low oil pressure LAND ROVER DISCOVERY 1995 Service Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 976, PDF Size: 14.57 MB

Page 20 of 976

04GENERAL SPECIFICATION DATA

2

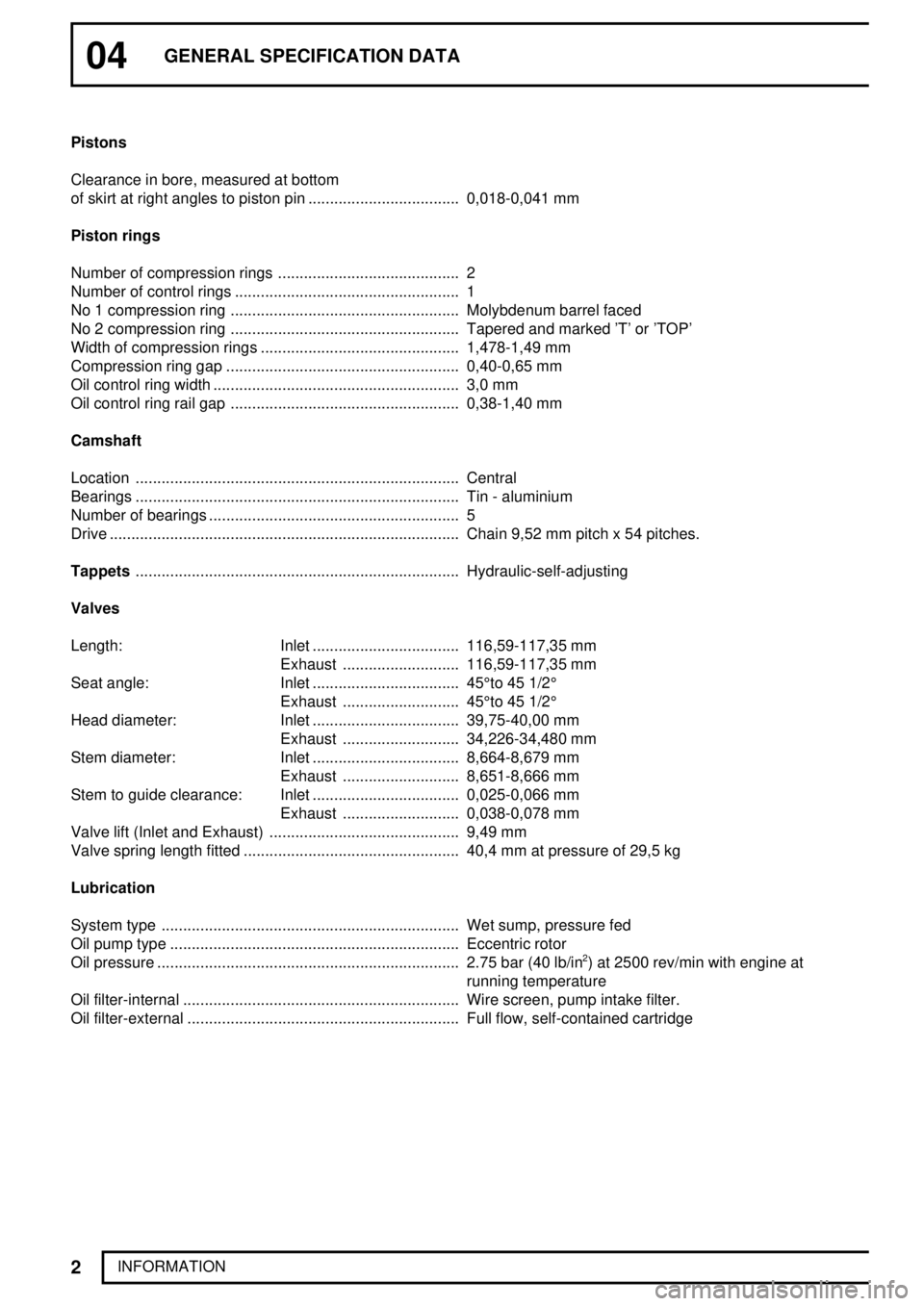

INFORMATION Pistons

Clearance in bore, measured at bottom

of skirt at right angles to piston pin 0,018-0,041 mm...................................

Piston rings

Number of compression rings 2..........................................

Number of control rings 1....................................................

No 1 compression ring Molybdenum barrel faced.....................................................

No 2 compression ring Tapered and marked 'T' or 'TOP'.....................................................

Width of compression rings 1,478-1,49 mm..............................................

Compression ring gap 0,40-0,65 mm......................................................

Oil control ring width 3,0 mm.........................................................

Oil control ring rail gap 0,38-1,40 mm.....................................................

