technical specifications Lancia Ypsilon 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2018, Model line: Ypsilon, Model: Lancia Ypsilon 2018Pages: 200, PDF Size: 4.53 MB

Page 3 of 200

Dear Customer,

We would like to congratulate and thank you for choosing a Lancia Ypsilon.

We have written this handbook to help you get to know all the features of your car and use it in the best possible way.

Here you will find information, advice and important warnings regarding use of your vehicle and how to achieve the best performance

from the technical features of your Lancia Ypsilon.

You are advised to read it right through before taking to the road for the first time, to become familiar with the controls and above all

with those concerning brakes, steering and transmission; at the same time, you can understand the car behaviour on different road

surfaces.

This document also provides a description of special features and tips, as well as essential information for the safe driving, care and

maintenance of your Lancia Ypsilon over time.

After reading it, you are advised to keep the handbook inside the car, for an easy reference and for making sure it remains on board

the car should it be sold.

In the attached Warranty Booklet you will also find a description of the Services that Lancia offers to its customers, the Warranty

Certificate and the detail of the terms and conditions for maintaining its validity.

We are sure that these will help you to get in touch with and appreciate your new vehicle and the service provided by the people at

Lancia.

Enjoy reading. Happy motoring!

WARNING

This Owner Handbook describes all versions of the Lancia Ypsilon; please consider only the information relevant to your

car’s trim level, engine and version. All data contained in this publication are purely indicative. FCA Italy S.p.A. can modify

the specifications of the vehicle model described in this publication at any time, for technical or marketing purposes.

For further information, contact a Lancia Dealership.

Page 72 of 200

DRIVING

ASSISTANCE

SYSTEMS

iTPMS System (indirect

Tyre Pressure

Monitoring System)

(for versions/markets, where provided)

67) 68) 69) 70) 71) 72)

The car can be equipped with the

iTPMS (indirect Tire Pressure

Monitoring System) which monitors the

tyre inflation status thanks to wheel

speed sensors.

The system warns the driver if one or

more tyres are flat by the

warning

light continuously lit on the instrument

panel and a dedicated warning

message on the display.

If one tyre only is flat, the system can

indicate its position: it is in any case

recommended to check the pressure

on all four tyres.

The system does not recognise the tyre

pressure value, but it is able to indicate

if the pressure of one or more tyres

falls below a certain pressure threshold.

This indication is displayed also when

turning the engine off and on again until

the RESET procedure is carried out.Reset procedure

The iTPMS needs an initial "self-

learning" phase (with length depending

on the driving style and road conditions:

optimal conditions being driving on a

straight road at 80 km/h for at least 20

minutes) which starts when the Reset

procedure is carried out.

The Reset procedure must be carried

out:

each time tyre pressure is modified;

when even only one tyre is changed;

when tyres are rotated/inverted;

when the space-saver wheel is

fitted.

Before carrying out the Reset

procedure, inflate the tyres to the rated

pressure values specified in the inflation

pressure table (see "Wheels" paragraph

in the "Technical specifications"

chapter).

If the Reset procedure is not carried

out, in all above cases, the

warning

light may give false indications on

one or more tyres.

To carry out the RESET procedure, with

the car stopped and the ignition device

at MAR, use the Main Menu as follows:

briefly press thebutton: the

display will show Reset;

press thebutton or the

button to select ("Yes" or "No");

briefly press thebutton: the

display will show "Confirm";

pressbutton orto select

("Yes" to Reset or "No" to exit the video

page);

press thebutton again to return

to the standard screen or to the main

menu according to where you are in the

menu.

At the end of the Reset procedure the

display will show the "Reset saved"

message, indicating that the self-

learning has been started and you will

hear an acoustic warning beep.

If the iTPMS self-learning is not properly

executed, the message is not

displayed, and no beep is heard.

Operating conditions

The system is active for speeds above

15 km/h.

In a few situations such as sporty

driving, particular conditions of the road

surface (e.g. icy, snowy, unsurfaced

roads...) the signalling may be delayed

or partial in detecting the contemporary

deflation of more than one tyre.

