length LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 237 of 455

STEERING

3

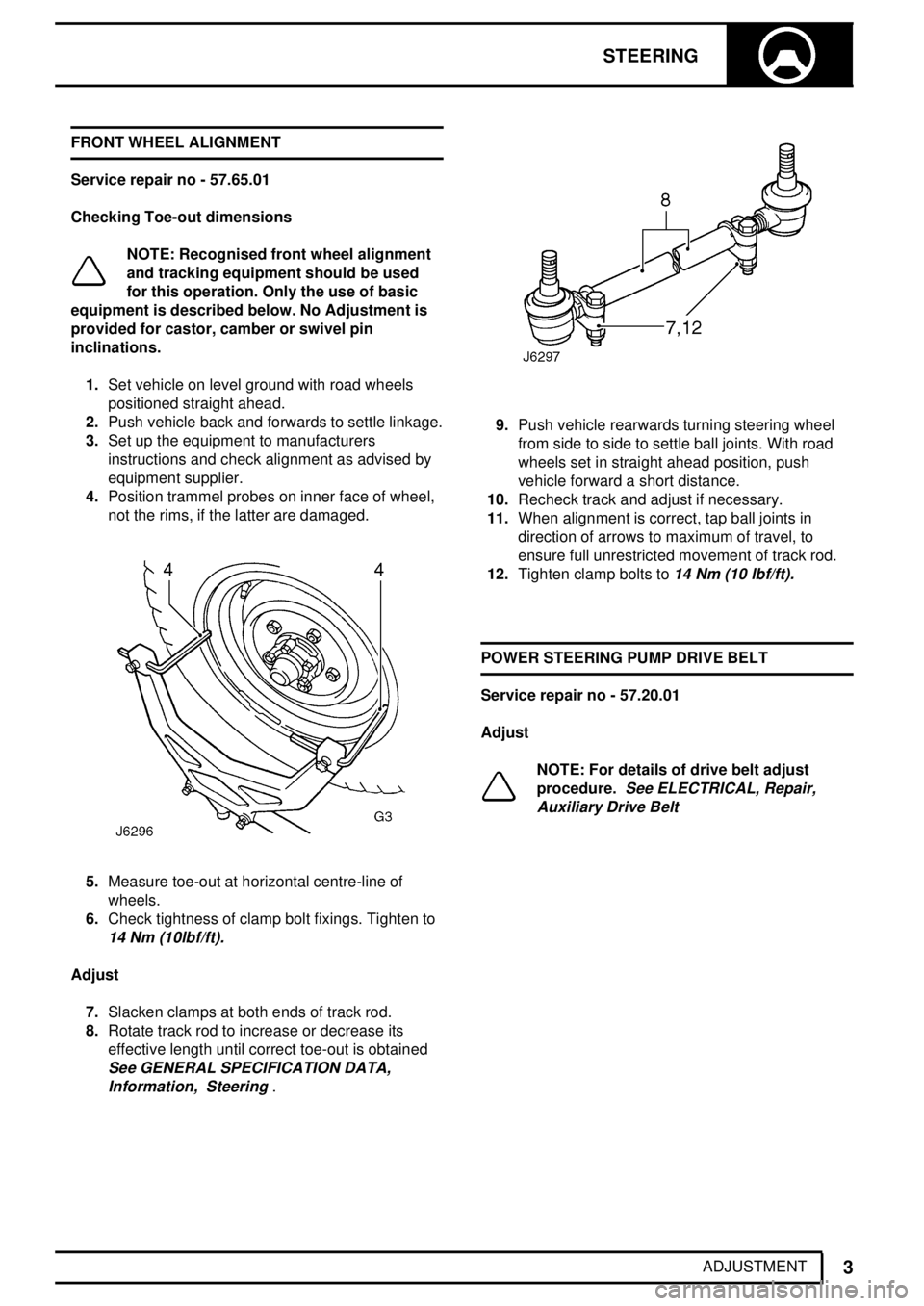

ADJUSTMENT FRONT WHEEL ALIGNMENT

Service repair no - 57.65.01

Checking Toe-out dimensions

NOTE: Recognised front wheel alignment

and tracking equipment should be used

for this operation. Only the use of basic

equipment is described below. No Adjustment is

provided for castor, camber or swivel pin

inclinations.