Camshaft

Location Central...........................................................................

Bearings Tin - aluminium...........................................................................

Number of bearings 5..........................................................

Drive Chain 9,52 mm pitch x 54 pitches..................................................................................

TappetsHydraulic-self-adjusting ...........................................................................

Valves

Length: Inlet 116,59-117,35 mm..................................

Exhaust 116,59-117,35 mm...........................

Seat angle: Inlet 45°to 45 1/2° ..................................

Exhaust 45°to 45 1/2° ...........................

Head diameter: Inlet 39,75-40,00 mm..................................

Exhaust 34,226-34,480 mm...........................

Stem diameter: Inlet 8,664-8,679 mm..................................

Exhaust 8,651-8,666 mm...........................

Stem to guide clearance: Inlet 0,025-0,066 mm..................................

Exhaust 0,038-0,078 mm...........................

Valve lift (Inlet and Exhaust) 9,49 mm............................................

Valve spring length fitted 40,4 mm at pressure of 29,5 kg..................................................

Lubrication

System type Wet sump, pressure fed.....................................................................

Oil pump type Eccentric rotor...................................................................

Oil pressure 2.75 bar (40 lb/in

2) at 2500 rev/min with engine at ......................................................................

running temperature

Oil filter-internal Wire screen, pump intake filter.................................................................

Oil filter-external Full flow, self-contained cartridge...............................................................

