engine LAND ROVER DISCOVERY 1995 Service Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 976, PDF Size: 14.57 MB

Page 926 of 976

ENGINE

OVERHAUL31

TIMING BELT REAR COVER AND OIL PUMP

Timing belt rear cover - remove

1.Remove timing belt, tensioner and gears.

2.Remove fuel injection pump.

3.Remove sump and oil pick-up pipe.

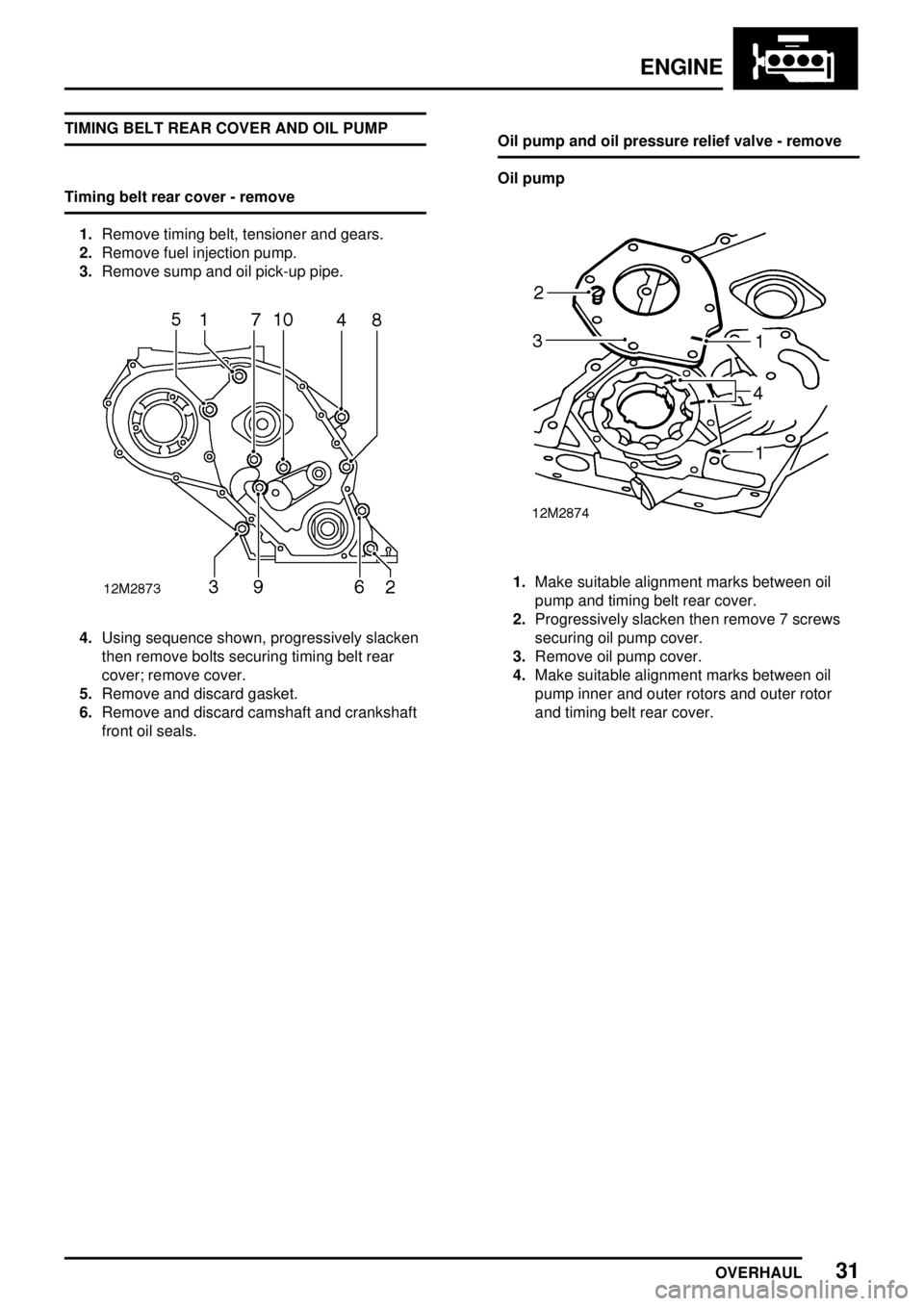

4.Using sequence shown, progressively slacken

then remove bolts securing timing belt rear

cover; remove cover.

5.Remove and discard gasket.

6.Remove and discard camshaft and crankshaft

front oil seals.Oil pump and oil pressure relief valve - remove

Oil pump

1.Make suitable alignment marks between oil

pump and timing belt rear cover.

2.Progressively slacken then remove 7 screws

securing oil pump cover.

3.Remove oil pump cover.

4.Make suitable alignment marks between oil

pump inner and outer rotors and outer rotor

and timing belt rear cover.

Page 927 of 976

ENGINE

32

OVERHAUL Oil pressure relief valve

1.Remove plug retaining oil pressure relief valve.

