starter removal LAND ROVER DISCOVERY 1995 Service Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 976, PDF Size: 14.57 MB

Page 86 of 976

Tdi

5

REPAIR

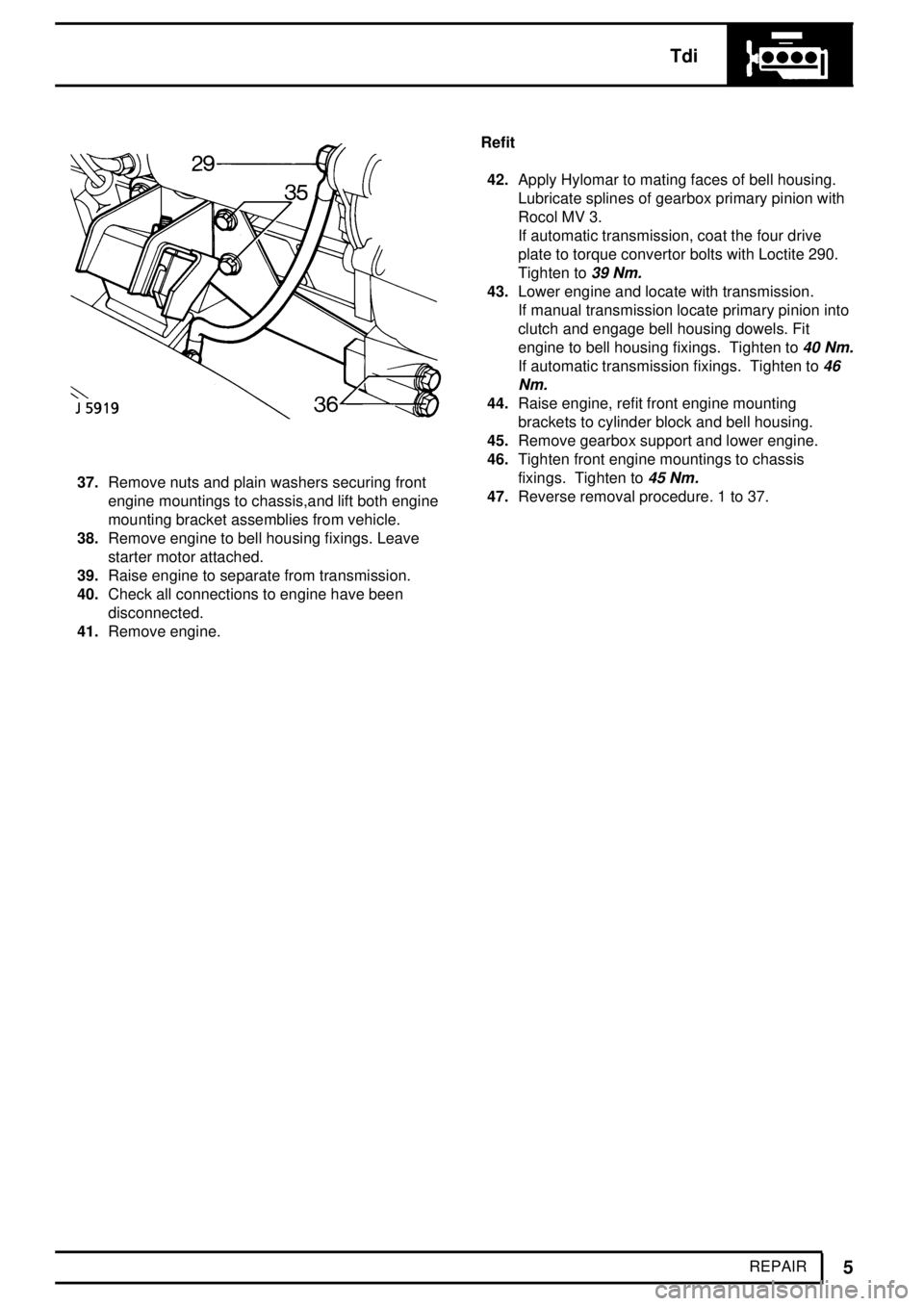

37.Remove nuts and plain washers securing front

engine mountings to chassis,and lift both engine

mounting bracket assemblies from vehicle.

38.Remove engine to bell housing fixings. Leave

starter motor attached.

39.Raise engine to separate from transmission.

40.Check all connections to engine have been

disconnected.

41.Remove engine.Refit

42.Apply Hylomar to mating faces of bell housing.

Lubricate splines of gearbox primary pinion with

Rocol MV 3.

If automatic transmission, coat the four drive

plate to torque convertor bolts with Loctite 290.

Tighten to

39 Nm.

43.Lower engine and locate with transmission.

If manual transmission locate primary pinion into

clutch and engage bell housing dowels. Fit

engine to bell housing fixings. Tighten to

40 Nm.

If automatic transmission fixings. Tighten to46

Nm.