Page 22 of 976

04GENERAL SPECIFICATION DATA

4

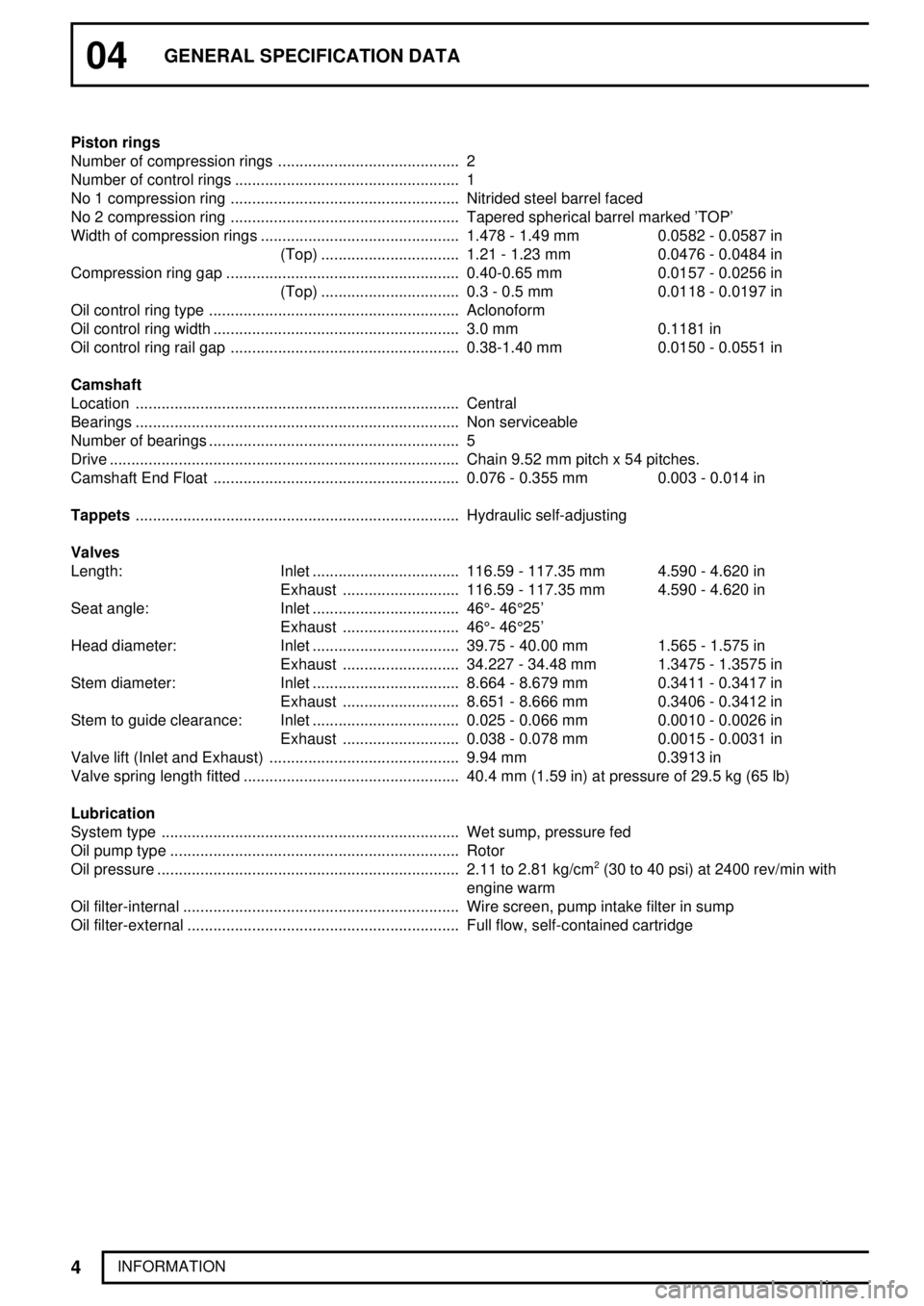

INFORMATION Piston rings

Number of compression rings 2..........................................

Number of control rings 1....................................................

No 1 compression ring Nitrided steel barrel faced.....................................................

No 2 compression ring Tapered spherical barrel marked 'TOP'.....................................................

Width of compression rings 1.478 - 1.49 mm.............................................. 0.0582 - 0.0587 in

(Top) 1.21 - 1.23 mm................................ 0.0476 - 0.0484 in

Compression ring gap 0.40-0.65 mm...................................................... 0.0157 - 0.0256 in

(Top) 0.3 - 0.5 mm................................ 0.0118 - 0.0197 in

Oil control ring type Aclonoform..........................................................

Oil control ring width 3.0 mm......................................................... 0.1181 in

Oil control ring rail gap 0.38-1.40 mm..................................................... 0.0150 - 0.0551 in

Camshaft

Location Central...........................................................................

Bearings Non serviceable...........................................................................

Number of bearings 5..........................................................

Drive Chain 9.52 mm pitch x 54 pitches..................................................................................

Camshaft End Float 0.076 - 0.355 mm......................................................... 0.003 - 0.014 in

TappetsHydraulic self-adjusting ...........................................................................

Valves

Length: Inlet 116.59 - 117.35 mm.................................. 4.590 - 4.620 in

Exhaust 116.59 - 117.35 mm........................... 4.590 - 4.620 in

Seat angle: Inlet 46°-46°25' ..................................

Exhaust 46°-46°25' ...........................

Head diameter: Inlet 39.75 - 40.00 mm.................................. 1.565 - 1.575 in

Exhaust 34.227 - 34.48 mm........................... 1.3475 - 1.3575 in

Stem diameter: Inlet 8.664 - 8.679 mm.................................. 0.3411 - 0.3417 in

Exhaust 8.651 - 8.666 mm........................... 0.3406 - 0.3412 in

Stem to guide clearance: Inlet 0.025 - 0.066 mm.................................. 0.0010 - 0.0026 in

Exhaust 0.038 - 0.078 mm........................... 0.0015 - 0.0031 in

Valve lift (Inlet and Exhaust) 9.94 mm............................................ 0.3913 in

Valve spring length fitted 40.4 mm (1.59 in) at pressure of 29.5 kg (65 lb)..................................................

Lubrication

System type Wet sump, pressure fed.....................................................................

Oil pump type Rotor...................................................................

Oil pressure 2.11 to 2.81 kg/cm

2(30 to 40 psi) at 2400 rev/min with ......................................................................

engine warm

Oil filter-internal Wire screen, pump intake filter in sump................................................................

Oil filter-external Full flow, self-contained cartridge...............................................................

