gearbox LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 465 of 873

44AUTOMATIC GEARBOX

4

SERVICE TOOLS

LRT-44-005 Control unit oil seal remover/replacer.

LST 113

LRT-44-006 Selector shaft oil seal replacer.

LST 114

LRT-44-007 Line pressure test gauge.

18G.502A

LRT-44-008 Hose and adaptor.

18G.502K

Page 467 of 873

PROPELLER SHAFTS

1

DESCRIPTION AND OPERATION PROPELLER SHAFT ALIGNMENT

Description

The front and rear propeller shafts have non-constant

velocity 'Hooks' type universal joints, with needle roller

bearings. The bearing cups are pre-packed with

lubricant on assembly and a grease nipple is fitted for

servicing as specified, in maintenance section.

Both shafts have Rilsan coated sliding splines to

accommodate the variation in distance between the

axles and transmission. The splines are pre-packed

with lubricant and sealed.

The rear shaft is fitted with a conventional joint at

gearbox end and the sliding joint sealed with a rubber

gaiter. An SGF rubber coupling is fitted at the

differential end of the shaft.

The front shaft which is shorter than the rear is

'Phased', with the joints at each end, A and B

mis-aligned as shown in RR4199.

The phasing is necessary on the front shaft only to

allow for greater variation in angular changes.

Catalyst vehicles

The front shaft is 'phased' as above but is of solid bar

construction.

Page 468 of 873

PROPELLER SHAFTS

1

FAULT DIAGNOSIS VIBRATION HARSHNESS

1.Check that the propeller shaft universal joints

and sliding splines are not siezed or worn and

that the shafts are correctly aligned.

NOTE: In the event that both shafts are

satisfactory, but the vibration/harshness is

still present, the transfer box operation

and balance of the road wheels should be

checked.

For transfer box operation.

See TRANSFER

GEARBOX, Fault diagnosis, LT230T Transfer Box

- Oil Leaks

For balance of road wheels.See WHEELS AND

TYRES, Repair, Wheel Balancing

Page 470 of 873

47PROPELLER SHAFTS

2

REPAIR 18.Press each cup into its respective yoke up to

lower land of circlip grooves. Damage may be

caused to cups and seals if cups pass this point.

19.Fit circlips and check no end float exists.

20.Engage spider in yokes of sliding member. Fit

bearing cups and circlips as described in

instructions 14 to 19.

21.Fit grease nipples to spider and sliding member.

22.Apply instructions 14 to 19 to opposite end of

propeller shaft.

23.Fit grease nipple and lubricate.

Refit

24.Fit propeller shafts to vehicle and tighten nuts to

47Nm

Refit FRONT propeller shaft so sliding joint end

of shaft is fitted to transfer gearbox.

Page 472 of 873

47PROPELLER SHAFTS

4

REPAIR REAR PROPELLER SHAFT

Service repair no - 47.15.03

NOTE: SGF rubber coupling should be left

attached to propeller shaft. Only remove

coupling from propeller shaft if

replacement is required.

Remove

1.Scribe alignment marks on flanges at both ends

of propeller shaft to ensure correct refitting.

2.Remove three nuts and bolts securing flexible

coupling to axle flange.

3.Remove nuts securing propeller shaft flange to

transfer gearbox.

4.Raise propeller shaft at gearbox end detach

coupling from spigot at differential and withdraw

shaft.

NOTE: For replacement of spigot (pinion

flange centralising peg).

See REAR AXLE

AND FINAL DRIVE, Overhaul, Axle

Differential Assembly

Overhaul

Service repair no - 47.15.12

NOTE: Refer to front propeller shaft

overhaul procedure for gearbox end of

shaft. The SGF rubber coupling is a

non-serviceable item.

Refit

5.Locate flexible coupling over spigot, align

scribed marks and secure at transfer gearbox.

Tighten to

47 Nm.

6.Secure flexible coupling to axle flange with three

nuts and bolts and Tighten to

78 Nm.

FLEXIBLE COUPLING

NOTE: Flexible coupling should only be

removed if a new coupling is to be fitted.

Remove

1.Remove rear propeller shaft.

See Rear

Propeller Shaft.

2.Remove nuts and bolts securing flexible

coupling to propeller shaft.

Refit

3.Reverse removal procedure. Fit nuts and bolts.

Tighten to

78 Nm.

Page 592 of 873

BRAKES

1

DESCRIPTION AND OPERATION BRAKES

Discovery vehicles have servo assisted brake

systems and the option of an anti-lock brake system.

Information in this section refers to components

relevant to both brake systems. Where the system

components are different they are referred to as ABS

or NON ABS

BRAKE SYSTEM NON ABS

Description

The servo assisted hydraulic braking system is the

dual line type, incorporating primary and secondary

hydraulic circuits.

NOTE: References made to primary or

secondary do not imply main service

brakes or emergency brakes but denote

hydraulic line identification.

