check engine LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 547 of 873

STEERING

5

REPAIR POWER STEERING SYSTEM - BLEED

Service repair no - 57.15.02

1.Ensure fluid in reservoir reaches dipstick

maximum.

2.Run engine to normal operating temperature.

3.Recheck and correct reservoir fluid level.

NOTE: During instructions 4 to 6, maintain

maximum fluid level in reservoir. Do not

increase engine speed or move steering

wheel.

4.With engine at idle speed, loosen bleed screw.

When fluid seeps past bleed screw retighten

screw.

5.Check fluid level.

6.Clean away fluid around bleed screw.

7.Check hose connections, pump and steering box

for fluid leaks by holding steering on full lock in

both directions.

CAUTION: Do not maintain this pressure

for more than 30 seconds in any one

minute to avoid overheating fluid and

possibly damaging seals.

8.Carry out road test.POWER STEERING FLUID RESERVOIR

Service repair no - 57.15.08

Remove

1.Remove undertray.

2.Position drain tin beneath reservoir.

3.Loosen mounting bracket clamp bolt, raise

reservoir to gain access to pipe clamps.

4.Loosen clamps, disconnect feed and return

hoses from reservoir, allow fluid to drain.

CAUTION: Plug the connections.

5.Remove reservoir.

CAUTION: Discard fluid drained from

system. Do not allow fluid to contact

paintwork, if spilled, remove fluid and

clean area with warm water.

Page 601 of 873

BRAKES

1

FAULT DIAGNOSIS ABS FAULT DIAGNOSIS

If a fault has occurred, or has been identified by ECU

self diagnostic function and ABS warning light is

illuminated. The system and components must be

checked to locate and rectify fault, using Testbook

diagnostics.

NOTE: If warning lamp has indicated a

fault in system, and no fault code has been

stored in memory, cause of fault is:

a) Failure in electrical supply

b) Bad ECU ground

c) Faulty warning light relay

d) ECU not connected

Before commencing fault diagnosis procedure

following items must be checked:

1.Inspect all exposed cables for damage or

abrasion.

2.Check ground on ABS system.

3.Battery - state of charge.

4.Check hub end-float.

5.All ABS fuses and electrical connections.

Fault rectification

1.Complete harness should be replaced if faults

are found in wiring harness.

2.DO NOT use unspecified cables or connectors,

as this could jeopardise safe function of ABS.

3.DO NOT attempt to open sealed 35 way

connector to ECU.FAULT DIAGNOSIS PROCEDURE

NOTE: If ABS warning light illuminates due

to large sensor air gap, fault will be

retained by the ECU memory. Where wheel

sensors have been pushed fully home prior to

test, The ECU will indicate a fault that has been

rectified.

NOTE: After any steering adjustment,

bearing replacement/adjustment, brake

disc replacement: Check hub end-float and

sensor clearance.

RELAYS AND FUSES ABS

The location and identification of ABS electrical relays

are given in the Electrical Troubleshooting Manual

For location and identification of ABS electrical fuses.

See ELECTRICAL, Repair, Fuse Box - Interioror.

See ELECTRICAL, Repair, Fuse Box - Engine

Compartment

Page 603 of 873

BRAKES

1

REPAIR GENERAL BRAKE SERVICE PRACTICE

Brake fluid precautions

WARNING: Do not allow brake fluid to

come into contact with eyes or skin.

CAUTION: Brake fluid can damage

paintwork, if spilled wash off immediately

with plenty of clean water.

CAUTION: Use only correct grade of brake

fluid. If an assembly fluid is required use

ONLY brake fluid. Do NOT use mineral oil,

i.e. engine oil etc.

CAUTION: Thoroughly clean all brake

calipers, pipes and fittings before

commencing work on any part of the brake

system. Failure to do so could cause foreign

matter to enter the system and cause damage to

seals and pistons which will seriously impair the

efficiency of the brake system.

·To ensure the brake system efficiency is not

impaired the following warnings must be

adhered to :-

·DO NOT use any petroleum based cleaning

fluids or any proprietary fluids containing

petrol.

·DO NOT use brake fluid previously bled from

the system.

·DO NOT flush the brake system with any fluid

other than the recommended brake fluid.

The brake system should be drained and flushed

at the recommended service intervals.

Cover all electrical terminals carefully to make

absolutely certain that no fluid enters the

terminals and plugs.FLUID LEVEL CHECK / TOP UP

WARNING: Clean reservoir body and filler

cap before removing cap. Use only fluid

from a sealed container.