Page 24 of 976

04GENERAL SPECIFICATION DATA

6

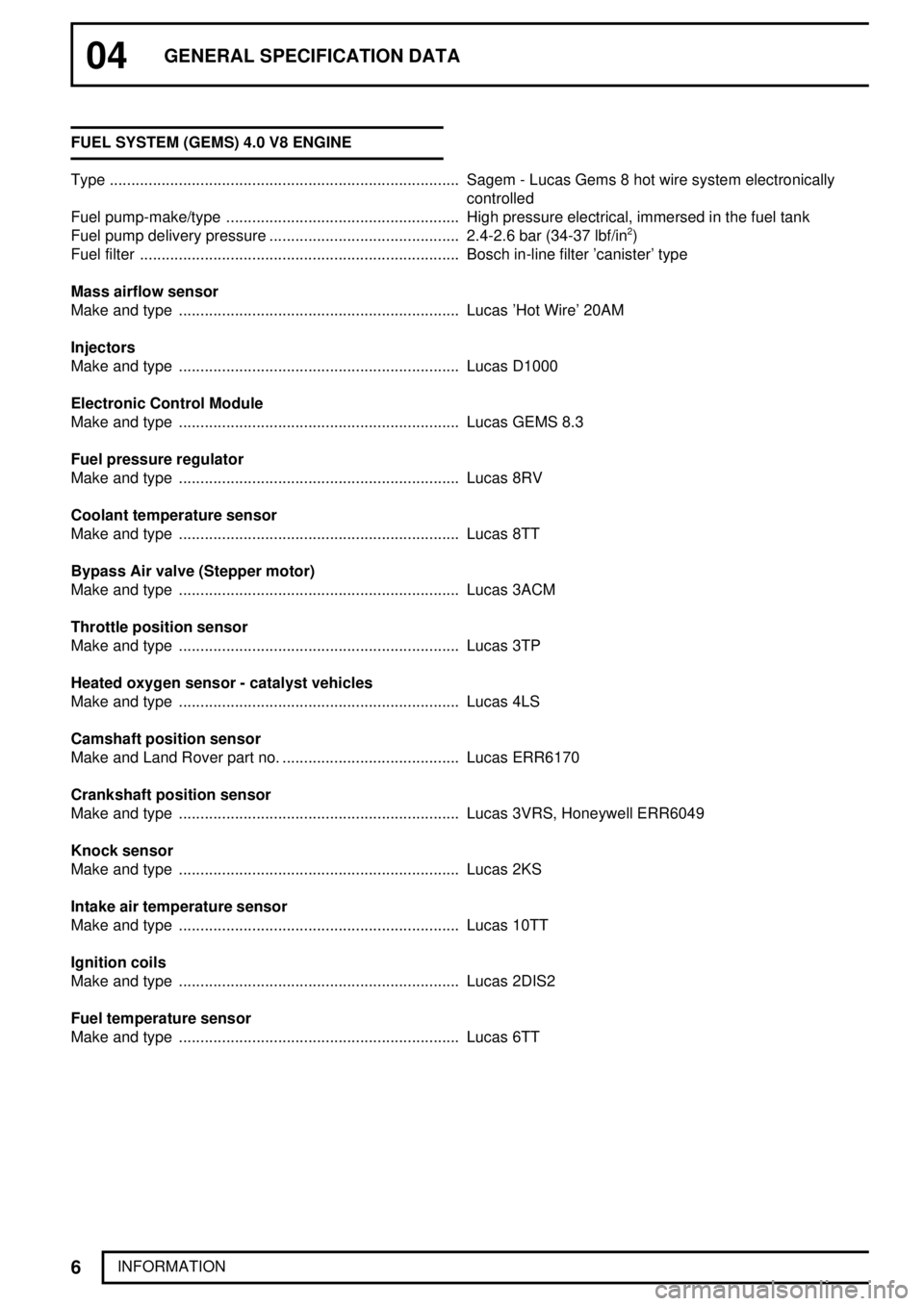

INFORMATION FUEL SYSTEM (GEMS) 4.0 V8 ENGINE

Type Sagem - Lucas Gems 8 hot wire system electronically.................................................................................

controlled

Fuel pump-make/type High pressure electrical, immersed in the fuel tank......................................................

Fuel pump delivery pressure 2.4-2.6 bar (34-37 lbf/in

2) ............................................

Fuel filter Bosch in-line filter 'canister' type..........................................................................

Mass airflow sensor

Make and type Lucas 'Hot Wire' 20AM.................................................................

Injectors

Make and type Lucas D1000.................................................................

Electronic Control Module

Make and type Lucas GEMS 8.3.................................................................

Fuel pressure regulator

Make and type Lucas 8RV.................................................................

Coolant temperature sensor

Make and type Lucas 8TT.................................................................

Bypass Air valve (Stepper motor)

Make and type Lucas 3ACM.................................................................

Throttle position sensor

Make and type Lucas 3TP.................................................................

Heated oxygen sensor - catalyst vehicles

Make and type Lucas 4LS.................................................................

Camshaft position sensor

Make and Land Rover part no. Lucas ERR6170.........................................

Crankshaft position sensor

Make and type Lucas 3VRS, Honeywell ERR6049.................................................................

Knock sensor

Make and type Lucas 2KS.................................................................

Intake air temperature sensor

Make and type Lucas 10TT.................................................................

Ignition coils

Make and type Lucas 2DIS2.................................................................

Fuel temperature sensor

Make and type Lucas 6TT.................................................................

