run flat LAND ROVER DEFENDER 1996 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 11 of 455

01INTRODUCTION

6

INFORMATION 3.Position an axle stand under right hand axle

tube, carefully lower jack until axle sits securely

on both axle stands, remove trolley jack.

4.Before commencing work on underside of

vehicle re-check security of vehicle on stands.

5.Reverse procedure when removing vehicle from

stands.

Raise rear of vehicle

1.Position cup of hydraulic arm under differential

casing.

2.Raise vehicle to enable axle stands to be

installed under left and right hand axle tubes.

3.Lower jack until axle sits securely on axle

stands, remove trolley jack.

4.Before commencing work on underside of

vehicle re-check security of vehicle on stands.

5.Reverse procedure when removing vehicle from

stands.

HYDRAULIC VEHICLE RAMP (FOUR POST)

Use only a 'drive on' type ramp which supports vehicle

on its road wheels. If a 'wheel-free' condition is

required, use a 'drive on' ramp incorporating a

'wheel-free' system providing support beneath axle

casings. Alternatively, place vehicle on a firm, flat floor

and support on axle stands.

TWO POST VEHICLE RAMPS

The manufacturer of LAND ROVER VEHICLES

DOES NOT recommend using 'Two Post' ramps

that employ four adjustable support arms. These

are NOT considered safe for Land Rover vehicles.

If vehicle is installed on a Two Post ramp

responsibility for safety of vehicle and personnel

performing service operations is in the hands of

the Service Provider.DYNAMOMETER TESTING

The front and rear axles cannot be driven

independently.

WARNING: DO NOT attempt to drive

individual wheels with vehicle supported

on floor jacks or stands.

Four wheel dynamometers

Provided that front and rear dynamometer rollers are

rotating at identical speeds and that normal workshop

safety standards are applied, there is no speed

restriction during testing except any that may apply to

the tyres.

Two wheel dynamometers

IMPORTANT: Use a four wheel dynamometer for

brake testing if possible.

If brake testing on a single axle rig is necessary it

must be carried out with propeller shaft to rear axle

removed, AND neutral selected in BOTH main

gearbox and transfer gearbox. When checking brakes,

run engine at idle speed to maintain servo vacuum.

If checking engine performance, the transfer box must

be in high range and propeller shaft to stationary axle

must be removed.

Page 39 of 455

GENERAL FITTING REMINDERS

7

INFORMATION COTTER PINS

1.Fit new cotter pins throughout when replacing

any unit.

2.Always fit cotter pins where cotter pins were

originally used. Do not substitute spring

washers: there is always a good reason for the

use of a cotter pin.

3.All cotter pins should be fitted as shown unless

otherwise stated.

NUTS

1.When tightening a slotted or castellated nut

never loosen it to insert cotter pin or locking wire

except in those recommended cases where this

forms part of an adjustment. If difficulty is

experienced, alternative washers or nuts should

be selected, or washer thickness reduced.

2.Where self-locking nuts have been removed it is

advisable to replace them with new ones of the

same type.

NOTE: Where bearing pre-load is involved

nuts should be tightened in accordance

with special instructions.

LOCKING WIRE

1.Fit new locking wire of the correct type for all

assemblies incorporating it.

2.Arrange wire so that its tension tends to tighten

the bolt heads, or nuts, to which it is fitted.SCREW THREADS

1.Both UNF and Metric threads to ISO standards

are used. See below for thread identification.

2.Damaged threads must always be discarded.

Cleaning up threads with a die or tap impairs the

strength and closeness of fit of the threads and

is not recommended.

3.Always ensure that replacement bolts are at

least equal in strength to those replaced.

4.Do not allow oil, grease or jointing compound to

enter blind threaded holes. The hydraulic action

on screwing in the bolt or stud could split the

housing.

5.Always tighten a nut or bolt to the recommended

torque value. Damaged or corroded threads can

affect the torque reading.

6.To check or re-tighten a bolt or screw to a

specified torque value first loosen a quarter of a

turn, then re-tighten to the correct value.

7.Oil thread lightly before tightening to ensure a

free running thread, except in the case of

threads treated with sealant/lubricant, and

self-locking nuts.

