length LAND ROVER DISCOVERY 1995 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 43 of 873

GENERAL SPECIFICATION DATA

25

INFORMATION VEHICLE DIMENSIONS

Dimensions

Overall length (including spare wheel) 4538 mm.............................

Overall length (including tow hitch) 4581 mm..................................

Overall width 2189 mm....................................................................

Overall height 1914 mm...................................................................

Wheelbase 2540 mm.......................................................................

Track front/rear 1486 mm.................................................................

Width between wheel boxes 1080 mm............................................

Seating capacity 5 to 7...............................................................

Performance

Tyre size fitted 205 R16 radial..................................................................

Tyre size fitted 235/70 R16 radial..................................................................

Max. gradient (EEC kerb weight) 45° .....................................

Approach angle (EEC kerb weight) 35° ..................................

Departure angle with tow hitch (EEC kerb weight) 20° ...........

Departure angle without tow hitch

(EEC kerb weight) 29° ............................................................

Ramp break over angle 33° ....................................................

Min. ground clearance (unladen) 204 mm.....................................

Wading depth 500 mm...................................................................

Towing weights

On road Off road

Unbraked trailers 750 kg.............................................................. 500 kg

Trailers with overrun brakes - Mpi 2750 kg.................................... 1000 kg

Trailers with overrun brakes - V8i & Tdi 3500 kg........................... 1000 kg

4 wheel trailers with coupled brakes

(FULLY BRAKED)* 4000 kg.......................................................... 1000 kg

NOTE: * Only applies to vehicles modified to accept coupled brakes.

NOTE: All weight figures are subject to local restrictions.

Page 56 of 873

GENERAL FITTING REMINDERS

7

INFORMATION COTTER PINS

1.Fit new cotter pins throughout when replacing

any unit.

2.Always fit cotter pins where cotter pins were

originally used. Do not substitute spring

washers: there is always a good reason for the

use of a cotter pin.

3.All cotter pins should be fitted as shown unless

otherwise stated.

NUTS

1.When tightening a slotted or castellated nut

never loosen it back to insert cotter pin or locking

wire except in those recommended cases where

this forms part of an adjustment. If difficulty is

experienced, alternative washers or nuts should

be selected, or washer thickness reduced.

2.Where self-locking nuts have been removed it is

advisable to replace them with new ones of the

same type.

NOTE: Where bearing pre-load is involved

nuts should be tightened in accordance

with special instructions.

LOCKING WIRE

1.Fit new locking wire of the correct type for all

assemblies incorporating it.

2.Arrange wire so that its tension tends to tighten

the bolt heads, or nuts, to which it is fitted.SCREW THREADS

1.Both UNF and Metric threads to ISO standards

are used. See below for thread identification.

2.Damaged threads must always be discarded.

Cleaning up threads with a die or tap impairs the

strength and closeness of fit of the threads and

is not recommended.

3.Always ensure that replacement bolts are at

least equal in strength to those replaced.

4.Do not allow oil, grease or jointing compound to

enter blind threaded holes. The hydraulic action

on screwing in the bolt or stud could split the

housing.

5.Always tighten a nut or bolt to the recommended

torque value. Damaged or corroded threads can

affect the torque reading.

6.To check or re-tighten a bolt or screw to a

specified torque value first loosen a quarter of a

turn, then re-tighten to the correct value.

7.Oil thread lightly before tightening to ensure a

free running thread, except in the case of

threads treated with sealant/lubricant, and

self-locking nuts.

UNIFIED THREAD IDENTIFICATION

1. Bolts

A circular recess is stamped in the upper surface

of the bolt head.

2. Nuts

A continuous line of circles is indented on one of

the flats of the hexagon, parallel to the axis of

the nut.

3. Studs, Brake Rods, etc.

The component is reduced to the core diameter

for a short length at its extremity.