44.Raise engine, refit front engine mounting

brackets to cylinder block and bell housing.

45.Remove gearbox support and lower engine.

46.Tighten front engine mountings to chassis

fixings. Tighten to

45 Nm.

47.Reverse removal procedure. 1 to 37.

Page 444 of 976

ZF

7

REPAIR Accessories removal/fitting

If fitting a replacement transmission assembly to the

vehicle, remove the following items from the existing

assembly and fit to the replacement.

CAUTION: It is important to remove the

spacer from the extension shaft and fit

onto the replacement unit.

50.Breather pipe union and washers from main

gearbox.

51.Breather pipe, union and washers from transfer

gearbox.

52.Main gearbox selector lever.

53.RH mounting bracket assembly.

54.Oil cooler pipe unions.

55.Fit blanks to all apertures where unions have

been removed and blank off pipe ends.

Refit

1.Fit transmission to cradle and hoist.

2.Locate hoist under vehicle and remove torque

convertor retaining strap.

3.Ensure low range gear is engaged.

4.Apply approved sealant to bell housing face.

5.Carefully raise assembly, align bell housing with

flywheel housing and bring mating faces

together.

6.Fit nuts and bolts to secure transmission to

engine.

7.Locate electrical wiring and breather pipes to

position.

8.Secure kick down cable clip to bell housing.

9.Raise hoist sufficiently to take weight.

10.Remove block and jack from engine sump.

11.Fit filler/dipstick tube to gearbox sump and

secure bracket to bell housing.

12.Apply Loctite to torque convertor bolts

13.Working through starter aperture refit the four

torque convertor to flexible drive securing bolts,

rotating crankshaft to gain access to bolt

locations.

14.Refit starter and heatshield.

15.Secure breather pipes and harness with ties.

16.Fit left hand mounting bracket assembly to

gearbox.

17.Raise transmission and support with a suitable

ramp [hoist] jack.

18.Remove two bolts securing transmission to

cradle, lower hoist and remove from under

vehicle.

19.Apply Loctite to above bolts and fit to transfer

gearbox input bearing support plate.

20.Fit chassis cross member.21.Secure gearbox mounting brackets to chassis

cross member.

22.Remove ramp [hoist] jack.

23.Connect electrical leads to differential lock

switch.

24.Connect inhibitor switch multi-plug.

25.Connect selector cable to lever on side of

gearbox.

26.Connect oil cooler pipes to gearbox and secure

retaining bracket to gearbox sump.

27.Secure silencer to chassis and refit exhaust front

pipe.

28.Refit front propeller shaft to transfer gearbox.

29.Refit rear propeller shaft.

See PROPELLER

SHAFTS, Overhaul, Flexible Coupling

30.Connect speedometer cable to transfer gearbox.

31.Refill transfer gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

32.Lower ramp [hoist] to ground level.

33.Reconnect turbo-charger hose to inter-cooler.

34.Reconnect top hose to radiator.

35.Refill cooling system with correct mixture of

coolant.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

36.Reconnect kick down cable to fuel injection

pump.

37.Secure breather pipe clip to rear of cylinder

head.

38.Engage harness with clips along top of

bulkhead.

39.On left hand drive vehicles only, connect

multi-plug to top of brake fluid reservoir.

40.Refit insulation pad to rocker cover and inlet

manifold, secure with oil filler cap.

41.Refit gaiter and knob to transfer gear lever.

42.Select high range gear.

43.Reconnect battery terminals.