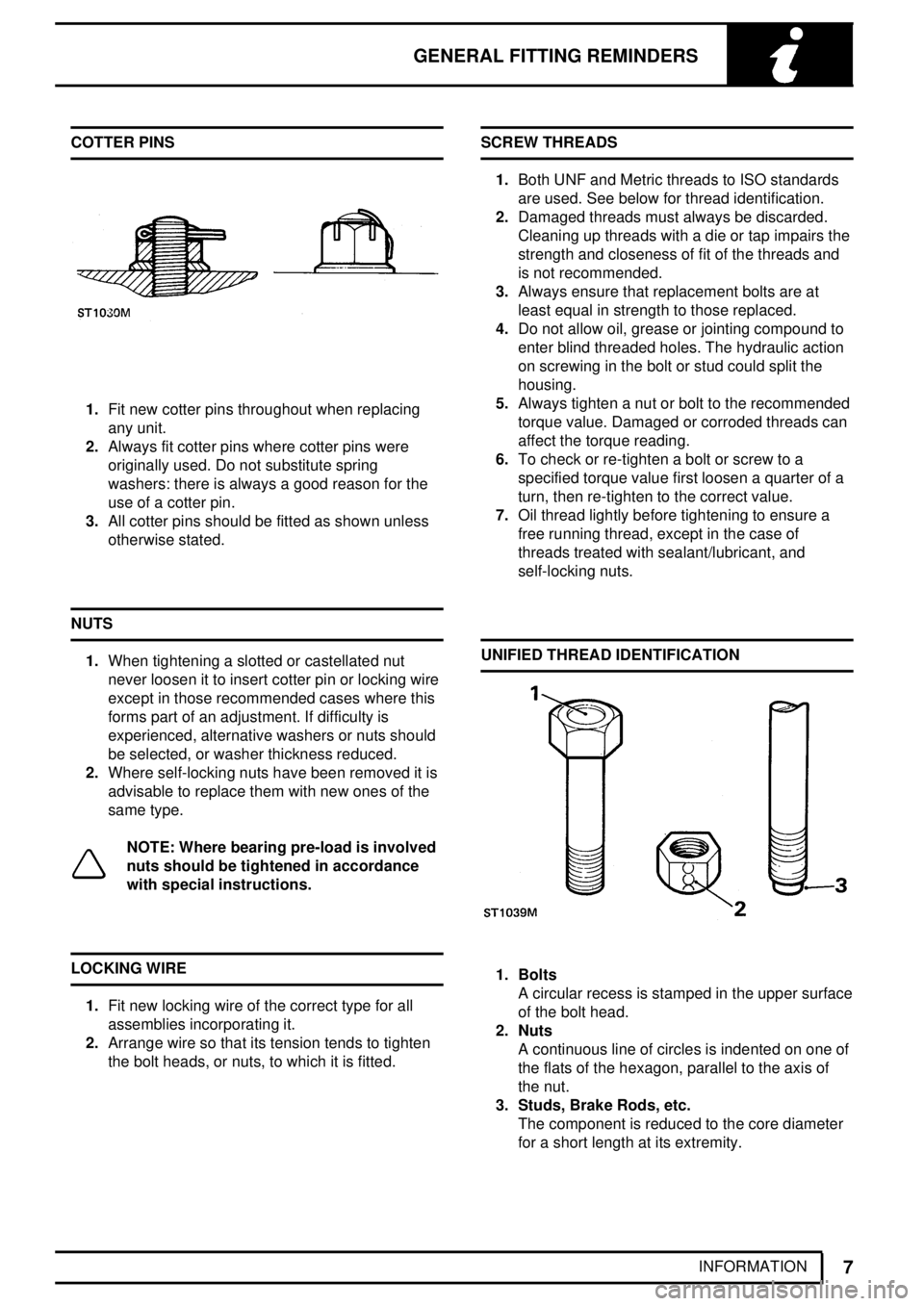

UNIFIED THREAD IDENTIFICATION

1. Bolts

A circular recess is stamped in the upper surface

of the bolt head.

2. Nuts

A continuous line of circles is indented on one of

the flats of the hexagon, parallel to the axis of

the nut.

3. Studs, Brake Rods, etc.

The component is reduced to the core diameter

for a short length at its extremity.

Page 232 of 455

57STEERING

10

FAULT DIAGNOSISREV: 05/99 VISUAL AND SAFETY CHECKS

WARNING: Before taking vehicle out on

the public highway for road test, it is

important that the following basic visual

checks are carried out to ensure that the vehicle

complies with legal requirements.

Tyres and wheel rims

1.Check and adjust tyre pressures

See

GENERAL SPECIFICATION DATA,

Information, Tyre Pressures

.

Note that this information refers to standard tyres

fitted as original equipment.

2.Check condition of tyres. Inspect for signs of

uneven wear, damage and feathering. Check

tread depth.

3.Ensure that the tyre make, type and general

condition are common across each axle.

4.Check wheel rims for signs of damage and

excessive run out.

5.Carry out road test

See Road Test Procedure

.

ROAD TEST PROCEDURE

General steering/handling problems can usually be

classified into one of the categories listed and ARE

GENERALLY RELATED TO THE AGE, CONDITION

AND USE OF THE VEHICLE.

