light LAND ROVER DEFENDER 1999 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 135 of 667

12ENGINE

10

REPAIR Refit

39.Clean mating faces of cylinder head and cylinder

block.

40.Check cylinder head for warping, across centre

and from corner to corner:

Maximum warp = 0.10 mm (0.004 in)

CAUTION: Cylinder heads may not be

refaced, replace cylinder head assembly if

warping exceeds figure given.

41.Ensure coolant and oil passages are clean.

42.Clean dowel holes and fit new dowels.

43.Fit new cylinder head gasket of the correct

thickness with the word’TOP’uppermost.

44.Using assistance, fit cylinder head and locate on

to dowels.

45.Carefully enter new cylinder head bolts together

with their captive washers,DO NOT DROP.

Lightly tighten bolts.

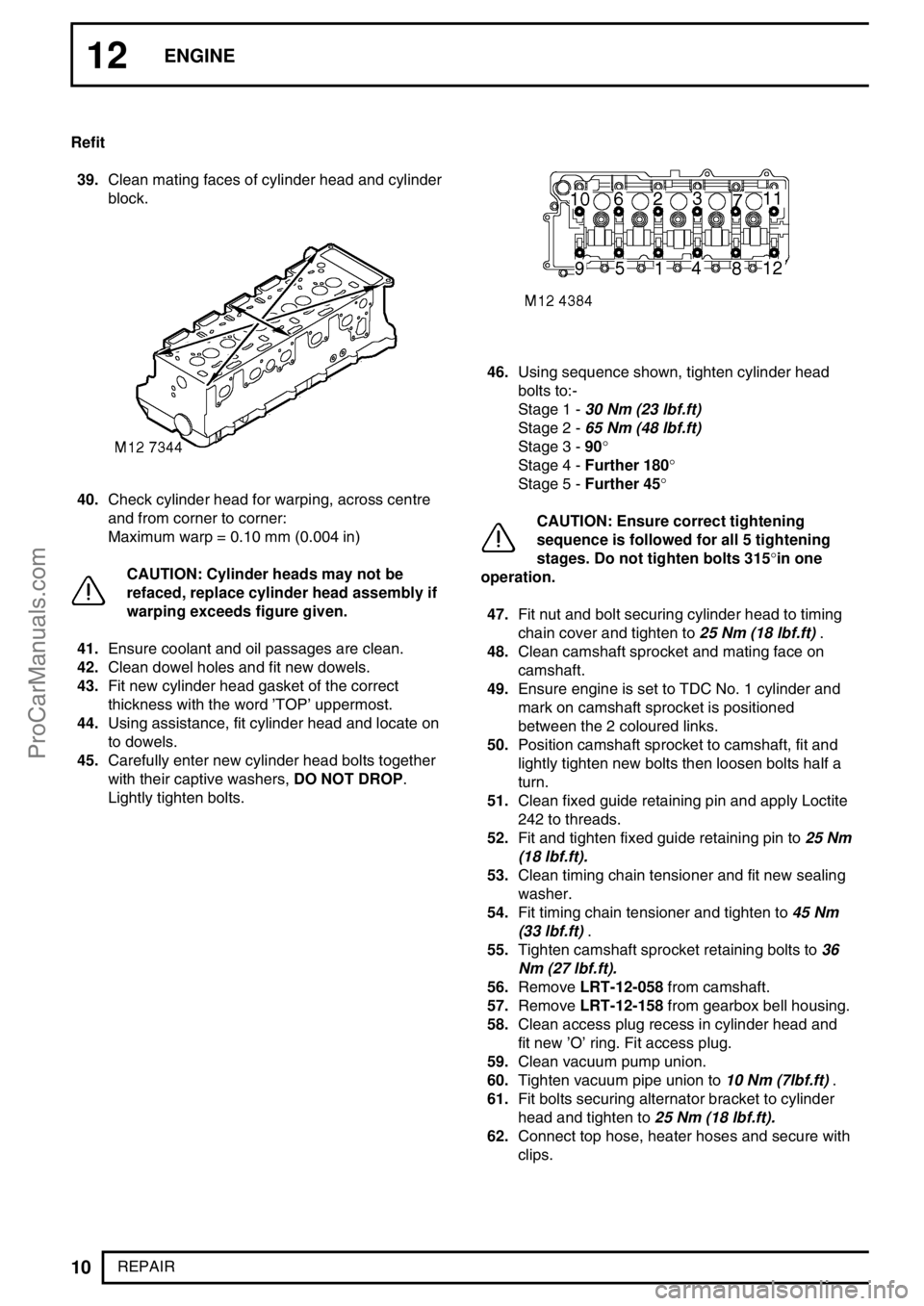

46.Using sequence shown, tighten cylinder head

bolts to:-

Stage 1 -30 Nm (23 lbf.ft)

Stage 2 -65 Nm (48 lbf.ft)

Stage 3 -90°

Stage 4 -Further 180°

Stage 5 -Further 45°

CAUTION: Ensure correct tightening

sequence is followed for all 5 tightening

stages. Do not tighten bolts 315°in one

operation.

47.Fit nut and bolt securing cylinder head to timing

chain cover and tighten to25 Nm (18 lbf.ft).

48.Clean camshaft sprocket and mating face on

camshaft.

49.Ensure engine is set to TDC No. 1 cylinder and

mark on camshaft sprocket is positioned

between the 2 coloured links.

50.Position camshaft sprocket to camshaft, fit and

lightly tighten new bolts then loosen bolts half a

turn.