44.Refill main gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

Page 640 of 976

75SUPPLEMENTARY RESTRAINT SYSTEM

4

DESCRIPTION AND OPERATION GENERAL PRECAUTIONS

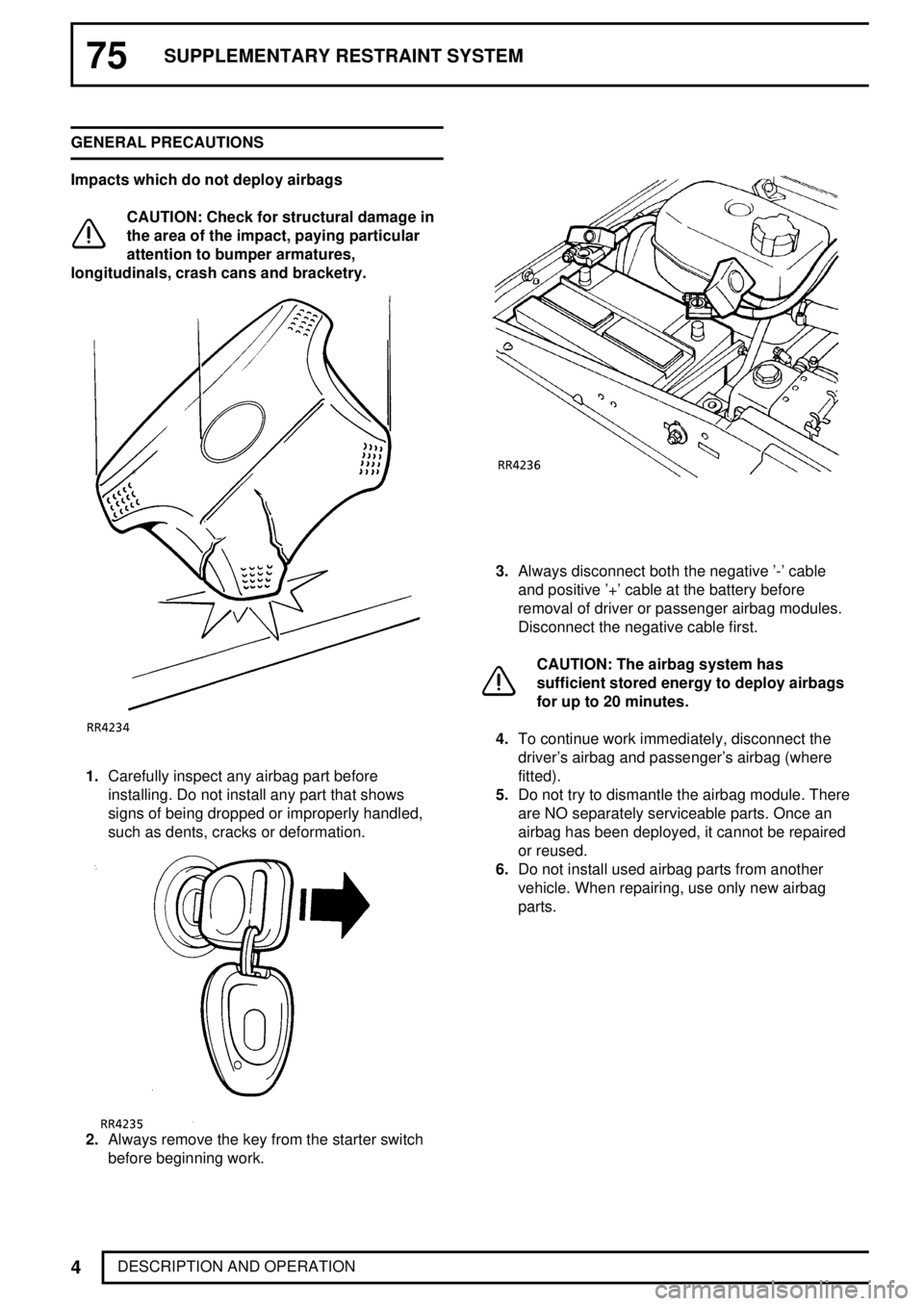

Impacts which do not deploy airbags

CAUTION: Check for structural damage in

the area of the impact, paying particular

attention to bumper armatures,

longitudinals, crash cans and bracketry.

1.Carefully inspect any airbag part before

installing. Do not install any part that shows

signs of being dropped or improperly handled,

such as dents, cracks or deformation.

2.Always remove the key from the starter switch

before beginning work.

3.Always disconnect both the negative '-' cable

and positive '+' cable at the battery before

removal of driver or passenger airbag modules.

Disconnect the negative cable first.

CAUTION: The airbag system has

sufficient stored energy to deploy airbags

for up to 20 minutes.

4.To continue work immediately, disconnect the

driver's airbag and passenger's airbag (where

fitted).

5.Do not try to dismantle the airbag module. There

are NO separately serviceable parts. Once an

airbag has been deployed, it cannot be repaired

or reused.

6.Do not install used airbag parts from another

vehicle. When repairing, use only new airbag

parts.