70

SAFETY

Page 114 of 200

WARNING

121)Modifications or repairs to the electric

system that are not carried out properly

or do not take the system technical

specifications into account can cause

malfunctions leading to the risk of fire.

122)Halogen bulbs contain pressurised

gas, in the case of breakage they may

burst causing glass fragments to be

projected outwards.

WARNING

51)Halogen bulbs must be handled

holding the metallic part only. Touching the

transparent part of the bulb with your

fingers may reduce the intensity of the

emitted light and even reduce the lifespan

of the bulb. In the event of accidental

contact, wipe the bulb with a cloth

moistened with alcohol and let the bulb

dry.

52)If possible, we recommend that you

have bulbs replaced at a Lancia

Dealership. The correct operation and

direction of the external lights are

absolutely essential for the safety of the car

and of compliance with the law.

REPLACING FUSES

123) 124) 125) 126) 127) 128)

GENERAL

To facilitate fuse replacement, use the

pliers hooked inside the fuse box lid on

the dashboard left-hand side.

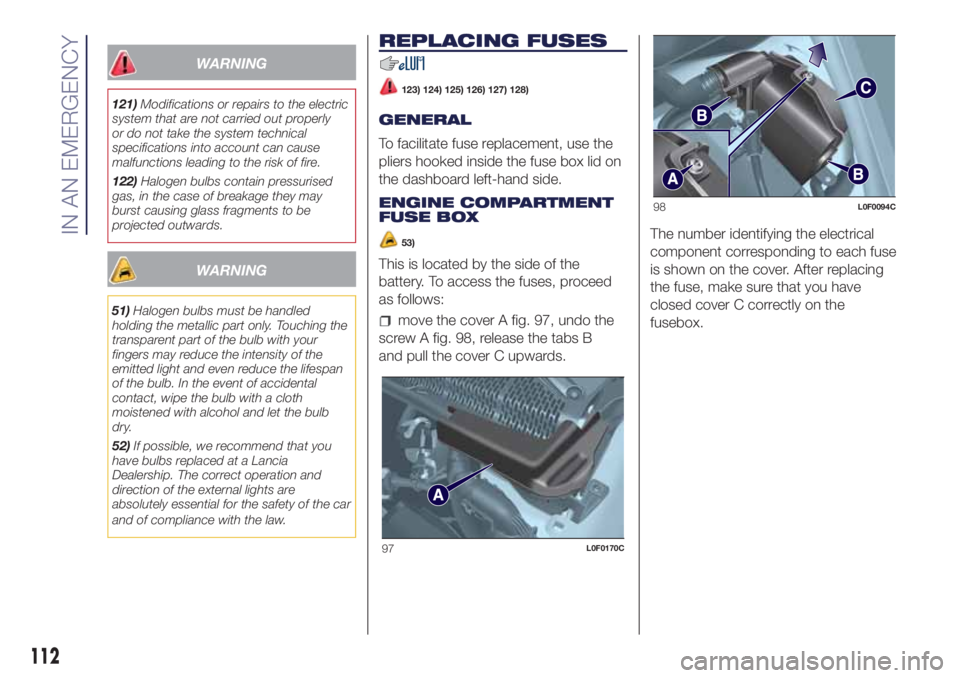

ENGINE COMPARTMENT

FUSE BOX

53)

This is located by the side of the

battery. To access the fuses, proceed

as follows:

move the cover A fig. 97, undo the

screw A fig. 98, release the tabs B

and pull the cover C upwards.The number identifying the electrical

component corresponding to each fuse

is shown on the cover. After replacing

the fuse, make sure that you have

closed cover C correctly on the

fusebox.

97L0F0170C

98L0F0094C

112

IN AN EMERGENCY

Page 122 of 200

132)The vehicle's driving characteristics

will be modified with the space-saver wheel

fitted. Avoid violent acceleration and

braking, abrupt steering and fast cornering.

