brake Lancia Ypsilon 2002 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2002, Model line: Ypsilon, Model: Lancia Ypsilon 2002Pages: 191, PDF Size: 2.45 MB

Page 130 of 191

127

G

CHECKING

FLUID LEVELS

fig. 1 - 1.2 versions

P4C00385

1.Engine oil - 2.Battery - 3.Brake

fluid - 4.Windscreen washer liquid -

5.Engine coolant - 6.Power-assisted

steering fluid.

1.Engine oil - 2.Battery - 3.Brake

fluid - 4.Windscreen washer liquid -

5.Engine coolant - 6.Power-assisted

steering fluid.

fig. 2 - 1.2 16Vversions

P4C00386

4C120-143 ING 11-03-2008 12:01 Pagina 127

Page 133 of 191

130

G

POWER-ASSISTED STEERING

FLUID (fig.s 1, 2)

Check the fluid level is not below the

MINmark visible on the reservoir

with the engine cold.

If necessary, add fluid making sure

that it has the same specifications as

the fluid in the reservoir.BRAKE FLUID (fig.s 1, 2)

Check that the fluid level in the

reservoir is at maximum level.

Periodically check that the warning

light on the instrument panel is work-

ing properly by pressing on the reser-

voir cover with the key at MAR.

Warning light

xshould come on.

If you need to add fluid, only use the

type classified DOT4. You are advised

in particular to use TUTELA TOP 4

with which the braking system was

originally filled.

Symbolπon the con-

tainer indicates synthetic

type brake fluid distin-

guishing it from the mineral kind.

Using mineral type fluids damages

the special rubber braking system

gaskets beyond repair.

Make sure the power-as-

sisted steering fluid does

not come into contact with

hot parts of the engine as it catches

fire very easily.

Do not push on the power

steering limit switch for

more than 15 seconds with

the engine running. This causes

noise and could damage the sys-

tem.Oil consumption is ex-

tremely low. If further top-

ping up is required soon

after the initial top-up, have the

system checked over at a LANCIA

Dealership for leaks.

4C120-143 ING 11-03-2008 12:01 Pagina 130

Page 134 of 191

131

G

Make sure the highly cor-

rosive brake fluid does not

drip onto the paintwork. If

it does, wash it off immediately

with water.

IMPORTANTBrake fluid is hygro-

scopic (meaning it absorbs humidity).

This is why the fluid should be

changed more frequently than shown

in the Service Schedule if the car is

mainly driven in areas with a high

percentage of humidity in the air.AIR CLEANER

REPLACEMENT

1.2 versions

Loosen the screws on the edge and

on the air cleaner cover A (fig. 3)and

remove the filtering element Bto be

replaced.1.2

16Vversions

Unscrew the three screws A (fig. 4),

remove cover Band remove the filter

elementCto be replaced.

The brake fluid is poiso-

nous and corrosive. If it

accidentally comes into

contact with the skin, wash with

neutral soap and water, then rinse

copiously. If swallowed, contact a

doctor immediately.

If you often drive on

dusty roads, the filter will

require changing more fre-

quently than indicated in the Ser-

vice Schedule.

Any cleaning operations

on the filter could damage

it, causing serious damage

to the engine.