1.Set vehicle on level ground with road wheels

positioned straight ahead.

2.Push vehicle back and forwards to settle linkage.

3.Set up the equipment to manufacturers

instructions and check alignment as advised by

equipment supplier.

4.Position trammel probes on inner face of wheel,

not the rims, if the latter are damaged.

5.Measure toe-out at horizontal centre-line of

wheels.

6.Check tightness of clamp bolt fixings. Tighten to

14 Nm (10lbf/ft).

Adjust

7.Slacken clamps at both ends of track rod.

8.Rotate track rod to increase or decrease its

effective length until correct toe-out is obtained

See GENERAL SPECIFICATION DATA,

Information, Steering

.

9.Push vehicle rearwards turning steering wheel

from side to side to settle ball joints. With road

wheels set in straight ahead position, push

vehicle forward a short distance.

10.Recheck track and adjust if necessary.

11.When alignment is correct, tap ball joints in

direction of arrows to maximum of travel, to

ensure full unrestricted movement of track rod.

12.Tighten clamp bolts to

14 Nm (10 lbf/ft).

POWER STEERING PUMP DRIVE BELT

Service repair no - 57.20.01

Adjust

NOTE: For details of drive belt adjust

procedure.

See ELECTRICAL, Repair,

Auxiliary Drive Belt

Page 240 of 455

STEERING

3

REPAIR REV: 05/99

NOTE: The steering column is a non

serviceable component and can only be

serviced as a complete assembly.

25.Fit main support bracket and padding to steering

column and manoeuvre column into position in

vehicle.

26.Loosely secure main support bracket and

harness bracket to bulkhead.

27.Loosely fit clamp and rubber packing strip to

column.

28.Loosely secure lower end of column to lower

support bracket.

29.Loosely secure clamp bracket to main support

bracket.

30.Working inside vehicle cab, fit tie-bar to column

bracket and secure with single bolt to

22 Nm (16

lbf/ft).

31.Finally, tighten main support bracket, clamp

bracket, upper clamp, and lower support bracket

nuts and bolts. (M6 bolts

9 Nm (6 lbf/ft),M8

bolts

22 Nm (16 lbf/ft).

32.Fit brake pedal boxSee BRAKES, Repair,

Brake pedal

.

33.Fit steering lock/switch in position and rotate

steering column inner shaft to line up slot with

switch plunger.

34.Secure lock to column with clamp and shear

bolts. Evenly tighten bolts but do not shear them.

35.Temporarily fit steering wheel and operate

switch and lock mechanism several times to

ensure it functions correctly.

36.Fully tighten switch retaining bolts until heads

shear.

37.Connect electrical leads to rear of switch. Fit

alarm system passive coil, if applicable.

See

ELECTRICAL, Repair, Vehicle immobilisation

and alarm system

.

38.Fit switch assembly on steering column and

tighten clamping screw.

39.Connect switch assembly multi-plugs and

electrical leads to main harness.

40.Offer up instrument panel, connect speedometer

cable, multi-plugs and electrical leads to main

harness. If applicable, fit vehicle alarm system

connections.

See ELECTRICAL, Repair,

Vehicle immobilisation and alarm system

.

41.Secure panel with 4 screws.

42.Locate top half of nacelle in position and fit to

switch gaiters/grommets.43.Fit lower half of nacelle and loosely tighten fixing

screws.

44.Ensure switch gaiters/grommets are correctly

located and fully tighten fixings.

45.Turn indicator cancelling ring so that slots are

vertical and lug with arrow points to the left, in

direction of indicator switch.

46.Fit steering wheel with finisher attachment lug at

bottom, ensuring that indicator cancelling forks

locate in cancelling ring slots.

47.Secure wheel with nut and new shake-proof

washer. Tighten to

43 Nm (32 lbf/ft).

48.Fit steering wheel decal.

49.If necessary, fit new universal joints to support.

Note that long joint is fitted to short length of

shaft and short joint to long end. Joints can only

be fitted one way to shaft.