2.Withdraw spring and plunger.Inspecting components

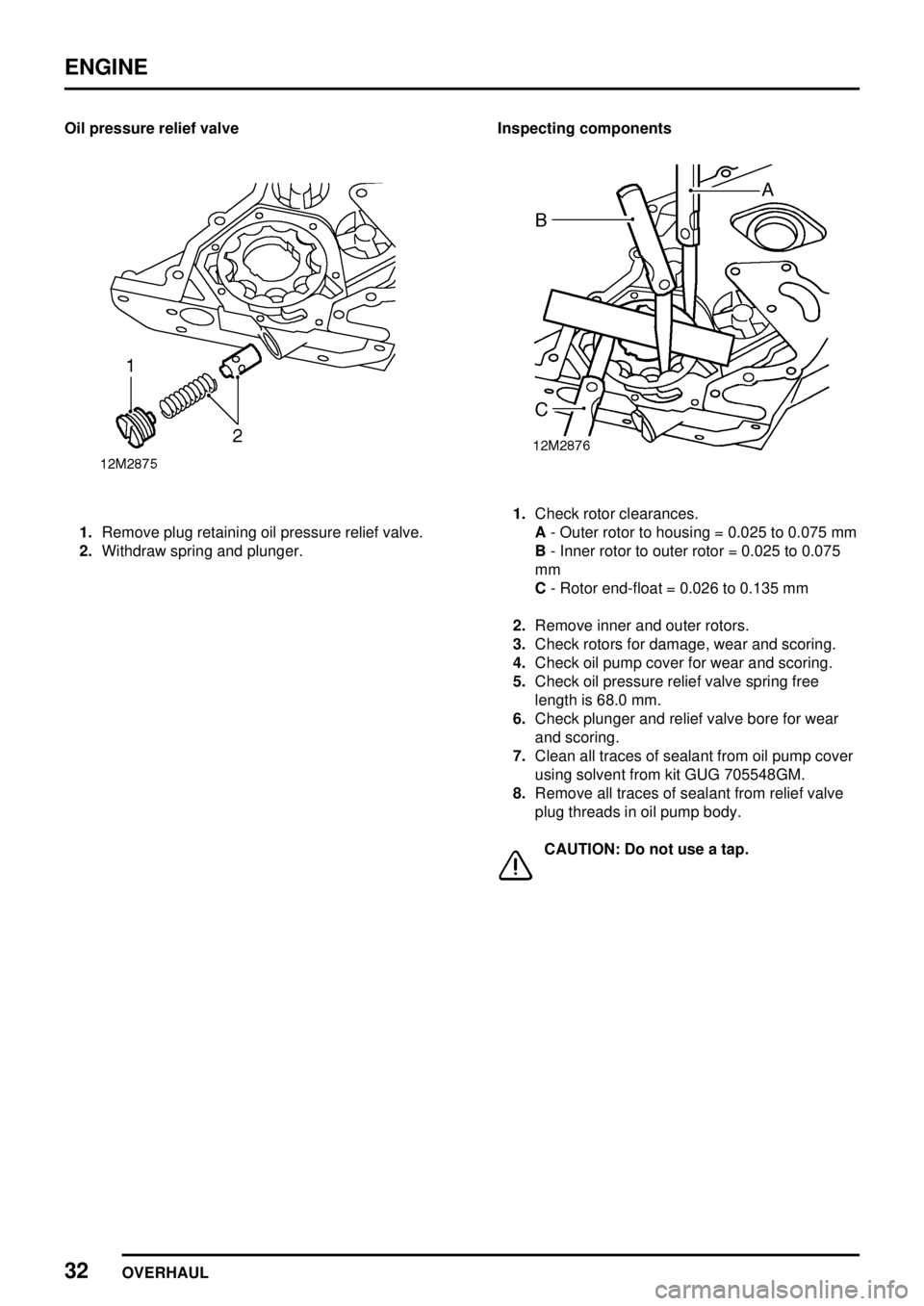

1.Check rotor clearances.

A- Outer rotor to housing = 0.025 to 0.075 mm

B- Inner rotor to outer rotor = 0.025 to 0.075

mm

C- Rotor end-float = 0.026 to 0.135 mm

2.Remove inner and outer rotors.

3.Check rotors for damage, wear and scoring.

4.Check oil pump cover for wear and scoring.

5.Check oil pressure relief valve spring free

length is 68.0 mm.

6.Check plunger and relief valve bore for wear

and scoring.

7.Clean all traces of sealant from oil pump cover

using solvent from kit GUG 705548GM.

8.Remove all traces of sealant from relief valve

plug threads in oil pump body.

CAUTION: Do not use a tap.

Page 928 of 976

ENGINE

OVERHAUL33

Oil pump and oil pressure relief valve - refit

Oil pump

1.Thoroughly clean timing belt rear cover,

remove all traces of gasket using suitable

gasket removal spray and a plastic scraper.

Remove all traces of sealant using solvent

from kit GUG 705548GM.

2.Ensure oil pump cover screw holes are clean

and dry.

3.Clean oil pump rotors and recess, lubricate

rotors and recess with engine oil.

CAUTION: Ensure alignment marks made

during dismantling are not erased.

4.Position inner and outer rotors in housing

ensuring that reference marks are aligned.

5.Apply bead of sealant from kit to outer edge of

oil pump cover, fit cover to housing ensuring

that reference marks are aligned.

6.Fit oil pump cover, fit and progressively tighten

7 screws.

7.Check that pump rotates freely.Oil pressure relief valve

1.Thoroughly clean oil pressure relief valve

plunger, spring and relief valve bore then

lubricate components with engine oil.

2.Insert plunger and spring into bore.

3.Smear threads of relief valve plug with Loctite

577.

4.Fit plug and tighten to 17 Nm.

Page 929 of 976

ENGINE

34

OVERHAUL Timing belt rear cover - refit

1.Remove all traces of gasket material from

cylinder block using suitable gasket removal

spray and a plastic scraper.

