brake application. If the brake light

turns on it may indicate that the park-

ing brake is applied, that the brake

fluid level is low, or that there is a

problem with the anti-lock brake sys-

tem.

The dual brake system provides a re-

serve braking capacity in the event of

a failure to a portion of the hydraulic

system. Failure of either half of the108

Page 116 of 233

dual brake system is indicated by the

Brake Warning Light which will turn

on when the brake fluid level in the

master cylinder has dropped below a

specified level.

The light will remain on until the

cause is corrected.

NOTE:

The light may flash momentarily

during sharp cornering maneuvers

which change fluid level condi-

tions. The vehicle should have ser-

vice performed, and the brake

fluid level checked.

If brake failure is indicated, immedi-

ate repair is necessary.WARNING!

Driving a vehicle with the brake

light on is dangerous. Part of the

brake system may have failed. It will

take longer to stop the vehicle. You

could have a collision. Have the ve-

hicle checked immediately.Vehicles equipped with Anti-Lock

brakes (ABS), are also equipped with

Electronic Brake Force Distribution

(EBD). In the event of an EBD failure,

the Brake Warning Light will turn on

along with the ABS Light. Immediate

repair to the ABS system is required.

The operation of the Brake Warning

Light can be checked by turning the

ignition switch from the OFF position

to the ON/RUN position. The light

should illuminate for approximately

three seconds. The light should then

turn off unless the parking brake is

applied or a brake fault is detected. If

the light does not illuminate, have the

light inspected by an authorized

dealer.

The light also will turn on when the

parking brake is applied with the ig-

nition switch in the ON/RUN posi-

tion.

NOTE:

This light shows only that the

parking brake is applied. It does

not show the degree of brake ap-

plication. 12. Tachometer

The silver area of the scale shows the

permissible engine revolutions-per-

minute (RPM x 1000) for each gear

range. Before reaching the red area,

ease up on the accelerator to prevent

engine damage.

13. Shift Lever Indicator

The Shift Lever Indicator is self-

contained within the instrument clus-

ter. It displays the gear position of the

automatic transmission.

NOTE:

You must apply the brakes before

shifting from PARK.

14. Odometer Display/Trip

Odometer Display

The odometer display shows the total

distance the vehicle has been driven.

The two trip odometers show indi-

vidual trip mileage. To switch from

odometer to trip odometers, press and

release the Trip Odometer button. To

reset a trip odometer, display the de-

sired trip odometer to be reset then

push and hold the button until the

display resets (approximately 2 sec-

onds). Refer to “Trip Odometer But-

ton” for additional information.

109

Page 139 of 233

SHALLOW STANDING WATER . . . . . . . . . . . 143

POWER STEERING . . . . . . . . . . . . . . . . . . . . . . 144 POWER STEERING FLUID CHECK . . . . . . . . 144

PARKING BRAKE . . . . . . . . . . . . . . . . . . . . . . . 145

ANTI-LOCK BRAKE SYSTEM (ABS) . . . . . . . . . 146

ELECTRONIC BRAKE CONTROL SYSTEM . . . . 147 ANTI-LOCK BRAKE SYSTEM (ABS) . . . . . . . 147

TRACTION CONTROL SYSTEM (TCS) . . . . . . 148

BRAKE ASSIST SYSTEM (BAS) . . . . . . . . . . . 148

ELECTRONIC STABILITY CONTROL (ESC) . . 149

ESC ACTIVATION/MALFUNCTIONINDICATOR LIGHT AND ESC OFF

INDICATOR LIGHT . . . . . . . . . . . . . . . . . . . . 150

TIRES — GENERAL INFORMATION . . . . . . . . . 151 TIRE PRESSURE . . . . . . . . . . . . . . . . . . . . . . 151

TIRE INFLATION PRESSURES . . . . . . . . . . . 151

RADIAL-PLY TIRES . . . . . . . . . . . . . . . . . . . 152

TIRE SPINNING . . . . . . . . . . . . . . . . . . . . . . 153

TREAD WEAR INDICATORS . . . . . . . . . . . . . 153

LIFE OF TIRE . . . . . . . . . . . . . . . . . . . . . . . . 153

REPLACEMENT TIRES . . . . . . . . . . . . . . . . . 154

TIRE CHAINS . . . . . . . . . . . . . . . . . . . . . . . . . . 154

TIRE ROTATION RECOMMENDATIONS . . . . . . 155

TIRE PRESSURE MONITOR SYSTEM (TPMS) . . 155 PREMIUM SYSTEM . . . . . . . . . . . . . . . . . . . . 157

FUEL REQUIREMENTS . . . . . . . . . . . . . . . . . . . 158

132

Page 150 of 233

SHALLOW STANDING

WATER

Although your vehicle is capable of

driving through shallow standing wa-

ter, consider the following Caution

and Warning before doing so.CAUTION!

