LAND ROVER DEFENDER 1996 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 301 of 455

70BRAKES

2

OVERHAUL MASTER CYLINDER

Service repair no - 70.30.09

Before starting overhaul procedure refer to general

brake service practice

See Repair, General brake

service practice

.

Dismantling master cylinder

1.Disconnect battery and remove master cylinder

from servo

See Repair, Master cylinder.

2.Before commencing overhaul procedure

thoroughly clean master cylinder and inspect

outer surfaces for damage and condition, renew

complete assembly if necessary.

3.The reservoir is a push fit in master cylinder and

secured by seals. Carefully ease reservoir from

master cylinder by rolling it from seals as

illustrated.

4.Using soft jaws, one either side of master

cylinder flange and clamp flange in a suitable

vice. Remove water ingress 'O' ring seal from

master cylinder to servo flange and discard.

5.Hold outside of transfer housing with a suitable

pair of grips, carefully pull, while working pliers in

a backwards and forwards rocking motion to

ease housing off master cylinder, discard

housing and vacuum seal.

6.Withdraw 2 reservoir seals from master cylinder

and note their positions in inlet ports for

reassembly. Discard both seals.

7.Remove retaining ring and 'O' ring seal from

machined outer surface of master cylinder,

discard both seal and retaining ring.

Page 302 of 455

BRAKES

3

OVERHAUL

8.Remove guide ring from mouth of master

cylinder which supports primary plunger

assembly and place to one side, this component

is not part of master cylinder service kit and is to

be refitted on assembly of unit.

9.Pull primary plunger assembly out of master

cylinder.

NOTE: The primary plunger assembly

cannot be broken down any further and is

serviced as a complete unit. Discard

assembly.

10.The secondary plunger assembly will remain at

bottom of master cylinder bore, plunger can be

easily expelled by tapping assembly on a piece

of timber until plunger appears at cylinder mouth,

carefully pull plunger from master cylinder.

11.If swirl tube was not expelled at same time as

secondary plunger, repeat above operation to

expel it from bottom of master cylinder bore and

discard.12.Clean all parts with Girling cleaning fluid or

unused brake fluid and place cleaned parts on to

a clean sheet of paper. Inspect cylinder bore and

plungers for signs of corrosion, ridges and score

marks. Provided working surfaces are in perfect

condition, new seals from a Girling Service

repair kit may be used.

Renewing secondary plunger seals

A.Springs

B.Seal retainer

C.Recuperating seal (primary cup)

D.Washer

E.'L' seal

13.Remove components above from secondary

plunger and discard:

NOTE: A small screwdriver with end

rounded and polished is required to

remove 'L' seal. DO NOT damage

secondary plunger.

14.Coat new seals in unused brake fluid and firstly

fit 'L' seal to plunger.

15.Fit washer followed by recuperating seal. Fit seal

retainer and springs, ensure springs are

correctly seated.

Page 303 of 455

70BRAKES

4

OVERHAUL Assembling master cylinder

CAUTION: It is important that the following

instructions are carried out precisely,

otherwise damage could be caused to new

seals when inserting plungers into cylinder bore.

Generous amounts of new brake fluid should be

used to lubricate parts during assembly.

NOTE: Thoroughly check that no debris is

lodged in fluid passageways and drillings.

If debris is found, carefully remove,

re-clean cylinder and re-check.

16.Fit new swirl tube to bottom of cylinder bore.

17.Lubricate secondary plunger and cylinder bore.

Offer plunger assembly to cylinder until

recuperation seal is resting centrally in mouth of

bore. Gently introduce plunger with a circular

rocking motion, as illustrated. Ensuring that seal

does not become trapped, ease seal into bore

and slowly push plunger down bore in one

continuous movement.

18.Fit primary plunger assembly using same

method as for secondary plunger, push plunger

down bore.

19.Fit original guide ring to support primary plunger.

20.Coat a new 'O' ring with brake fluid and fit to its

respective groove on outer location surface of

master cylinder.

CAUTION: 'O' ring should not be rolled

down outer location surface of master

cylinder but should be slightly stretched

and eased down cylinder and into its groove. Do

not over stretch seal.21.Fit a new retaining ring on outer surface of

master cylinder ensuring that serrations of ring

are facing mounting flange.

22.Fit two new reservoir seals in their respective

ports.

23.Fit a new vacuum seal to either primary plunger

or to bottom of transfer housing bore, open face

of seal towards primary plunger guide ring.

