jacking points LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 12 of 667

INTRODUCTION

5

INFORMATION JACKING

The following instructions must be carried out before

raising the vehicle off the ground.

1.Use a solid level ground surface.

2.Apply parking brake.

3.Select 1st gear in main gearbox.

4.Select Low range in transfer gearbox.

CAUTION: To avoid damage occurring to

the under body components of the vehicle

the following jacking procedures must be

adhered to.

DO NOT POSITION JACKS OR AXLE STANDS

UNDER THE FOLLOWING COMPONENTS.

Body structure

Bumpers

Fuel lines

Brake lines

Front radius arms

Panhard rod

Steering linkage

Rear Trailing links

Fuel tank

Engine sump

Gearbox bell housing

Jack or support vehicle by axles only.

Vehicle jack

The jack provided with the vehicle is only intended to

be used in an emergency, for changing a tyre. Do

NOTuse the jack for any other purpose. Refer to

Owner’s Manual for vehicle jack location points and

procedure. Never work under a vehicle supported by

the vehicle jack.

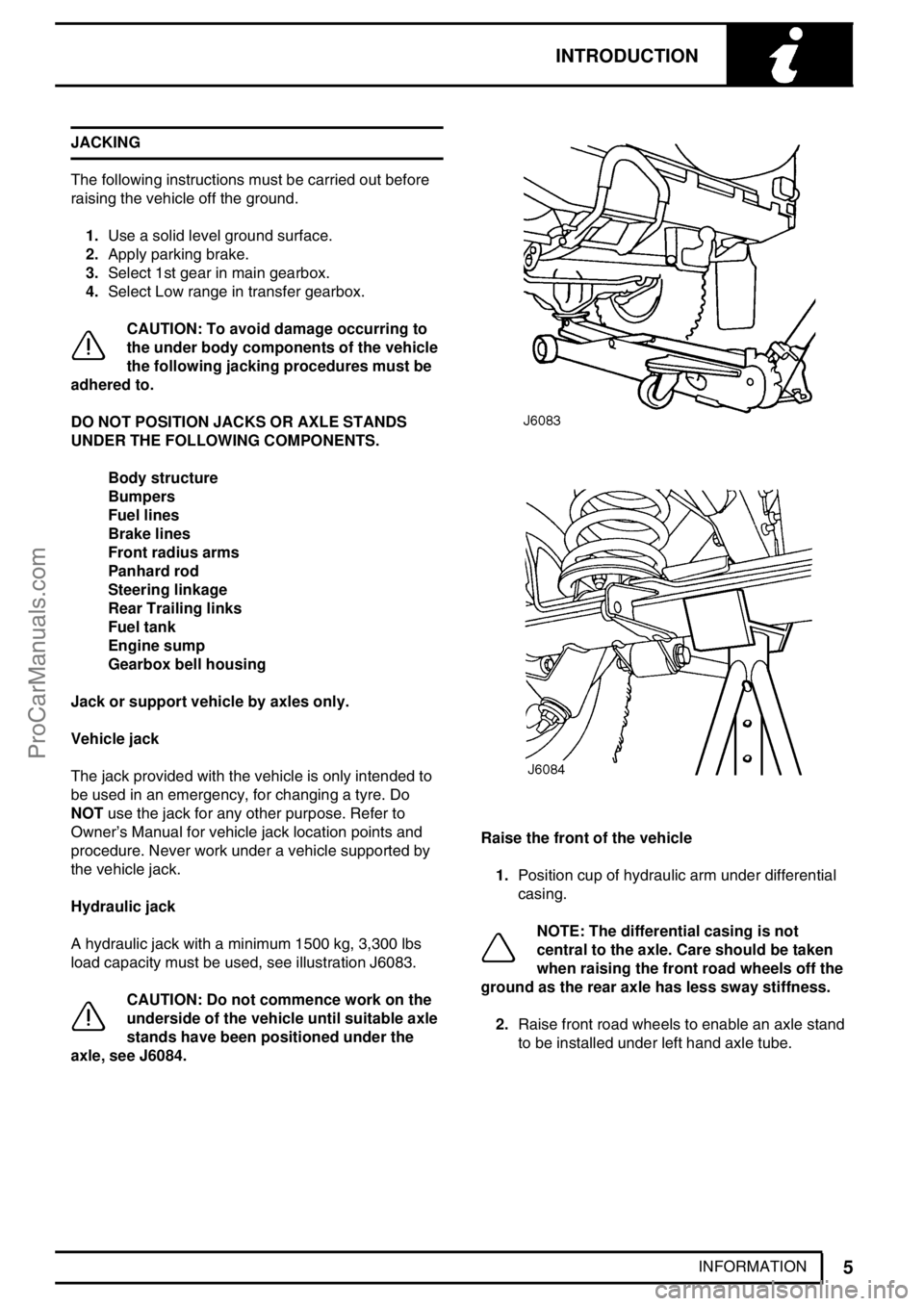

Hydraulic jack

A hydraulic jack with a minimum 1500 kg, 3,300 lbs

load capacity must be used, see illustration J6083.