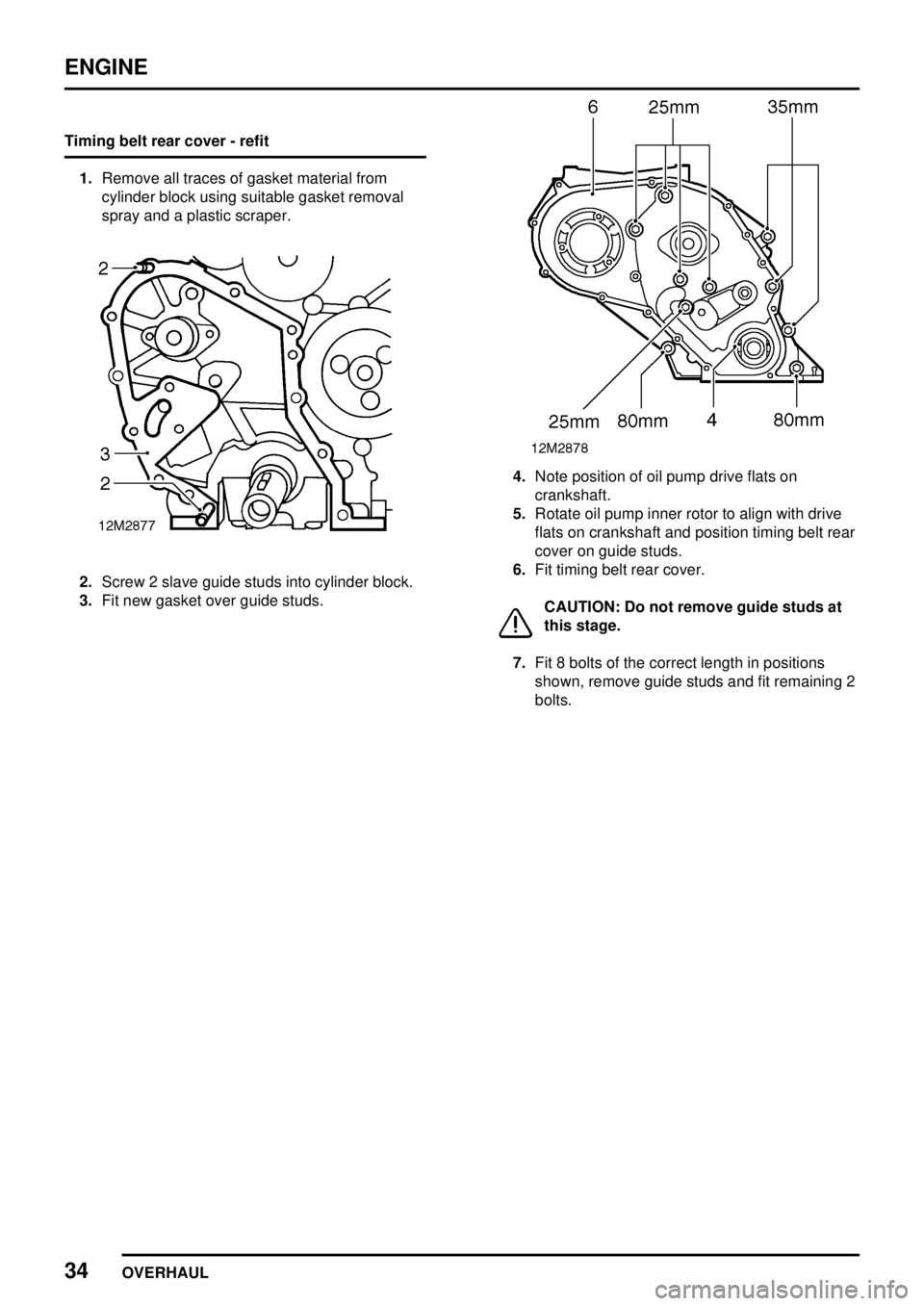

2.Screw 2 slave guide studs into cylinder block.

3.Fit new gasket over guide studs.

4.Note position of oil pump drive flats on

crankshaft.

5.Rotate oil pump inner rotor to align with drive

flats on crankshaft and position timing belt rear

cover on guide studs.

6.Fit timing belt rear cover.

CAUTION: Do not remove guide studs at

this stage.