The overall duration of the space-saver

wheel is of about 3000 km, after which the

relevant tyre must be replaced with another

one of the same type. Never install a

standard tyre on a rim that is designed for

use with a space-saver wheel. Have the

wheel repaired and refitted as soon as

possible. Using two or more space-saver

wheels at the same time is forbidden.

Do not apply grease to the bolt threads

before fitting: they could come unscrewed.

133)The jack shall only be used for raising

the car model it has been supplied with.

Never use the jack for other purposes,

such as raising other car models. Never

use the jack for repair operations under the

vehicle. Incorrect positioning of the jack

may cause the vehicle to fall. Do not use

the jack for loads higher than the one

shown on its label. The space-saver wheel

cannot be fitted with snow chains. If a

front (drive) tyre is punctured and chains

are needed, use a standard wheel from the

rear axle and install the space-saver wheel

on the rear axle. In this way, with two

normal drive wheels at the front axle, it is

possible to use snow chains.

134)If the hub cap is not fitted correctly, it

may come off when the car is travelling.

Never tamper with the inflation valve. Never

introduce tools of any kind between rim

and tyre. Check tyre and space-saver

wheel pressures regularly, complying with

the values given in the "Technical

specifications" chapter.135)Be very careful when removing/

refitting the hub cap due to the proximity of

the brake disc. We recommend using

heat protection gloves.

WARNING

54)When turning the jack handle make

sure that it can turn freely without scraping

your hand against the ground. The moving

components of the jack ("worm screw"

and joints) can also cause injuries: avoid

touching them. If you come into contact

with lubricating grease, clean yourself

thoroughly.

55)Contact a Lancia Dealership as soon

as possible to have the correct tightening

of the wheel bolts checked.

"Fix&Go Automatic"

KIT

136) 137) 138) 139) 140)

56)3)

DESCRIPTION

It is located in a special container in the

luggage compartment. The container

also includes a screwdriver and the tow

hook.

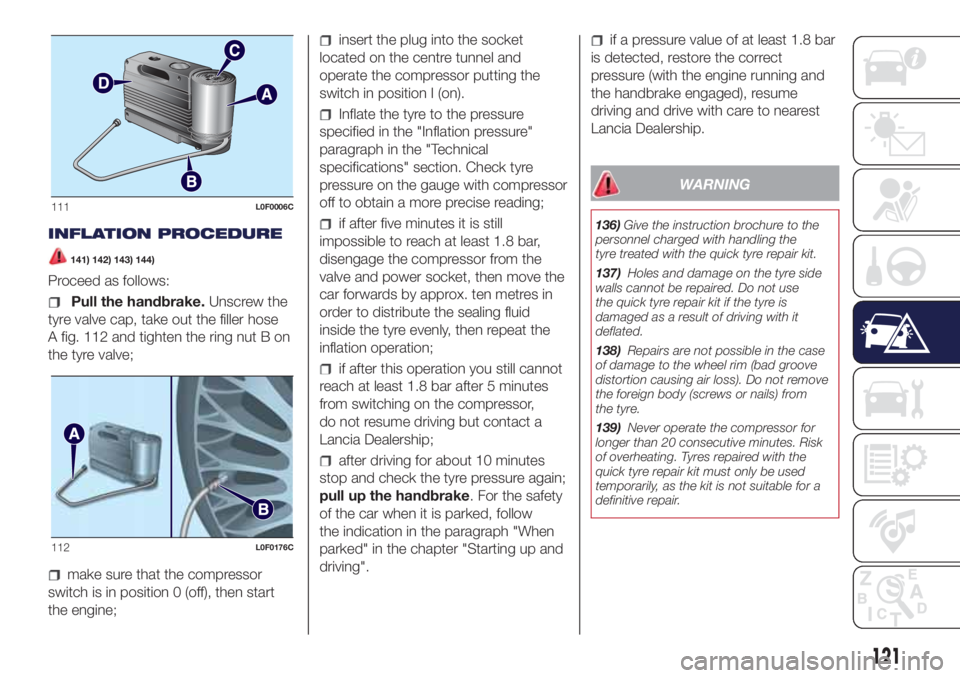

The kit fig. 111 also contains:

a spray bottle A with the sealant,

equipped with filling pipe B;

sticker C bearing the notice “max.