Always check the depth of thestanding water before driving

through it. Never drive through

standing water that is deeper than

the bottom of the tire rims

mounted on the vehicle.

Determine the condition of the

road or the path that is under

water and if there are any ob-

stacles in the way before driving

through the standing water.

Do not exceed 8 km/h when driv-

ing through standing water. This

will minimize wave effects.

(Continued)

CAUTION!(Continued)

Driving through standing water

may cause damage to your vehi-

cle’s drivetrain components. Al-

ways inspect your vehicle’s fluids

(i.e., engine oil, transmission,

axle, etc.) for signs of contamina-

tion (i.e., fluid that is milky or

foamy in appearance) after driv-

ing through standing water. Do

not continue to operate the vehicle

if any fluid appears contami-

nated, as this may result in further

damage. Such damage is not cov-

ered by the New Vehicle Limited

Warranty.

Getting water inside your vehi-

cle’s engine can cause it to lock up

and stall out, and cause serious

internal damage to the engine.

Such damage is not covered by the

New Vehicle Limited Warranty.

WARNING!

Driving through standing waterlimits your vehicle’s traction ca-

pabilities. Do not exceed 8 km/h

when driving through standing

water.

Driving through standing water

limits your vehicle’s braking ca-

pabilities, which increases stop-

ping distances. Therefore, after

driving through standing water,

drive slowly and lightly press on

the brake pedal several times to

dry the brakes.

Getting water inside your vehi-

cle’s engine can cause it to lock up

and stall out, and leave you

stranded.

Failure to follow these warnings

may result in injuries that are se-

rious or fatal to you, your passen-

gers, and others around you.

143

Page 177 of 233

(C) Injecting TIREFIT Sealant

Into The Deflated Tire:

Always start the engine beforeturning ON the TIREFIT kit.

NOTE:

Manual transmission vehicles

must have the parking brake en-

gaged and the shift lever in NEU-

TRAL.

After pressing the Power Button (4), the sealant (white fluid) will

flow from the Sealant Bottle (1)

through the Sealant Hose (6) and

into the tire.

NOTE:

Sealant may leak out through the

puncture in the tire.

If the sealant (white fluid) does not

flow within 0 – 10 seconds through

the Sealant Hose (6):

1. Press the Power Button (4) to turn

Off the TIREFIT kit. Disconnect the

Sealant Hose (6) from the valve stem.

Make sure the valve stem is free of

debris. Reconnect the Sealant Hose

(6) to the valve stem. Check that the

Mode Select Knob (5) is in the Sealant Mode position and not Air Mode.

Press the Power Button (4) to turn On

the TIREFIT kit.

2. Connect the Power Plug (8) to a

different 12 Volt power outlet in your

vehicle or another vehicle, if avail-

able. Make sure the engine is running

before turning ON the TIREFIT kit.

3. The Sealant Bottle (1) may be

empty due to previous use. Call for

assistance.

NOTE:

If the Mode Select Knob (5) is on

Air Mode and the pump is operat-

ing, air will dispense from the Air

Pump Hose (7) only, not the Seal-

ant Hose (6).

If the sealant (white fluid) does

flow

through the Sealant Hose (6):

1. Continue to operate the pump un-

til sealant is no longer flowing

through hose (typically takes 30 -

70 seconds). As the sealant flows

through the Sealant Hose (6), the

Pressure Gauge (3) can read as high

as 5 Bar. The Pressure Gauge (3) will

decrease quickly from approximately 70 psi (5 Bar) to the actual tire pres-

sure when the Sealant Bottle (1) is

empty.

2. The pump will start to inject air

into the tire immediately after the

Sealant Bottle (1) is empty. Continue

to operate the pump and inflate the

tire to the pressure indicated on the

tire pressure label on the driver-side

latch pillar (recommended pressure).

Check the tire pressure by looking at

the Pressure Gauge (3).

If the tire does not inflate to at least

1.8 Bar pressure within 15 min-

utes:

The tire is too badly damaged. Do

not attempt to drive the vehicle fur-

ther. Call for assistance.