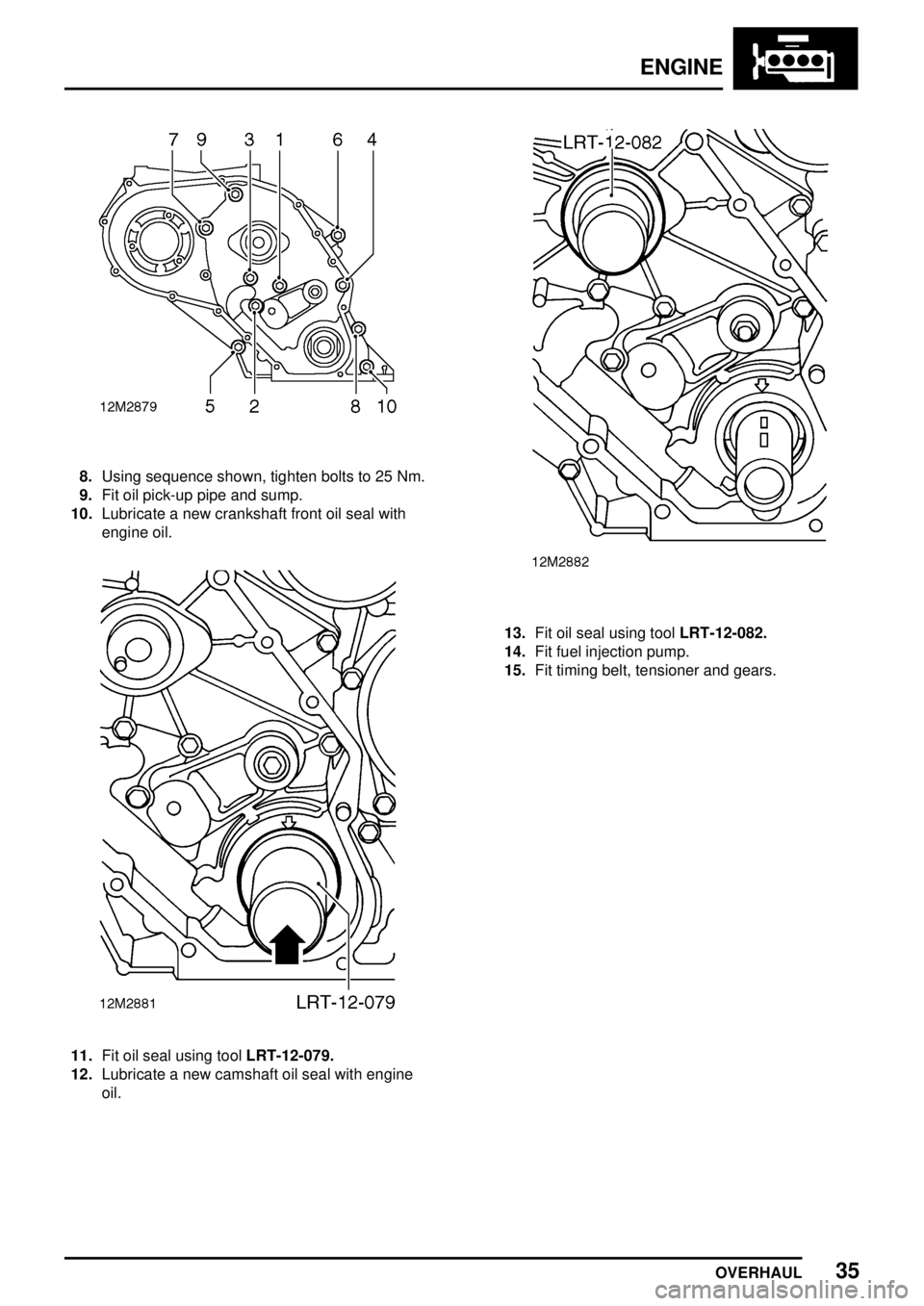

7.Fit 8 bolts of the correct length in positions

shown, remove guide studs and fit remaining 2

bolts.

Page 930 of 976

ENGINE

OVERHAUL35

8.Using sequence shown, tighten bolts to 25 Nm.

9.Fit oil pick-up pipe and sump.

10.Lubricate a new crankshaft front oil seal with

engine oil.

11.Fit oil seal using toolLRT-12-079.

12.Lubricate a new camshaft oil seal with engine

oil.

13.Fit oil seal using toolLRT-12-082.

14.Fit fuel injection pump.

15.Fit timing belt, tensioner and gears.