Page 28 of 976

04GENERAL SPECIFICATION DATA

10

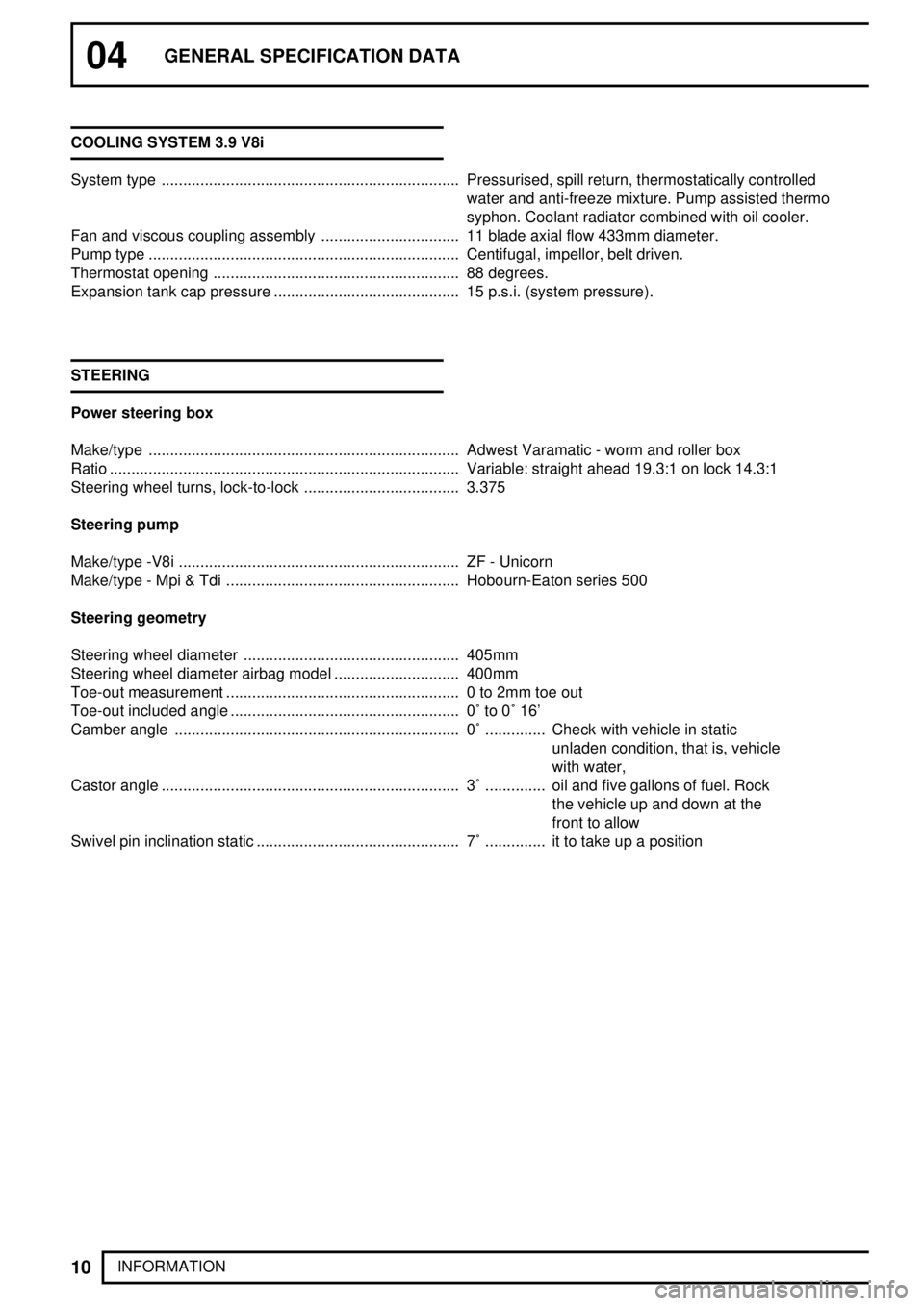

INFORMATION COOLING SYSTEM 3.9 V8i

System type Pressurised, spill return, thermostatically controlled.....................................................................

water and anti-freeze mixture. Pump assisted thermo

syphon. Coolant radiator combined with oil cooler.

Fan and viscous coupling assembly 11 blade axial flow 433mm diameter.................................

Pump type Centifugal, impellor, belt driven.........................................................................

Thermostat opening 88 degrees..........................................................

Expansion tank cap pressure 15 p.s.i. (system pressure)............................................

STEERING

Power steering box

Make/type Adwest Varamatic - worm and roller box........................................................................

Ratio Variable: straight ahead 19.3:1 on lock 14.3:1.................................................................................

Steering wheel turns, lock-to-lock 3.375....................................

Steering pump

Make/type -V8i ZF - Unicorn.................................................................

Make/type - Mpi & Tdi Hobourn-Eaton series 500......................................................

Steering geometry

Steering wheel diameter 405mm..................................................

Steering wheel diameter airbag model 400mm.............................

Toe-out measurement 0 to 2mm toe out......................................................

Toe-out included angle 0Ê to 0Ê 16'.....................................................