WARNING: Ensure that all road tests are

conducted by suitably qualified drivers in

a safe and legal manner, and where local

traffic conditions allow.

1.Carry out visual and safety checks

See Visual

and Safety Checks

.

Confirm general nature of complaint with customer,

simulating where possible the conditions under which

the problem occurs. Carry out following road test

procedure to establish the problem.2.Steering load assessment - drive at 16 km/h (10

mph). Put 90°turn input into steering wheel,

check self centering. The self centering should

be equal on each lock but not necessarily return

to exactly straight ahead without assistance from

the driver.

3.Steering assessment - drive at 64 km/h (40 mph)

on a staight FLAT road (no camber), check for

steering veer. The vehicle should follow a

straight path with NO tendency to follow a

curved path. If vehicle veers towards the kerb,

vehicle may be 'camber sensitive'. A small

amount of veer in direction of camber is

acceptable.

4.Directional stability assessment - drive at 112

km/h (70 mph) or maximum legal speed on a

straight flat road. Carry out a normal lane

change. Vehicle should quickly settle into a new

straight path.

5.Braking assessment (medium effort) - drive at 96

km/h (60 mph) on a straight flat road. Apply

steady medium braking effort, noting any

tendency to veer. Carry out brake test three

times, if a veer is consistently noted carry out a

braking efficiency test on a rolling road.

6.Braking assessment (full effort) - drive at 96

km/h (60 mph) on a straight flat road. Apply full

braking effort, noting any tendency to veer. Carry

out brake test three times, if a veer is

consistently noted carry out a braking efficiency

test on a rolling road.

If the symptom described by the customer is stiff

steering or steering niggle, carry out stiff steering

procedure

See Stiff Steering Checklist.

If not, proceed with basic checks and adjustments

See Visual Check and Basic Adjustments.

Page 305 of 455

WHEELS AND TYRES

1

FAULT DIAGNOSIS TYRE WEAR CHART

FAULT CAUSE REMEDY

Rapid wear at Tyres under-inflated Inflate to correct pressure

shoulders Worn suspension components Replace worn components

i.e. ball joints, panhard

rod bushes, steering damper

Excessive cornering speeds

Rapid wear at

centreTyres over-inflated Inflate to correct pressure

of tread

Wear at one

shoulderTrack out of adjustment Adjust track to correct figure

Bent panhard rod Check and replace worn or damaged

components

Bald spots or tyre Wheel out of balance Balance wheel and tyre

cupping assembly

Excessive radial runout Check runout and replace tyre

if necessary

Shock absorber worn Replace shock absorber

Excessive braking

Tyre scalloped Track out of adjustment Adjust toe to correct figure

Worn suspension components Replace tyre as necessary

Excessive cornering speeds

CAUTION: This diagnosis chart is for general guidance only and does not necessarily include

every cause of abnormal tyre wear.

Page 308 of 455

74WHEELS AND TYRES

2

REPAIRREV: 05/99 When the indicators appear in two or more adjacent

grooves, at three locations around the tyre, a new tyre

must be fitted.

NOTE: DO NOT attempt to interchange

tyres, e.g. from front to rear, as tyre wear

produces characteristic patterns

depending on their position. If tyre position is

changed after wear has occured, the performance

of the tyre will be adversely affected.

NOTE: Territorial vehicle regulations

governing tyre wear MUST be adhered to.

WHEELS INSPECTION

Regularly check the condition of the wheels. Replace

any wheel that is bent, cracked, dented or has

excessive runout.

VALVES INSPECTION

Check condition of inflation valve. Replace any valve

that is worn, cracked, loose, or leaking air.TYRE PRESSURES

Maximum tyre life and performance will be

obtained only if tyres are maintained at the correct

pressures.

Tyre pressures must be checked at least once a week

and preferably daily, if the vehicle is used off road.

The tyre inflation pressure is calculated to give the

vehicle satisfactory ride and steering characteristics

without compromising tyre tread life. For

recommended tyre pressures in all conditions

See

GENERAL SPECIFICATION DATA, Information,

Wheels and Tyres

.

Always check tyre inflation pressures using an

accurate gauge and inflate tyres to the

recommended pressures only.

Check and adjust tyre pressuresONLYwhen the

tyres are cold, vehicle parked for three hours or more,

or driven for less than 3.2 km (2 miles) at speeds

below 64 km/h (40 mph). Do not reduce inflation

pressures if the tyres are hot or the vehicle has been

driven for more than 3.2 km (2 miles) at speeds over

64 km/h (40 mph), as pressures can increase by 0.41

bars (6 lb/in

2) over cold inflation pressures.

CheckALLtyre pressures including the spare. Refit

the valve caps as they form a positive seal and keep

dust out of the valve.