Page 931 of 976

ENGINE

36

OVERHAUL OIL FILTER HEAD

Remove

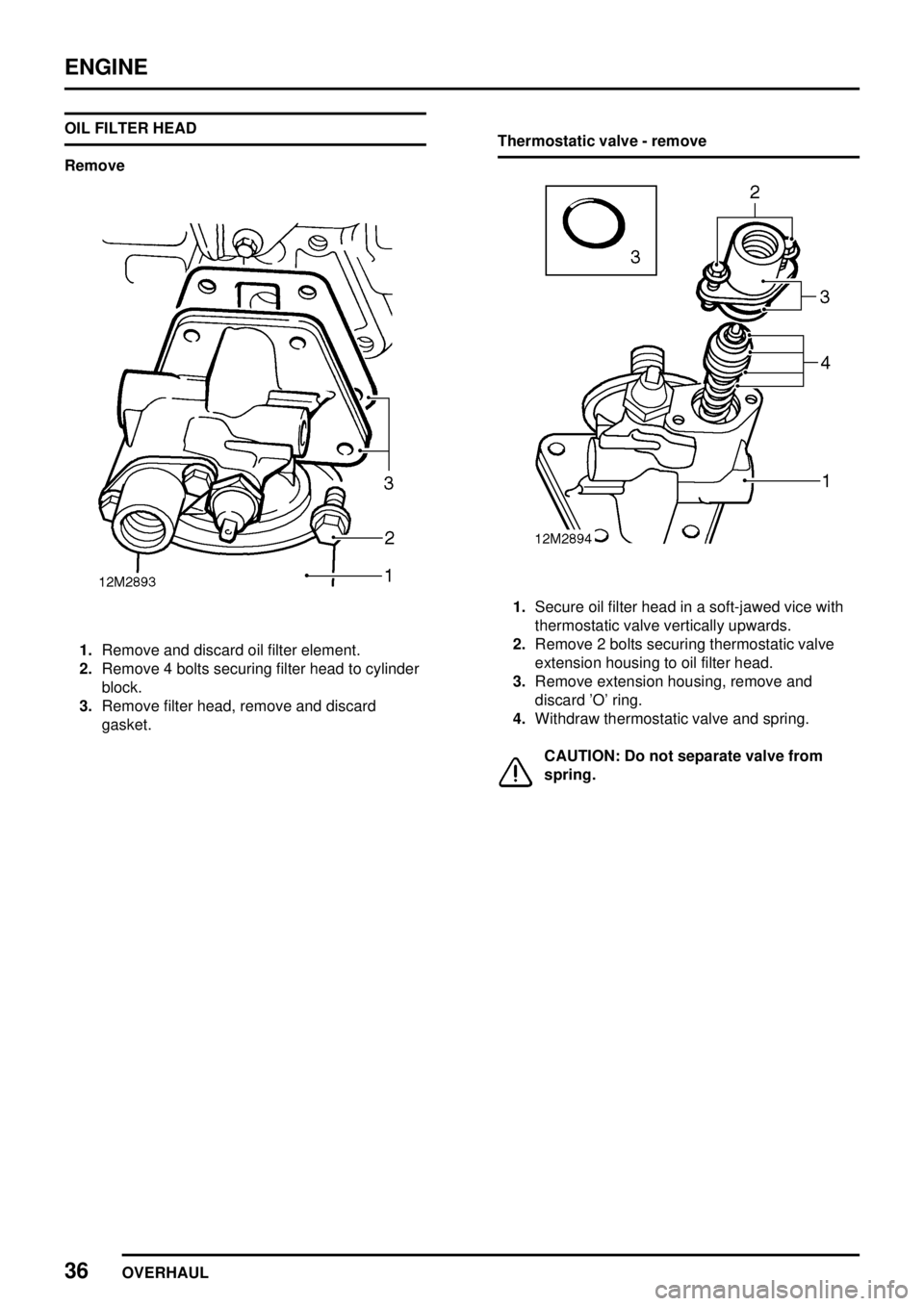

1.Remove and discard oil filter element.

2.Remove 4 bolts securing filter head to cylinder

block.

3.Remove filter head, remove and discard

gasket.Thermostatic valve - remove

1.Secure oil filter head in a soft-jawed vice with

thermostatic valve vertically upwards.

2.Remove 2 bolts securing thermostatic valve

extension housing to oil filter head.

3.Remove extension housing, remove and

discard 'O' ring.

4.Withdraw thermostatic valve and spring.

CAUTION: Do not separate valve from

spring.