51.Clean fixed guide retaining pin and apply Loctite

242 to threads.

52.Fit and tighten fixed guide retaining pin to25 Nm

(18 lbf.ft).

53.Clean timing chain tensioner and fit new sealing

washer.

54.Fit timing chain tensioner and tighten to45 Nm

(33 lbf.ft).

55.Tighten camshaft sprocket retaining bolts to36

Nm (27 lbf.ft).

56.RemoveLRT-12-058from camshaft.

57.RemoveLRT-12-158from gearbox bell housing.

58.Clean access plug recess in cylinder head and

fit new’O’ring. Fit access plug.

59.Clean vacuum pump union.

60.Tighten vacuum pipe union to10 Nm (7lbf.ft).

61.Fit bolts securing alternator bracket to cylinder

head and tighten to25 Nm (18 lbf.ft).

62.Connect top hose, heater hoses and secure with

clips.

ProCarManuals.com

Page 152 of 667

ENGINE

27

REPAIR Refit

9.Clean sump and mating faces.

10.Apply a bead of sealant, Part No. STC 3254 to

joint faces of timing chain cover and crankshaft

rear oil seal.

11.Position new sump gasket.

CAUTION: Gasket must be fitted dry.

12.Position sump, fit bolts ensuring they are in their

correct fitted position, lightly tighten bolts.

13.Fit bolts securing sump to gearbox bell housing

and tighten to15 Nm (11 lbf.ft).

14.Using sequence shown, tighten sump bolts to25

Nm (18 lbf.ft).

15.Tighten sump to gearbox bell housing bolts to50

Nm (37 lbf ft).

16.Fit new gasket to centrifuge drain pipe and

tighten bolts to10 Nm (7 lbf.ft).

17.Fit exhaust front pipe.See MANIFOLD AND

EXHAUST SYSTEM, Repair.

18.Refill engine with oil.

19.Reconnect battery negative lead.

20.Refit battery cover.

ProCarManuals.com

Page 164 of 667

ENGINE

5

OVERHAUL Refit

1.Thoroughly clean cylinder block and cylinder

head mating faces.

2.Ensure coolant and oil passageways are clear

and bolt holes are clean and dry.

3.Ensure locating dowel holes in cylinder block are

clean and dry.

4.Fit new plastic locating dowels in cylinder block.

5.Fit new cylinder head gasket of the correct

thickness with the word’TOP’uppermost.

CAUTION: Gasket must be fitted dry.

6.Ensure that camshaft timing pinLRT-12-158is

still in position and using assistance, fit cylinder

head.

7.Carefully enter new cylinder head bolts together

with their captive washers,DO NOT DROP.

Lightly tighten bolts.

CAUTION: Cylinder head bolts are

pre-lubricated and do not require

additional lubrication.