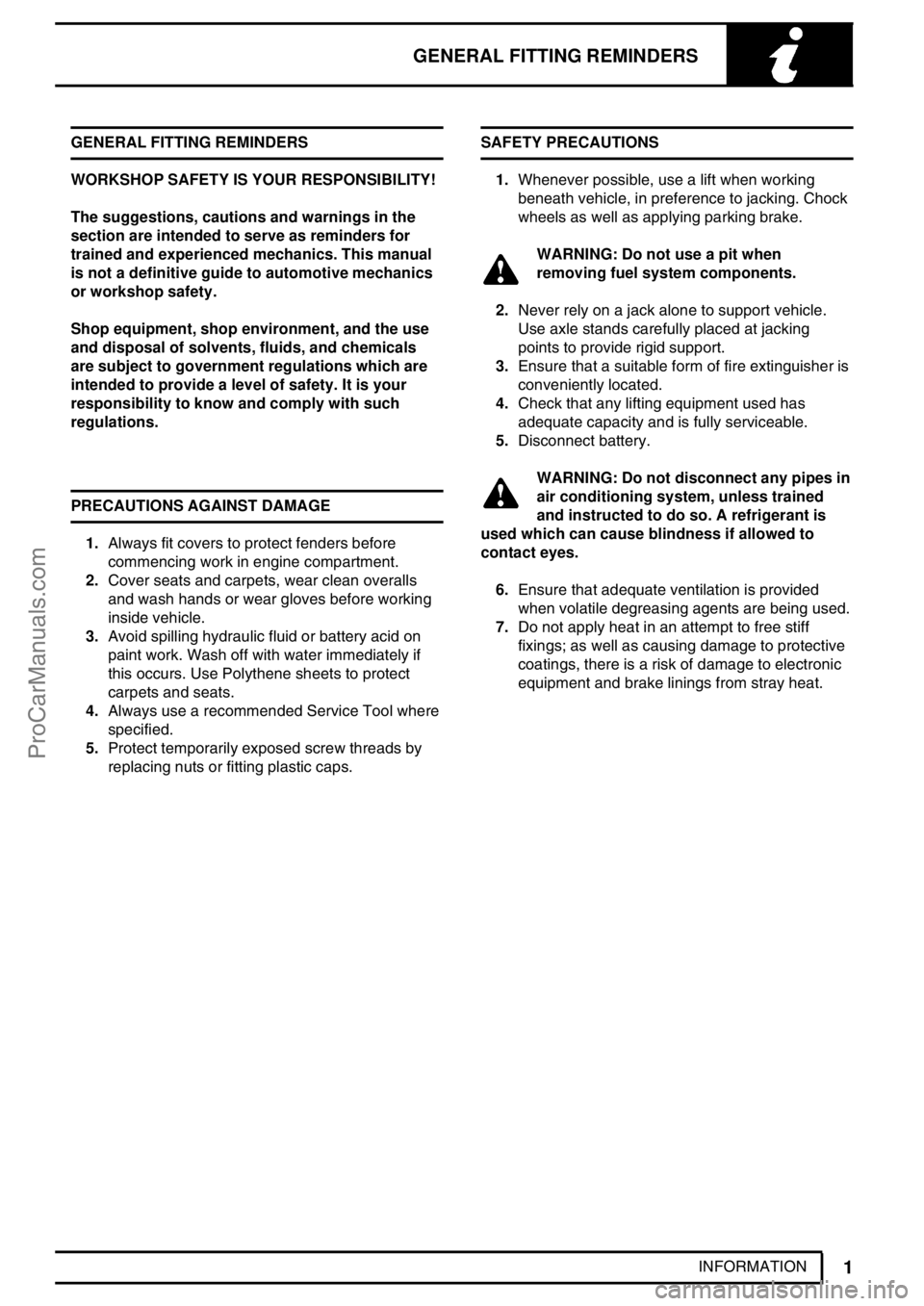

CAUTION: Do not commence work on the

underside of the vehicle until suitable axle

stands have been positioned under the

axle, see J6084.