fig. 3

P4C00421

fig. 4

P4C00413

4C120-143 ING 11-03-2008 12:01 Pagina 131

Page 147 of 191

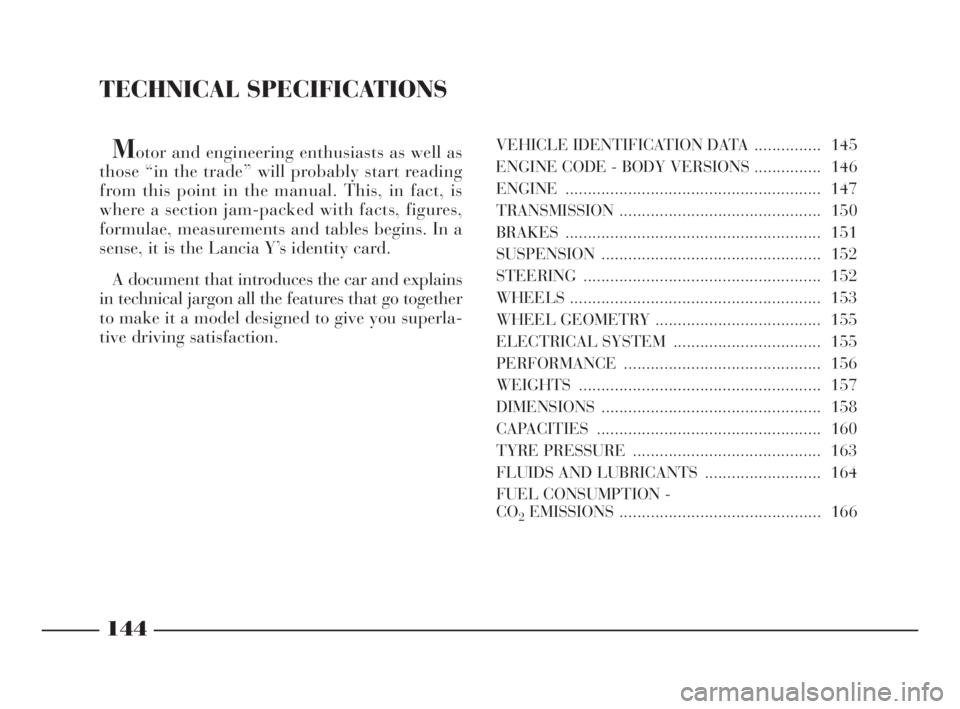

TECHNICAL SPECIFICATIONS

Motor and engineering enthusiasts as well as

those “in the trade” will probably start reading

from this point in the manual. This, in fact, is

where a section jam-packed with facts, figures,

formulae, measurements and tables begins. In a

sense, it is the Lancia Y’s identity card.

A document that introduces the car and explains

in technical jargon all the features that go together

to make it a model designed to give you superla-

tive driving satisfaction.VEHICLE IDENTIFICATION DATA ............... 145

ENGINE CODE - BODY VERSIONS............... 146

ENGINE......................................................... 147

TRANSMISSION............................................. 150

BRAKES......................................................... 151

SUSPENSION ................................................. 152

STEERING..................................................... 152

WHEELS........................................................ 153

WHEEL GEOMETRY ..................................... 155

ELECTRICAL SYSTEM ................................. 155

PERFORMANCE............................................ 156

WEIGHTS...................................................... 157

DIMENSIONS................................................. 158

CAPACITIES .................................................. 160

TYRE PRESSURE .......................................... 163

FLUIDS AND LUBRICANTS .......................... 164

FUEL CONSUMPTION -

CO

2EMISSIONS ............................................. 166

144

G

4C144-167 ING 11-03-2008 12:02 Pagina 144

Page 154 of 191

151

G

Drive transmission to the front

wheels by means of half-shafts con-

nected to the differential assembly

and the wheels with CV joints.

The ratios are:Final drive gear and differential as-

sembly incorporated in the gearbox.

Version Final drive ratio Number of teeth

1.2 3.438 16/55

1.216V3.438 16/55

1.216VM Nrosso3.867 15/58

BRAKES

SERVICE AND EMERGENCY

BRAKES

Cross-over hydraulic circuit control.

8" vacuum brake booster.

Front: disc, floating caliper type with

operating cylinder for each wheel.

Rear: drum type with self-centring

shoes with operating cylinder for each

wheel.

Automatic take up of clearance due

to friction lining wear.

Brake effort apportioning valve

working on the hydraulic circuit of

the rear brakes (for versions without

ABS).

Four channel, four sensor ABS (op-

tional for 1.2 versions, standard for LX

and 1.2

16Vversions) with electronic

brake force distributor.

HANDBRAKE

Controlled by a lever, it works me-

chanically on the rear brake shoes.