24.Lubricate vacuum seal with brake fluid, fit

transfer housing to master cylinder, push

housing fully up to cylinder mounting flange. Do

not adjust transfer housing after fitting.

25.Lubricate a new water ingress seal with brake

fluid, slightly stretch seal and ease it down

housing until seal is in correct position between

housing and flange.

26.Roll reservoir into top of master cylinder,

reversing procedure described in instruction 3.

27.Fit master cylinder to servo

See Repair,

Master cylinder

.

28.Reconnect battery, and road test vehicle.

Page 304 of 455

WHEELS AND TYRES

1

DESCRIPTION AND OPERATION TYPES OF WHEEL RIMS AND TYRES

Description

Dependent on specification and model type, the

vehicle is equipped with pressed steel or alloy wheel

rims, both using tubeless radial ply tyres.

Tyre codes

The text, codes and numbers moulded into the tyre

wall vary between tyre manufacturers, however most

tyres are marked with the information shown in the

illustrated example.

NOTE: The illustration is an example of the

type of markings moulded into tyres and is

for guidance only. For specific tyre

specifications

See GENERAL SPECIFICATION

DATA, Information, Tyre size and pressures

.1.Type of tyre construction -Radial Ply

2.Load index -104

3.Speed symbol -SorT

4.USA Tyre quality grading -Tread wear 160

Traction A temperature B

5.Tread wear indicators moulded into tread pattern

are located at intervals around the tyre and

marked by a code -E66 103S6

6.Tyres with 'Mud Snow' type tread pattern are

marked -M&S

7.Tyre reinforcing mark -Reinforced

8.USA Load and pressure secification -

(900Kg(1984LBS) at 340KA (50PSI) MACS

PRESS

9.Tyre size -205 16 ot 235/70 R16

10.Type of tyre -TUBELESS

11.Country of manufacture -MADE IN GREAT

BRITAIN

12.USA Compliance symbol and identification -

DOT AB7C DOFF 267

13.European type approval identification -E11

01234

14.Tyre construction -SIDE WALL 2 PLIES

RAYON. TREAD 2 RAYON 2 STEEL

15.Manufacturers brand name/type -TRACTION

PLUS mzx M

Page 305 of 455

WHEELS AND TYRES

1

FAULT DIAGNOSIS TYRE WEAR CHART

FAULT CAUSE REMEDY

Rapid wear at Tyres under-inflated Inflate to correct pressure

shoulders Worn suspension components Replace worn components

i.e. ball joints, panhard

rod bushes, steering damper

Excessive cornering speeds

Rapid wear at

centreTyres over-inflated Inflate to correct pressure

of tread

Wear at one

shoulderTrack out of adjustment Adjust track to correct figure

Bent panhard rod Check and replace worn or damaged

components

Bald spots or tyre Wheel out of balance Balance wheel and tyre

cupping assembly

Excessive radial runout Check runout and replace tyre

if necessary

Shock absorber worn Replace shock absorber

Excessive braking

Tyre scalloped Track out of adjustment Adjust toe to correct figure

Worn suspension components Replace tyre as necessary

Excessive cornering speeds

CAUTION: This diagnosis chart is for general guidance only and does not necessarily include

every cause of abnormal tyre wear.

Page 306 of 455

74WHEELS AND TYRES

2

FAULT DIAGNOSIS FAULT - SYMPTOMS

Vibration through steering wheel

1.Check tyre pressures

See Repair, Tyre

Pressures

.

2.Check condition of tyres

See Tyre Wear Chart.

3.Check front wheel alignment

See STEERING,

Adjustment, Front Wheel Alignment

.

4.Check wheel balance

See Repair, Wheel

Balancing

.

NOTE: In the event that any apparent

vibration is not eliminated at this stage

See PROPELLER SHAFTS, Fault

diagnosis, Vibration Harshness

.

NOTE: In the event that any apparent

vibration is not eliminated at this stage, go

to steering Fault Diagnosis, Fault -

Symptom (Steering vibration, road wheel

shimmy/wobble)

See STEERING, Fault diagnosis,

Steering Faults

.