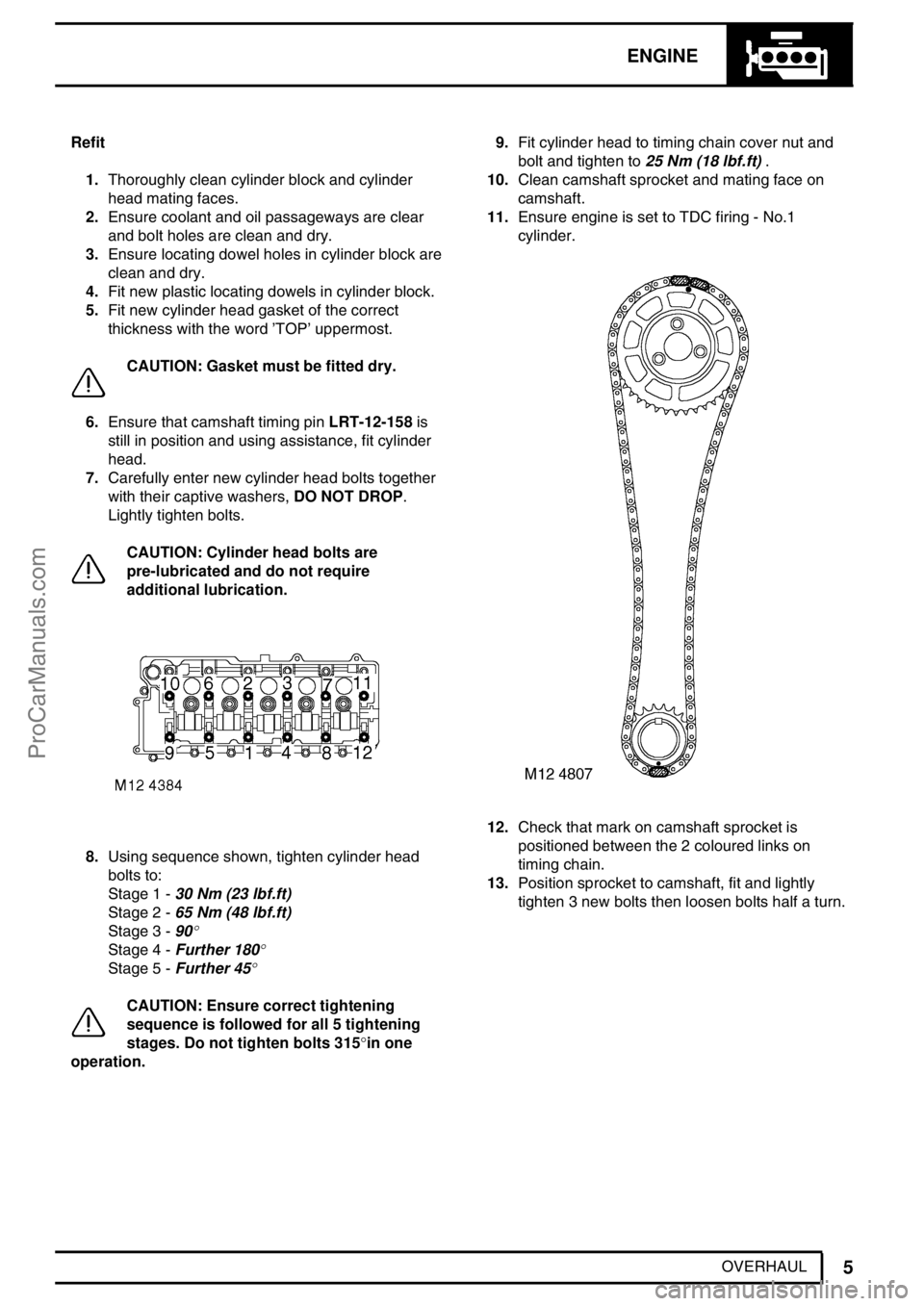

8.Using sequence shown, tighten cylinder head

bolts to:

Stage 1 -30 Nm (23 lbf.ft)

Stage 2 -65 Nm (48 lbf.ft)

Stage 3 -90

°

Stage 4 -Further 180°

Stage 5 -Further 45°

CAUTION: Ensure correct tightening

sequence is followed for all 5 tightening

stages. Do not tighten bolts 315°in one

operation.9.Fit cylinder head to timing chain cover nut and

bolt and tighten to25 Nm (18 lbf.ft).

10.Clean camshaft sprocket and mating face on

camshaft.

11.Ensure engine is set to TDC firing - No.1

cylinder.

12.Check that mark on camshaft sprocket is

positioned between the 2 coloured links on

timing chain.

13.Position sprocket to camshaft, fit and lightly

tighten 3 new bolts then loosen bolts half a turn.

