light Lancia Thema 2013 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2013, Model line: Thema, Model: Lancia Thema 2013Pages: 336, PDF Size: 3.87 MB

Page 255 of 336

Pin

Number Function Wire

Color

5 Right Rear Position,

Side Marker

Lights, and

Rear Regis-

tration Plate

Illumination

Device. b Brown

6 Stoplights Red

7 Left Rear Position,

Side Marker

Lights, and

Rear Regis-

tration Plate

Illumination

Device. b Black

8 Reverse lights Red/ Black

9

Permanent

Power Supply

(+12V)

Brown/

White

10

Power Supply

Controlled

by Ignition

Switch (+12V)

Red

Pin

Number Function Wire

Color

11 a Return for Contact

(Pin) 10 White

12 Reserve for Future Allo-

cation Red/

Blue

13 a Return for Contact

(Pin) 9 White

Note: The allocation pin 12 has

been changed from “Coding for

coupled Trailer” to “Reserve for

Future Allocation.”

a The three return circuits shall not

be connected electrically in the

trailer.

b The rear position registration

plate illumination device shall be

connected such that no light of the

device has a common connection

with both pins 5 and 7. TOWING TIPS

Before setting out on a trip, practice

turning, stopping, and backing up the

trailer in an area located away from

heavy traffic.

Automatic Transmission

The DRIVE range can be selected

when towing. The transmission con-

trols include an adaptive drive strat-

egy to avoid frequent shifting when

towing. However, if frequent shifting

does occur while in DRIVE, use

the AutoStick® shift control (for

versions/markets, where provided) to

manually select a lower gear.

NOTE: Selecting a lower gear

while operating the vehicle under

heavy loading conditions will im-

prove performance and extend

transmission life by reducing ex-

cessive shifting and heat buildup.

This action will also provide better

engine braking.

249

Page 256 of 336

If you REGULARLY tow a trailer for

more than 45 minutes of continuous

operation, then change the automatic

transmission fluid and filter as speci-

fied for “police, taxi, fleet, or frequent

trailer towing.” Refer to the “Mainte-

nance Schedule” for the proper main-

tenance intervals.

Electronic Speed Control

Do not use in hilly terrain or withheavy loads.

When using the speed control, if you experience speed drops greater

than 16 km/h, disengage until you

can get back to cruising speed.

Use speed control in flat terrain and with light loads to maximize fuel

efficiency.

AutoStick® (for versions/markets,

where provided)

– When using the AutoStick® shift control, select the highest gear that

allows for adequate performance

and avoids frequent downshifts. For example, choose “4” if the de-

sired speed can be maintained.

Choose “3” or “2” if needed to

maintain the desired speed.

– To prevent excess heat generation, avoid continuous driving at high

RPM. Reduce vehicle speed as nec-

essary to avoid extended driving at

high RPM. Return to a higher gear

or vehicle speed when grade and

road conditions allow.

Cooling System

To reduce potential for engine and

transmission overheating, take the

following actions:

City Driving

When stopped for short periods of

time, shift the transmission into NEU-

TRAL and increase engine idle speed.

Highway Driving

Reduce speed.

Air Conditioning

Turn off temporarily. TRAILER HITCH

ATTACHING POINTS

Your vehicle will require extra equip-

ment to tow a trailer safely and effi-

ciently. The trailer tow hitch must be

attached to your vehicle using the

provided attaching points on the ve-

hicle's frame. Refer to the following

chart to determine the accurate at-

taching points. Other equipment,

such as trailer sway controls and

braking equipment, trailer equalizing

(leveling) equipment and low profile

mirrors, may also be required or

strongly recommended.

250

Page 279 of 336

ONBOARD DIAGNOSTIC

SYSTEM — OBD II

Your vehicle is equipped with a so-

phisticated onboard diagnostic sys-

tem called OBD II. This system moni-

tors the performance of the emissions,

engine, and automatic transmission

control systems. When these systems

are operating properly, your vehicle

will provide excellent performance

and fuel economy, as well as engine

emissions well within current govern-

ment regulations.