Camber angle 0Ê.................................................................. Check with vehicle in static..............

unladen condition, that is, vehicle

with water,

Castor angle 3Ê..................................................................... oil and five gallons of fuel. Rock..............

the vehicle up and down at the

front to allow

Swivel pin inclination static 7Ê............................................... it to take up a position..............

Page 38 of 976

04GENERAL SPECIFICATION DATA

20

INFORMATION Lubrication

System Wet sump, pressure fed.............................................................................

Pressure, engine warm at normal operating speeds 25 - 55lbf/in

2= 1,76 - 3,87Kgf cm2........

Oil pump:

- Type G-rotor integral with front cover.......................................................................

- Drive off crankshaft nose.....................................................................

Oil pressure relief valve Non-adjustable....................................................

Relief valve spring:

- Full length 51,6mm......................................................................

- Compressed length at 7.71Kg load 31mm................................

Oil filter Screw-on disposable canister.............................................................................

Engine oil cooler Combined with coolant radiator and intercooler...............................................................

FUEL SYSTEM - 300 Tdi

Fuel lift pump type Mechanical with hand primer............................................................

Fuel lift pump pressure 42 - 55 kpa at 1800 rpm.....................................................

Fuel filter Paper element in disposable canister..........................................................................

Air cleaner Paper element type........................................................................

COOLING SYSTEM - 300 Tdi

System type Pressurised, spill return, thermostatically controlled.....................................................................

water and anti freeze mixture. Pump assisted thermo

syphon. Coolant radiator combined with oil cooler and

turbo intercooler.

Cooling fan 11 blade axial flow 433 mm diameter. 1.29:1 drive.......................................................................

ratio. Viscous coupling.

Pump type Centrifugal, impellor, belt driven.........................................................................

Thermostat opening 88° .........................................................

Expansion tank cap pressure 15lbf/in

2= 1,06Kgf cm2(system pressure) ...........................................

CLUTCH - 300 Tdi

Type Valeo diaphragm spring.................................................................................

Centre plate diameter 235 mm.......................................................

Facing material Verto F202 grooved.................................................................

Release bearing Ball journal...............................................................

Page 49 of 976

05ENGINE TUNING DATA

6

INFORMATION ENGINE - Mpi - 2.0 LITRE

Type/Capacity 20 T4/1994 cm

3..................................................................

Firing order 1-3-4-2.......................................................................

Compression ration 10 : 1..........................................................

Idle speed:

Controlled by ECM 875±50 rev/min ...........................................................

Exhaust gas Co content:

- Catalyst 0.5% Max. Not adjustable..................................................................

- Non Catalyst 1,0±25% adjustable using Testbook .........................................................

Ignition

Knock sensor ADU 8229...................................................................

Crankshaft sensor ADU 7340............................................................

Ignition Coils

Type NEC 10049.................................................................................

Primary resistance at 20°C 0.4 to 0.61 ohm..............................................

Consumption - engine idling 0.25 to 0.75 amp.............................................

Spark Plugs

Type/Gap GSP 6662 -0,85 mm.........................................................................

Multipoint Fuel Injection

Type Indirect multipoint injection with engine control module.................................................................................

using speed/density method of air flow measurement.

Fuel pressure regulator MKW 10011....................................................

Fuel pump delivery pressure 2.3 - 2.5 bar............................................

Throttle potentiometer voltage

- Throttle closed 0 - 1 Volt......................................................

- Throttle open 4 - 5 Volts.........................................................

MEMS engine control module MKC 10121..........................................

95 RON minimum -UNLEADEDfuel

CAUTION: Do not use LEADED fuel as it will

damage the catalyst. Serious damage to the

engine may occur if a lower octane number fuel

than that recommended is used.

Page 54 of 976

GENERAL FITTING REMINDERS

5

INFORMATION JOINTS AND JOINT FACES

1.Always use correct gaskets where they are

specified.

2.Use jointing compound only when

recommended. Otherwise fit joints dry.

3.When jointing compound is used, apply in a thin

uniform film to metal surfaces; take great care to

prevent it from entering oilways, pipes or blind

tapped holes.

4.Remove all traces of old jointing materials prior

to reassembly. Do not use a tool which could

damage joint faces.

5.Inspect joint faces for scratches or burrs and

remove with a fine file or oil stone; do not allow

removed material or dirt to enter tapped holes or

enclosed parts.

6.Blow out any pipes, channels or crevices with

compressed air, fit new 'O' rings or seals

displaced by air blast.FLEXIBLE HYDRAULIC PIPES, HOSES

1.Before removing any brake or power steering

hose, clean end fittings and area surrounding

them as thoroughly as possible.