ProCarManuals.com

Page 166 of 667

ENGINE

7

OVERHAUL CYLINDER HEAD GASKET SELECTION

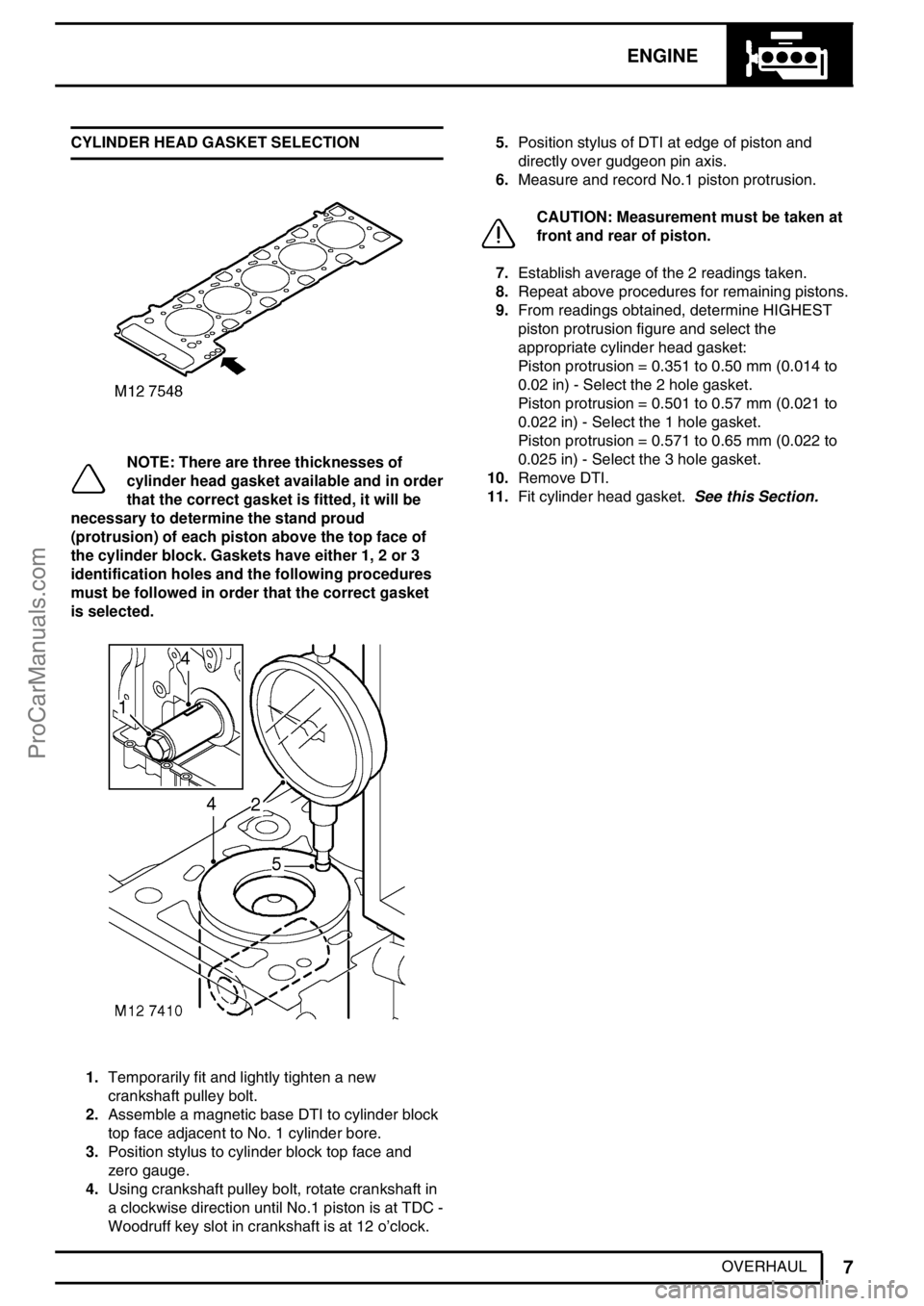

NOTE: There are three thicknesses of

cylinder head gasket available and in order

that the correct gasket is fitted, it will be

necessary to determine the stand proud

(protrusion) of each piston above the top face of

the cylinder block. Gaskets have either 1, 2 or 3

identification holes and the following procedures

must be followed in order that the correct gasket

is selected.

1.Temporarily fit and lightly tighten a new

crankshaft pulley bolt.

2.Assemble a magnetic base DTI to cylinder block

top face adjacent to No. 1 cylinder bore.

3.Position stylus to cylinder block top face and

zero gauge.

4.Using crankshaft pulley bolt, rotate crankshaft in

a clockwise direction until No.1 piston is at TDC -

Woodruff key slot in crankshaft is at 12 o’clock.5.Position stylus of DTI at edge of piston and

directly over gudgeon pin axis.

6.Measure and record No.1 piston protrusion.

CAUTION: Measurement must be taken at

front and rear of piston.

7.Establish average of the 2 readings taken.

8.Repeat above procedures for remaining pistons.

9.From readings obtained, determine HIGHEST

piston protrusion figure and select the

appropriate cylinder head gasket:

Piston protrusion = 0.351 to 0.50 mm (0.014 to

0.02 in) - Select the 2 hole gasket.

Piston protrusion = 0.501 to 0.57 mm (0.021 to

0.022 in) - Select the 1 hole gasket.

Piston protrusion = 0.571 to 0.65 mm (0.022 to

0.025 in) - Select the 3 hole gasket.

10.Remove DTI.

11.Fit cylinder head gasket.See this Section.

ProCarManuals.com

Page 177 of 667

12ENGINE

18

OVERHAUL

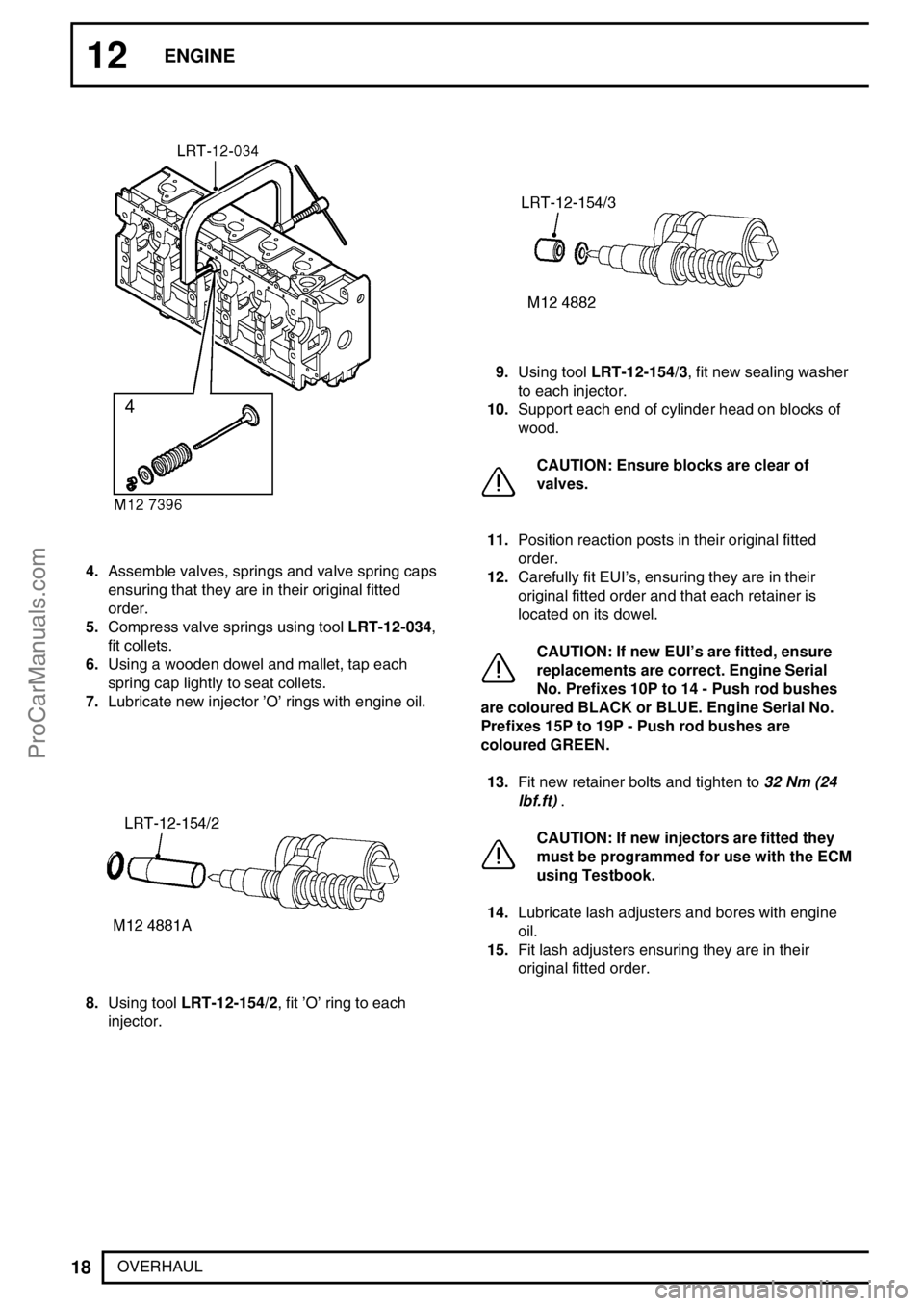

4.Assemble valves, springs and valve spring caps

ensuring that they are in their original fitted

order.