The brake pedal is connected to a vacuum assisted

mechanical servo which in turn operates a tandem

master cylinder. The front disc brake calipers each

house four pistons, these pistons are fed by the

secondary hydraulic circuit. The rear disc brake

calipers each house two pistons, these are fed by the

primary hydraulic circuit via a pressure reducing valve.

A brake fluid level switch is incorporated into the

reservoir cap assembly, the switch will immediately

illuminate a warning light in the instrument binnacle

indicating low fluid or sudden fluid loss.

The brake fluid reservoir is divided, the section closest

to the servo feeds the primary circuit and the section

furthest from the servo feeds the secondary circuit.

Under normal operating conditions both the primary

and secondary circuits operate simultaneously on

brake pedal application. In the event of a failure in the

primary circuit the secondary circuit will still function. If

the secondary circuit fails the primary circuit will still

function. The brake pedal travel will be longer in the

event of a half system failure.If the servo should fail, both hydraulic circuits will still

function but would require greater pedal effort due to

the lack of vacuum assistance. The hand operated

parking brake acts on a brake drum at the rear of the

transfer gearbox and is completely independent of the

hydraulic circuits.

Hydraulic circuit non ABS

Key

A = Primary hydraulic circuit

B = Secondary hydraulic circuit

C = Pressure reducing valve

Page 635 of 873

74WHEELS AND TYRES

6

REPAIR WHEELS

Remove

WARNING: The parking brake acts on

transmission, not rear wheels, and may

not hold vehicle when jacking unless

following procedure is used. If one front wheel

and one rear wheel is raised no vehicle holding or

braking effect is possible. Wheels MUST be

chocked in all circumstances.

Apply parking brake, select 'P' or a gear in main

gearbox and engage low gear in transfer box.

1.Loosen five wheel nuts.

2.Using a suitable trolley jack raise vehicle and

place on axle stands.

See INTRODUCTION,

Information, Jacking

3.Remove wheel nuts and carefully withdraw

wheel over studs.Refit

4.Ensure that retaining studs and nuts are clean.

5.Alloy wheels: Lightly coat wheel mounting spigot

face with a suitable anti-seize compound to

minimise possibility of adhesion between wheel

and spigot face.

6.Refit wheel taking care not to damage stud

threads. (Do not apply oil)

7.Fit wheel nuts and turn by hand for at least three

full threads before using any form of wheel

wrench.

8.Tighten nuts as much as possible using a

suitable wrench.

9.Lower vehicle and finally tighten nuts to correct

torque sequence shown. Alloy wheels and steel

wheels:

130Nm.

Page 767 of 873

82AIR CONDITIONING

2

REPAIR PERIODIC MAINTENANCE

Routine servicing, apart from visual checks, is not

necessary. The visual inspections are as follows:

Condenser

With a water hose or air line, clean the fins of the

condenser to remove flies, leaves, etc. Check the pipe

connections for signs of oil leakage.

Compressor

Check pipe connections for signs of oil leakage.

Check flexible hoses for swelling. Examine the

compressor belt for tightness and condition.

Sight glass and Receiver/Drier

Examine the sight glass for bubbles with the system

operating. Check connections for leakage.

Evaporator

Examine the refrigeration connections at the unit. If

the system should develop a fault, or if erratic

operation is noticed,

See Fault diagnosis,

Refrigeration System Faults

RECEIVER DRIER

Service repair no - 82.17.01

Remove

CAUTION: If receiver/drier is to be refitted,

the ports must be blanked off immediately

on disconnection. Exposed life of unit is

only 15 minutes.

1.Disconnect battery negative lead.

2.Recover refrigerant from system.

See

Adjustment, Refrigerant Recovery Recycling

Recharging

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

3.Remove 3 screws from bonnet locking platform

and remove radiator grille.

Automatic gearbox

4.Remove 4 bolts securing transmission oil cooler

to body.

Page 768 of 873

AIR CONDITIONING

3

REPAIR 5.Disconnect 2 pipe unions from oil cooler. Use a

second wrench to support hose adapter.

6.Remove transmission oil cooler. Seal

connections.

All models

7.Remove bolt securing receiver/drier clamp.

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

8.Move receiver/drier just sufficiently to gain

access to pipe flange bolts without distorting the

pipes.

9.Remove bolt securing each pipe flange to

receiver/drier.

10.Disengage pipe flanges and withdraw

receiver/drier from mounting bracket.

11.Remove 'O' ring from each pipe flange.Refit

12.Fit new 'O' ring to each pipe flange, lubricate

with refrigerant oil.

13.Position receiver/drier in mounting bracket with

inlet and outlet connections correctly aligned.

14.Engage pipe flanges, fit bolts in turn and tighten.

15.Fit clamp bolt.

Automatic gearbox

16.Refit transmission oil cooler. Use a second

wrench to support pipe unions.

17.Check gearbox fluid level, top-up if necessary.

All models

18.Evacuate and recharge air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

19.Perform a leak test on disturbed joints.