80 km/h”, to be placed in a position

visible to the driver (on the instrument

panel) after fixing the tyre;

a compressor D including a pressure

gauge and connections, found in the

compartment;

instruction brochure, to be used for

prompt and correct use of the quick

tyre repair kit and then to be handed to

the personnel charged with handling

the treated tyre;

a pair of protective gloves located in

the side compartment of the

compressor;

adapters for inflating different

elements.

120

IN AN EMERGENCY

Page 123 of 200

INFLATION PROCEDURE

141) 142) 143) 144)

Proceed as follows:

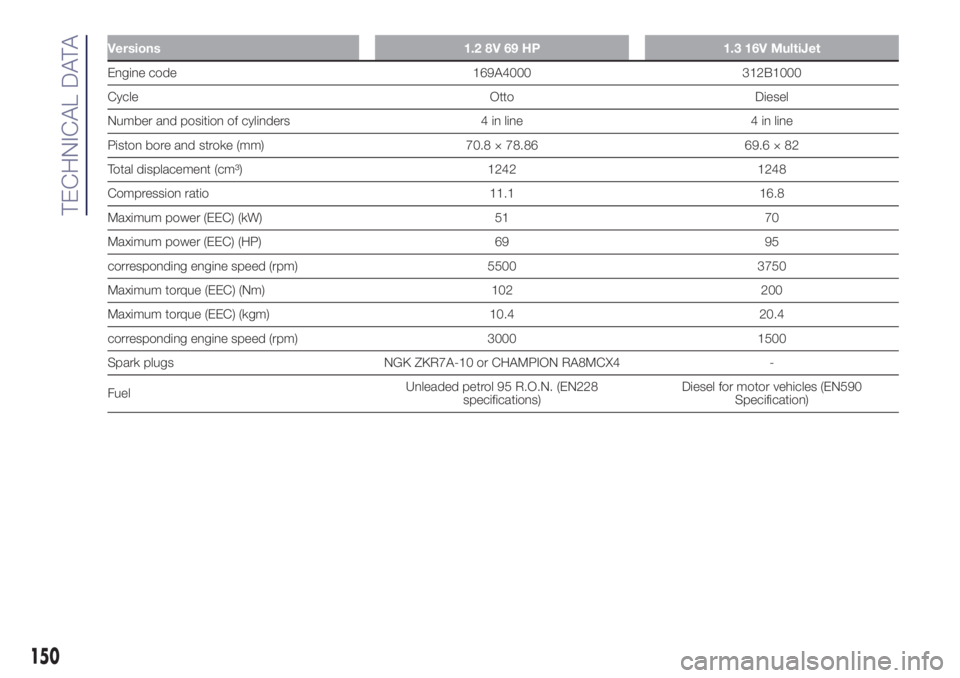

Pull the handbrake.Unscrew the

tyre valve cap, take out the filler hose

A fig. 112 and tighten the ring nut B on

the tyre valve;

make sure that the compressor

switch is in position 0 (off), then start

the engine;

insert the plug into the socket

located on the centre tunnel and

operate the compressor putting the

switch in position I (on).

Inflate the tyre to the pressure

specified in the "Inflation pressure"

paragraph in the "Technical

specifications" section. Check tyre

pressure on the gauge with compressor

off to obtain a more precise reading;

if after five minutes it is still

impossible to reach at least 1.8 bar,

disengage the compressor from the

valve and power socket, then move the

car forwards by approx. ten metres in

order to distribute the sealing fluid

inside the tyre evenly, then repeat the

inflation operation;

if after this operation you still cannot

reach at least 1.8 bar after 5 minutes

from switching on the compressor,

do not resume driving but contact a

Lancia Dealership;

after driving for about 10 minutes

stop and check the tyre pressure again;

pull up the handbrake. For the safety

of the car when it is parked, follow

the indication in the paragraph "When

parked" in the chapter "Starting up and

driving".

if a pressure value of at least 1.8 bar

is detected, restore the correct

pressure (with the engine running and

the handbrake engaged), resume

driving and drive with care to nearest

Lancia Dealership.