5.Compress valve springs using toolLRT-12-034,

fit collets.

6.Using a wooden dowel and mallet, tap each

spring cap lightly to seat collets.

7.Lubricate new injector’O’rings with engine oil.

8.Using toolLRT-12-154/2, fit’O’ring to each

injector.

9.Using toolLRT-12-154/3, fit new sealing washer

to each injector.

10.Support each end of cylinder head on blocks of

wood.

CAUTION: Ensure blocks are clear of

valves.

11.Position reaction posts in their original fitted

order.

12.Carefully fit EUI’s, ensuring they are in their

original fitted order and that each retainer is

located on its dowel.

CAUTION: If new EUI’s are fitted, ensure

replacements are correct. Engine Serial

No. Prefixes 10P to 14 - Push rod bushes

are coloured BLACK or BLUE. Engine Serial No.

Prefixes 15P to 19P - Push rod bushes are

coloured GREEN.

13.Fit new retainer bolts and tighten to32 Nm (24

lbf.ft).

CAUTION: If new injectors are fitted they

must be programmed for use with the ECM

using Testbook.

14.Lubricate lash adjusters and bores with engine

oil.

15.Fit lash adjusters ensuring they are in their

original fitted order.

ProCarManuals.com

Page 178 of 667

ENGINE

19

OVERHAUL 16.Lubricate finger followers with engine oil.

17.Fit finger followers ensuring they are in their

original fitted order.

18.Lubricate cams and bearing journals on

camshaft, cylinder head and camshaft carrier

with engine oil.

19.Position camshaft in cylinder head with the

timing pin hole in the vertical position.

20.Apply an even film of sealant, Part No. STC

4600 to camshaft carrier face and spread to an

even film using a roller.

CAUTION: Ensure sealant does not block

oilways (arrowed) or contaminate

camshaft bearings. Assembly and bolt

tightening must be completed within 20 minutes

of applying sealant.

21.Fit camshaft carrier ensuring it is correctly

located on dowels.

22.Fit and lightly tighten new camshaft carrier bolts.

23.Using sequence shown, progressively tighten

bolts to25 Nm (18 lbf.ft).

24.Lubricate a new camshaft rear oil seal with

engine oil, fit seal using a suitable mandrel.

25.Position rocker shaft on camshaft carrier,

ensuring rocker shaft is located on dowel.

26.Fit new rocker shaft retaining bolts and working

from the centre outwards, tighten bolts

progressively to32 Nm (24 lbf.ft).27.Lubricate a new’O’ring with engine oil and fit to

injector harness multiplug.

28.Fit injector harness and connect multiplugs.

29.Clean fuel connector block and mating face.

30.Lubricate a new fuel filter’O’ring with engine oil.

31.Fit new fuel filter,’O’ring and gasket.

CAUTION: Gasket must be fitted dry.

32.Fit fuel connector block spacer and gasket (if

fitted).

33.Fit fuel connector block, fit bolts and tighten to

25 Nm (18 lbf.ft).

34.Clean glow plugs.

35.Fit glow plugs to cylinder head and tighten to16

Nm (12 lbf.ft).

36. Engine Serial No. Prefixes 15P to 19P:-

Lubricate new’O’rings with engine oil and fit to

spill return pipe; fit pipe and tighten connectors

to20 Nm (15 lbf.ft).

37.Fit new cylinder head gasket.See this Section.

CAUTION: Ensure that the fuel injector

rockers are adjusted following the

procedures given in Gasket - Cylinder

head - Refit.

ProCarManuals.com

Page 179 of 667

12ENGINE

20

OVERHAUL GASKET - ENGINE SUMP

Service repair no - 12.60.38.01

Remove

1.Remove 2 bolts securing centrifuge oil drain pipe

to sump, remove and discard gasket.

2.Using sequence shown and noting their fitted

positions, remove 20 bolts securing sump to

cylinder block.

3.Remove sump, remove and discard gasket.

CAUTION: Do not lever between sump and

cylinder block.Refit

1.Clean sump and mating faces, ensure bolt holes

in cylinder block are clean and dry.

2.Using suitable solvent, remove all traces of

sealant from joint faces of timing chain cover and

crankshaft rear oil seal housing.

3.Clean centrifugal filter oil drain pipe and mating

faces.

4.Apply a bead of sealant, Part No. STC 3254 to

joint faces of timing chain cover and crankshaft

rear oil seal housing.

CAUTION: Assembly and bolt tightening

must be completed within 20 minutes of

applying sealant.

5.Position new sump gasket.

CAUTION: Gasket must be fitted dry.

6.Position sump, fit and lightly tighten bolts

ensuring they are in their original fitted positions.