If any of these systems require service,

the OBD II system will turn on the

“Malfunction Indicator Light (MIL).”

It will also store diagnostic codes and

other information to assist your ser-

vice technician in making repairs. Al-

though your vehicle will usually be

drivable and not need towing, see

your authorized dealer for service as

soon as possible.

CAUTION!

Prolonged driving with the MILon could cause further damage

to the emissions control system. It

could also affect fuel economy

and driveability. The vehicle

must be serviced before any emis-

sions tests can be performed.

If the MIL is flashing while the engine is running, severe catalytic

converter damage and power loss

will soon occur. Immediate ser-

vice is required.

REPLACEMENT PARTS

Use of genuine parts for normal/

scheduled maintenance and repairs is

highly recommended to ensure the

designed performance. Damage or

failures caused by the use of parts

which are not quality-equivalent to

genuine parts for maintenance and

repairs will not be covered by the

manufacturer’s warranty. MAINTENANCE

PROCEDURES

The pages that follow contain the

re-

quired maintenance services deter-

mined by the engineers who designed

your vehicle.

Besides those maintenance items

specified in the fixed maintenance

schedule, there are other components

which may require servicing or re-

placement in the future.

CAUTION!

Failure to properly maintain your

vehicle or perform repairs and ser-

vice when necessary could result

in more costly repairs, damage to

other components or negatively

impact vehicle performance. Im-

mediately have potential malfunc-

tions examined by an authorized

dealership or qualified repair cen-

ter.

(Continued)

273

Page 285 of 336

WINDSHIELD WIPER

BLADES

Clean the rubber edges of the wiper

blades and the windshield periodi-

cally with a sponge or soft cloth and a

mild nonabrasive cleaner. This will

remove accumulations of salt or road

film.

Operation of the wipers on dry glass

for long periods may cause deteriora-

tion of the wiper blades. Always use

washer fluid when using the wipers to

remove salt or dirt from a dry wind-

shield.

Avoid using the wiper blades to re-

move frost or ice from the windshield.

Keep the blade rubber out of contact

with petroleum products such as en-

gine oil, gasoline, etc.

NOTE: Life expectancy of wiper

blades varies depending on geo-

graphical area and frequency of

use. Poor performance of blades

may be present with chattering,

marks, water lines or wet spots. If

any of these conditions are pres-

ent, clean the wiper blades or re-

place as necessary.ADDING WASHER FLUID

The windshield washer and the head-

light washer share the same fluid res-

ervoir. The fluid reservoir is located in

the front of the engine compartment.

Be sure to check the fluid level in the

reservoir at regular intervals. Fill the

reservoir with windshield washer

solvent (not radiator antifreeze) and

operate the system for a few seconds

to flush out the residual water.

When refilling the washer fluid reser-

voir, apply some washer fluid to a

cloth or towel and wipe the wiper

blades clean. This will help blade per-

formance.

To prevent freeze-up of your wind-

shield washer system in cold weather,

select a solution or mixture that meets

or exceeds the temperature range of

your climate. This rating information

can be found on most washer fluid

containers.

The fluid reservoir will hold nearly

4 Liters of washer fluid when the mes-

sage “Low Washer Fluid” appears in

the Electronic Vehicle Information

Center (EVIC).

WARNING!Commercially available windshield

washer solvents are flammable. They

could ignite and burn you. Care must

be exercised when filling or working

around the washer solution.CAUTION!

Car maintenance should be done at

a LANCIA Dealership. For routine

and minor maintenance operations

you wish to carry out yourself, we

do recommend you have the proper

equipment, genuine LANCIA spare

parts and the necessary fluids; do

not however carry out these opera-

tions if you have no experience.

INTERVENTION

REGENERATION

STRATEGY –

3.0L DIESEL ENGINE

This vehicle is equipped with a state-

of-the-art engine and exhaust system

containing a diesel particulate filter.