WARNING

136)Give the instruction brochure to the

personnel charged with handling the

tyre treated with the quick tyre repair kit.

137)Holes and damage on the tyre side

walls cannot be repaired. Do not use

the quick tyre repair kit if the tyre is

damaged as a result of driving with it

deflated.

138)Repairs are not possible in the case

of damage to the wheel rim (bad groove

distortion causing air loss). Do not remove

the foreign body (screws or nails) from

the tyre.

139)Never operate the compressor for

longer than 20 consecutive minutes. Risk

of overheating. Tyres repaired with the

quick tyre repair kit must only be used

temporarily, as the kit is not suitable for a

definitive repair.

111L0F0006C

112L0F0176C

121

Page 142 of 200

ENGINE OIL

60)

Check the oil level a few minutes (about

5) after the engine has stopped, with

the vehicle parked on level ground.

For the 1.2 8V 69HP and 1.3 16V

Multijet versions

Take out the engine oil dipstick B, clean

it with a lint-free cloth and reinsert it.

Extract the engine oil dipstick again and

check that the level is between the

MIN and MAX marks on the dipstick.

The range between the MIN. and MAX.

marks corresponds to about 1 litre of

oil.

If the oil level is near or under the MIN

line, add oil through the filler A until

it reaches the MAX line.

For 0.9 TwinAir versions

The engine oil dipstick A is integral with

cap A. Loosen the cap, clean the

dipstick with a cloth that does not leave

traces, reinsert the dipstick and

re-tighten the cap. Unscrew the plug

again and check that the engine oil level

is between the MIN and MAX marks

on the dipstick.Engine oil consumption

61)5)

The maximum engine oil consumption

is usually 400 grams every 1000 km.

When the car is new, the engine needs

to run in, therefore the engine oil

consumption can only be considered

stabilised after the first 5,000 - 6,000

km.

IMPORTANT After adding or changing

the oil, let the engine turn over for a few

seconds and wait a few minutes after

turning it off before you check the level.

ENGINE COOLANT FLUID

154)62)

The coolant level must be checked

when the engine is cold and must

range between the MIN and MAX

marks on the reservoir.

If the level is too low, undo the reservoir

plug C (see previous pages) and add

the fluid as described in the chapter

"Technical Specifications".

WINDSCREEN/REAR

WINDOW WASHING FLUID

155)

If the level is too low, raise reservoir cap

D (see previous pages) and add the

fluid described in the chapter "Technical

Specifications".BRAKE FLUID

156) 157)63)

Check that the fluid is at the maximum

level (the fluid level in the reservoir

must not exceed the MAX mark). If the

fluid level in the tank is too low, undo

reservoir cap E (see previous pages)

and add the fluid described in the

chapter "Technical Specifications".

NOTE Carefully clean the plug of the

reservoir E and the surrounding surface.

Take great care to ensure that

impurities do not enter the reservoir

when the cap is opened.

Always use a funnel with a built-in filter

with a mesh of 0.12 mm or less.

IMPORTANT Brake fluid is hygroscopic

(i.e. it absorbs moisture). For this

reason, if the car is mainly used in areas

with a high degree of atmospheric

humidity, the fluid must be replaced at

more frequent intervals than specified in

the "Scheduled Servicing Plan".

DUAL FUNCTION SYSTEM

GEARBOX HYDRAULIC

ACTUATION SYSTEM OIL

For oil and filter changing, go

exclusively to a Lancia Dealership.