Page 932 of 976

ENGINE

OVERHAUL37

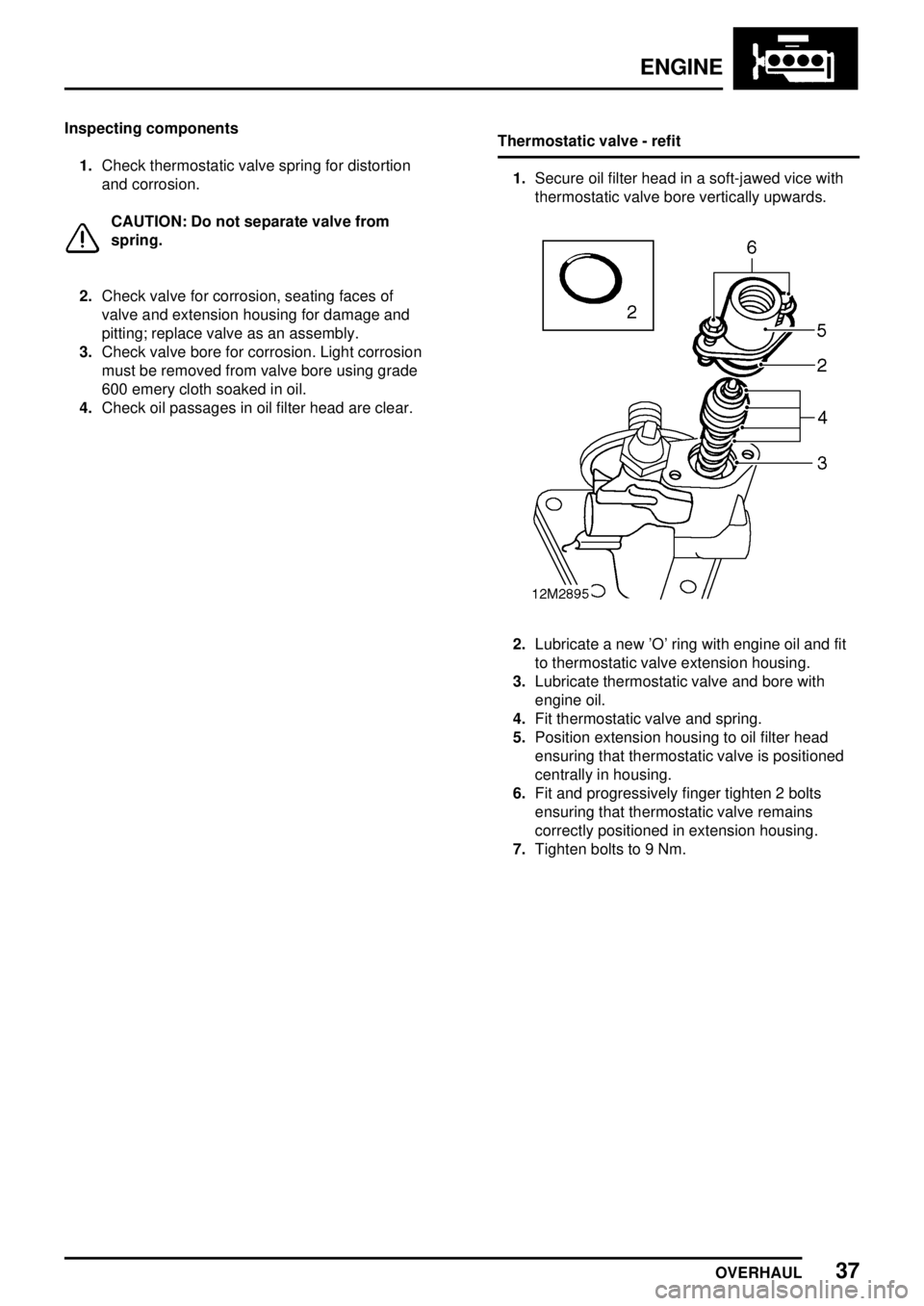

Inspecting components

1.Check thermostatic valve spring for distortion

and corrosion.

CAUTION: Do not separate valve from

spring.

2.Check valve for corrosion, seating faces of

valve and extension housing for damage and

pitting; replace valve as an assembly.

3.Check valve bore for corrosion. Light corrosion

must be removed from valve bore using grade

600 emery cloth soaked in oil.

4.Check oil passages in oil filter head are clear.Thermostatic valve - refit

1.Secure oil filter head in a soft-jawed vice with

thermostatic valve bore vertically upwards.

2.Lubricate a new 'O' ring with engine oil and fit

to thermostatic valve extension housing.

3.Lubricate thermostatic valve and bore with

engine oil.

4.Fit thermostatic valve and spring.

5.Position extension housing to oil filter head

ensuring that thermostatic valve is positioned

centrally in housing.

6.Fit and progressively finger tighten 2 bolts

ensuring that thermostatic valve remains

correctly positioned in extension housing.

7.Tighten bolts to 9 Nm.

Page 933 of 976

ENGINE

38

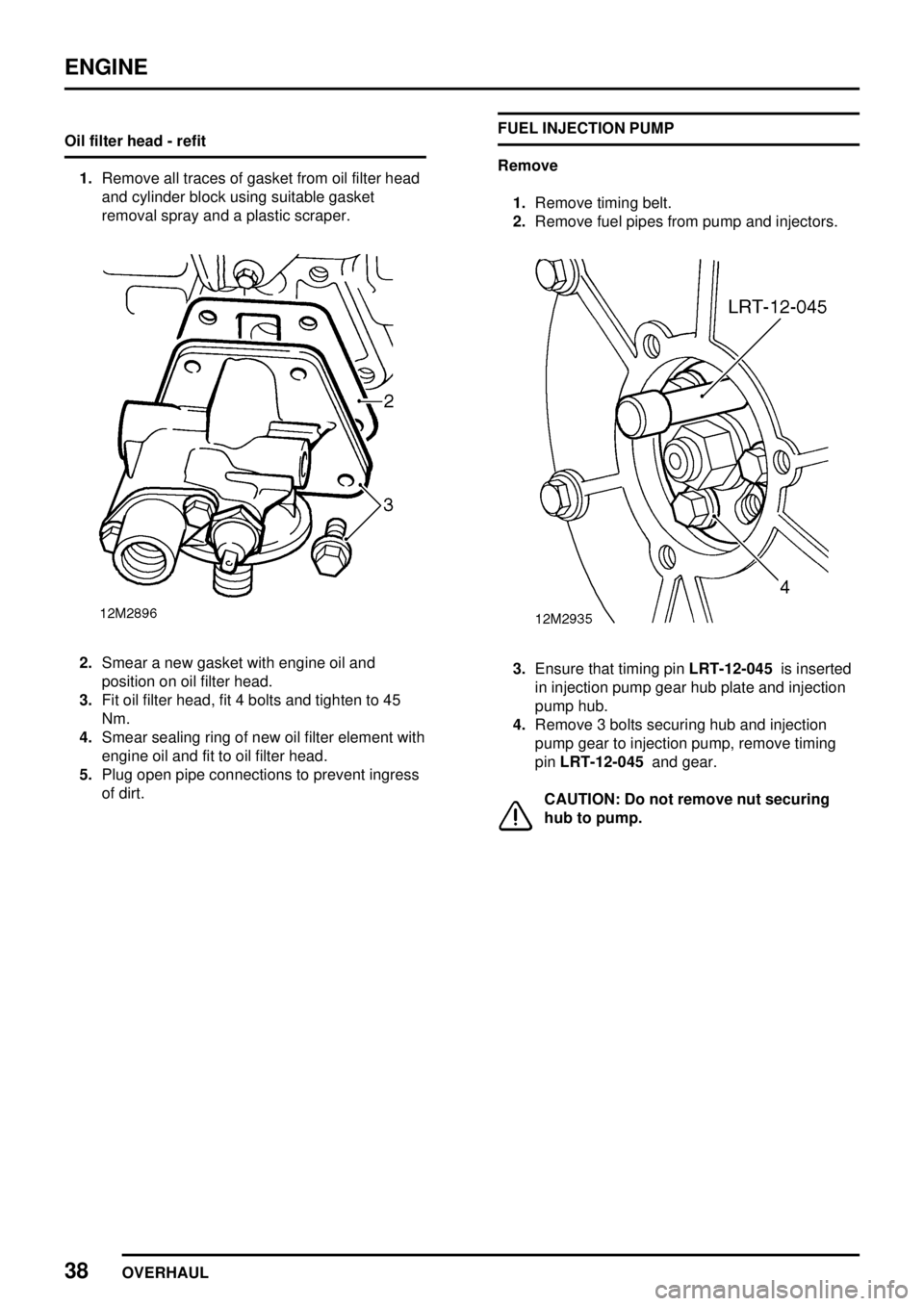

OVERHAUL Oil filter head - refit

1.Remove all traces of gasket from oil filter head

and cylinder block using suitable gasket

removal spray and a plastic scraper.