Raise the front of the vehicle

1.Position cup of hydraulic arm under differential

casing.

NOTE: The differential casing is not

central to the axle. Care should be taken

when raising the front road wheels off the

ground as the rear axle has less sway stiffness.

2.Raise front road wheels to enable an axle stand

to be installed under left hand axle tube.

ProCarManuals.com

Page 44 of 667

GENERAL FITTING REMINDERS

1

INFORMATION GENERAL FITTING REMINDERS

WORKSHOP SAFETY IS YOUR RESPONSIBILITY!

The suggestions, cautions and warnings in the

section are intended to serve as reminders for

trained and experienced mechanics. This manual

is not a definitive guide to automotive mechanics

or workshop safety.

Shop equipment, shop environment, and the use

and disposal of solvents, fluids, and chemicals

are subject to government regulations which are

intended to provide a level of safety. It is your

responsibility to know and comply with such

regulations.

PRECAUTIONS AGAINST DAMAGE

1.Always fit covers to protect fenders before

commencing work in engine compartment.

2.Cover seats and carpets, wear clean overalls

and wash hands or wear gloves before working

inside vehicle.

3.Avoid spilling hydraulic fluid or battery acid on

paint work. Wash off with water immediately if

this occurs. Use Polythene sheets to protect

carpets and seats.

4.Always use a recommended Service Tool where

specified.

5.Protect temporarily exposed screw threads by

replacing nuts or fitting plastic caps.SAFETY PRECAUTIONS

1.Whenever possible, use a lift when working

beneath vehicle, in preference to jacking. Chock

wheels as well as applying parking brake.

WARNING: Do not use a pit when

removing fuel system components.

2.Never rely on a jack alone to support vehicle.

Use axle stands carefully placed at jacking

points to provide rigid support.

3.Ensure that a suitable form of fire extinguisher is

conveniently located.

4.Check that any lifting equipment used has

adequate capacity and is fully serviceable.

5.Disconnect battery.

WARNING: Do not disconnect any pipes in

air conditioning system, unless trained

and instructed to do so. A refrigerant is

used which can cause blindness if allowed to

contact eyes.

6.Ensure that adequate ventilation is provided

when volatile degreasing agents are being used.

7.Do not apply heat in an attempt to free stiff

fixings; as well as causing damage to protective

coatings, there is a risk of damage to electronic

equipment and brake linings from stray heat.

ProCarManuals.com

Page 532 of 667

PANEL REPAIRS

7

SEALING AND CORROSION PROTECTION Hook Nozzle on Flexible Lance:The rigid hook

produces a highly atomised, forward-directed, fully

conical spray pattern having long range and good

dispersion characteristics. This combination has good

directional capabilities for the treatment of short,

narrow sections and may also be used for direct

spraying of inner wheel arches etc.

Position the flat area at the end of the lance at 180°to

the nozzle spray direction. This will help to guide the

spray more accurately when it is concealed in a box

section or access hole.

For general spraying move the nozzle in an arc from

side to side, to ensure full coverage.

NOTE: Keep all wax injection/application

equipment clean. Use white spirit for this

purpose immediately after wax injection

operations.

Precautions during Body Repairs and Handling

Take care when handling the vehicle in the workshop.

PVC underbody sealers, seam sealers, underbody

wax and body panels may be damaged if the vehicle

is carelessly lifted.

Always follow the correct lifting, jacking and towing

procedures as shown inGENERAL INFORMATION

DATA, Information section, paying particular

attention to the following points:

Locate trolley jack pads properly before

lifting and lower the jack fully before

withdrawal.

Use only the approved hoisting points

when overhead hoisting is required.

Locate the lifting heads of wheel-free lifts

correctly, with rubber or similar material

placed between lifting head and

underbody.Steam Cleaning and Dewaxing

Due to the high temperatures generated by steam

cleaning equipment, there is a risk that certain trim

items could be damaged and some adhesives and

corrosion prevention materials softened or liquified.

Adjust the equipment so that the nozzle temperature

does not exceed 90°C (194°F). Take care not to allow

the steam jet to dwell on one area, and keep the

nozzle at least 300mm (11.8in.) from panel surfaces.

Do NOT remove wax or lacquer from underbody or

underbonnet areas during repairs. Should it be

necessary to steam clean these areas, apply a new

coating of wax or underbody protection as soon as

possible.

ProCarManuals.com