Page 823 of 976

ELECTRICAL

3

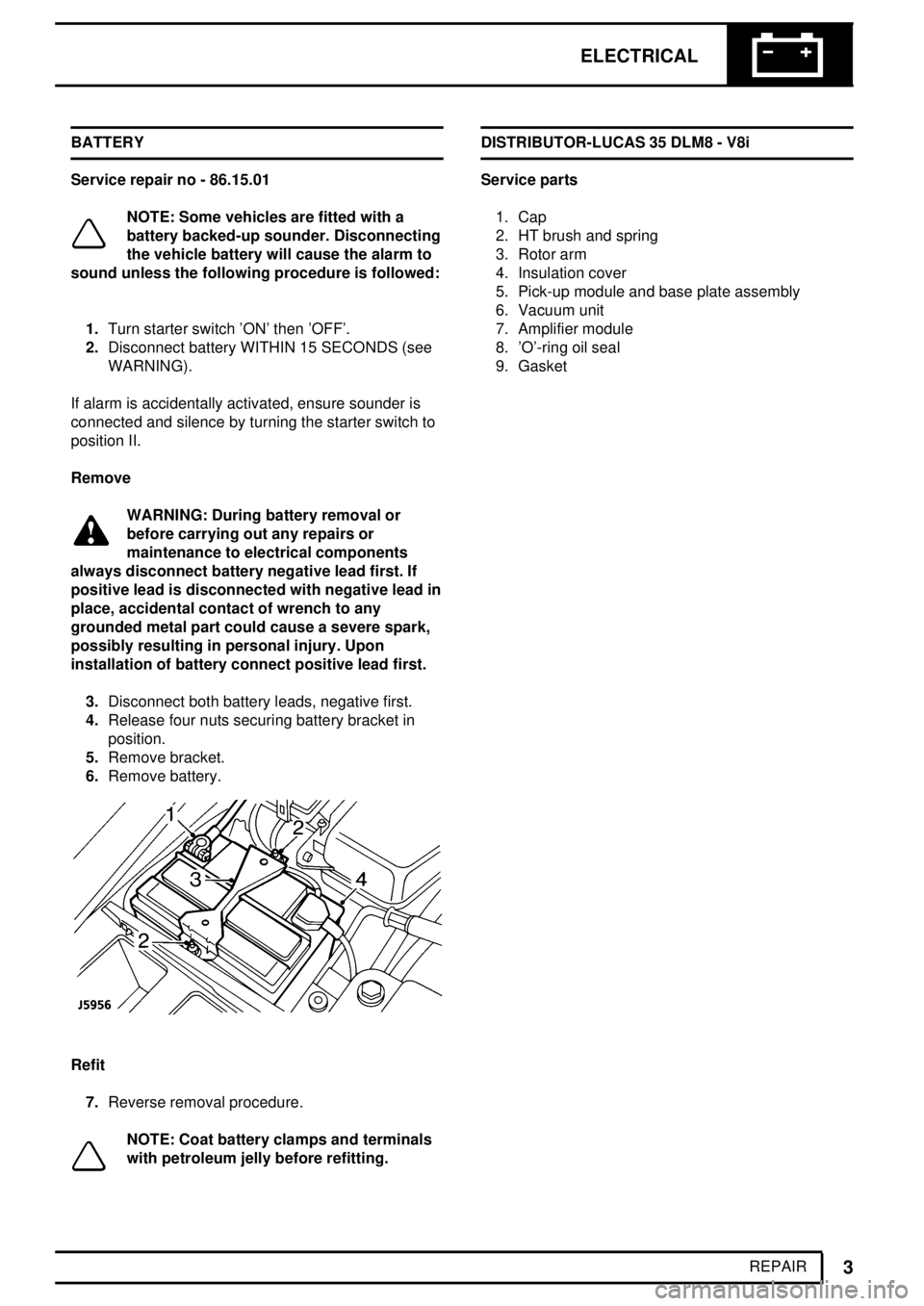

REPAIR BATTERY

Service repair no - 86.15.01

NOTE: Some vehicles are fitted with a

battery backed-up sounder. Disconnecting

the vehicle battery will cause the alarm to

sound unless the following procedure is followed:

1.Turn starter switch 'ON' then 'OFF'.

2.Disconnect battery WITHIN 15 SECONDS (see

WARNING).

If alarm is accidentally activated, ensure sounder is

connected and silence by turning the starter switch to

position II.

Remove

WARNING: During battery removal or

before carrying out any repairs or

maintenance to electrical components

always disconnect battery negative lead first. If

positive lead is disconnected with negative lead in

place, accidental contact of wrench to any

grounded metal part could cause a severe spark,

possibly resulting in personal injury. Upon

installation of battery connect positive lead first.

3.Disconnect both battery leads, negative first.

4.Release four nuts securing battery bracket in

position.

5.Remove bracket.

6.Remove battery.

Refit

7.Reverse removal procedure.