4C144-167 ING 11-03-2008 12:02 Pagina 151

Page 160 of 191

157

G

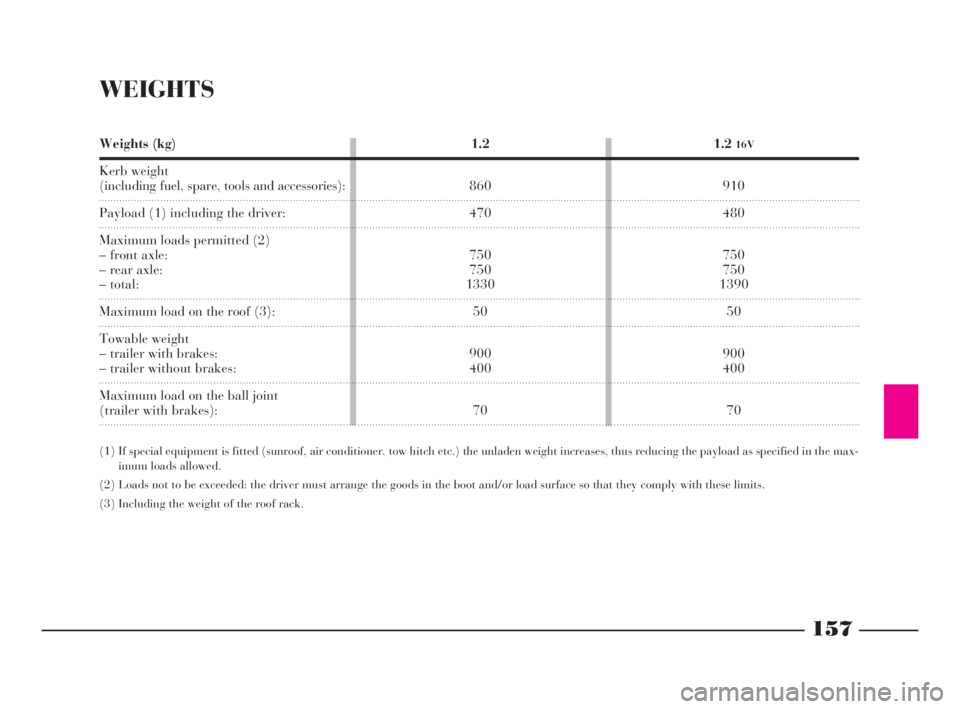

WEIGHTS

Weights (kg)

Kerb weight

(including fuel, spare, tools and accessories):

Payload (1) including the driver:

Maximum loads permitted (2)

– front axle:

– rear axle:

– total:

Maximum load on the roof (3):

Towable weight

– trailer with brakes:

– trailer without brakes:

Maximum load on the ball joint

(trailer with brakes):1.2

16V

910

480

750

750

1390

50

900

400

70 1.2

860

470

750

750

1330

50

900

400

70

(1) If special equipment is fitted (sunroof, air conditioner, tow hitch etc.) the unladen weight increases, thus reducing the payload as specified in the max-

imum loads allowed.

(2) Loads not to be exceeded: the driver must arrange the goods in the boot and/or load surface so that they comply with these limits.

(3) Including the weight of the roof rack.

4C144-167 ING 11-03-2008 12:02 Pagina 157

Page 163 of 191

160

G

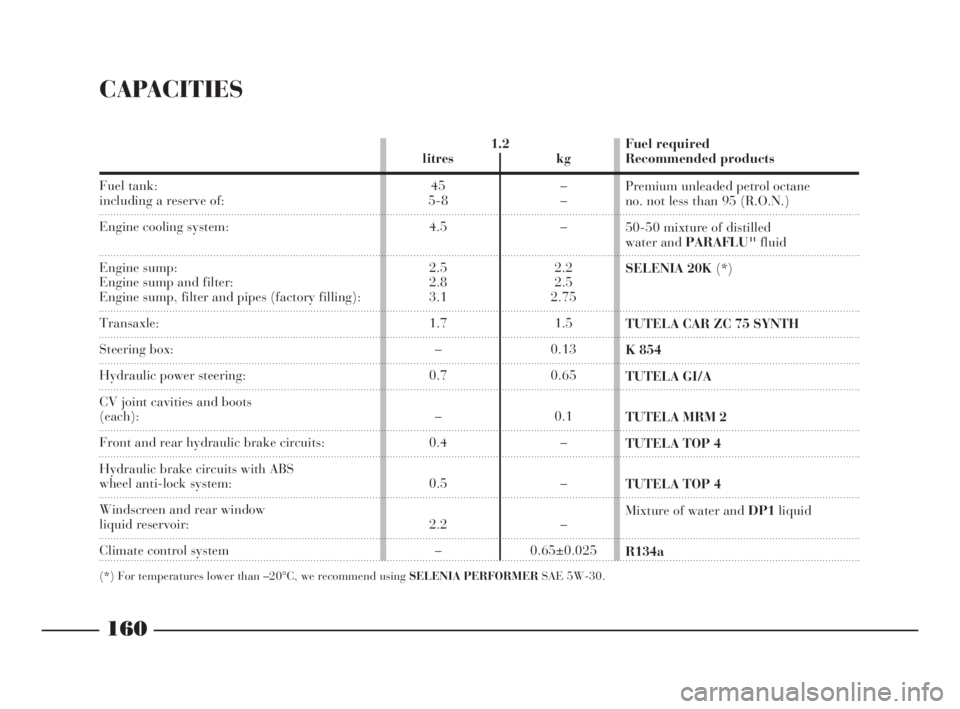

CAPACITIES

Fuel tank:including a reserve of:

Engine cooling system:

Engine sump:

Engine sump and filter:

Engine sump, filter and pipes (factory filling):

Transaxle:

Steering box:

Hydraulic power steering:

CV joint cavities and boots

(each):

Front and rear hydraulic brake circuits:

Hydraulic brake circuits with ABS

wheel anti-lock system:

Windscreen and rear window

liquid reservoir:

Climate control system

(*) For temperatures lower than –20°C, we recommend using SELENIA PERFORMERSAE 5W-30.