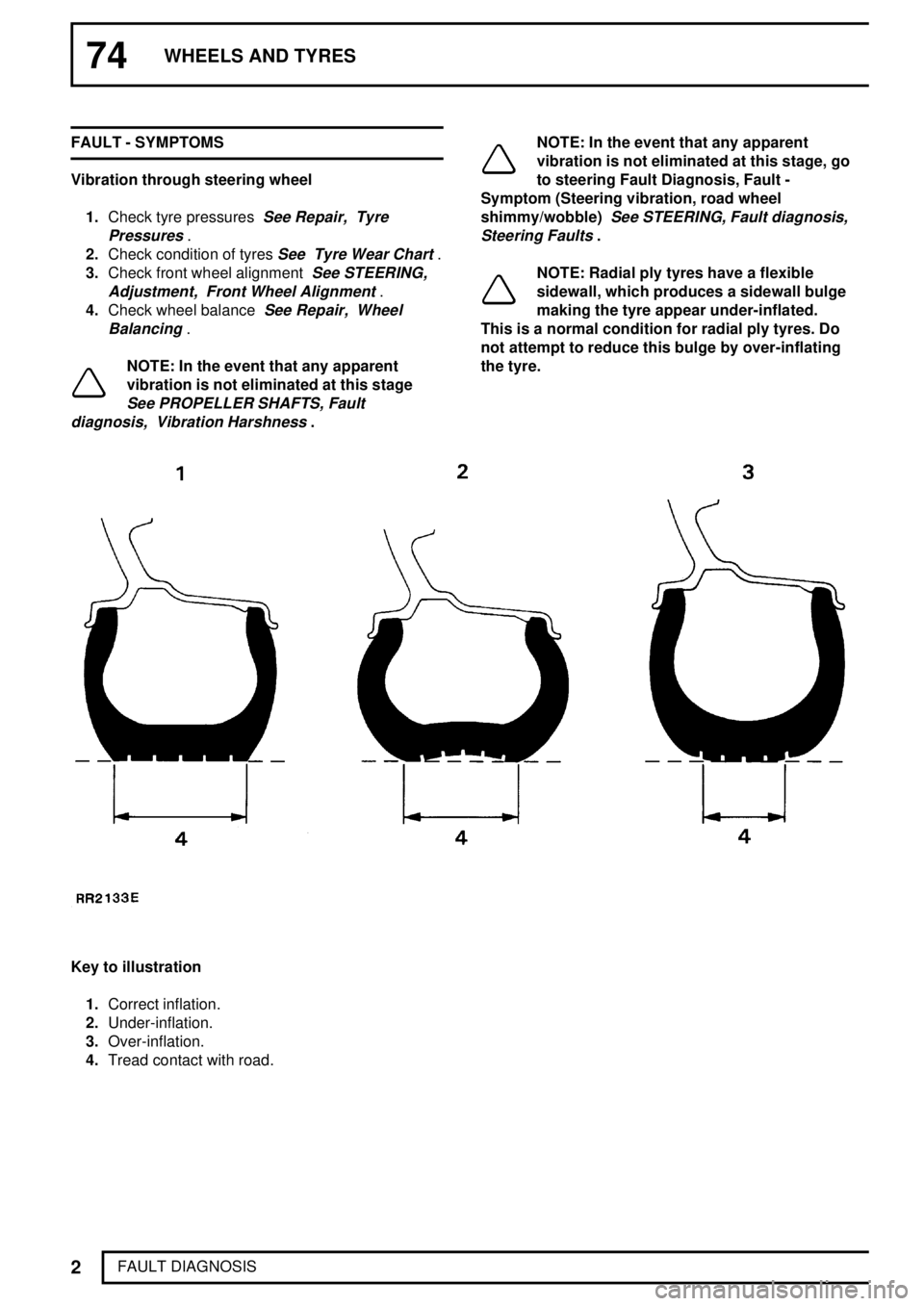

NOTE: Radial ply tyres have a flexible

sidewall, which produces a sidewall bulge

making the tyre appear under-inflated.

This is a normal condition for radial ply tyres. Do

not attempt to reduce this bulge by over-inflating

the tyre.

Key to illustration

1.Correct inflation.

2.Under-inflation.

3.Over-inflation.

4.Tread contact with road.

Page 307 of 455

WHEELS AND TYRES

1

REPAIR REV: 05/99 GENERAL INFORMATION

WARNING: This is a multi-purpose vehicle

with wheels and tyres designed for both

on and off road usage. Only use wheels

and tyres specified for use on the vehicle.

The vehicle is equipped with tubeless 'S','T' or 'H'

rated radial ply tyres as standard equipment. The

tyres are of European metric size and must not be

confused with the "P" size metric tyres available in

North America.

Vehicle wheel sets, including spare wheel, must be

fitted with the same make and type of tyre to the

correct specification and tread pattern. Under no

circumstances must cross-ply or bias-belted tyres be

used.

For tyre specification and pressures

See GENERAL

SPECIFICATION DATA, Information, Wheels and

Tyres

.