1.Park vehicle on level ground.

2.Check level is between 'MIN' and 'MAX' marks.

3.If level is below 'MIN' mark top up fluid level to

'MAX' mark on reservoir, using correct fluid.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended Lubricants and

Fluids

Do not fill reservoir above maximum line

Page 742 of 873

HEATING AND VENTILATION

1

FAULT DIAGNOSIS HEATER OUTPUT

Symptom:-

Heater emits cold air.

1.Engine running: Check coolant valve opens as a

temperature control is moved from COLD.

2.Check for engine running cold.

See COOLING

SYSTEM, Fault diagnosis, Engine Runs Cold

3.Check heater pipes and hoses for blockage or

restriction.

4.Check heater matrix for blockage or restriction,

flush system.

Heater emits warm air.

5. Engine running:Check coolant valve closes

when both temperature controls are moved to

COLD.

Page 759 of 873

82AIR CONDITIONING

4

FAULT DIAGNOSISFAULT CAUSE REMEDY

E.

NOISY

EXPANSION

VALVE

(steady hissing)1. Low refrigerant charge; evident by

bubbles in sight glass.1. Leak test. Repair or replace

components as required.

F.1. Expansion valve not operating 1. Refer to C-2, C-3, D-1

INSUFFICIENTproperly. and E.

COOLING2. Low refrigerant charge-evident 2. Refer to B-1 and E.

by bubbles in sight glass.

3. Compressor not pumping. 3. Refer to B-2 and B-3

G.1. Belt tension. 1. Adjust belt tension.

COMPRESSOR2. Excessive head pressure. 2. Refer to A-1 through

BELTA-4 and C-6.

SLIPPING3. Incorrect alignment of pulleys 3. Repair as needed.

or worn belt not riding properly.

4. Nicked or broken pulley. 4. Replace as needed.

5. Seized compressor. 5. Replace compressor.

1. Loose or missing mounting bolts. 1. Repair as necessary.

2. Broken mounting bracket. 2. Replace bracket.

3. Loose flywheel or clutch 3. Repair as necessary.

retaining bolt.

H.4. Rough idler pulley bearing. 4. Replace bearing.

ENGINE5. Bent, loose, or improperly 5. Repair as necessary.

NOISEmounted engine drive pulley.

AND/OR6. Defective compressor bearing. 6. Replace bearing.

VIBRATION7. Insecure mountings of 7. Repair as necessary.

accessories; generator, power

steering, air filter, etc.

8. Excessive head pressure. 8. Refer to A-1, A-2, A-3

A-4 and C-6.

9. Incorrect compressor oil level. 9. Refer to compressor Oil

Level Check.

HEATER AND AIR CONDITIONING - CIRCUIT

DIAGRAMS

1.For details of heating and air conditioning

electrics

See Electrical Trouble Shooting

Manual.

Page 763 of 873

82AIR CONDITIONING

4

ADJUSTMENT Evacuation and recharging

1.Add refrigerant oil to compressor if necessary.

2.Renew the receiver/drier.

CAUTION: When a major repair has been

carried out, a leak test should be carried

out using inert gas.

3.Connect a Refrigerant Station to the high and

low pressure servicing connections.

CAUTION: Whenever the refrigerant

system is opened, the receiver/drier must

be renewed immediately before evacuating

and recharging the system.

4.Operate the refrigerant evacuation system

according to the manufacturer's instructions.

NOTE: If the vacuum reading is below

700mmHg after 15 minutes, suspect a leak

in the system. Partially recharge the

system and check for leaks using an electronic

leak tester. Check suction lines first, then run the

compressor for 5 minutes and then check the high

pressure lines.

CAUTION: The system must be evacuated

immediately before recharging

commences. Delay between evacuation

and recharging is not permitted.

5.Operate the refrigerant recharging system

according to the manufacturer's instructions:-

Refrigerant required to charge system:

Without rear air conditioning = 0.90kg (32 fl/oz)

With rear air conditioning = 1.15kg (40 fl/oz)

6.If the full charge has not been accepted by the

system, start the engine and run it at 1500

rev/min for a minimum of 2 minutes.

Switch on the air conditioning system, open the

car windows, set the temperature control to cold

and switch the blower to maximum speed.

7.Consult Refrigerant Station Manual for correct

procedure to complete the charge.

8.Carry out the air conditioning system

performance test.LEAK TEST SYSTEM

The following instructions refer to an electronic type

Refrigerant Leak Detector for use with R134a, which

are the safest and most sensitive.

