rims Lancia Thesis 2008 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2008, Model line: Thesis, Model: Lancia Thesis 2008Pages: 386, PDF Size: 4.96 MB

Page 96 of 386

95

GENERAL NOTES

Do not apply stickers or

other objects to the steer-

ing wheel, to the passen-

ger's airbag cover or to the roof

side cover. Do not place objects

(like mobile phones) on the dash-

board on passenger side since

they could interfere with proper

passenger's airbag deployment

and cause severe injuries.

If the ¬warning light

does not turn on when

turning the ignition key to

MAR or if it stays on when travel-

ling (together with message on dis-

play), this could indicate a failure

in safety retaining systems; under

this condition air bags or preten-

sioners could not trigger in the

event of collision or, in a restricted

number of cases, they could trig-

ger accidentally. Stop the car and

contact Lancia Dealership to have

the system checked immediately.

Do not cover the back

rest of front and rear seats

with trims or covers there

are not set for the use of side bags.

Do not travel with

objects on your lap or in

front of you nor with a

pipe, pencil or similar between

your lips. You could seriously

hurt yourself if the airbag inflates

in a collision.

Always drive with both

hands on the rim of the

steering wheel so that the

airbag is free to inflate during a

head-on collision and protect you

from serious injury. Do not drive

with your body bending towards

the steering wheel, but sit in an

upright position with your back

resting against the seat.If an attempt has been

made to steal the car, or if

it has actually been stolen

or has been vandalised in anyway

or subjected to flooding, have the

airbag system checked over at a

Lancia Dealership.

It is important to

remember that the airbag

can be fired even when

the car is stationary if it is hit by

another vehicle travelling at suit-

able speed. As a consequence,

never sit children in the front

seat, even if the car is not moving.

On the contrary, the airbags will

not be fired if the car is crashed

into when the key is not inserted

or turned. Consequently, in this

case, the fact that the system is

not fired does not indicate a fault.

Page 257 of 386

256

Make sure that any mats

are appropriate in size:

any hindrance, even

slight, to the braking system may

require a higher pedal stroke

than normal.

Water, ice and salt on

the road may deposit on

brake disks, reducing

braking efficiency the first time

they are used.Driving while drunk or

under the influence of

drugs or certain medi-

cines is dangerous both for you

and other road users.

Always fasten both front

and back seat belts,

including child restraint

systems if there are children trav-

elling with you. Travelling with

seat belts unfastened increases

the risk of injury or death if you

are involved in a collision. Take care when fitting

additional spoilers, alloy

rims and wheel caps: they

might reduce ventilation of the

brakes, thus their efficiency dur-

ing abrupt braking or long down-

hill slopes.

Never drive with objects

on the floor in front of the

driver’s seat: they might

get stuck under the pedals mak-

ing it impossible to accelerate or

brake.

Page 275 of 386

274

Signal the presence of

the stopped car according

to the laws in force: haz-

ard lights, reflecting triangle, etc.

Passengers should get out of the

car and stay clear from oncoming

traffic while the wheel is being

changed.

IF A TYRE

IS PUNCTURED

Follow the instructions on this and

the following pages to use the jack

and the spare wheel correctly.If the wheel is being

changed on a steep or

badly surfaced road,

place wedges or other suitable

material under the wheels to stop

the car from moving.

Have the punctured tyre

repaired and fitted back as soon

as possible. Do not lubricate the

bolt threads before fitting them

back: they could come loose.

Wheel bolts are specific

for the type of rim (alloy

or steel) fitted. Never use,

also if in an emergency, wheel

bolts for another type of rim.

When changing rims (alloy rims

instead of steel ones or vice

versa), also the whole wheel bolt

set shall be changed with other

bolts specific for the new type of

rim adopted.The jack should only be

used to change a wheel on

the car for which it was

designed. It should not be put to

other uses or employed to raise

other models of car. Under no

circumstances should it be used

when carrying out repairs under

the car.

An incorrectly positioned jack

may cause the car to fall.

Do not use the jack to lift loads

exceeding those indicated on the

label attached to the jack itself.

The wheel cap may fly off when

the car is moving if it is not fas-

tened correctly. Never tamper

with the inflation valve. Do not

insert tools between the rim and

the tyre.

Check the tyre and spare wheel

pressure regularly. Tyre pressure

is shown in the “Technical

Specifications” chapter.