2.Smear a new gasket with engine oil and

position on oil filter head.

3.Fit oil filter head, fit 4 bolts and tighten to 45

Nm.

4.Smear sealing ring of new oil filter element with

engine oil and fit to oil filter head.

5.Plug open pipe connections to prevent ingress

of dirt.FUEL INJECTION PUMP

Remove

1.Remove timing belt.

2.Remove fuel pipes from pump and injectors.3.Ensure that timing pinLRT-12-045is inserted

in injection pump gear hub plate and injection

pump hub.

4.Remove 3 bolts securing hub and injection

pump gear to injection pump, remove timing

pinLRT-12-045and gear.

CAUTION: Do not remove nut securing

hub to pump.

Page 934 of 976

ENGINE

OVERHAUL39

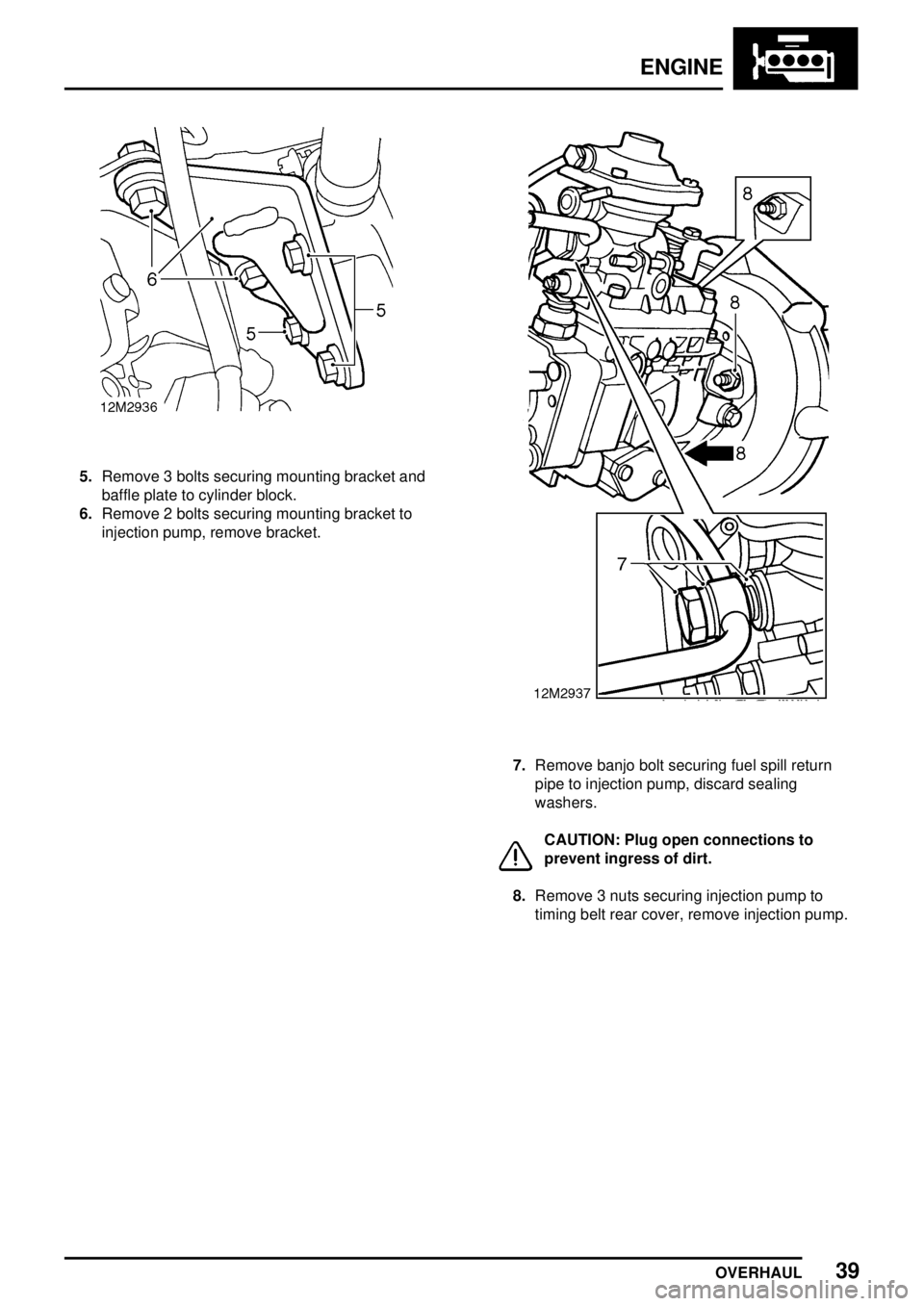

5.Remove 3 bolts securing mounting bracket and

baffle plate to cylinder block.