6)

140

SERVICING AND CARE

Page 152 of 200

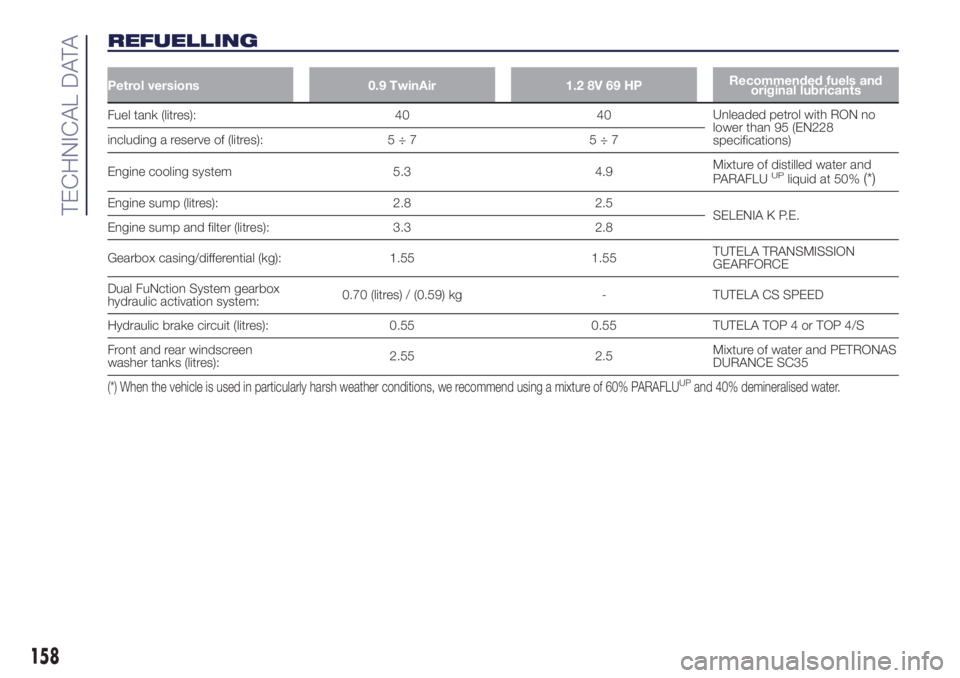

Versions 1.2 8V 69 HP 1.3 16V MultiJet

Engine code 169A4000 312B1000

Cycle Otto Diesel

Number and position of cylinders 4 in line 4 in line

Piston bore and stroke (mm) 70.8 × 78.86 69.6 × 82

Total displacement (cm³) 1242 1248

Compression ratio 11.1 16.8

Maximum power (EEC) (kW) 51 70

Maximum power (EEC) (HP) 69 95

corresponding engine speed (rpm) 5500 3750

Maximum torque (EEC) (Nm) 102 200

Maximum torque (EEC) (kgm) 10.4 20.4

corresponding engine speed (rpm) 3000 1500

Spark plugs NGK ZKR7A-10 or CHAMPION RA8MCX4 -

FuelUnleaded petrol 95 R.O.N. (EN228

specifications)Diesel for motor vehicles (EN590

Specification)

