stop start LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 148 of 667

ENGINE

23

REPAIR FILTER - OIL

Service repair no - 12.60.04

Remove

1.Remove 3 bolts and remove engine acoustic

cover.

2.Release clip and disconnect breather hose from

camshaft cover.

3.Release clips and disconnect air flow meter from

air filter.

4.Disconnect multiplug from air flow meter.

5.Loosen clip screw and remove air inlet hose

from turbocharger.

6.Remove 3 bolts and remove manifold heat

shield.

7.Clean area around filter head and place a

container beneath engine.

8.Using a strap wrench, unscrew and discard filter.

Refit

9.Clean mating face of filter head.

10.Lubricate sealing ring of new filter with clean

engine oil.

11.Fit filter and tighten by hand until it seats then

tighten a further half turn.

12.Start and run engine to check for leaks.

13.Stop engine, wait a few minutes, then check oil

level.

14.Top up engine oil.

15.Position exhaust manifold heat shield and

tighten 3 bolts.

16.Position air inlet hose to turbocharger and

tighten clip screw.

17.Connect air flow meter to air filter and secure

clips.

18.Connect air flow meter multiplug.

19.Connect breather hose and secure with clip.

20.Position engine acoustic cover.

ProCarManuals.com

Page 236 of 667

ENGINE MANAGEMENT SYSTEM

13

DESCRIPTION AND OPERATION Voltage generation from the CKP sensor is relative to engine speed. The values from a good CKP sensor are as

follows:

2 to 3 volts with engine cranking.

Rising to 6 to 6.5 volts from 1000 rev/min upwards.

The above readings are dependent upon the correct air gap between the tip of the CKP sensor and the passing

teeth of the reluctor ring.

The CKP sensor can fail or supply an incorrect signal if one or more of the following occurs:

Sensor assembly loose.

Incorrect spacer fitted.

Sensor open circuit.

Sensor short circuit.

Incorrect fitting and integrity of the sensor.

Water ingress.

In the event of a CKP sensor signal failure, any of the following symptoms may be observed:

Engine cranks but fails to start.

Engine misfires (CKP sensor incorrectly fitted).

Engine runs roughly or stalls (CKP sensor incorrectly fitted).

The CKP sensor does not have a back-up strategy. If it fails the engine will stop running and fail to start.

ProCarManuals.com

Page 244 of 667

ENGINE MANAGEMENT SYSTEM

21

DESCRIPTION AND OPERATION RELAY - FUEL PUMP

The fuel pump relay is located in the engine compartment fuse box. It switches on the fuel pump to draw fuel from

the tank to the electronic unit injectors (EUI).

Input / Output

The fuel pump relay is a 4 pin normally open relay. The fuel pump relay (C0730-4) is provided with a feed by the

main relay (C0063-78) via header 291 on a brown/orange wire. An earth path is provided for the fuel pump relay

(C0730-6) via the ECM (C658-5) on a blue/purple wire. This energises the fuel pump relay and allows a feed to be

provided to the fuel pump. When the ECM interrupts the earth, the relay is de-energised and the fuel pump stops

operating.

The fuel pump relay can fail in one or more of the following ways:

Relay open circuit.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

Broken relay return spring.

In the event of a fuel pump relay failure any of the following symptoms may be observed:

Engine will crank but not start.

If the engine is running, it will stop.

RELAY - MAIN

The main relay is located in the engine compartment fuse box and supplies battery voltage to the following:

The ECM.

The MAF sensor.

Fuel pump relay.

Input / Output

The main relay is a 4 pin normally open relay, which must be energised to provide a voltage to the ECM. The main

relay (C0063-86) is provided with an earth path via a transistor within the ECM (C0658-21) on a blue/red wire.

When the earth path is completed, the relay is energised and supplies the ECM (C0658-3, C0658-22 & C0658-27)

with a feed on brown/orange wires via header 291.

The main relay can fail in the following ways:

Relay open circuit.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

Broken relay return spring.

In the event of a main relay failure any of the following symptoms may be observed:

Engine will crank but not start.

If the engine is running, it will stop.

For the ECM start up to take place the ignition feed when the switch is in position’II’must be greater than 6.0

volts.

ProCarManuals.com

Page 268 of 667

FUEL SYSTEM

1

ADJUSTMENT HEATER PLUG TEST

Service repair no - 19.90.20.01

Check

1. Test out of engine

2.Remove heater plug.See Repair.

3.UsingLRT-12-511,connect RED lead to battery

’+’positive and the BLACK lead to battery’-’

negative.

4.Position heater plug into tester and retain with

spring loaded bar.

5.Connect YELLOW lead to heater plug terminal.

6.Press red button on tester and note ammeter

reading. Keep button depressed, heater plug tip

should start to glow after 5 seconds

CAUTION: The heater plug tip must glow

first, if it fails to do so, replace heater plug.

7.The ammeter reading should show an initial

current draw of 25 amps, which should fall to 12

amps after 20 seconds.