The engine and exhaust after-

treatment system work together to

279

Page 291 of 336

CAUTION!(Continued)

parts and the necessary fluids; do

not however carry out these opera-

tions if you have no experience.

Master Cylinder – Brake Fluid

Level Check

Check the fluid level in the master

cylinder immediately if the brake sys-

tem warning light indicates system

failure.

Check the fluid level in the master

cylinder when performing underhood

services.

Clean the top of the master cylinder

area before removing the cap. Add

fluid to bring the level up to the

“MAX” mark on the side of the master

cylinder reservoir.

Add enough fluid to bring the level up

to the requirements described on the

brake fluid reservoir. With disc

brakes, fluid level can be expected to

fall as the brake pads wear. However,

low fluid level may be caused by a

leak and a checkup may be needed. Use only manufacturer's recom-

mended brake fluid. Refer to “Fluids,

Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for fur-

ther information.

WARNING!

Use only manufacturer's recom-

mended brake fluid. Refer to

“Fluids, Lubricants, and Genuine

Parts” in “Maintaining Your Ve-

hicle” for further information.

Using the wrong type of brake

fluid can severely damage your

brake system and/or impair its

performance. The proper type of

brake fluid for your vehicle is also

identified on the original factory

installed hydraulic master cylin-

der reservoir.

To avoid contamination from for-

eign matter or moisture, use only

new brake fluid or fluid that has

been in a tightly closed container.

Keep the master cylinder reser-

voir cap secured at all times.

Brake fluid in a open container

(Continued)

WARNING!(Continued)

absorbs moisture from the air re-

sulting in a lower boiling point.

This may cause it to boil unex-

pectedly during hard or pro-

longed braking, resulting in sud-

den brake failure. This could

result in a accident.

Overfilling the brake fluid reser- voir can result in spilling brake

fluid on hot engine parts, causing

the brake fluid to catch fire.

Brake fluid can also damage

painted and vinyl surfaces, care

should be taken to avoid its con-

tact with these surfaces.

Do not allow petroleum based

fluid to contaminate the brake

fluid. Brake seal components

could be damaged, causing par-

tial or complete brake failure.

This could result in an accident.

285

Page 293 of 336

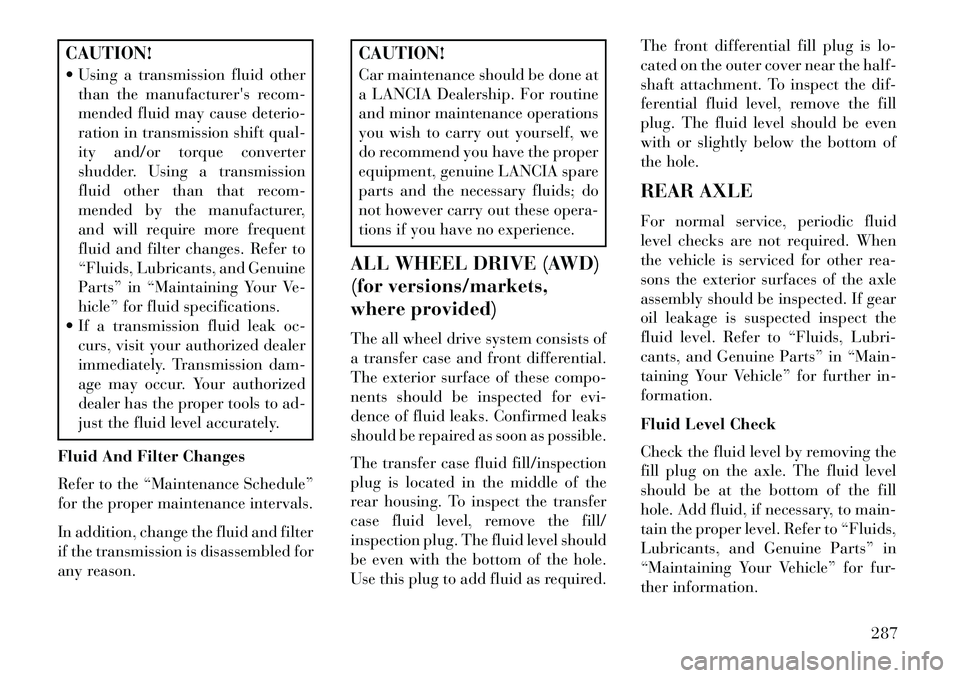

CAUTION!