2.Obtain appropriate plugs or caps before

detaching hose end fittings, so that ports can be

immediately covered to exclude dirt.

3.Clean hose externally and blow through with

airline. Examine carefully for cracks, separation

of plies, security of end fittings and external

damage. Reject any hose found faulty.

4.When refitting hose, ensure that no unnecessary

bends are introduced, and that hose is not

twisted before or during tightening of union nuts.

5.Containers for hydraulic fluid must be kept

absolutely clean.

6.Do not store brake fluid in an unsealed

container. It will absorb water, and fluid in this

condition would be dangerous to use due to a

lowering of its boiling point.

7.Do not allow brake fluid to be contaminated with

mineral oil, or use a container which has

previously contained mineral oil.

8.Do not re-use brake fluid bled from system.

9.Always use clean brake fluid to clean hydraulic

components.

10.Fit a cap to seal a hydraulic union and a plug to

its socket after removal to prevent ingress of dirt.

11.Absolute cleanliness must be observed with

hydraulic components at all times.

12.After any work on hydraulic systems, inspect

carefully for leaks underneath the vehicle while a

second operator applies maximum pressure to

the brakes (engine running) and operates the

steering.

Page 65 of 976

MAINTENANCE

3

MAINTENANCE VEHICLE EXTERIOR

CHECK/ADJUST HEADLAMP ALIGNMENT

Check/adjust headlamp and auxiliary alignment.

CHECK FRONT WHEEL ALIGNMENT

Use recognised wheel alignment equipment to

perform this check and adjustment.

See STEERING,

Adjustment, Front Wheel Alignment

REMOVE WHEELS, CHECK TYRES

Check tyres (including spare) for compliance with

manufacturers' specification.

Check visually for cuts, lumps, bulges, uneven tread

wear and tread depth. Check road wheels for

damage.

Check/adjust tyre pressures.

CHECK/TIGHTEN TOWING BRACKET FITTINGSINSPECT BRAKE PADS FOR WEAR, CALIPERS

FOR LEAKS AND CONDITION

Check thickness of brake pads, fit new pads if

minimum thickness is less than 3,0mm. Check brake

pads for oil contamination. If new brake pads required.

See BRAKES, Repair, Front Brake Pads

or.See BRAKES, Repair, Rear Brake Pads

WARNING: When renewing brake pads, it

is essential that only genuine components

with correct grade of lining are used.

Always fit new pads as complete axle sets, NEVER

individually or as a single wheel set. Serious

consequences could result from out of balance

braking due to mixing of linings.

Refit road wheels

Fit road wheels in original hub position. Secure in

position with wheel nuts, do not fully tighten wheel

nuts at this stage, lower vehicle and finally tighten

wheel nuts to correct torque.

Alloy wheels:

130 Nm.

Steel wheels:130 Nm.

LUBRICATE ALL HINGES, DOOR CHECK

MECHANISMS, BONNET [HOOD] CATCHES AND

FUEL FILLER FLAP

Page 74 of 976

10MAINTENANCE

12

MAINTENANCE

EXTERNALLY CHECK INTERCOOLER FOR

OBSTRUCTION - Tdi

Clear any trapped dirt or flies from vanes of

intercooler

CLEAN INTERCOOLER ELEMENT - Tdi

Remove

1.Remove intercooler element.

2.Flush intercooler with ICI 'GENKLENE'or

à oD-SOLVE' propriety cleaner, following the

manufacturer's instructions.

3.Dry the intercooler completely ensuring that no

liquid remains in the element.

Refit

4.Refit intercooler element.UNDER VEHICLE MAINTENANCE

Vehicles operating under severe conditions of dust,

sand, mud and water should have oils changed and

lubrication carried out at more frequent intervals than

is recommended in maintenance schedules.

RENEW ENGINE OIL AND FILTER - Tdi

CAUTION: Serious damage to the

turbocharger will result if engine is run

above idling speed before oil pressure is

restored.

RENEW ENGINE OIL - V8i

RENEW ENGINE OIL AND FILTER - V8i

CAUTION: To prevent an airlock occuring

after removing filter, fill new filter with oil

and fit immediately after removing old

filter. If airlock does occur fill oil pump with

petroleum jelly.

RENEW ENGINE OIL AND FILTER - Mpi

CHECK/TOP UP MANUAL GEARBOX OIL - V8i

1.Site vehicle on lift or level ground.