CAUTION: When a major repair has been

carried out, a leak test should be carried

out using an inert gas (see below).

1.Place the vehicle in a well ventilated area but

free from draughts, as leakage from the system

could be dissipated without detection.

2.Follow the instructions issued by the

manufacturer of the particular leak detector

being used.

3.Commence searching for leaks by passing the

detector probe around all joints and components,

refrigerant gas is heavier than air.

4.Insert the probe into an air outlet of the

evaporator or into the evaporator drain tube.

Switch the air conditioning blower on and off at

intervals of ten seconds. Any leaking refrigerant

will be gathered in by the blower and detected.

5.Insert the probe between the magnetic clutch

and compressor to check the shaft seal for

leaks.

6.Check all service valve connections, valve plate,

head and base plate joints and back seal plate.

7.Check the condenser for leaks at the pipe

unions.

8.If any leaks are found, the system must be

discharged before rectification.

9.Rectify any leaks and recheck for leaks during

evacuation prior to charging.

Leak test using inert gas

Use Nitrogen or Helium gas.

1.Connect gas line to recharging station.

2.Pressurise system to 3 bar.

3.Carry out leak test as above.

Page 764 of 873

AIR CONDITIONING

5

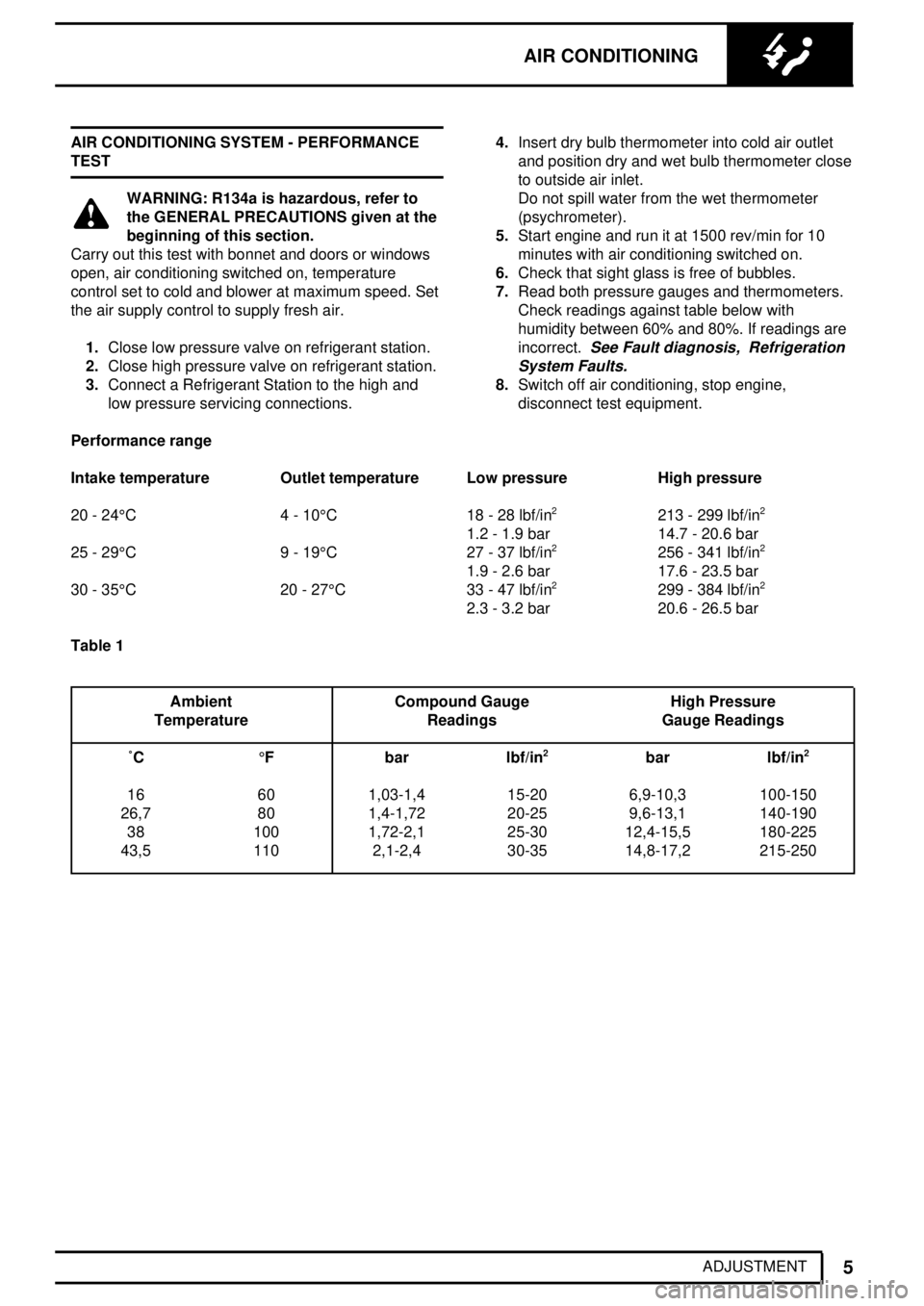

ADJUSTMENT AIR CONDITIONING SYSTEM - PERFORMANCE

TEST

WARNING: R134a is hazardous, refer to

the GENERAL PRECAUTIONS given at the

beginning of this section.

Carry out this test with bonnet and doors or windows

open, air conditioning switched on, temperature

control set to cold and blower at maximum speed. Set

the air supply control to supply fresh air.

1.Close low pressure valve on refrigerant station.

2.Close high pressure valve on refrigerant station.

3.Connect a Refrigerant Station to the high and

low pressure servicing connections.4.Insert dry bulb thermometer into cold air outlet

and position dry and wet bulb thermometer close

to outside air inlet.

Do not spill water from the wet thermometer

(psychrometer).

5.Start engine and run it at 1500 rev/min for 10

minutes with air conditioning switched on.

6.Check that sight glass is free of bubbles.

7.Read both pressure gauges and thermometers.

Check readings against table below with

humidity between 60% and 80%. If readings are

incorrect.

See Fault diagnosis, Refrigeration

System Faults.

8.Switch off air conditioning, stop engine,

disconnect test equipment.

Performance range