Using a transmission fluid otherthan the manufacturer's recom-

mended fluid may cause deterio-

ration in transmission shift qual-

ity and/or torque converter

shudder. Using a transmission

fluid other than that recom-

mended by the manufacturer,

and will require more frequent

fluid and filter changes. Refer to

“Fluids, Lubricants, and Genuine

Parts” in “Maintaining Your Ve-

hicle” for fluid specifications.

If a transmission fluid leak oc-

curs, visit your authorized dealer

immediately. Transmission dam-

age may occur. Your authorized

dealer has the proper tools to ad-

just the fluid level accurately.

Fluid And Filter Changes

Refer to the “Maintenance Schedule”

for the proper maintenance intervals.

In addition, change the fluid and filter

if the transmission is disassembled for

any reason.

CAUTION!

Car maintenance should be done at

a LANCIA Dealership. For routine

and minor maintenance operations

you wish to carry out yourself, we

do recommend you have the proper

equipment, genuine LANCIA spare

parts and the necessary fluids; do

not however carry out these opera-

tions if you have no experience.

ALL WHEEL DRIVE (AWD)

(for versions/markets,

where provided)

The all wheel drive system consists of

a transfer case and front differential.

The exterior surface of these compo-

nents should be inspected for evi-

dence of fluid leaks. Confirmed leaks

should be repaired as soon as possible.

The transfer case fluid fill/inspection

plug is located in the middle of the

rear housing. To inspect the transfer

case fluid level, remove the fill/

inspection plug. The fluid level should

be even with the bottom of the hole.

Use this plug to add fluid as required. The front differential fill plug is lo-

cated on the outer cover near the half-

shaft attachment. To inspect the dif-

ferential fluid level, remove the fill

plug. The fluid level should be even

with or slightly below the bottom of

the hole.

REAR AXLE

For normal service, periodic fluid

level checks are not required. When

the vehicle is serviced for other rea-

sons the exterior surfaces of the axle

assembly should be inspected. If gear

oil leakage is suspected inspect the

fluid level. Refer to “Fluids, Lubri-

cants, and Genuine Parts” in “Main-

taining Your Vehicle” for further in-

formation.

Fluid Level Check

Check the fluid level by removing the

fill plug on the axle. The fluid level

should be at the bottom of the fill

hole. Add fluid, if necessary, to main-

tain the proper level. Refer to “Fluids,

Lubricants, and Genuine Parts” in

“Maintaining Your Vehicle” for fur-

ther information.

287

Page 296 of 336

Cleaning Headlights

Your vehicle has plastic headlights

that are lighter and less susceptible to

stone breakage than glass headlights.Plastic is not as scratch resistant as

glass and therefore different lens clean-

ing procedures must be followed.To minimize the possibility of scratch-

ing the lenses and reducing light out-

put, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild

soap solution followed by rinsing.Do not use abrasive cleaning compo-

nents, solvents, steel wool or other ag-

gressive material to clean the lenses.Glass Surfaces

All glass surfaces should be cleaned

on a regular basis with any commer-

cial household-type glass cleaner.

Never use an abrasive type cleaner.

Use caution when cleaning the inside

rear window equipped with an elec-

tric defroster. Do not use scrapers or

other sharp instruments that may

scratch the elements.When cleaning the rear view mirror,

spray cleaner on the towel or rag that

you are using. Do not spray cleaner

directly on the mirror.

Cleaning Plastic Instrument

Cluster Lenses

The lenses in front of the instruments

in this vehicle are molded in clear

plastic. When cleaning the lenses,

care must be taken to avoid scratch-

ing the plastic.