NOTE: Coat battery clamps and terminals

with petroleum jelly before refitting.DISTRIBUTOR-LUCAS 35 DLM8 - V8i

Service parts

1. Cap

2. HT brush and spring

3. Rotor arm

4. Insulation cover

5. Pick-up module and base plate assembly

6. Vacuum unit

7. Amplifier module

8. 'O'-ring oil seal

9. Gasket

Page 863 of 976

ELECTRICAL

43

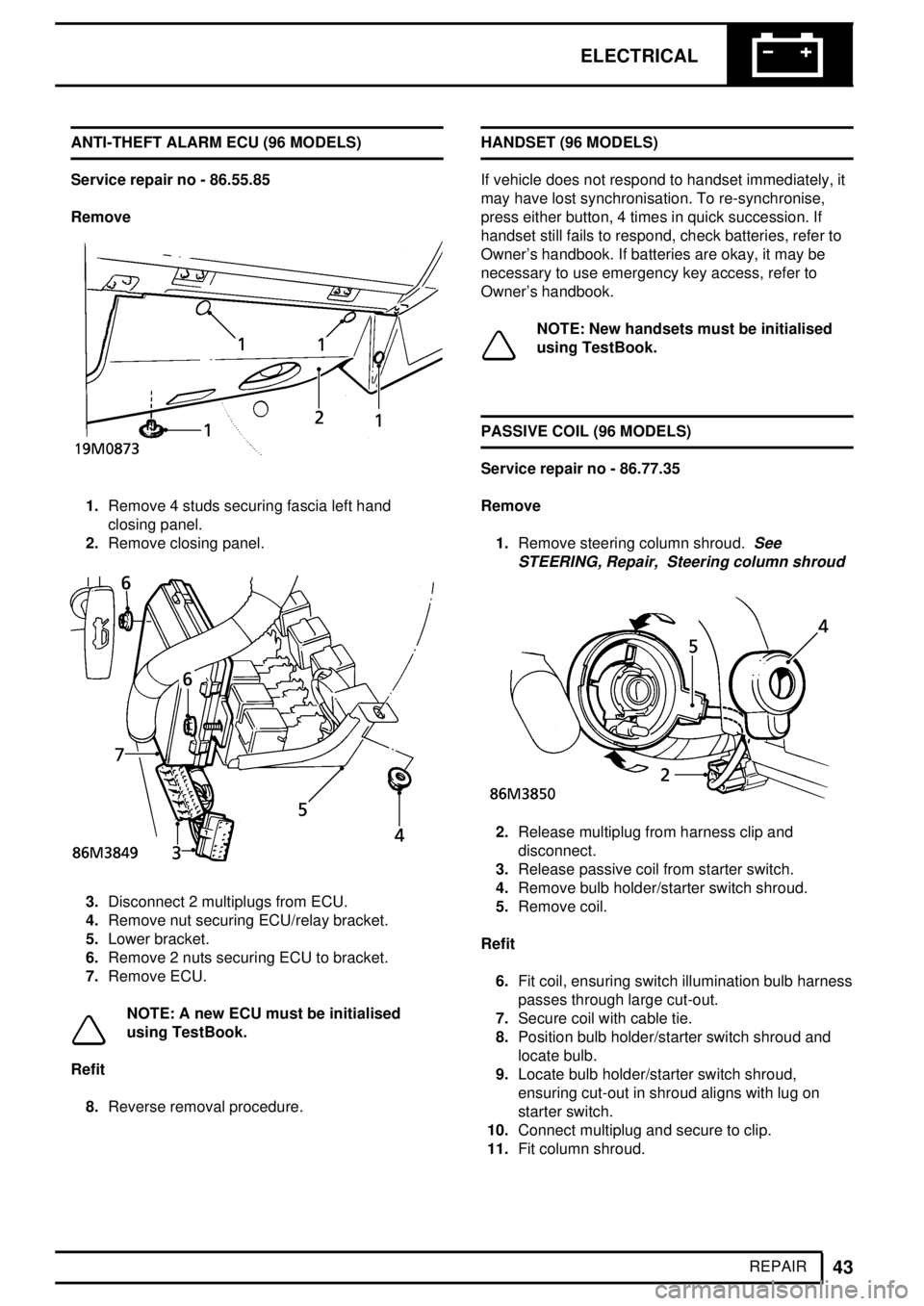

REPAIR ANTI-THEFT ALARM ECU (96 MODELS)

Service repair no - 86.55.85

Remove

1.Remove 4 studs securing fascia left hand

closing panel.

2.Remove closing panel.

3.Disconnect 2 multiplugs from ECU.

4.Remove nut securing ECU/relay bracket.

5.Lower bracket.

6.Remove 2 nuts securing ECU to bracket.

7.Remove ECU.

NOTE: A new ECU must be initialised

using TestBook.

Refit

8.Reverse removal procedure.HANDSET (96 MODELS)

If vehicle does not respond to handset immediately, it

may have lost synchronisation. To re-synchronise,

press either button, 4 times in quick succession. If

handset still fails to respond, check batteries, refer to

Owner's handbook. If batteries are okay, it may be

necessary to use emergency key access, refer to

Owner's handbook.

NOTE: New handsets must be initialised

using TestBook.

PASSIVE COIL (96 MODELS)

Service repair no - 86.77.35

Remove

1.Remove steering column shroud.

See

STEERING, Repair, Steering column shroud

2.Release multiplug from harness clip and

disconnect.

3.Release passive coil from starter switch.

4.Remove bulb holder/starter switch shroud.

5.Remove coil.

Refit

6.Fit coil, ensuring switch illumination bulb harness

passes through large cut-out.

7.Secure coil with cable tie.

8.Position bulb holder/starter switch shroud and

locate bulb.

9.Locate bulb holder/starter switch shroud,

ensuring cut-out in shroud aligns with lug on

starter switch.

10.Connect multiplug and secure to clip.

11.Fit column shroud.