Steel wheels

Tubeless tyres are mounted on 7.0 inch wide by 16

inch diameter steel wheels.

Alloy Wheels

Tubeless tyres are mounted on 7.0 inch wide by 16

inch diameter cast aluminium alloy wheels. The

surface has a paint finish covered with a clear

polyurethane lacquer. Care must be taken when

handling the wheel to avoid scratching or chipping the

finish.

The alloy wheel rim is of the asymmetric hump

type incorporating a safety hump to improve

location of the tyre bead in its seat. If difficulty is

experienced in fitting tyres to this type of rim

See

Tyre Fitting

.

WARNING: DO NOT fit an inner tube to an

alloy wheel.TYRE INSPECTION

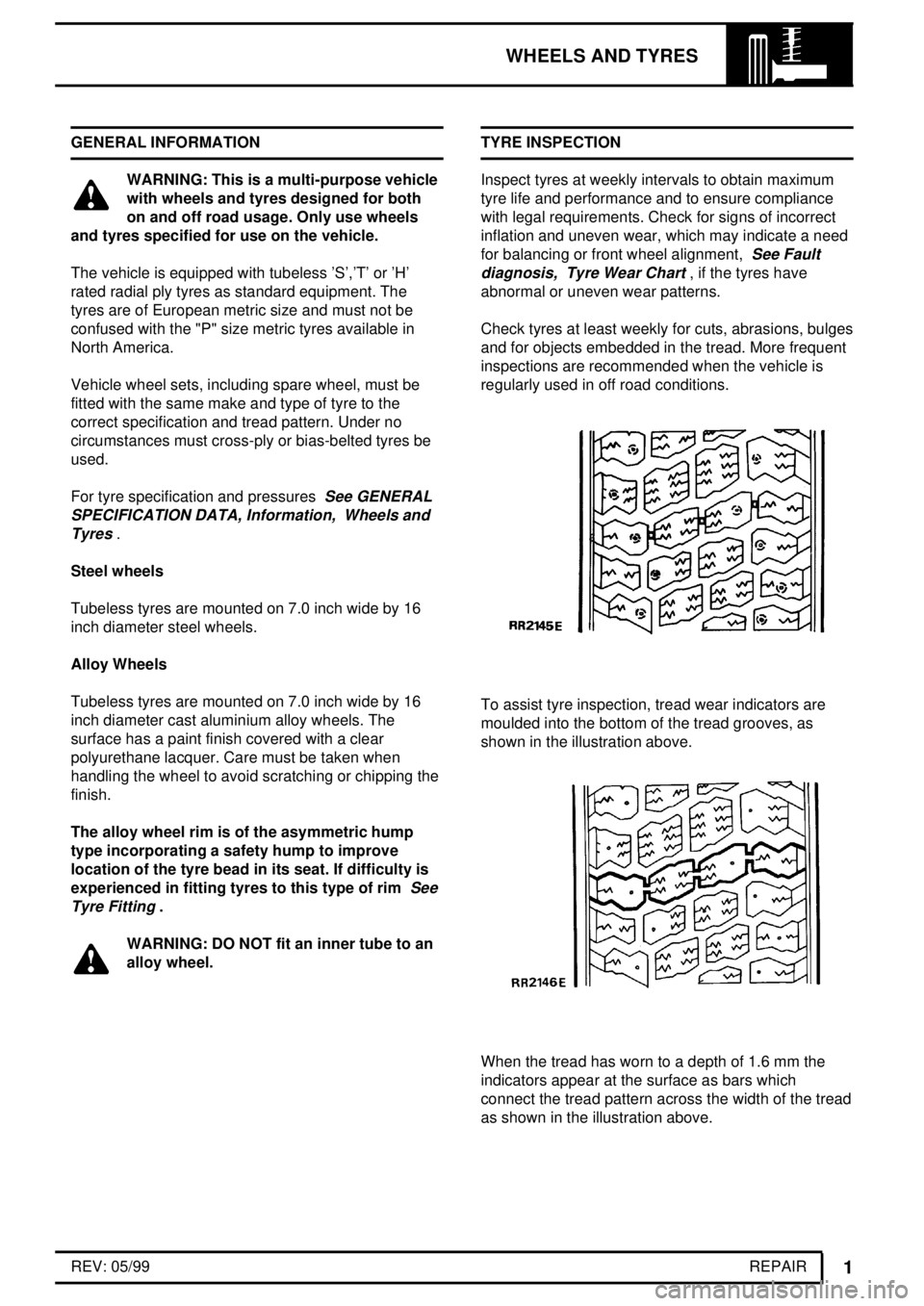

Inspect tyres at weekly intervals to obtain maximum

tyre life and performance and to ensure compliance

with legal requirements. Check for signs of incorrect

inflation and uneven wear, which may indicate a need

for balancing or front wheel alignment,

See Fault

diagnosis, Tyre Wear Chart

, if the tyres have

abnormal or uneven wear patterns.