ProCarManuals.com

Page 181 of 667

12ENGINE

22

OVERHAUL Refit

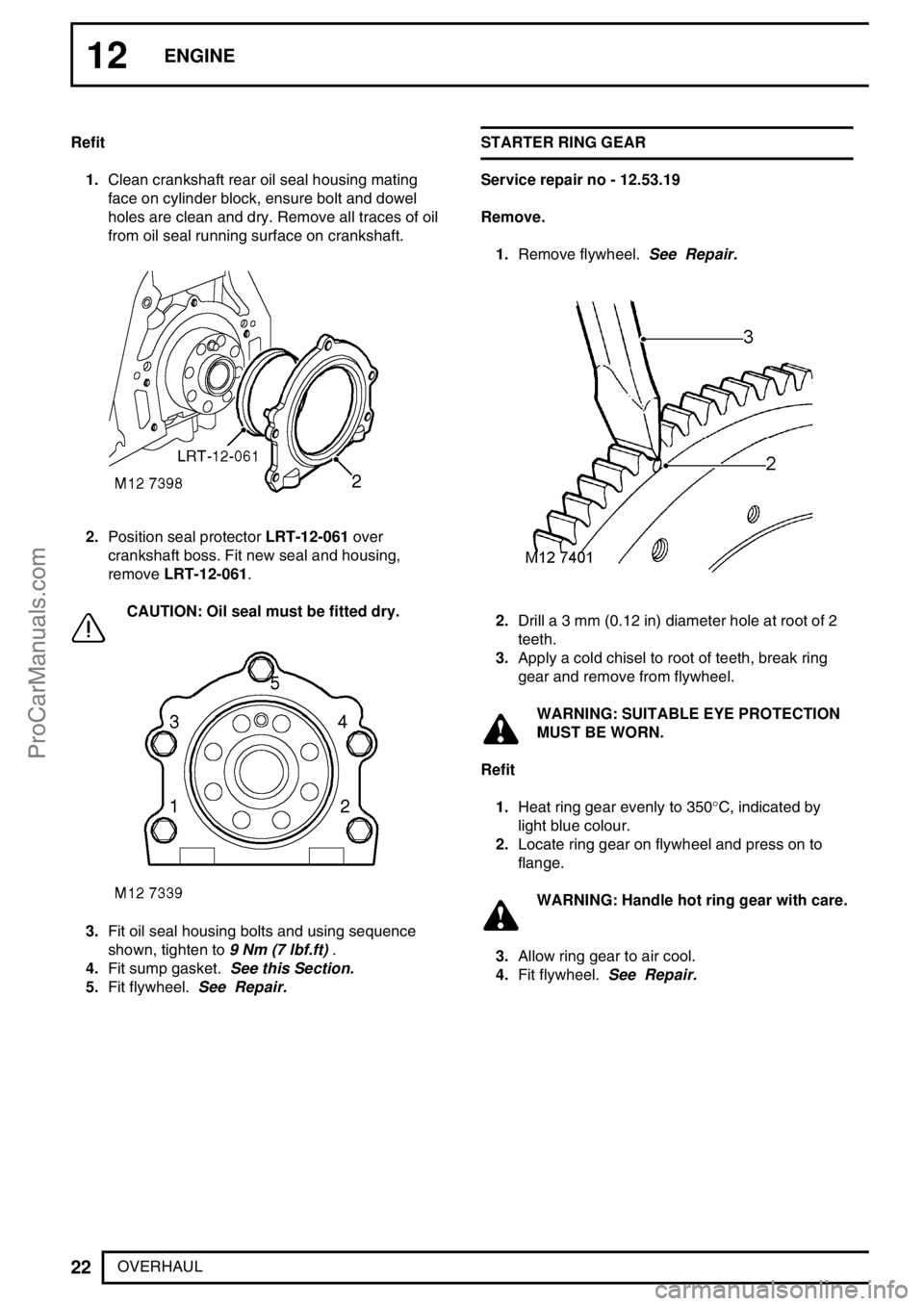

1.Clean crankshaft rear oil seal housing mating

face on cylinder block, ensure bolt and dowel

holes are clean and dry. Remove all traces of oil

from oil seal running surface on crankshaft.

2.Position seal protectorLRT-12-061over

crankshaft boss. Fit new seal and housing,

removeLRT-12-061.

CAUTION: Oil seal must be fitted dry.

3.Fit oil seal housing bolts and using sequence

shown, tighten to9 Nm (7 lbf.ft).

4.Fit sump gasket.See this Section.

5.Fit flywheel.See Repair.STARTER RING GEAR

Service repair no - 12.53.19

Remove.

1.Remove flywheel.See Repair.

2.Drill a 3 mm (0.12 in) diameter hole at root of 2

teeth.

3.Apply a cold chisel to root of teeth, break ring

gear and remove from flywheel.

WARNING: SUITABLE EYE PROTECTION

MUST BE WORN.

Refit

1.Heat ring gear evenly to 350°C, indicated by

light blue colour.

2.Locate ring gear on flywheel and press on to

flange.

WARNING: Handle hot ring gear with care.

3.Allow ring gear to air cool.

4.Fit flywheel.See Repair.