2.Remove oil filler level plug. If necessary, inject

new oil into the gearbox until it runs out of filler

hole. Fit plug. Tighten to

30 Nm.

RENEW MANUAL GEARBOX OIL - Tdi - Mpi

RENEW MANUAL GEARBOX OIL - V8i

Page 112 of 976

12ENGINE

4

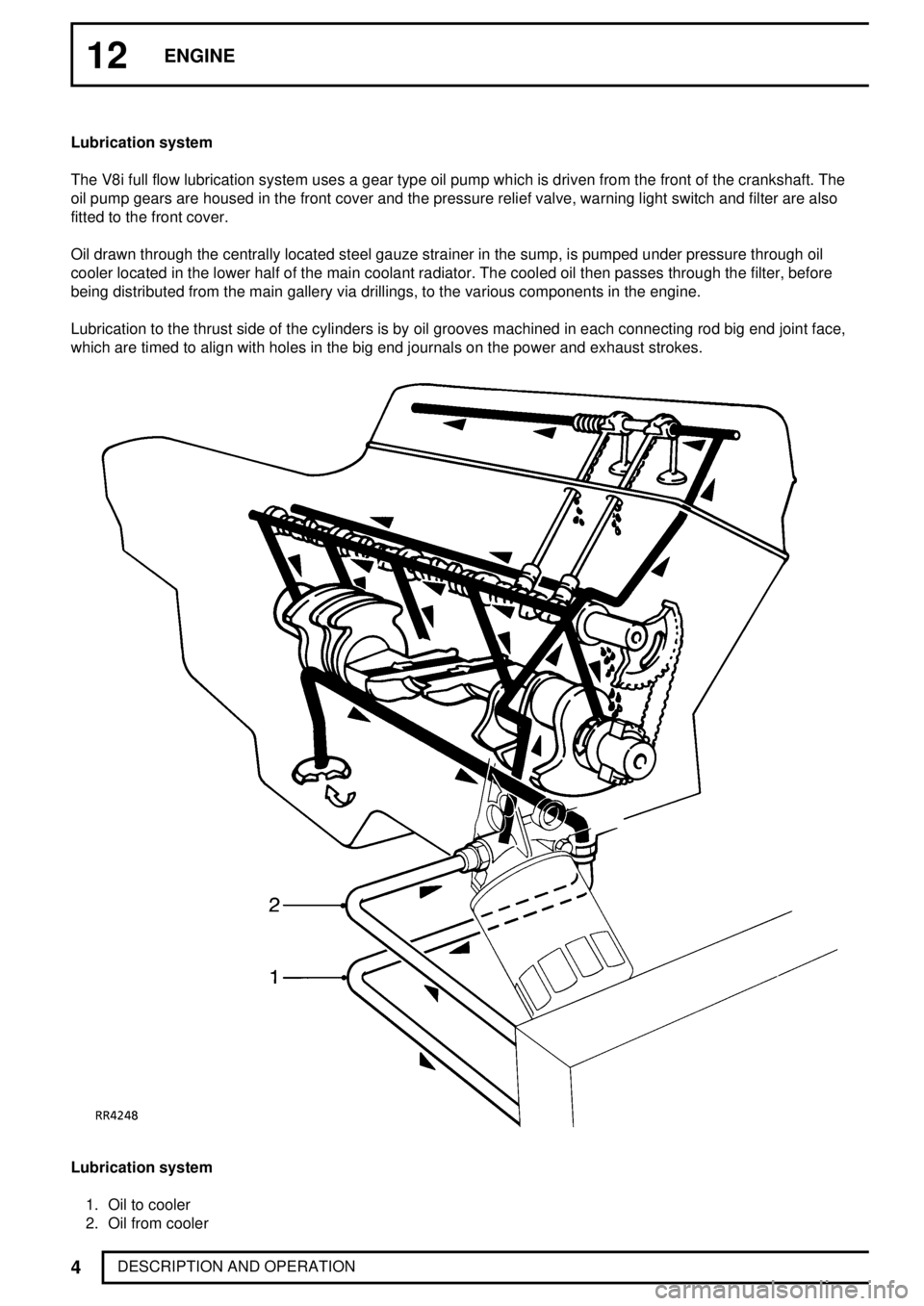

DESCRIPTION AND OPERATION Lubrication system

The V8i full flow lubrication system uses a gear type oil pump which is driven from the front of the crankshaft. The

oil pump gears are housed in the front cover and the pressure relief valve, warning light switch and filter are also

fitted to the front cover.

Oil drawn through the centrally located steel gauze strainer in the sump, is pumped under pressure through oil

cooler located in the lower half of the main coolant radiator. The cooled oil then passes through the filter, before

being distributed from the main gallery via drillings, to the various components in the engine.

Lubrication to the thrust side of the cylinders is by oil grooves machined in each connecting rod big end joint face,

which are timed to align with holes in the big end journals on the power and exhaust strokes.

Lubrication system

1. Oil to cooler

2. Oil from cooler