Page 865 of 976

ELECTRICAL

45

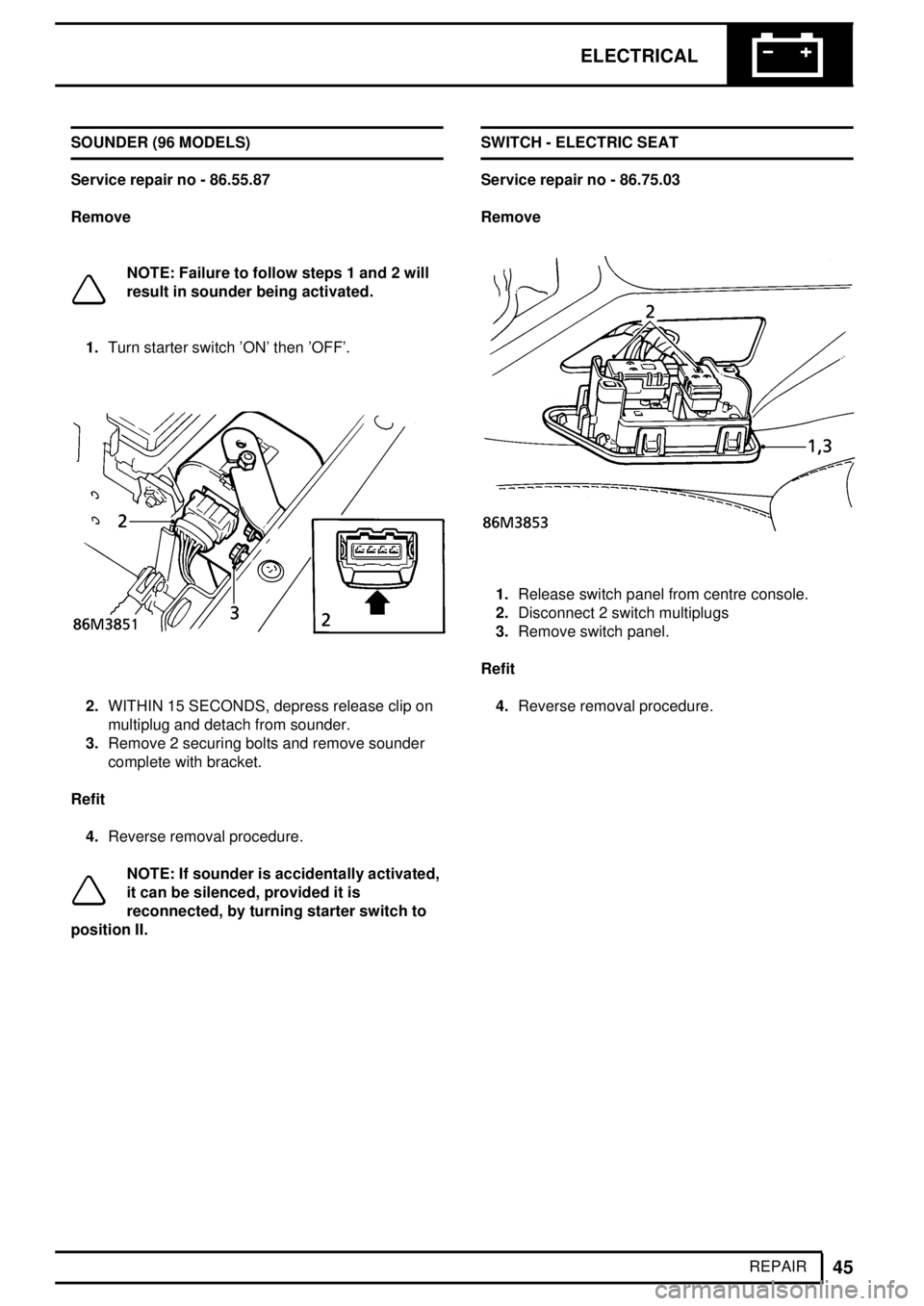

REPAIR SOUNDER (96 MODELS)

Service repair no - 86.55.87

Remove

NOTE: Failure to follow steps 1 and 2 will

result in sounder being activated.

1.Turn starter switch 'ON' then 'OFF'.

2.WITHIN 15 SECONDS, depress release clip on

multiplug and detach from sounder.

3.Remove 2 securing bolts and remove sounder

complete with bracket.

Refit

4.Reverse removal procedure.

NOTE: If sounder is accidentally activated,

it can be silenced, provided it is

reconnected, by turning starter switch to

position II.SWITCH - ELECTRIC SEAT

Service repair no - 86.75.03

Remove

1.Release switch panel from centre console.

2.Disconnect 2 switch multiplugs

3.Remove switch panel.

Refit

4.Reverse removal procedure.