ProCarManuals.com

Page 184 of 667

ENGINE

25

OVERHAUL

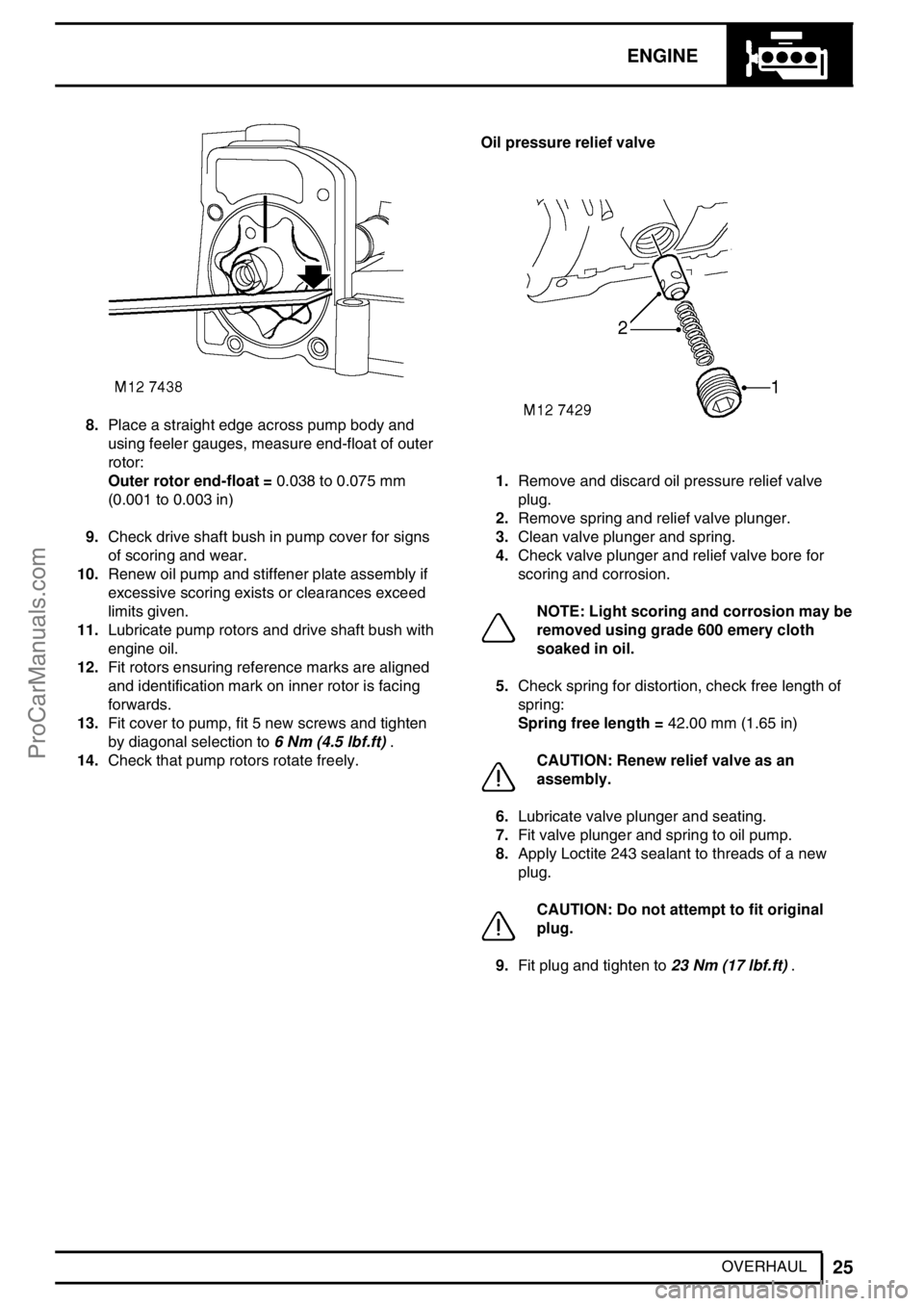

8.Place a straight edge across pump body and

using feeler gauges, measure end-float of outer

rotor:

Outer rotor end-float =0.038 to 0.075 mm

(0.001 to 0.003 in)

9.Check drive shaft bush in pump cover for signs

of scoring and wear.

10.Renew oil pump and stiffener plate assembly if

excessive scoring exists or clearances exceed

limits given.

11.Lubricate pump rotors and drive shaft bush with

engine oil.

12.Fit rotors ensuring reference marks are aligned

and identification mark on inner rotor is facing

forwards.

13.Fit cover to pump, fit 5 new screws and tighten

by diagonal selection to6 Nm (4.5 lbf.ft).

14.Check that pump rotors rotate freely.Oil pressure relief valve

1.Remove and discard oil pressure relief valve

plug.

2.Remove spring and relief valve plunger.

3.Clean valve plunger and spring.

4.Check valve plunger and relief valve bore for

scoring and corrosion.

NOTE: Light scoring and corrosion may be

removed using grade 600 emery cloth

soaked in oil.

5.Check spring for distortion, check free length of

spring:

Spring free length =42.00 mm (1.65 in)

CAUTION: Renew relief valve as an

assembly.

6.Lubricate valve plunger and seating.

7.Fit valve plunger and spring to oil pump.

8.Apply Loctite 243 sealant to threads of a new

plug.

CAUTION: Do not attempt to fit original

plug.

9.Fit plug and tighten to23 Nm (17 lbf.ft).

ProCarManuals.com

Page 187 of 667

12ENGINE

28

OVERHAUL Inspection

1.Clean all components.

2.Check condition of timing chain running surfaces

on adjustable and fixed guides.

CAUTION: Adjustable guide fitted to

Engine Serial No. Prefixes 15P to 19P may

be fitted to Engine Serial No. Prefixes 10P

to 14P provided that timing chain tensioner having

a YELLOW colour coded body is also fitted.

3.Check timing chains and sprockets for signs of

wear.