1. Clean with a wet soft rag. A mild

soap solution may be used, but do not

use high alcohol content or abrasive

cleaners. If soap is used, wipe clean

with a clean damp rag.

2. Dry with a soft cloth.

Seat Belt Maintenance

Do not bleach, dye, or clean the belts

with chemical solvents or abrasive

cleaners. This will weaken the fabric.

Sun damage can also weaken the fabric.If the belts need cleaning, use a mild

soap solution, or lukewarm water. Do

not remove the belts from the vehicle

to wash them.Replace the belts if they appear frayed

or worn or if the buckles do not work

properly.

Cleaning The Center Console

Cupholders

Clean with a damp cloth or towel using

a mild detergent with the cupholder in

the center console.NOTE: The cupholder cannot be

removed.

FUSES

Integrated Power ModuleThe Integrated Power Module is lo-

cated in the engine compartment. This

module contains fuses and relays.

Integrated Power Module

290

Page 301 of 336

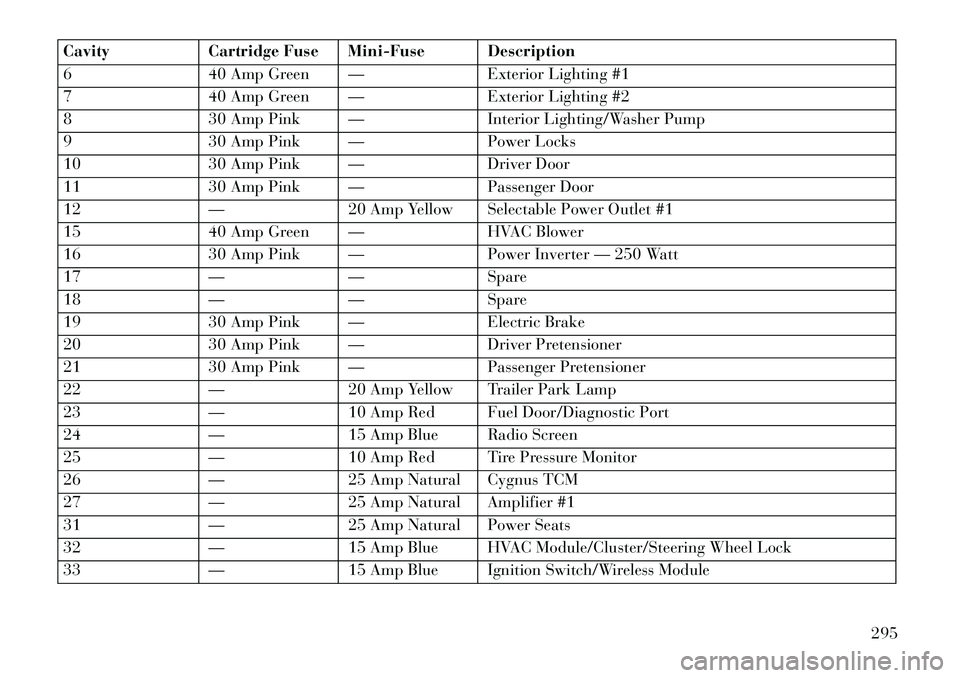

CavityCartridge Fuse Mini-Fuse Description

6 40 Amp Green — Exterior Lighting #1

7 40 Amp Green — Exterior Lighting #2