8.Refit heater plug.See Repair.FUEL SYSTEM - BLEED

Service repair no - 19.50.07

Fuel Purging Procedure

1.If the vehicle runs out of fuel, or the fuel level is

so low that the fuel system draws air into the fuel

rail, the fuel rail will need to be purged before the

engine will start. This can be achieved by

following a set procedure. The process does not

require the use of any specialist equipment and

can be performed by the driver of the vehicle.

The process is as follows:

2.Switch off ignition and wait 15 seconds.

3.Turn ignition key to position 2 and wait 3

minutes, (this ensures that the fuel system

purges all the air from the fuel rail within the

cylinder head).

4.Depress the throttle pedal to more than 90% of

its total travel, (to the throttle stop).

5.Crank the engine keeping the throttle pedal

depressed.

NOTE: This operation is controlled by the

ECM and it is important that the purging

operation is not carried out on a vehicle

that has not run out of fuel. If it is carried out

unnecessarily it can lead to the engine flooding

and failing to start.

This operation will be cancelled:

6.As soon as engine speed exceeds 600 rev/min.

7.The driver allows the throttle pedal to close to a

position less than 90% of its travel.

8.The ignition key is released from the start

position.

NOTE: The engine must not be cranked for

more than 30 seconds in any one period.

9.Repeat the above procedure if the engine fails to

start.

ProCarManuals.com

Page 608 of 667

86 - ELECTRICAL

CONTENTS

Page

DESCRIPTION AND OPERATION

SECURITY AND CENTRAL DOOR LOCKING 1....................................................

SECURITY AND CENTRAL DOOR LOCKING 2....................................................

ANTI-THEFT ALARM - FROM 02MY 3...................................................................

IMMOBILISATION SYSTEM - FROM 02MY 12......................................................

CENTRAL DOOR LOCKING (CDL) - FROM 02MY 15...........................................

ANTI-THEFT ALARM SYSTEM SELF TEST 17.....................................................

FASCIA CONSOLE 18............................................................................................

HEATED FRONT SCREEN - FROM 02MY 20.......................................................

HEATED FRONT SEATS - FROM 02MY 22..........................................................

ELECTRIC FRONT WINDOWS - FROM 02MY 24.................................................

PASSENGER COMPARTMENT FUSE BOX 26.....................................................

UNDER SEAT FUSE BOX 27.................................................................................

ADJUSTMENT

HEADLAMPS - ALIGN BEAM 1..............................................................................

SOLENOID/MOTOR - FRONT DOOR - ADJUST 1................................................

REPAIR

BELT - AUXILLARY DRIVE 1.................................................................................

HARNESS - INJECTORS 1....................................................................................

STARTER MOTOR 2..............................................................................................

CENTRE HIGH MOUNTED STOP LIGHT (CHMSL) - UP TO 02MY 2...................

ALTERNATOR 3.....................................................................................................

HORN - LH 4...........................................................................................................

HEADLAMP 5.........................................................................................................

LAMP - TAIL 6.........................................................................................................

RADIO6 ..................................................................................................................

SPEAKER - FRONT 7.............................................................................................

SWITCH - TRANSMISSION BRAKE 7...................................................................

LAMP - FRONT FLASHER 8..................................................................................

BATTERY - DISCONNECT - FROM 02MY 8..........................................................

MOTOR & REGULATOR - FRONT DOOR - FROM 02MY 9..................................

SWITCH - FASCIA - FROM 02MY 10.....................................................................

HARNESS - FRONT DOOR - FROM 02MY 10.......................................................

SOLENOID/MOTOR - TAIL DOOR - FROM 02MY 11............................................

SOLENOID/MOTOR - FRONT DOOR - FROM 02MY 12.......................................

SOLENOID/MOTOR - REAR DOOR - FROM 02MY 13.........................................

HARNESS - REAR DOOR - FROM 02MY 14.........................................................

REVERSE AND FOG GUARD LAMP - BULB 15....................................................

ProCarManuals.com

Page 609 of 667

86 - ELECTRICAL

CONTENTS

Page

LAMP ASSEMBLY - CENTRE HIGH MOUNTED STOP LIGHT (CHMSL) -

FROM 02MY 16......................................................................................................

FLASHER UNIT - HAZARD WARNING - FROM 02MY 16.....................................

RELAY - HEATED FRONT SCREEN - FROM 02MY 17........................................

RELAY - REAR FOG GUARD - FROM 02MY 18...................................................

RELAY - STARTER - FROM 02MY 19...................................................................

SWITCH - HEADLAMP LEVELLING - FROM 02MY 19.........................................

CIGAR LIGHTER - FRONT - FROM 02MY 20........................................................