6.Remove 2 bolts securing mounting bracket to

injection pump, remove bracket.

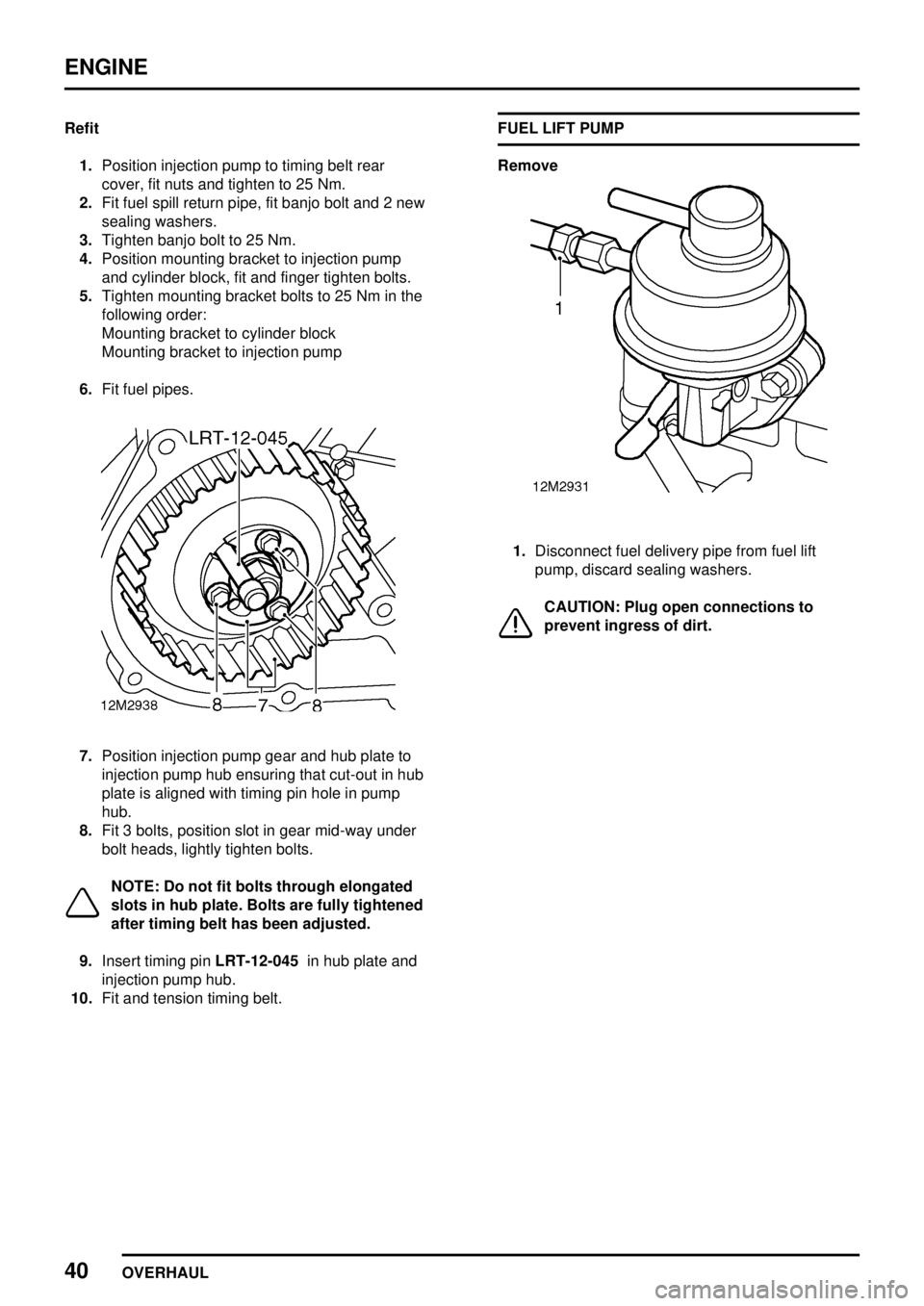

7.Remove banjo bolt securing fuel spill return

pipe to injection pump, discard sealing

washers.

CAUTION: Plug open connections to

prevent ingress of dirt.

8.Remove 3 nuts securing injection pump to

timing belt rear cover, remove injection pump.

Page 935 of 976

ENGINE

40

OVERHAUL Refit

1.Position injection pump to timing belt rear

cover, fit nuts and tighten to 25 Nm.

2.Fit fuel spill return pipe, fit banjo bolt and 2 new

sealing washers.

3.Tighten banjo bolt to 25 Nm.

4.Position mounting bracket to injection pump

and cylinder block, fit and finger tighten bolts.

5.Tighten mounting bracket bolts to 25 Nm in the

following order:

Mounting bracket to cylinder block

Mounting bracket to injection pump

6.Fit fuel pipes.

7.Position injection pump gear and hub plate to

injection pump hub ensuring that cut-out in hub

plate is aligned with timing pin hole in pump

hub.

8.Fit 3 bolts, position slot in gear mid-way under

bolt heads, lightly tighten bolts.

NOTE: Do not fit bolts through elongated

slots in hub plate. Bolts are fully tightened

after timing belt has been adjusted.

9.Insert timing pinLRT-12-045in hub plate and

injection pump hub.

10.Fit and tension timing belt.FUEL LIFT PUMP

Remove

1.Disconnect fuel delivery pipe from fuel lift

pump, discard sealing washers.

CAUTION: Plug open connections to

prevent ingress of dirt.