20.Carry out a functional check.

Page 827 of 873

ELECTRICAL

7

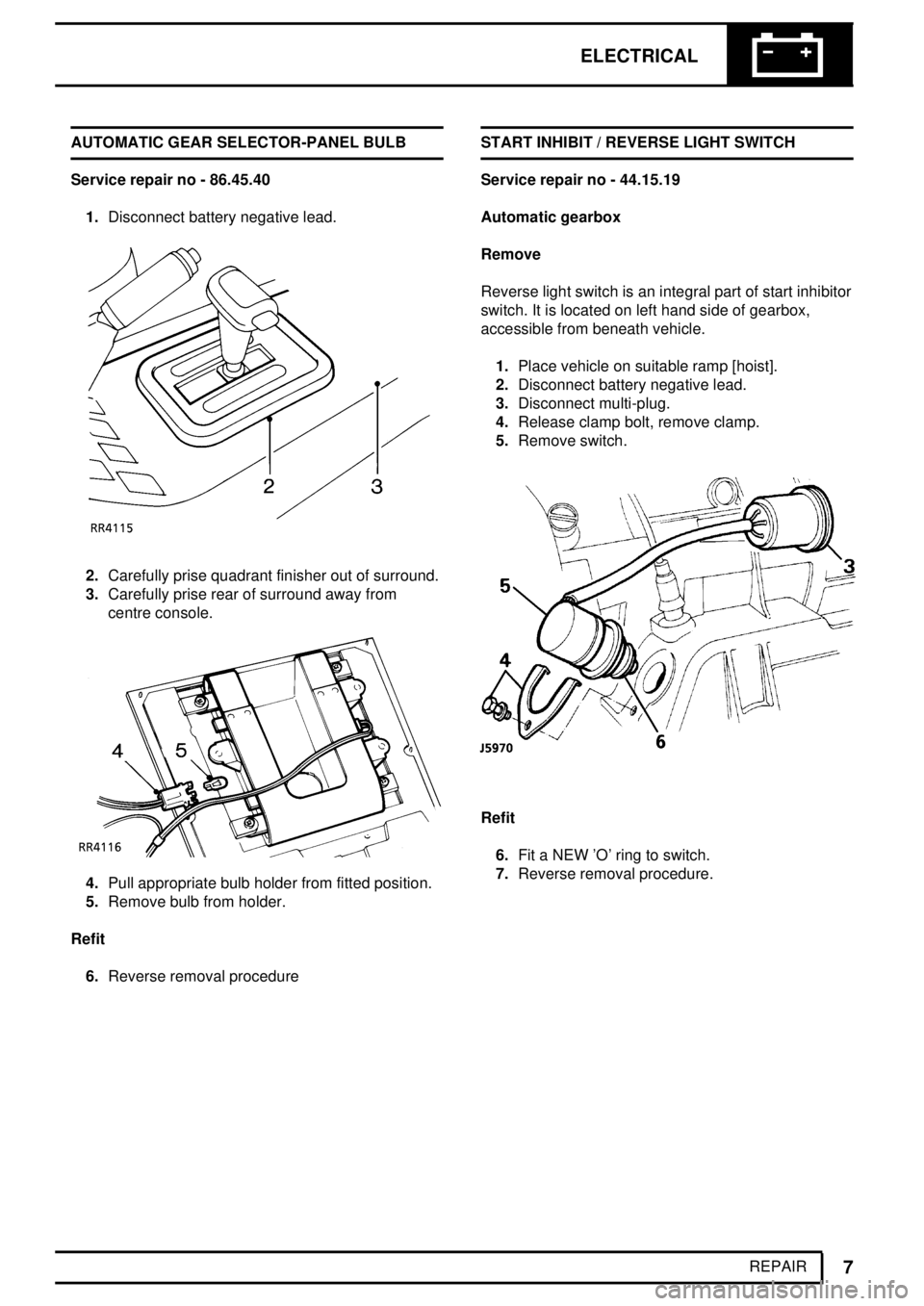

REPAIR AUTOMATIC GEAR SELECTOR-PANEL BULB

Service repair no - 86.45.40

1.Disconnect battery negative lead.

2.Carefully prise quadrant finisher out of surround.

3.Carefully prise rear of surround away from

centre console.

4.Pull appropriate bulb holder from fitted position.

5.Remove bulb from holder.

Refit

6.Reverse removal procedureSTART INHIBIT / REVERSE LIGHT SWITCH

Service repair no - 44.15.19

Automatic gearbox

Remove

Reverse light switch is an integral part of start inhibitor

switch. It is located on left hand side of gearbox,

accessible from beneath vehicle.

1.Place vehicle on suitable ramp [hoist].

2.Disconnect battery negative lead.

3.Disconnect multi-plug.

4.Release clamp bolt, remove clamp.

5.Remove switch.

Refit

6.Fit a NEW 'O' ring to switch.

7.Reverse removal procedure.