NOTE:

If the tire becomes over-inflated,

press the Deflation Button to re-

duce the tire pressure to the rec-

ommended inflation pressure be-

fore continuing.

If the tire inflates to the recom-

mended pressure or is at least 1.8

Bar pressure within 15 minutes:

170

Page 186 of 233

7

MAINTAINING YOUR VEHICLE

ENGINE COMPARTMENT — 2.4L . . . . . . . . . . . 181

ONBOARD DIAGNOSTIC SYSTEM — OBD II . . . 182

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . 182

MAINTENANCE PROCEDURES . . . . . . . . . . . . . 182 ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . 183

ENGINE OIL FILTER . . . . . . . . . . . . . . . . . . . 184

ENGINE AIR CLEANER FILTER . . . . . . . . . . 184

MAINTENANCE-FREE BATTERY . . . . . . . . . 185

AIR CONDITIONER MAINTENANCE . . . . . . . 186

A/C AIR FILTER . . . . . . . . . . . . . . . . . . . . . . 186

BODY LUBRICATION . . . . . . . . . . . . . . . . . . . 187

WINDSHIELD WIPER BLADES . . . . . . . . . . . 188

ADDING WASHER FLUID . . . . . . . . . . . . . . . 188

EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . 189

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . 190

BRAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . 193

AUTOMATIC TRANSMISSION . . . . . . . . . . . . 194

APPEARANCE CARE AND PROTECTIONFROM CORROSION . . . . . . . . . . . . . . . . . . . . 196

CLEANING CENTER CONSOLE CUPHOLDERS . . . . . . . . . . . . . . . . . . . . . . . . 198

179

Page 188 of 233

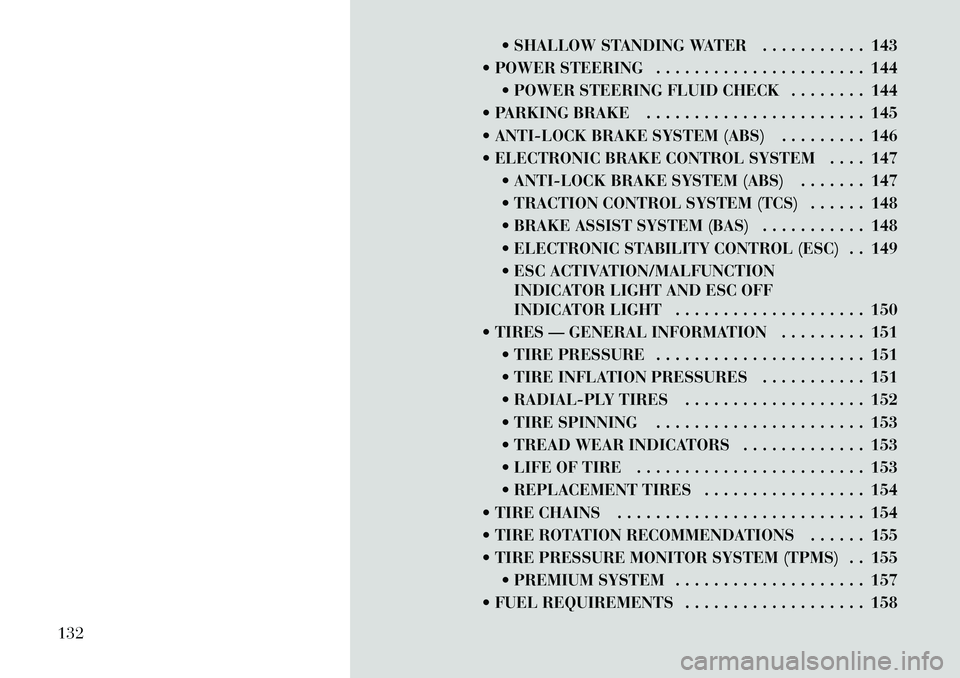

ENGINE COMPARTMENT — 2.4L1 — Engine Coolant Reservoir6 — Air Cleaner Filter

2 — Power Steering Fluid Reservoir 7 — Engine Oil Fill

3 — Brake Fluid Reservoir 8 — Coolant Pressure Cap

4 — Power Distribution Center (Fuses) 9 — Engine Oil Dipstick

5 — Integrated Power Module (Fuses) 10 — Washer Fluid Reservoir

181

Page 200 of 233

Points To Remember

NOTE:

When the vehicle is stopped after a

few kilometers of operation, you

may observe vapor coming from

the front of the engine compart-

ment. This is normally a result of

moisture from rain, snow, or high

humidity accumulating on the ra-

diator and being vaporized when

the thermostat opens, allowing hot

engine coolant (antifreeze) to enter

the radiator.