50.With steering lock engaged and road wheels in

straight ahead position, align reassembly marks,

and fit collapsible shaft assembly with long leg of

shaft to steering box. Fit pinch bolts and tighten

to

25 Nm (18 lbf/ft).

Page 245 of 455

57STEERING

8

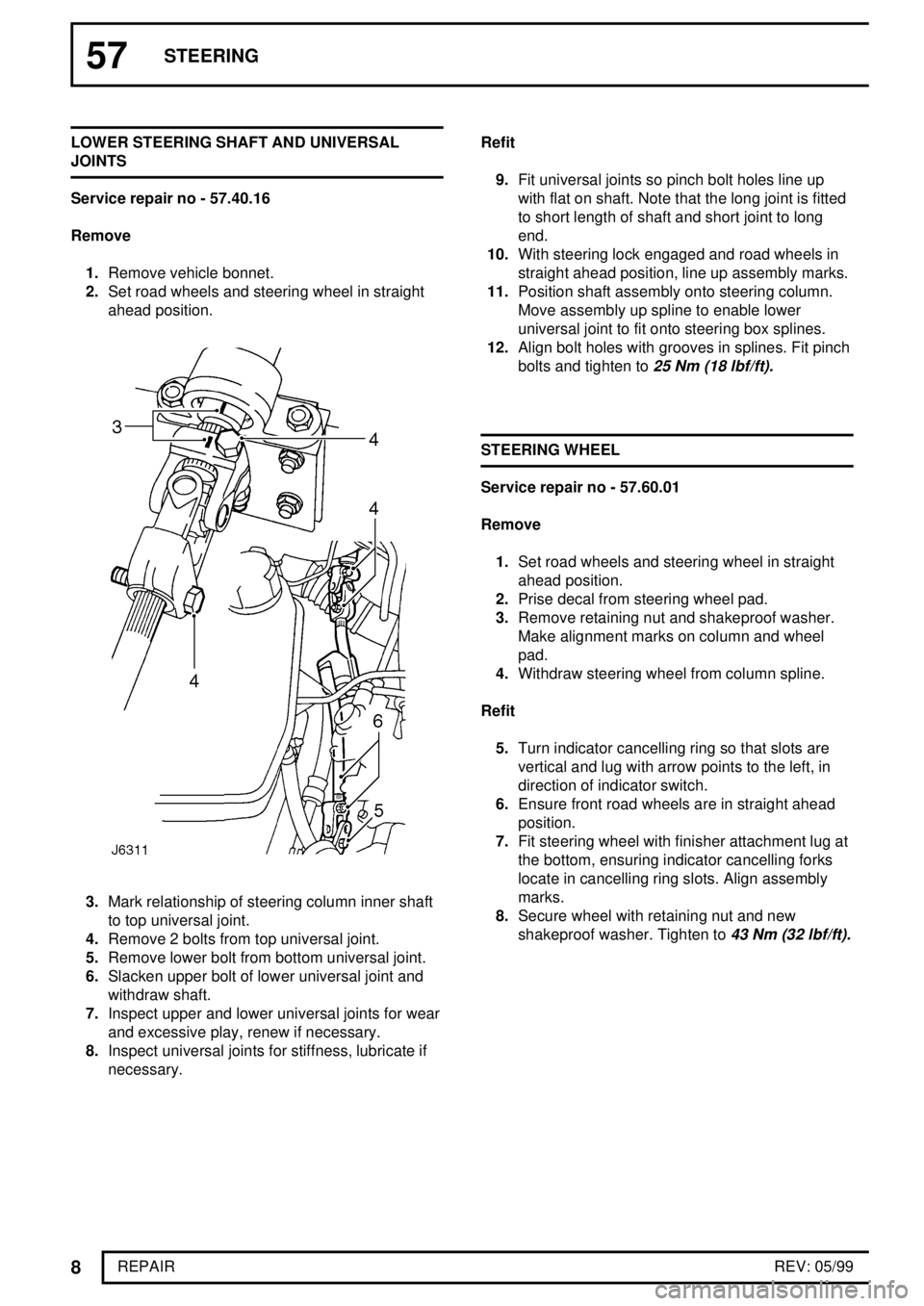

REPAIRREV: 05/99 LOWER STEERING SHAFT AND UNIVERSAL

JOINTS

Service repair no - 57.40.16

Remove

1.Remove vehicle bonnet.

2.Set road wheels and steering wheel in straight

ahead position.

3.Mark relationship of steering column inner shaft

to top universal joint.

4.Remove 2 bolts from top universal joint.

5.Remove lower bolt from bottom universal joint.

6.Slacken upper bolt of lower universal joint and

withdraw shaft.