1.2

litres kg

45 –

5-8 –

4.5 –

2.5 2.2

2.8 2.5

3.1 2.75

1.7 1.5

–0.13

0.7 0.65

– 0.1

0.4 –

0.5 –

2.2 –

– 0.65±0.025Fuel required

Recommended products

Premium unleaded petrol octane

no. not less than 95 (R.O.N.)

50-50 mixture of distilled

water and PARAFLU

11fluid

SELENIA 20K(*)

TUTELA CAR ZC 75 SYNTH

K 854

TUTELA GI/A

TUTELA MRM 2

TUTELA TOP 4

TUTELA TOP 4

Mixture of water and DP1liquid

R134a

rs

4C144-167 ING 11-03-2008 12:02 Pagina 160

Page 164 of 191

161

G

Fuel tank:

including a reserve of:

Engine cooling system:

Engine sump:

Engine sump and filter:

Engine sump, filter and pipes (factory filling):

Transaxle:

Steering box:

Hydraulic power steering:

CV joint cavities and boots

(each):

Front and rear hydraulic brake circuits:

Hydraulic brake circuits with ABS

wheel anti-lock system:

Windscreen and rear window

liquid reservoir:

Climate control system:

(*) For temperatures lower than –20°C, we recommend using SELENIA PERFORMERSAE 5W-30.

1.216V

litres kg

45 –

5-8 –

4.5 –

2.5 2.2

2.8 2.5

3.1 2.75

1.7 1.5

–0.13

0.7 0.65

– 0.1

0.4 –

0.5 –

2.2 –

– 0.65±0.025

Fuel required

Recommended products

Premium unleaded petrol octane

no. not less than 95 (R.O.N.)

50-50 mixture of distilled

water and PARAFLU

11fluid

SELENIA 20K(*)

TUTELA CAR ZC 75 SYNTH

K 854

TUTELA GI/A

TUTELA MRM 2

TUTELA TOP 4

TUTELA TOP 4

Mixture of water and DP1liquid

R134a

4C144-167 ING 11-03-2008 12:02 Pagina 161

Page 168 of 191

165

G

Use

Drive lubricantsand grease

Steering box lubricant

Brake products

Radiatorantifreeze

Windscreen

washer liquidApplications

Manual gearbox

and differentials

CV Joints

Hydraulic

power steering

Rack steering box

Brake circuit

component

lubrication

Hydraulic brake

and clutch controls

50-50 mix

down to –35°C

To be used neat Recommended

fluids and lubricants

TUTELA CAR

ZC 75 SYNTH

TUTELA MRM 2

TUTELA GI/A

K 854

SP 349

TUTELA TOP 4

PARAFLU

11

DP1 Specifications of fluids and lubricants

to use for best car operation

SAE 75W80 EP oil exceeding API GL5 and

MIL - L - 2105 D LEV specifications

Molybdenum disulphide, lithium-soap based grease,

water-resistant NLGI consistency no. 2

ATF DEXRON II D LEV, SAE 10W oil

Lithium-soap base grease, containing molybdenum

sulphide NLGI consistency no. 000

Special grease compatible with brake fluid

Synthetic fluid: NTHSA n° 116 DOT 4 ISO 4925,

SAE J-1703, CUNA NC 956 - 01

Protective compound with ethylene glycol base

antifreeze: CUNA NC 956 - 16

Alcohol and surfactants mixture: CUNA NC 956 - 11

4C144-167 ING 11-03-2008 12:02 Pagina 165

Page 176 of 191

173

G

For mechanical connections, the fol-

lowing must be used:

– “CUNA 501” 1

stclass ball coupling

(CUNA NC 138-40 table);

– “CUNA 501” 1

stclass socket cou-

pling (CUNA NC 438-40 table).For the electric connection a 7-pole,

12 Volt coupling must be used

(CUNA UNI 9128).

The electric coupling must be fixed

on a special mount to be attached to

the ball coupling.

The electrical functions for the cou-

pling must be connected as illustrated

in(fig. 5).

In addition to the electrical connec-

tions (illustrated in the diagram that

follows), only the lead for powering

an electric brake and the lead to

power a light inside the trailer not ex-

ceeding 15W may be connected to the

car’s electrical system.

The electric brake must be powered

directly from the battery by means of

a lead with a cross-section no less

than 2.5 sq. mm.

Location of the components

on the car:

1.Left taillight (rear foglight con-

nection) - 2.Right taillight (brake

lights connection) - 3.Pole socket -

4.Trailer direction indicators power

supply relays - 5.High-amp fusebox

-6.Branching box. TOW HITCH INSTALLATION

(fig. 5)

The tow hitch must be fixed to the

body by an expert in accordance with

the following instructions and with

any additional instructions or infor-

mation provided by the tow hitch

manufacturer.

fig. 5

P4C00416

4C168-176 ING 11-03-2008 12:03 Pagina 173