If an examination of your engine com-

partment shows no evidence of radia-

tor or hose leaks, the vehicle may be

safely driven. The vapor will soon dis-

sipate.

Do not overfill the coolant recoverybottle.

Check engine coolant (antifreeze) freeze point in the radiator and in

the coolant recovery bottle. If en-

gine coolant (antifreeze) needs to

be added, the contents of the cool-

ant recovery bottle must also be

protected against freezing. If frequent engine coolant (anti-

freeze) additions are required, or if

the level in the coolant recovery

bottle does not drop when the en-

gine cools, the cooling system

should be pressure tested for leaks.

Maintain engine coolant (anti- freeze) concentration at 50% en-

gine coolant (antifreeze) (mini-

mum) and distilled water for

proper corrosion protection of your

engine, which contains aluminum

components.

Make sure that the radiator and coolant recovery bottle overflow

hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your vehicle is equipped with air

conditioning, keep the front of the

condenser clean.

Do not change the thermostat for Summer or Winter operation. If re-

placement is ever necessary, install

ONLY the correct type thermostat.

Other designs may result in unsat-

isfactory cooling performance, poor

gas mileage, and increased emis-

sions. BRAKE SYSTEM

In order to assure brake system per-

formance, all brake system compo-

nents should be inspected periodi-

cally. Refer to the “Maintenance

Schedule” for the proper maintenance

intervals.

WARNING!

Riding the brakes can lead to brake

failure and possibly a collision. Driv-

ing with your foot resting or riding

on the brake pedal can result in ab-

normally high brake temperatures,

excessive lining wear, and possible

brake damage. You would not have

your full braking capacity in an

emergency.CAUTION!

Car maintenance should be done at

a LANCIA Dealership. For routine

and minor maintenance operations

you wish to carry out yourself, we do

recommend you have the proper

equipment, genuine LANCIA spare

parts and the necessary fluids; do

not however carry out these opera-

tions if you have no experience.

193

Page 201 of 233

Master Cylinder – Brake Fluid

Level Check

Check the fluid level in the master

cylinder immediately if the brake sys-

tem warning light indicates system

failure.

Check the fluid level in the master

cylinder when performing underhood

services.

Clean the top of the master cylinder

area before removing the cap. If nec-

essary, add fluid to bring the fluid

level up to the requirements described

on the brake fluid reservoir.

Overfilling of fluid is not recom-

mended because it may cause leaking

in the system.

Fluid level can be expected to fall as

the brake pads wear. Brake fluid level

should be checked when pads are re-

placed. However, low fluid level may

be caused by a leak and a checkup

may be needed.

Use only manufacturer's recom-

mended brake fluid. Refer to “Fluids,

Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for fur-

ther information.

WARNING!

Use the manufacturer’s recom- mended brake fluid or a quality-

equivalent product. Refer to “Flu-

ids, Lubricants, and Genuine

Parts” in “Maintaining Your Ve-

hicle” for further information. Us-

ing the wrong type of brake fluid

can severely damage your brake

system and/or impair its perfor-

mance.

To avoid contamination from for-

eign matter or moisture, use only

new brake fluid or fluid that has

been in a tightly closed container.

Keep the master cylinder reservoir

cap secured at all times. Brake

fluid in a open container absorbs

moisture from the air resulting in

a lower boiling point. This may

cause it to boil unexpectedly dur-

ing hard or prolonged braking,

resulting in sudden brake failure.

This could result in a collision.

(Continued)

WARNING!(Continued)

Overfilling the brake fluid reser-

voir can result in spilling brake

fluid on hot engine parts, causing

the brake fluid to catch fire. Brake

fluid can also damage painted and

vinyl surfaces, care should be

taken to avoid its contact with

these surfaces.

Do not allow petroleum based

fluid to contaminate the brake

fluid. Brake seal components

could be damaged, causing partial

or complete brake failure. This

could result in a collision.

AUTOMATIC

TRANSMISSION

The automatic transmission and dif-

ferential assembly are contained

within a single housing.

The fluid level in the automatic trans-

mission should be checked whenever

the vehicle is serviced. Operation with

an improper fluid level will greatly

reduce the life of the transmission and

the fluid.

194