ProCarManuals.com

Page 641 of 667

86ELECTRICAL

2

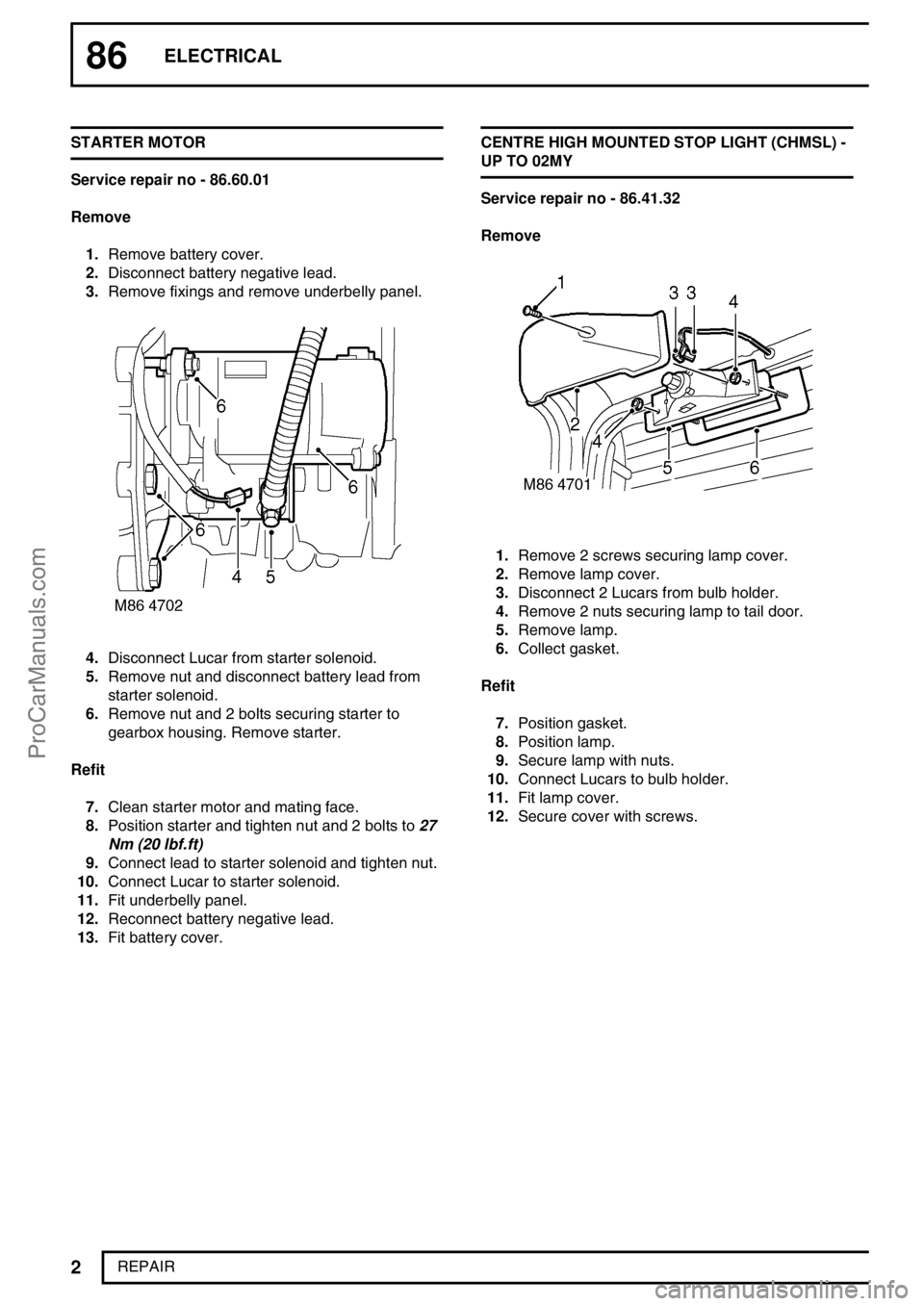

REPAIR STARTER MOTOR

Service repair no - 86.60.01

Remove

1.Remove battery cover.

2.Disconnect battery negative lead.

3.Remove fixings and remove underbelly panel.

4.Disconnect Lucar from starter solenoid.

5.Remove nut and disconnect battery lead from

starter solenoid.

6.Remove nut and 2 bolts securing starter to

gearbox housing. Remove starter.

Refit

7.Clean starter motor and mating face.

8.Position starter and tighten nut and 2 bolts to27

Nm (20 lbf.ft)

9.Connect lead to starter solenoid and tighten nut.

10.Connect Lucar to starter solenoid.

11.Fit underbelly panel.

12.Reconnect battery negative lead.

13.Fit battery cover.CENTRE HIGH MOUNTED STOP LIGHT (CHMSL) -

UP TO 02MY

Service repair no - 86.41.32

Remove

1.Remove 2 screws securing lamp cover.

2.Remove lamp cover.

3.Disconnect 2 Lucars from bulb holder.

4.Remove 2 nuts securing lamp to tail door.

5.Remove lamp.

6.Collect gasket.

Refit

7.Position gasket.

8.Position lamp.

9.Secure lamp with nuts.

10.Connect Lucars to bulb holder.

11.Fit lamp cover.

12.Secure cover with screws.

ProCarManuals.com