Page 277 of 386

276

8) Unscrew manually the jack han-

dleA(fig. 7) and remove it from the

containerB.9) Open the tool bag and take out

the tools to be used (fig. 8):

1– tow ring

2– flat/cross-head screwdriver

3– ratchet wrench

4– ratchet wrench bush

5– wheel bolt (for versions with

alloy rims)

6– tool for removing the hub cap

(for versions with alloy rims)

7– bush for unscrewing/screwing

the wheel bolts by hand8– wrench for power steering re-

servoir cap screws

9– wrench for actuating the sun-

roof in an emergency (where fitted)

10) On versions with alloy rims,

remove the press-fit wheel hub cap

A(fig. 9), pulling it by tool Bfitted

intoC. On versions with steel rims,

remove the press-fit wheel cap A

(fig. 10).

fig. 8

L0A0326b

fig. 7

L0A0038b

fig. 9

L0A6024b

fig. 10

L0A6025b

Page 280 of 386

279

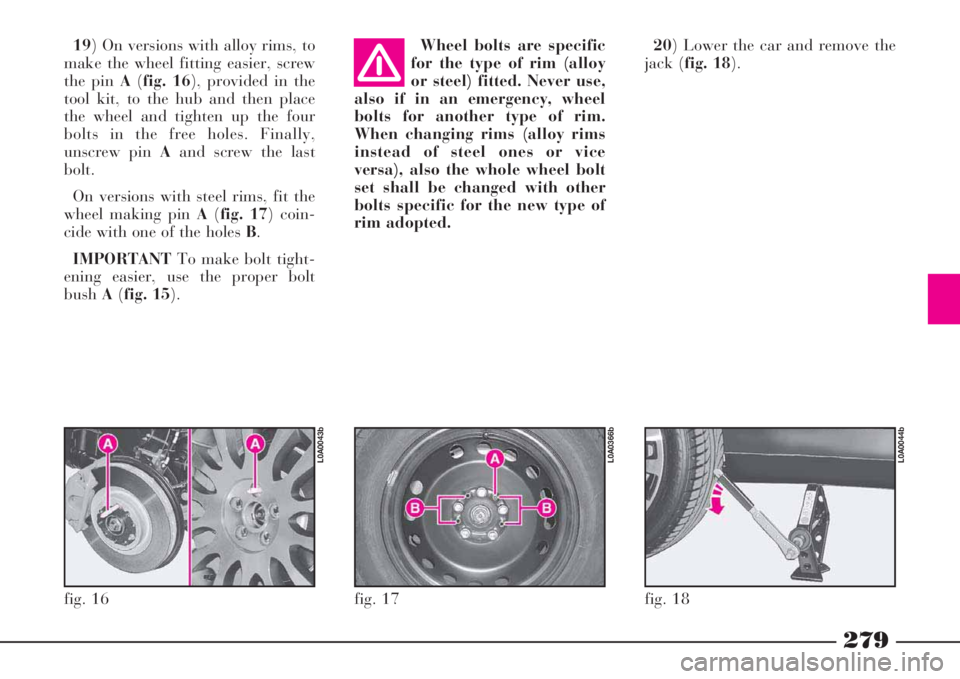

19) On versions with alloy rims, to

make the wheel fitting easier, screw

the pin A(fig. 16), provided in the

tool kit, to the hub and then place

the wheel and tighten up the four

bolts in the free holes. Finally,

unscrew pin Aand screw the last

bolt.

On versions with steel rims, fit the

wheel making pin A(fig. 17) coin-

cide with one of the holes B.

IMPORTANTTo make bolt tight-

ening easier, use the proper bolt

bushA(fig. 15).Wheel bolts are specific

for the type of rim (alloy

or steel) fitted. Never use,

also if in an emergency, wheel

bolts for another type of rim.

When changing rims (alloy rims

instead of steel ones or vice

versa), also the whole wheel bolt

set shall be changed with other

bolts specific for the new type of

rim adopted.20) Lower the car and remove the

jack (fig. 18).

fig. 16

L0A0043b

fig. 17

L0A0366b

fig. 18

L0A0044b

Page 281 of 386

280

Bolt tightening torque

must be 98 Nm (10 kgm).

After replacing the

wheel, you are advised to have

the wheel bolt tightening checked

at a Lancia Dealership as soon as

possible.

Insufficient tightening could

actually make the wheel bolts

loosen too much, with clearly

dangerous consequences. If the

bolts are tightened too much, they

could be damaged and their

resistance might be compro-

mised.23) Place the removed wheel, the

jack and the tools in the boot and

fasten appropriately.

IMPORTANTPut the jack back

intoB(fig. 8) and clamp it by

screwing handle A(fig. 8) manually

in order to prevent vibrations during

travelling.

fig. 19

L0A0045b

fig. 20

L0A0365b

fig. 21

L0A6027b

21) Tighten up the wheel bolts in a

criss-cross fashion, following the

sequence shown:

-fig. 19= versions with alloy rims

-fig. 20= versions with steel rims.

22) On versions with alloy rims,

refit the wheel hub cap pressing it

slightly. On versions with steel rims,

approach the wheel cap making the

inflating valve A(fig. 21) coincide

with flaring B. Press the cap circum-

ference starting near the inflating

valve and proceeding until fitting

the cap completely.

IMPORTANTThe wheel hub cap

(alloy rims) or the wheel cap (steel

rims) may fly off when the car is

moving if it is not fastened correctly.