Page 867 of 976

ELECTRICAL

47

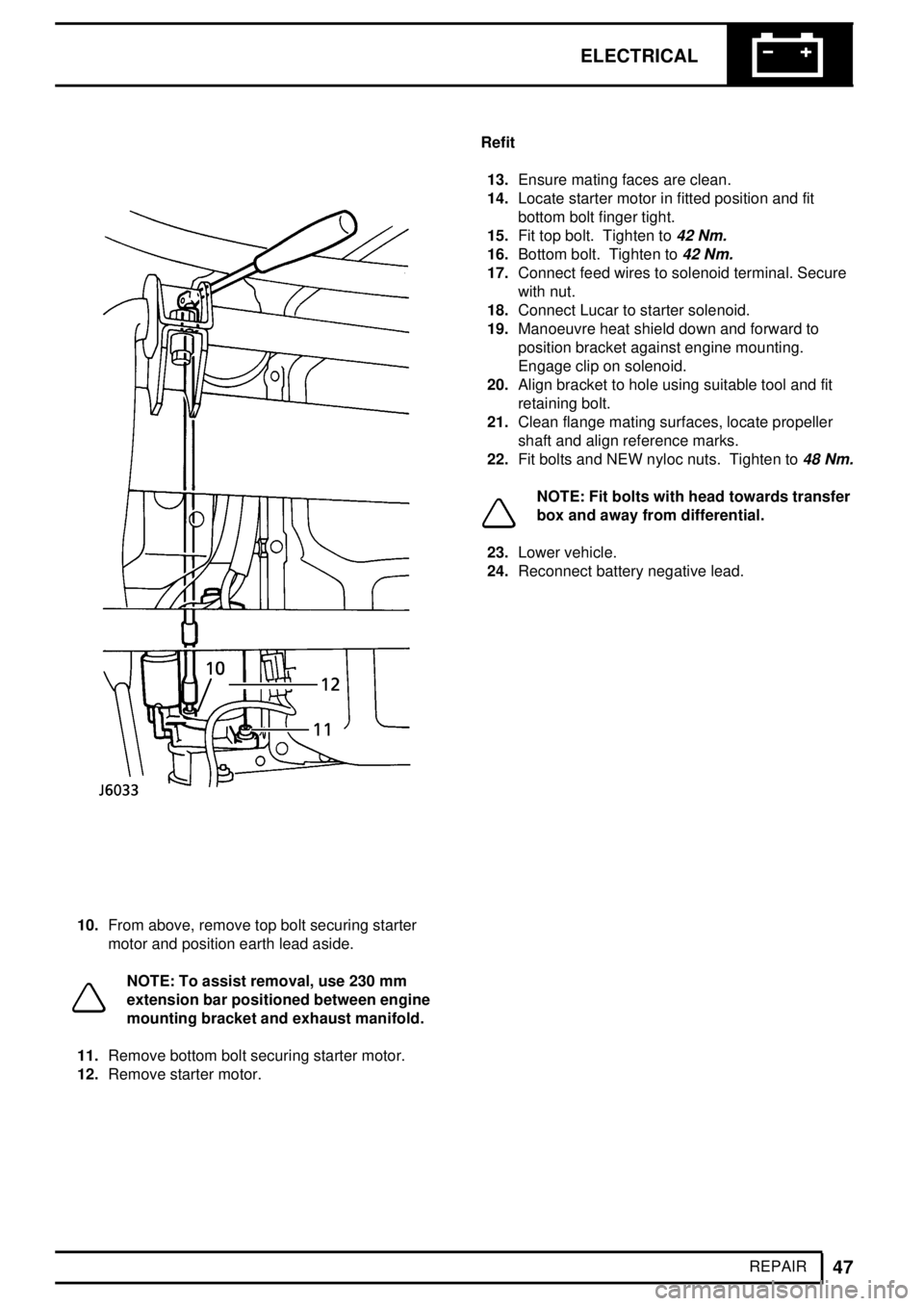

REPAIR

10.From above, remove top bolt securing starter

motor and position earth lead aside.

NOTE: To assist removal, use 230 mm

extension bar positioned between engine

mounting bracket and exhaust manifold.

11.Remove bottom bolt securing starter motor.

12.Remove starter motor.Refit

13.Ensure mating faces are clean.

14.Locate starter motor in fitted position and fit

bottom bolt finger tight.

15.Fit top bolt. Tighten to

42 Nm.

16.Bottom bolt. Tighten to42 Nm.

17.Connect feed wires to solenoid terminal. Secure

with nut.

18.Connect Lucar to starter solenoid.

19.Manoeuvre heat shield down and forward to

position bracket against engine mounting.

Engage clip on solenoid.

20.Align bracket to hole using suitable tool and fit

retaining bolt.

21.Clean flange mating surfaces, locate propeller

shaft and align reference marks.

22.Fit bolts and NEW nyloc nuts. Tighten to

48 Nm.

NOTE: Fit bolts with head towards transfer

box and away from differential.

23.Lower vehicle.

24.Reconnect battery negative lead.