7.Inspect upper and lower universal joints for wear

and excessive play, renew if necessary.

8.Inspect universal joints for stiffness, lubricate if

necessary.Refit

9.Fit universal joints so pinch bolt holes line up

with flat on shaft. Note that the long joint is fitted

to short length of shaft and short joint to long

end.

10.With steering lock engaged and road wheels in

straight ahead position, line up assembly marks.

11.Position shaft assembly onto steering column.

Move assembly up spline to enable lower

universal joint to fit onto steering box splines.

12.Align bolt holes with grooves in splines. Fit pinch

bolts and tighten to

25 Nm (18 lbf/ft).

STEERING WHEEL

Service repair no - 57.60.01

Remove

1.Set road wheels and steering wheel in straight

ahead position.

2.Prise decal from steering wheel pad.

3.Remove retaining nut and shakeproof washer.

Make alignment marks on column and wheel

pad.

4.Withdraw steering wheel from column spline.

Refit

5.Turn indicator cancelling ring so that slots are

vertical and lug with arrow points to the left, in

direction of indicator switch.

6.Ensure front road wheels are in straight ahead

position.

7.Fit steering wheel with finisher attachment lug at

the bottom, ensuring indicator cancelling forks

locate in cancelling ring slots. Align assembly

marks.

8.Secure wheel with retaining nut and new

shakeproof washer. Tighten to

43 Nm (32 lbf/ft).

Page 252 of 455

STEERING

15

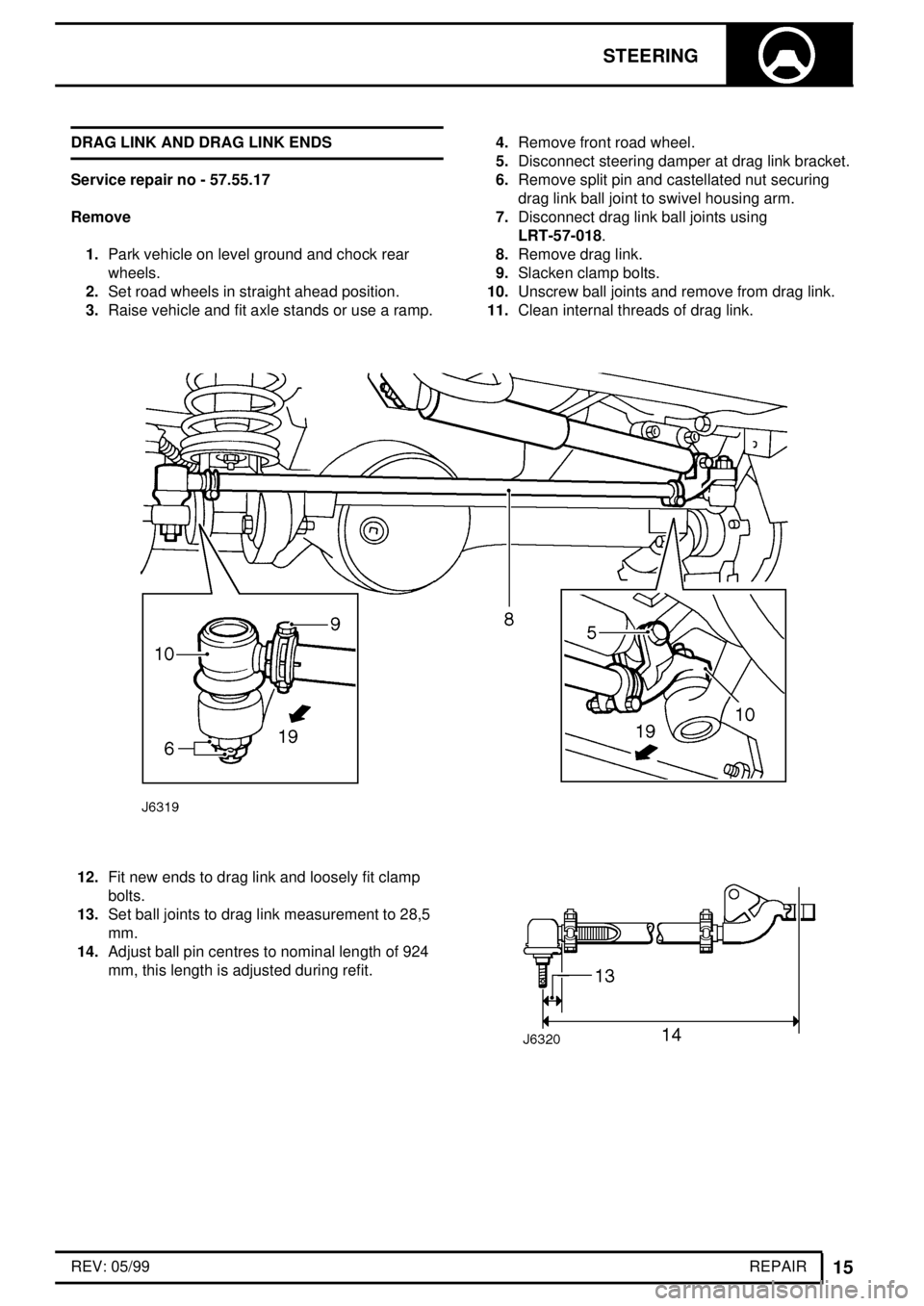

REPAIR REV: 05/99 DRAG LINK AND DRAG LINK ENDS

Service repair no - 57.55.17

Remove

1.Park vehicle on level ground and chock rear

wheels.

2.Set road wheels in straight ahead position.

3.Raise vehicle and fit axle stands or use a ramp.4.Remove front road wheel.

5.Disconnect steering damper at drag link bracket.

6.Remove split pin and castellated nut securing

drag link ball joint to swivel housing arm.

7.Disconnect drag link ball joints using

LRT-57-018.

8.Remove drag link.

9.Slacken clamp bolts.

10.Unscrew ball joints and remove from drag link.

11.Clean internal threads of drag link.

12.Fit new ends to drag link and loosely fit clamp

bolts.

13.Set ball joints to drag link measurement to 28,5

mm.