CAUTION: Timing chains and sprockets

fitted to Engine Serial No. Prefixes 15P to

19P may be fitted to Engine Serial No.

Prefixes 10P to 14P as an assembly only, oil pump

sprockets are interchangeable. Timing chains

fitted to Engine Serial No. Prefixes 15P to 19P

have BRONZE coloured timing links.

4.Check that drilling in timing chain lubrication jet

is clear.

5.Clean oil seal recess in timing cover and oil seal

running surface on crankshaft.

6.Remove all traces of sealant from mating faces

of timing cover and cylinder block using suitable

solvent.

CAUTION: Do not use metal scrapers.

7.Ensure bolt and dowel holes are clean and dry.

8.Clean oil pump sprocket bolt threads.Refit

1.Fit timing chain lubrication jet.

2.Fit bolt securing lubrication jet and tighten to10

Nm (7 lbf.ft).

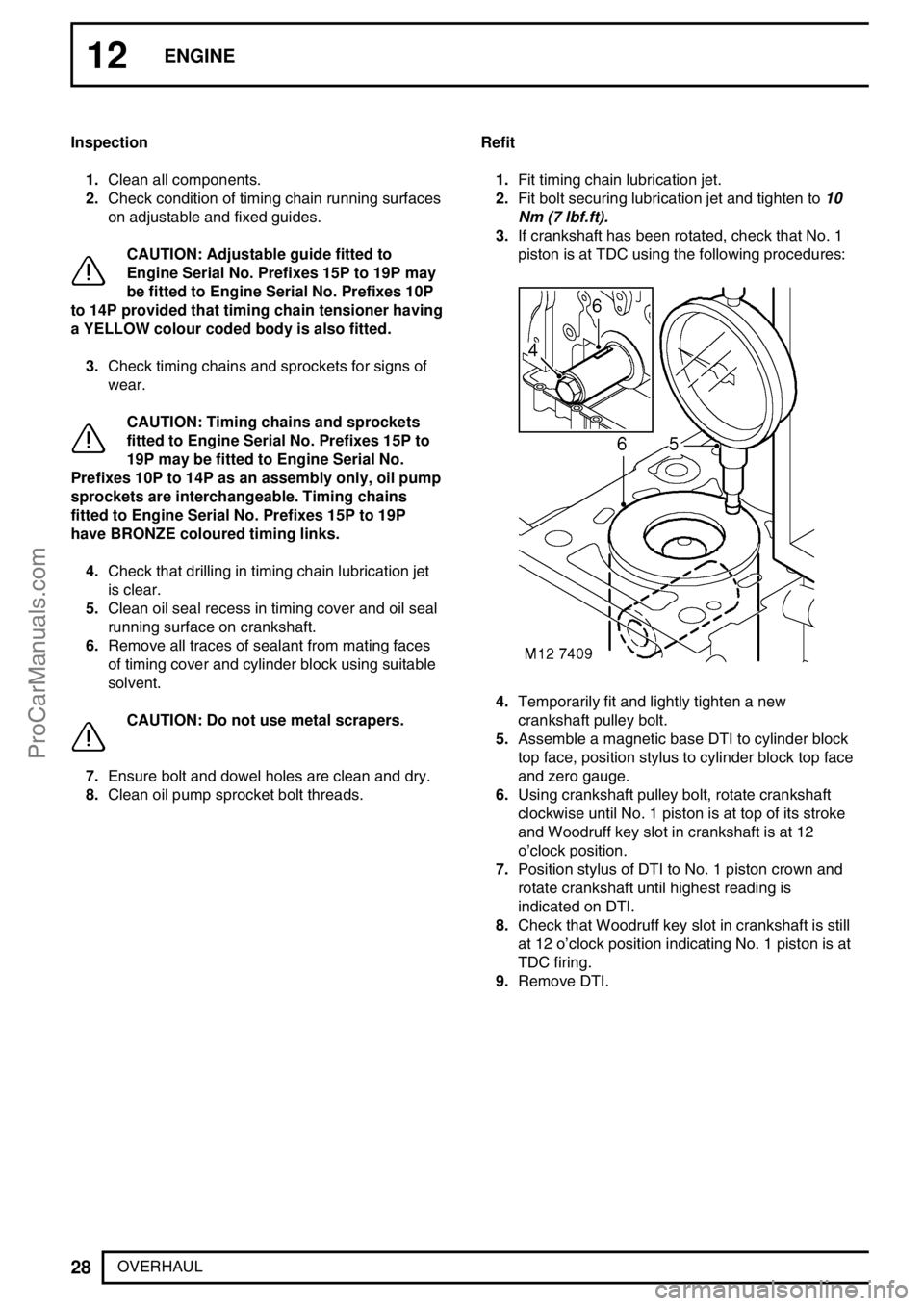

3.If crankshaft has been rotated, check that No. 1

piston is at TDC using the following procedures:

4.Temporarily fit and lightly tighten a new

crankshaft pulley bolt.

5.Assemble a magnetic base DTI to cylinder block

top face, position stylus to cylinder block top face

and zero gauge.

6.Using crankshaft pulley bolt, rotate crankshaft

clockwise until No. 1 piston is at top of its stroke

and Woodruff key slot in crankshaft is at 12

o’clock position.

7.Position stylus of DTI to No. 1 piston crown and

rotate crankshaft until highest reading is

indicated on DTI.

8.Check that Woodruff key slot in crankshaft is still

at 12 o’clock position indicating No. 1 piston is at

TDC firing.

9.Remove DTI.

ProCarManuals.com