150

TECHNICAL DATA

Page 160 of 200

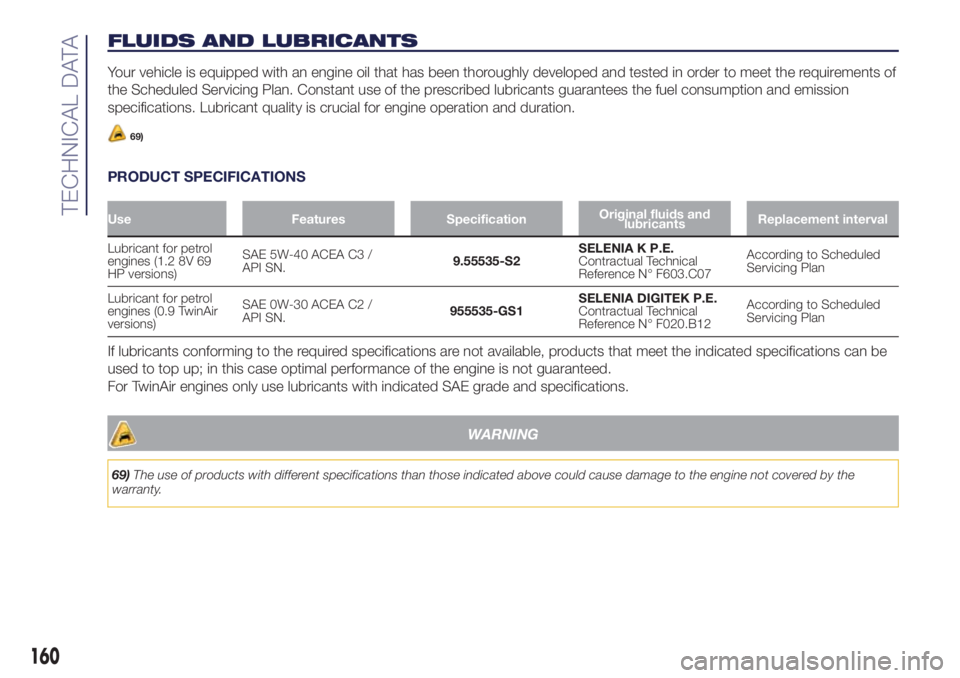

REFUELLING

Petrol versions 0.9 TwinAir 1.2 8V 69 HPRecommended fuels and

original lubricants

Fuel tank (litres): 40 40Unleaded petrol with RON no

lower than 95 (EN228

specifications) including a reserve of (litres): 5 ÷ 7 5 ÷ 7

Engine cooling system 5.3 4.9Mixture of distilled water and

PARAFLU

UPliquid at 50%(*)

Engine sump (litres): 2.8 2.5

SELENIA K P.E.

Engine sump and filter (litres): 3.3 2.8

Gearbox casing/differential (kg): 1.55 1.55TUTELA TRANSMISSION

GEARFORCE

Dual FuNction System gearbox

hydraulic activation system:0.70 (litres) / (0.59) kg - TUTELA CS SPEED

Hydraulic brake circuit (litres): 0.55 0.55 TUTELA TOP 4 or TOP 4/S

Front and rear windscreen

washer tanks (litres):2.55 2.5Mixture of water and PETRONAS

DURANCE SC35

(*) When the vehicle is used in particularly harsh weather conditions, we recommend using a mixture of 60% PARAFLUUPand 40% demineralised water.

158

TECHNICAL DATA

Page 162 of 200

FLUIDS AND LUBRICANTS

Your vehicle is equipped with an engine oil that has been thoroughly developed and tested in order to meet the requirements of

the Scheduled Servicing Plan. Constant use of the prescribed lubricants guarantees the fuel consumption and emission

specifications. Lubricant quality is crucial for engine operation and duration.

69)

PRODUCT SPECIFICATIONS

Use Features SpecificationOriginal fluids and

lubricantsReplacement interval

Lubricant for petrol

engines (1.2 8V 69

HP versions)SAE 5W-40 ACEA C3 /

API SN.9.55535-S2SELENIA K P.E.

Contractual Technical

Reference N° F603.C07According to Scheduled

Servicing Plan

Lubricant for petrol

engines (0.9 TwinAir

versions)SAE 0W-30 ACEA C2 /

API SN.955535-GS1SELENIA DIGITEK P.E.

Contractual Technical

Reference N° F020.B12According to Scheduled

Servicing Plan

If lubricants conforming to the required specifications are not available, products that meet the indicated specifications can be

used to top up; in this case optimal performance of the engine is not guaranteed.

For TwinAir engines only use lubricants with indicated SAE grade and specifications.

WARNING

69)The use of products with different specifications than those indicated above could cause damage to the engine not covered by the

warranty.