14.Adjust ball pin centres to nominal length of 924

mm, this length is adjusted during refit.

Page 253 of 455

57STEERING

16

REPAIR 15.Centralise steering box

See Adjustment,

Centralise steering box

.

16.Align steering wheel, if necessary.

CAUTION: A drag link that is damaged or

bent must be renewed. DO NOT attempt

repair.

17.Fit drag link to swivel housing arms and tighten

nuts to

40 Nm (30 lbf/ft).Fit new split pins.

18.Ensure full steering travel is obtained between

lock stops

See Adjustment, Steering lock

stops

. Adjust drag link length to suit.

19.Tap ball joints in direction shown so both pins

are in same angular plane.

20.Tighten clamp bolts to

14 Nm (10 lbf/ft).

21.Refit road wheel and remove axle stands or

vehicle from ramp.

22.Road test vehicle.

23.If driving straight ahead and steering wheel is

offset by 0°±5°in either direction, correct by

adjusting drag link length.

WARNING: To correct steering wheel

deviations greater than±5°remove and

reposition steering wheel

See Steering

wheel

.

Page 265 of 455

FRONT SUSPENSION

1

REPAIR SELF LOCKING NUTS

WARNING: Where self locking nuts are

removed, they must be replaced with new

nuts of same specification.

PANHARD ROD

Service repair no - 60.10.07.

Remove

1.Remove fixings at mounting arm.

2.Remove fixings at axle bracket.

3.Remove panhard rod.

4.Using a suitable length of steel tubing, press out

flexible bushes. Ensure tubing locates on outer

edge of bush and not on rubber inner.

Refit

5.Fit replacement bushes.

CAUTION: Apply pressure to outer edge of

bush, and not rubber inner.

6.Fit panhard rod to axle bracket and mounting

arm. Tighten fixings to

88 Nm (65 lbf/ft).

RADIUS ARM

Service repair no - 60.10.16.

Remove

1.Loosen road wheel retaining nuts.

2.Raise front of vehicle. Support chassis on stands

and remove wheel.

3.Support front axle weight with jack.

4.Remove radius arm to chassis side member

fixings.

5.Disconnect track rod at ball joint.

Page 266 of 455

60FRONT SUSPENSION

2

REPAIRREV: 05/99

6.Remove fixings, radius arm to axle.

7.Lower radius arm front end to clear axle and

remove from vehicle.

8.Using suitable length of steel tubing, press out

flexible bushes.