Page 868 of 976

86ELECTRICAL

48

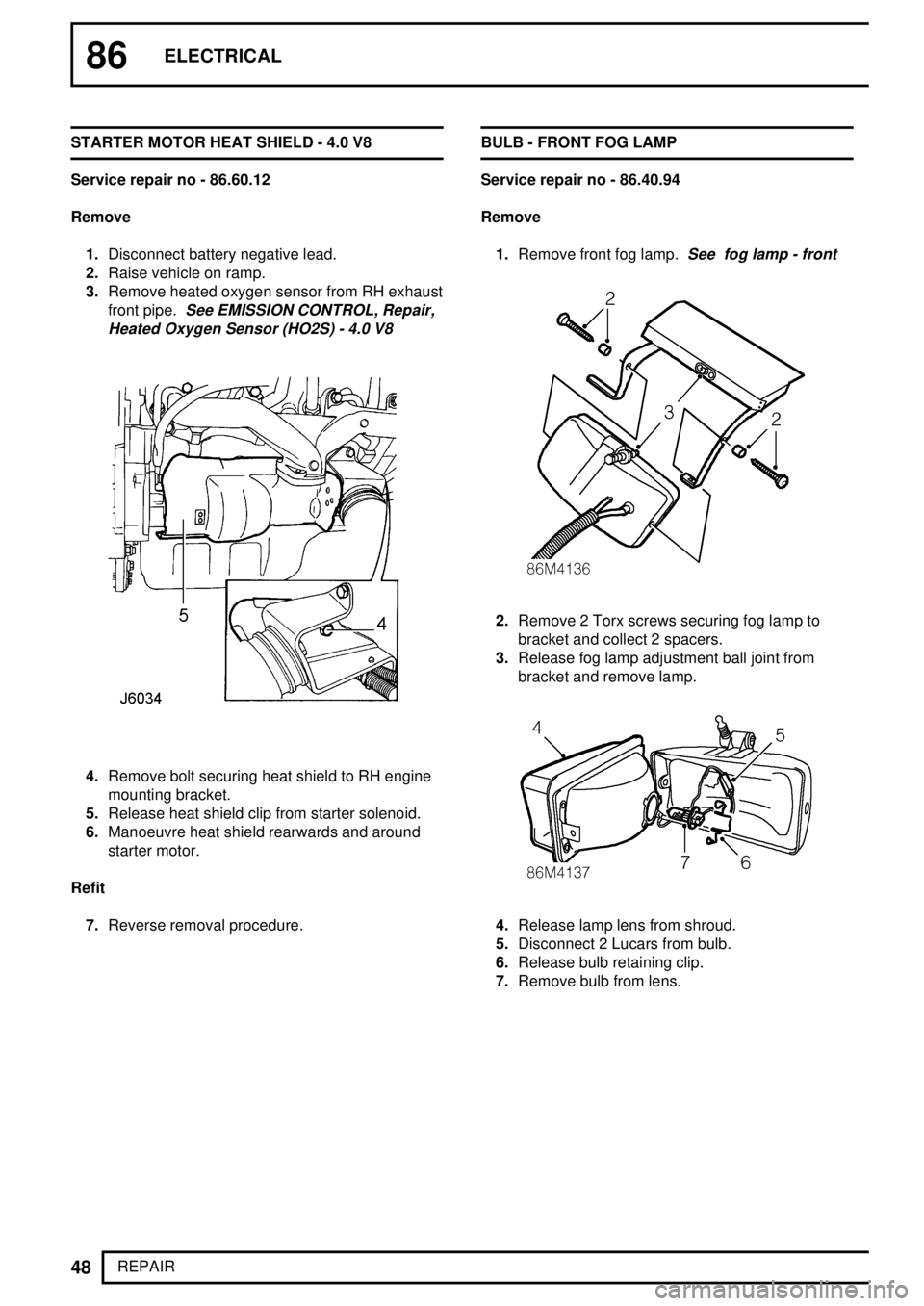

REPAIR STARTER MOTOR HEAT SHIELD - 4.0 V8

Service repair no - 86.60.12

Remove

1.Disconnect battery negative lead.

2.Raise vehicle on ramp.

3.Remove heated oxygen sensor from RH exhaust

front pipe.

See EMISSION CONTROL, Repair,

Heated Oxygen Sensor (HO2S) - 4.0 V8

4.Remove bolt securing heat shield to RH engine

mounting bracket.

5.Release heat shield clip from starter solenoid.

6.Manoeuvre heat shield rearwards and around

starter motor.

Refit

7.Reverse removal procedure.BULB - FRONT FOG LAMP

Service repair no - 86.40.94

Remove

1.Remove front fog lamp.

See fog lamp - front

2.Remove 2 Torx screws securing fog lamp to

bracket and collect 2 spacers.

3.Release fog lamp adjustment ball joint from

bracket and remove lamp.

4.Release lamp lens from shroud.

5.Disconnect 2 Lucars from bulb.

6.Release bulb retaining clip.

7.Remove bulb from lens.