Page 355 of 386

354

2.4

7Jx16 H2-39

215/60 R16 (95W)

215/60 ZR16 (95W)

7Jx17 H2-41

225/50 R17 (94W)

225/50 ZR17 (94W)

215/60 R16 (95H) M+S

2.0 TB

7Jx16 H2-39

215/60 R16 (95W)

215/60 ZR16 (95W)

7Jx17 H2-41

225/50 R17 (94W)

225/50 ZR17 (94W)

215/60 R16 (95H) M+S

2.4 CAE

7Jx16 H2-39

215/60 R16 (95W)

215/60 ZR16 (95W)

7Jx17 H2-41

225/50 R17 (94W)

225/50 ZR17 (94W)

215/60 R16 (95H) M+S

2.0 TB

2.3

2.32.4

2.3

2.32.4 CAE

2.3

2.3

WHEELS

Standard tyres

Rims

Tyres

Optional tyres

Rims

Tyres (*)

Snow tyres

(*) Chains cannot be fitted on these tyres

COLD TYRE INFLATION PRESSURE (excluding snow tyres)

Front and rear tyres

- average load bar

- full load bar

Page 356 of 386

355

3.2 V6 CAE

2.3

2.3

2.4 JTD 20VCAE 3.2 V6 CAE

Standard tyres

Rims7Jx16 H2-39 7Jx16 H2-39

Tyres215/60 R16 (95W) 215/60 R16 (95W)215/60 ZR16 (95W) 215/60 ZR16 (95W)

Optional tyres

Rims7Jx17 H2-37 7Jx17 H2-41

7Jx17 H2-41

8Jx18 H2-37

Tyres (*)225/50 R17 (94W) 225/50 R17 (94W)

225/50 ZR17 (94W) 225/50 ZR17 (94W)

235/40 ZR18 (95Y)

Snow tyres215/60 R16 (95H) M+S 215/60 R16 (95H) M+S

(*) Chains cannot be fitted on these tyres

COLD TYRE INFLATION PRESSURE (excluding snow tyres)

Front and rear tyres

- average load bar

- full load bar

(*) Pressure for 235/40 ZR 18 (95Y) tyre2.4 JTD

20VCAE

2.3/2.7 (*)

2.3/2.7 (*)

Page 357 of 386

356

RIMS AND TYRES

Alloy rims or steel.

Tubeless tyres with radial carcass.

The homologated tyres are listed in

the log book.

IMPORTANTIn the event of dis-

crepancies between information

given in the Owner Handbook and

that shown in the Log Book, refer to

the latter one.

To ensure safety of the car in

movement, it must be fitted with

tyres of specified size and of the

same make and type on all wheels.

IMPORTANTDo not use inner

tubes with tubeless tyres. CORRECT TYRE READING

Below, please find the instructions

needed to understand the meaning

of the code stamped on the tyre, as

shown in fig. 6.

The code may be in one of the ways

given in the example.

Example:

225/50 R 17 94 W

or

225/50 ZR 17 94W

fig. 6

L0A0257b

225= Nominal width (S, distance

in mm between sides)

50= Percentage height/width

ratio (H/S)

R= Radial tyre

ZR= Radial tyre, with speed over

240 km/h

17= Rim diameter in inches (Ø)

94= Load index (capacity)

W= Maximum speed index.

Page 378 of 386

377

- Comfort Seats ................... 68

- head restraints .................. 66

- heating ............................. 67

Rearview mirror lights ............ 214

Rearview mirrors

- external ............................ 72

- internal ............................. 71

Recognition system

(Keyless System) ................. 44

- Autoclose function ............ 51

- bonnet opening ................. 50

- central locking/opening

of windows and sunroof ..... 52

- CID device ........................ 44

- CID device battery

replacement ....................... 54

- door unlocking to

access car........................... 49

- knob for activating

instrument panel and

engine start-up .................. 47- locking the door and

leaving the car ................... 50

- failure indication .............. 53

- “Garage” position

(emergency actuation) ...... 46

- locking the door and

leaving the car ................... 50

- ministerial homologation .. 53

- request for additional CID

devices .............................. 53

- system settings .................. 52

Remote control (CONNECT) .. 19

Rev counter ............................ 107

Reverse lights

- bulb replacement .............. 286

Rims ....................................... 354

- correct rim reading ............ 357

- important ......................... 356

Roof rack/ski rack................... 240

- anchorage points................ 240

Rubber tubing

(maintenance) ..................... 333Safe driving ........................... 255

- before getting behind the

wheel ................................... 255

- driving at night .................. 257

- driving in the fog ............... 258

- driving in the mountains .... 258

- driving in the rain .............. 257

- driving on snow and ice ..... 259

- driving with ABS ................ 259

- when travelling .................. 255

Seat belts

- front seat belt height

adjustment .......................... 77

- general instructions ............ 79

- how to keep seat belts

in proper working order ...... 80

- load limiting devices ........... 79

- pretensioners ...................... 78

- use ...................................... 76

Side/taillights

- control ................................ 97