Intake temperature Outlet temperature Low pressure High pressure

20 - 24°C4-10°C 18 - 28 lbf/in

2213 - 299 lbf/in2

1.2 - 1.9 bar 14.7 - 20.6 bar

25 - 29°C9-19°C 27 - 37 lbf/in2256 - 341 lbf/in2

1.9 - 2.6 bar 17.6 - 23.5 bar

30 - 35°C20-27°C 33 - 47 lbf/in2299 - 384 lbf/in2

2.3 - 3.2 bar 20.6 - 26.5 bar

Table 1

Ambient Compound Gauge High Pressure

Temperature Readings Gauge Readings

ÊC°F bar lbf/in

2bar lbf/in2

16 60 1,03-1,4 15-20 6,9-10,3 100-150

26,7 80 1,4-1,72 20-25 9,6-13,1 140-190

38 100 1,72-2,1 25-30 12,4-15,5 180-225

43,5 110 2,1-2,4 30-35 14,8-17,2 215-250

Page 765 of 873

82AIR CONDITIONING

6

ADJUSTMENT SYSTEM TEST

1.Place the vehicle in a ventilated, shaded area

free from excessive draught, with the doors and

windows open.

2.Check that the surface of the condenser is not

restricted with dirt, leaves, flies, etc. Do not

neglect to check the surface between the

condenser and the radiator. Clean as necessary.

3.Switch on the ignition and the air conditioner air

flow control. Check that the blower is operating

efficiently at low, medium and high speeds.

Switch off the blower and the ignition.

4.Check that the evaporator condensate drain

tubes are open and clear.

5.Check the tension of the compressor driving belt,

and adjust if necessary.

6.Inspect all connections for the presence of

refrigerant oil. If oil is evident, check for leaks,

and repair as necessary.

NOTE: The compressor oil is soluble in

Refrigerant R134a and is deposited when

the refrigerant evaporates from a leak.

7.Start the engine.

8.Set the temperature controls to cold and switch

the air conditioner blower control on and off

several times, checking that the magnetic clutch

on the compressor engages and releases each

time.9.With the temperature control at maximum

cooling and the blower control at high speed,

warm up the engine and fast idle at 1000

rev/min. Check the sight glass for bubbles or

foam. The sight glass should be generally clear

after five minutes running, occasional bubbles

being acceptable. Continuous bubbles may

appear in a serviceable system on a cool day, or

if there is insufficient air flow over the condenser

at a high ambient temperature.

10.Repeat at 1800 rev/min.

11.Gradually increase the engine speed to the high

range, and check the sight glass at intervals.

12.Check for frosting on the service valves.

13.Check the high pressure hoses and connections

by hand for varying temperature. Low

temperature indicates a restriction or blockage at

that point.