Refit

9.Press in replacement bushes.

CAUTION: When pressing in new bushes

press on outer edge of bush and not

rubber inner.

10.Fit radius arm to axle mounting.

11.Fit track rod at ball joint.

12.Fit radius arm to chassis. Tighten bolts to

176

Nm (130 lbf/ft).

13.Fully tighten radius arm to axle fixings to197 Nm

(145 lbf/ft).

14.Fit road wheel, remove chassis stands and jack.

Tighten wheel nuts to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

FRONT SHOCK ABSORBER

Service repair no - 60.30.02.

Remove

1.Loosen road wheel retaining nuts.

2.Support chassis on stands and remove road

wheel.

3.Support axle weight with jack.

4.Remove shock absorber lower fixing and

withdraw cupwasher, rubber bush and seating

washer.

5.Remove four shock absorber bracket fixings.

6.Withdraw shock absorber and bracket assembly.

7.Withdraw lower seating washer, rubber bush and

cupwasher.

8.Remove fixings, shock absorber to mounting

bracket.

9.Withdraw mounting bracket.

10.Lift off top seating washer, rubber bush and

cupwasher.

Page 324 of 455

CHASSIS AND BODY

3

REPAIR

Refit

7.Remove any trim fasteners held in door panel.

Refit or insert new clips to trim panel.

8.Ensure that anti-vibration pads are in position

and offer-up trim casing to door. Align fasteners

with holes in door and firmly push trim into

position.

9.Fit bezels to locking button and remote control

lever.

10.Fit single screw behind remote control lever.

11.Fit door pull and secure with 2 screws and

finisher caps.

12.Fit window regulator handle and retain with

single screw and finisher.WINDOW REGULATOR - REAR SIDE DOOR

Service repair no - 76.31.45

Remove

1.Remove door trim casing

See Door trim casing

.

2.Remove plastic sheet.

3.Temporarily fit handle, wind window up to its

fullest extent and support glass with a length of

timber, to prevent it falling when removing

regulator.

4.Remove 4 screws retaining regulator to

mounting panel and withdraw regulator whilst

sliding lifting arm button from lifting channel. To

assist this operation, remove timber and lower

glass.

Page 331 of 455

76CHASSIS AND BODY

10

REPAIR SILL LOCKING BUTTON - FRONT DOOR

Service repair no - 76.37.29

Remove

1.Remove door trim casing

See Door trim

casing

.

2.Peel back sufficient of plastic sheet to expose

mechanism.

3.Release spring clip and disconnect operating rod

from latch mechanism.

4.Remove 2 screws and withdraw locking button

assembly.

Refit

5.Secure locking button assembly to door with 2

screws.

6.Connect operating rod to latch mechanism and

secure with spring clip.

7.Re-seal plastic sheet and fit door trim casing

See Door trim casing.WINDOW REGULATOR - FRONT DOOR

Service repair no - 76.31.45

Remove

1.Remove door trim casing

See Door trim casing

.

2.Remove plastic sheet.

3.Temporarily fit handle, position window half open

and support with a length of timber.

4.Remove 2 lower screws securing mounting

panel to door and slacken 3 upper screws.

5.Remove 4 screws retaining window regulator to

mounting panel and slide operating arms from

channels attached to glass and mounting panel

and remove regulator.

Refit

6.Insert regulator operating arms into channels.

7.Fit and tighten mounting panel lower screws and

tighten upper screws.

8.Position holes in regulator to line-up with holes in

mounting panel and secure with 4 screws.

9.Temporarily fit regulator handle and check that

glass can be raised and lowered without tight

spots.

10.Secure plastic sheet.

11.Fit door trim casing

See Door trim casing.

Page 335 of 455

76CHASSIS AND BODY

14

REPAIR DOOR GLASS - FRONT DOOR

Service repair no - 76.31.01

Remove

1.Remove mounting panel

See Mounting panel

- front door

.

2.Remove window regulator.

3.Push glass up to top of its travel and support

with a suitable length of timber.

4.Remove 2 self tapping screws securing window

glass runner on latch side of door and single

screw from hinge side.

5.Taking care not to damage paint, prise exterior

waist weather strip from door.

6.Remove timber support and lower glass to

bottom of door.

7.Ease runner from glass at hinge side of door, lift

glass over bottom edge of door and withdraw.