160

TECHNICAL DATA

Page 163 of 200

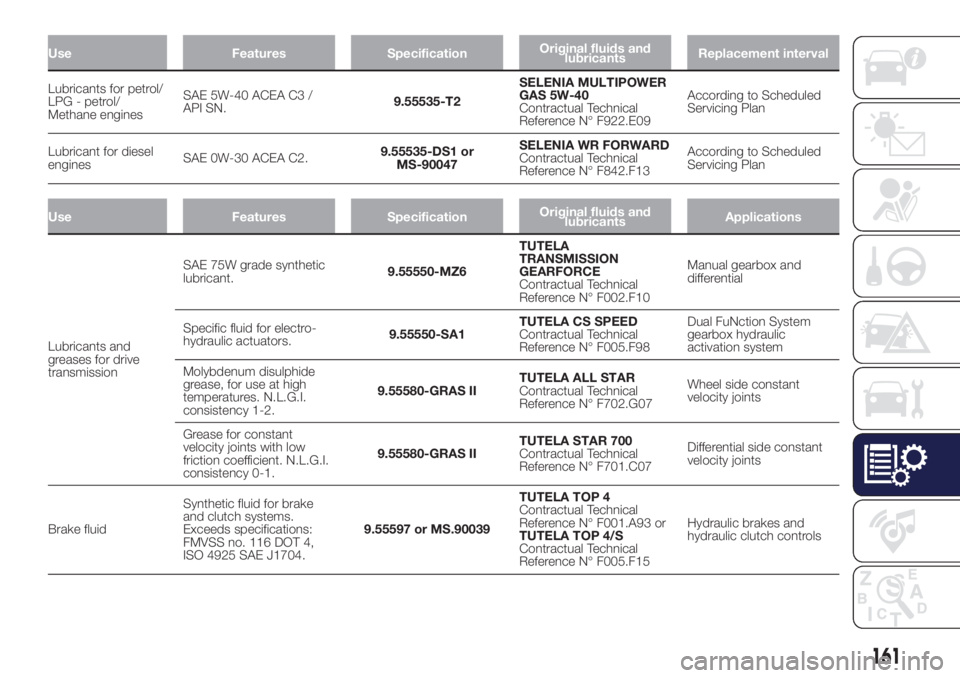

Use Features SpecificationOriginal fluids and

lubricantsReplacement interval

Lubricants for petrol/

LPG - petrol/

Methane enginesSAE 5W-40 ACEA C3 /

API SN.9.55535-T2SELENIA MULTIPOWER

GAS 5W-40

Contractual Technical

Reference N° F922.E09According to Scheduled

Servicing Plan

Lubricant for diesel

enginesSAE 0W-30 ACEA C2.9.55535-DS1 or

MS-90047SELENIA WR FORWARD

Contractual Technical

Reference N° F842.F13According to Scheduled

Servicing Plan

Use Features SpecificationOriginal fluids and

lubricantsApplications

Lubricants and

greases for drive

transmissionSAE 75W grade synthetic

lubricant.9.55550-MZ6TUTELA

TRANSMISSION

GEARFORCE

Contractual Technical

Reference N° F002.F10Manual gearbox and

differential

Specific fluid for electro-

hydraulic actuators.9.55550-SA1TUTELA CS SPEED

Contractual Technical

Reference N° F005.F98Dual FuNction System

gearbox hydraulic

activation system

Molybdenum disulphide

grease, for use at high

temperatures. N.L.G.I.

consistency 1-2.9.55580-GRAS IITUTELA ALL STAR

Contractual Technical

Reference N° F702.G07Wheel side constant

velocity joints

Grease for constant

velocity joints with low

friction coefficient. N.L.G.I.

consistency 0-1.9.55580-GRAS IITUTELA STAR 700

Contractual Technical

Reference N° F701.C07Differential side constant

velocity joints

Brake fluidSynthetic fluid for brake

and clutch systems.

Exceeds specifications:

FMVSS no. 116 DOT 4,

ISO 4925 SAE J1704.9.55597 or MS.90039TUTELA TOP 4

Contractual Technical

Reference N° F001.A93 or

TUTELA TOP 4/S

Contractual Technical

Reference N° F005.F15Hydraulic brakes and

hydraulic clutch controls

161