8 30 Amp Pink — Interior Lighting/Washer Pump

9 30 Amp Pink — Power Locks

10 30 Amp Pink — Driver Door

11 30 Amp Pink — Passenger Door

12 —20 Amp Yellow Selectable Power Outlet #1

15 40 Amp Green — HVAC Blower

16 30 Amp Pink — Power Inverter — 250 Watt

17 —— Spare

18 —— Spare

19 30 Amp Pink — Electric Brake

20 30 Amp Pink — Driver Pretensioner

21 30 Amp Pink — Passenger Pretensioner

22 —20 Amp Yellow Trailer Park Lamp

23 —10 Amp Red Fuel Door/Diagnostic Port

24 —15 Amp Blue Radio Screen

25 —10 Amp Red Tire Pressure Monitor

26 —25 Amp Natural Cygnus TCM

27 —25 Amp Natural Amplifier #1

31 —25 Amp Natural Power Seats

32 —15 Amp Blue HVAC Module/Cluster/Steering Wheel Lock

33 —15 Amp Blue Ignition Switch/Wireless Module

295

Page 302 of 336

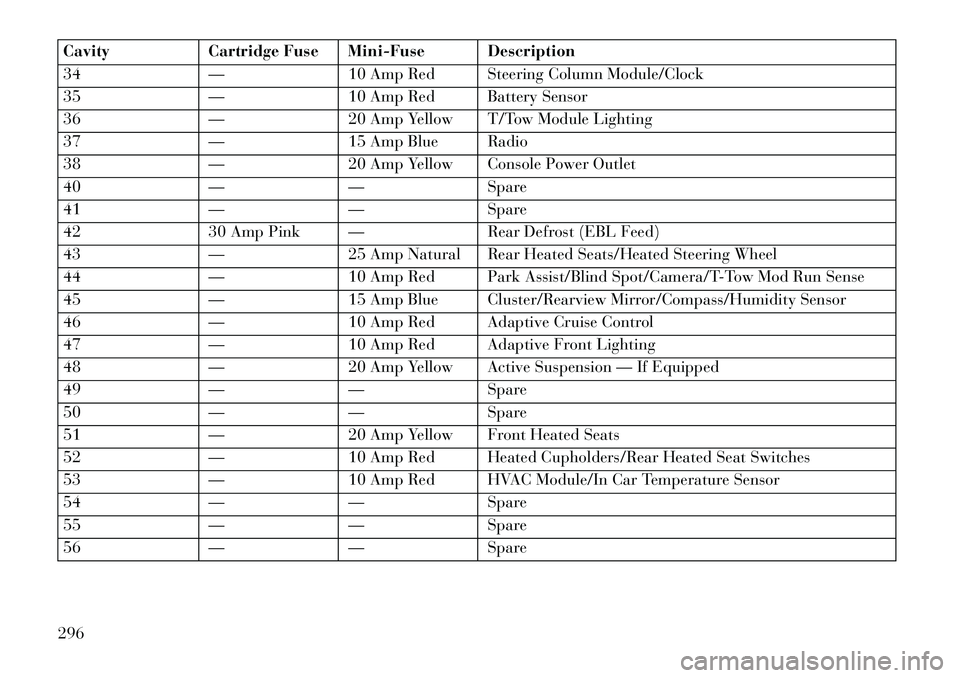

CavityCartridge Fuse Mini-Fuse Description

34 —10 Amp Red Steering Column Module/Clock

35 —10 Amp Red Battery Sensor

36 —20 Amp Yellow T/Tow Module Lighting

37 —15 Amp Blue Radio

38 —20 Amp Yellow Console Power Outlet

40 —— Spare

41 —— Spare

42 30 Amp Pink — Rear Defrost (EBL Feed)