Check tyres at least weekly for cuts, abrasions, bulges

and for objects embedded in the tread. More frequent

inspections are recommended when the vehicle is

regularly used in off road conditions.

To assist tyre inspection, tread wear indicators are

moulded into the bottom of the tread grooves, as

shown in the illustration above.

When the tread has worn to a depth of 1.6 mm the

indicators appear at the surface as bars which

connect the tread pattern across the width of the tread

as shown in the illustration above.

Page 308 of 455

74WHEELS AND TYRES

2

REPAIRREV: 05/99 When the indicators appear in two or more adjacent

grooves, at three locations around the tyre, a new tyre

must be fitted.

NOTE: DO NOT attempt to interchange

tyres, e.g. from front to rear, as tyre wear

produces characteristic patterns

depending on their position. If tyre position is

changed after wear has occured, the performance

of the tyre will be adversely affected.

NOTE: Territorial vehicle regulations

governing tyre wear MUST be adhered to.

WHEELS INSPECTION

Regularly check the condition of the wheels. Replace

any wheel that is bent, cracked, dented or has

excessive runout.

VALVES INSPECTION

Check condition of inflation valve. Replace any valve

that is worn, cracked, loose, or leaking air.TYRE PRESSURES

Maximum tyre life and performance will be

obtained only if tyres are maintained at the correct

pressures.

Tyre pressures must be checked at least once a week

and preferably daily, if the vehicle is used off road.

The tyre inflation pressure is calculated to give the

vehicle satisfactory ride and steering characteristics

without compromising tyre tread life. For

recommended tyre pressures in all conditions

See

GENERAL SPECIFICATION DATA, Information,

Wheels and Tyres

.

Always check tyre inflation pressures using an

accurate gauge and inflate tyres to the

recommended pressures only.

Check and adjust tyre pressuresONLYwhen the

tyres are cold, vehicle parked for three hours or more,

or driven for less than 3.2 km (2 miles) at speeds

below 64 km/h (40 mph). Do not reduce inflation

pressures if the tyres are hot or the vehicle has been

driven for more than 3.2 km (2 miles) at speeds over

64 km/h (40 mph), as pressures can increase by 0.41

bars (6 lb/in

2) over cold inflation pressures.

CheckALLtyre pressures including the spare. Refit

the valve caps as they form a positive seal and keep

dust out of the valve.

Page 309 of 455

WHEELS AND TYRES

3

REPAIR WHEEL BALANCING

CAUTION: It is essential that all wheel

balancing is carried out off the vehicle.

The use of on the vehicle balancing could

cause component damage or personal injury and

MUST NOT be attempted.

NOTE: Before attempting to balance a

wheel and tyre assembly clean all mud and

dirt deposits from both inside and outside

rims and remove existing balance weights.

Remove stones from the tyre tread in order to avoid

operator injury during dynamic balancing and to obtain

the correct balance.

Inspect tyres for damage and correct tyre pressures

and balance according to the equipment

manufacturer's instructions.

Steel wheels

Clean area of wheel rim and attach balance weights in

position shown.

Alloy wheels

Clean area of wheel rim and attach adhesive balance

weights in position shown. Cut through rear face of

weight strip to detach required weights.

CAUTION: Use only correct adhesive

balance weights to avoid damage to

aluminium wheel rim. DO NOT attempt to

use a steel wheel weight on an aluminium wheel.

Page 310 of 455

74WHEELS AND TYRES

4

REPAIR Static balance

Wheel tramp

A- Heavy spot.

B- Add balance weights here.

C- Centre line of spindle.

Static balance is the equal distribution of weight

around the wheel. A statically unbalanced wheel will

cause a bouncing action called wheel tramp. This

condition will eventually cause uneven tyre wear.Dynamic balance

Wheel shimmyA- Heavy spot.

B- Add balance weights here.

C- Centre line of spindle.

Dynamic balance is the equal distribution of weight on

each side of the centre line so that when the wheel

spins there is no tendency for side to side movement.

A dynamically unbalanced wheel will cause wheel

shimmy.