14.Switch off the air conditioning blower and stop

the engine.

15.If the air conditioning equipment is still not

satisfactory, carry out a pressure test as

previously described in this section.

COMPRESSOR DRIVE BELT

Service repair no - 82.10.01.

Tdi -

See ENGINE, Repair, Compressor drive belt

V8i and MpiSee ENGINE, Repair, Drive belt

Page 770 of 873

AIR CONDITIONING

5

REPAIR COMPRESSOR

Service repair no - 82.10.20

Remove

1.Disconnect battery negative lead.

2.Recover refrigerant from air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

3.Remove screws retaining centre panel to fan

cowl

4.Remove centre panel.

V8i engine illustrated

5.Remove 2 bolts securing hose flanges to

compressor.

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.6.Disconnect high pressure hose from

compressor.

7.Disconnect low pressure hose from compressor.

8.Remove 'O' ring from each flange.

9.Disconnect electrical lead from compressor

clutch.

10.Release drive belt from compressor pulley.

See

ENGINE, Repair, Drive Belt

11.Remove 4 bolts securing compressor to

mounting bracket.

12.Remove compressor from mounting bracket.

Refit

13.New compressor to be fitted: Drain oil from new

compressor outlet port. Drain and measure oil

from old compressor. Measure new oil equal to

amount drained from old compressor, add 30 ml

extra to this amount and refill new compressor

through outlet port.

14.Locate compressor in mounting bracket, fit bolts.

Tighten to

25 Nm.

15.Connect electrical lead to compressor clutch.

16.Fit new 'O' rings to high and low pressure hose

flanges, lubricate with refrigerant oil.

17.Engage hose flanges, fit bolts. Tighten to

10

Nm.

18.Fit compressor drive belt.See ENGINE, Repair,

Drive Belt

19.Fit centre panel to fan cowl.

20.Evacuate and recharge air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

21.Perform a leak test on disturbed joints.

22.Carry out a functional check.

Page 804 of 873

ELECTRICAL

1

DESCRIPTION AND OPERATION ELECTRICAL EQUIPMENT

DESCRIPTION

The electrical system is Negative ground, and it is

most important to ensure correct polarity of the

electrical connections at all times. Any incorrect

connections made when reconnecting cables may

cause irreparable damage to the semi-conductor

devices used in the generator and regulator. Incorrect

polarity would also seriously damage any

transistorized equipment such as radio and

tachometer etc.

WARNING: During battery removal or

before carrying out any repairs or

maintenance to electrical components

always disconnect the battery negative lead first.

If the positive lead is disconnected with the

negative lead in place, accidental contact of the

wrench to any grounded metal part could cause a

severe spark, possibly resulting in personal

injury. Upon installation of the battery the positive

lead should be connected first.

GENERATOR

The generator is a three phase, field sensed unit. The

rotor and stator windings produce three phase

alternating current, AC, which is rectified to direct

current, DC. The electronic voltage regulator unit

controls the generator output voltage by high

frequency switching of the rotor field circuit. Use only

the correct Vehicle replacement fan belt. Occasionally

check that the engine and generator pulleys are

accurately aligned.

It is essential that good electrical connections are

maintained at all times. Of particular importance are

those in the charging circuit (including those at the

battery) which should be occasionally inspected to

see that they are clean and tight. In this way any

significant increase in circuit resistance can be

prevented.Do not disconnect battery cables while the engine is

running or damage to the semi-conductor devices

may occur. It is also inadvisable to break or make any

connections in the generator charging and control

circuits while the engine is running.

The electronic voltage regulator employs micro-circuit

techniques resulting in improved performance under

difficult service conditions. The whole assembly is

encapsulated in silicone rubber and housed in an

aluminium heat sink, ensuring complete protection

against the adverse effects of temperature, dust, and

moisture etc.

The regulating voltage is set during manufacture to

give the required regulating voltage range of 14.2±

0.2 volts, and no adjustment is necessary. The only

maintenance needed is the occasional check on

terminal connections and wiping with a clean dry

cloth.

The generator system provides for direct connection

of a charge (ignition) indicator warning light, and

eliminates the need for a field switching relay or

warning light control unit. As the warning lamp is

connected in the charging circuit, lamp failure will

cause loss of charge. Lamp should be checked

regularly and spare carried.

When using rapid charge equipment to re-charge the

battery, the battery must be disconnected from the

vehicle.

NOTE: For description and operation of

electrical circuits see separate publication:

Electrical Troubleshooting Manual.