43 —25 Amp Natural Rear Heated Seats/Heated Steering Wheel

44 —10 Amp Red Park Assist/Blind Spot/Camera/T-Tow Mod Run Sense

45 —15 Amp Blue Cluster/Rearview Mirror/Compass/Humidity Sensor

46 —10 Amp Red Adaptive Cruise Control

47 —10 Amp Red Adaptive Front Lighting

48 —20 Amp Yellow Active Suspension — If Equipped

49 —— Spare

50 —— Spare

51 —20 Amp Yellow Front Heated Seats

52 —10 Amp Red Heated Cupholders/Rear Heated Seat Switches

53 —10 Amp Red HVAC Module/In Car Temperature Sensor

54 —— Spare

55 —— Spare

56 —— Spare

296

Page 304 of 336

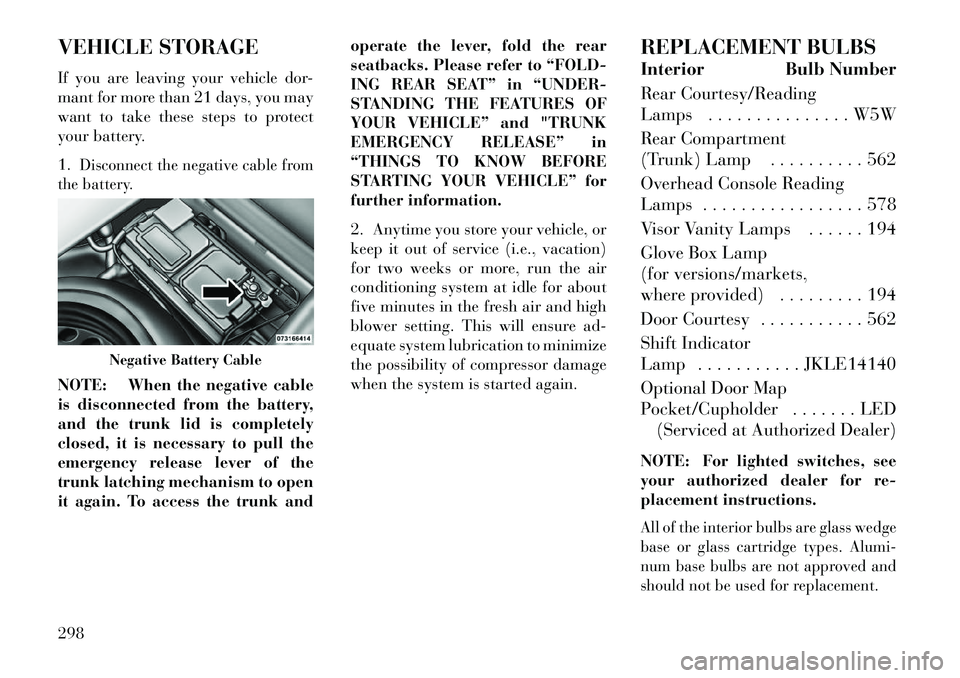

VEHICLE STORAGE

If you are leaving your vehicle dor-

mant for more than 21 days, you may

want to take these steps to protect

your battery.

1.

Disconnect the negative cable from

the battery.

NOTE: When the negative cable

is disconnected from the battery,

and the trunk lid is completely

closed, it is necessary to pull the

emergency release lever of the

trunk latching mechanism to open

it again. To access the trunk and operate the lever, fold the rear

seatbacks. Please refer to “FOLD-

ING REAR SEAT” in “UNDER-

STANDING THE FEATURES OF

YOUR VEHICLE” and "TRUNK

EMERGENCY RELEASE” in

“THINGS TO KNOW BEFORE

STARTING YOUR VEHICLE” for

further information.

2. Anytime you store your vehicle, or

keep it out of service (i.e., vacation)

for two weeks or more, run the air

conditioning system at idle for about

five minutes in the fresh air and high

blower setting. This will ensure ad-

equate system lubrication to minimize

the possibility of compressor damage

when the system is started again.

REPLACEMENT BULBS

Interior Bulb Number

Rear Courtesy/Reading

Lamps . . . . . . . . . . . . . . . W5W

Rear Compartment

(Trunk) Lamp . . . . . . . . . . 562

Overhead Console Reading

Lamps . . . . . . . . . . . . . . . . . 578

Visor Vanity Lamps . . . . . . 194

Glove Box Lamp

(for versions/markets,

where provided) . . . . . . . . . 194

Door Courtesy . . . . . . . . . . . 562

Shift Indicator

Lamp . . . . . . . . . . . JKLE14140

Optional Door Map

Pocket/Cupholder . . . . . . . LED

(Serviced at Authorized Dealer)

NOTE: For lighted switches, see

your authorized dealer for re-

placement instructions.

All of the interior bulbs are glass wedge

base or glass cartridge types. Alumi-

num base bulbs are not approved and

should not be used for replacement.

Negative Battery Cable

298