Page 71 of 873

MAINTENANCE

9

MAINTENANCE

CHECK CONDITION OF DRIVE BELT - V8i - Tdi -

Mpi

RENEW - V8i - Tdi

Renew drive belt V8i.See ENGINE, Repair, Drive

Belt Renew

Renew drive belt Tdi.See ENGINE, Repair, Drive

Belt Renew

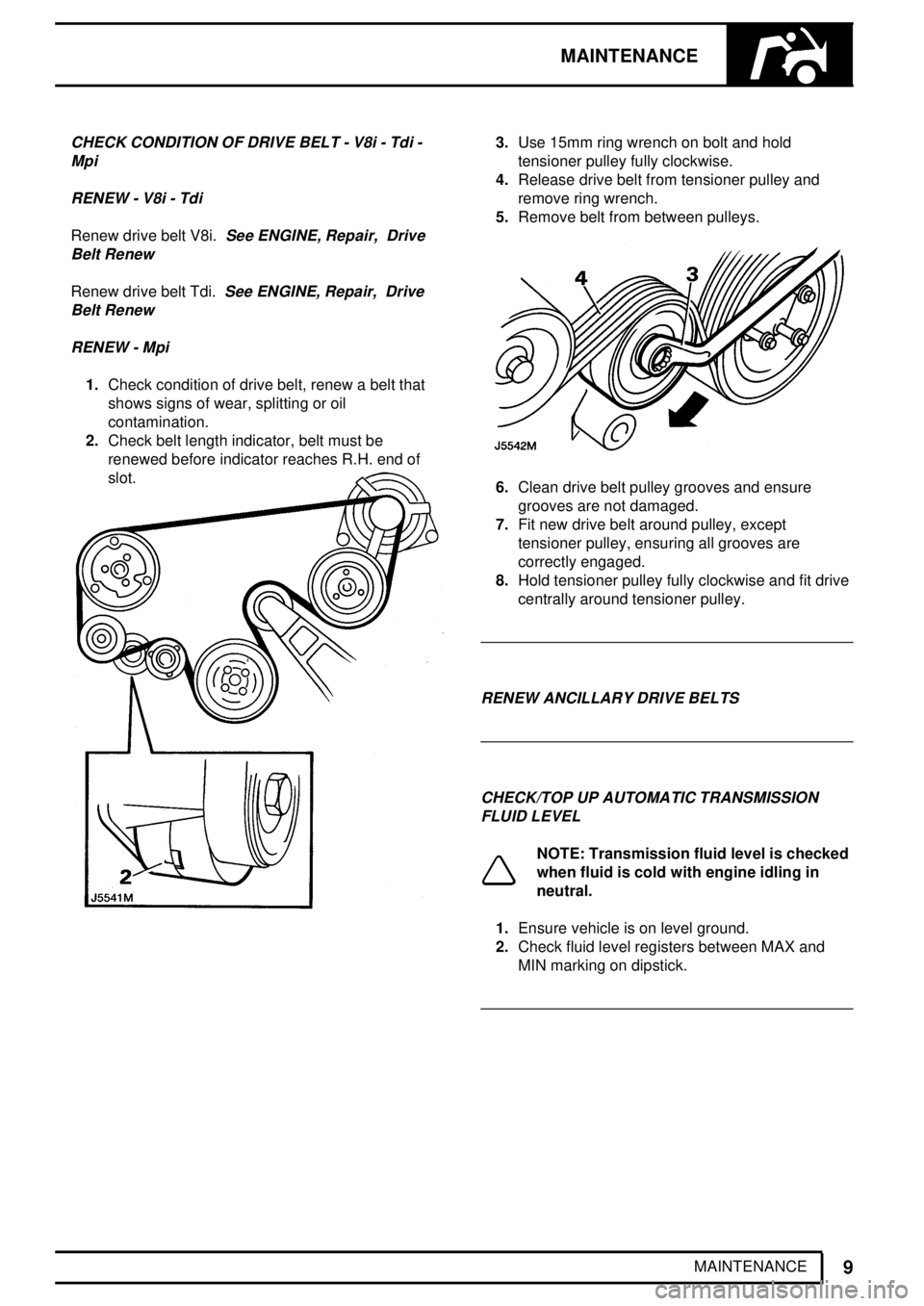

RENEW - Mpi

1.Check condition of drive belt, renew a belt that

shows signs of wear, splitting or oil

contamination.

2.Check belt length indicator, belt must be

renewed before indicator reaches R.H. end of

slot.

3.Use 15mm ring wrench on bolt and hold

tensioner pulley fully clockwise.

4.Release drive belt from tensioner pulley and

remove ring wrench.

5.Remove belt from between pulleys.

6.Clean drive belt pulley grooves and ensure

grooves are not damaged.

7.Fit new drive belt around pulley, except

tensioner pulley, ensuring all grooves are

correctly engaged.

8.Hold tensioner pulley fully clockwise and fit drive

centrally around tensioner pulley.

RENEW ANCILLARY DRIVE BELTS

CHECK/TOP UP AUTOMATIC TRANSMISSION

FLUID LEVEL

NOTE: Transmission fluid level is checked

when fluid is cold with engine idling in

neutral.

1.Ensure vehicle is on level ground.

2.Check fluid level registers between MAX and

MIN marking on dipstick.

Page 93 of 873

12ENGINE

12

REPAIR FRONT COVER/TIMING GEAR HOUSING GASKET

Service repair no - 12.65.10

Remove

1.Remove timing belt and gears.

See Camshaft

Drive Belt and Gears

2.Remove fuel injection pump.See FUEL

SYSTEM, Repair, Fuel Injection Pump and

Timing

3.Remove engine oil sump.See Oil Sump

4.Remove oil pick up strainer.See Oil Pick-Up

Strainer

5.Remove bolts securing timing gear housing to

block.

6.Withdraw timing gear housing complete with

gasket.

7.Clean all gasket material from mating faces.

Refit

8.Fit slave guide studs to locate gasket.

9.Fit new gasket, over slave studs, to cylinder

block.

10.Align flats on oil pump with flats on crankshaft.

11.Fit front cover to block taking care not to damage

oil seal.

12.Secure with bolts of correct length in locations

where slave studs are not fitted (ST3482).

13.Remove slave studs and fit correct length bolts.

14.Tighten to

25 Nm.

15.Fit oil pick-up strainer.See Oil Pick-Up

Strainer

16.Fit oil sump.See Oil Sump

17.Refit fuel injection pump.See FUEL SYSTEM,

Repair, Fuel Injection Pump and Timing

Page 97 of 873

12ENGINE

16

REPAIR 8.Ensure housing seal is correctly seated in its

groove in new housing and seal assembly.

9.Fit new assembly, with former/guide in-situ, over

crankshaft flange, this action will eject

former/guide.

10.Secure assembly to cylinder block with five bolts

tightened to correct torque, removing slave studs

individually and inserting bolts.

11.Refit flywheel.

See Flywheel

12.Refit clutch.See CLUTCH, Repair, Clutch

Assembly

13.Refit gearbox.See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

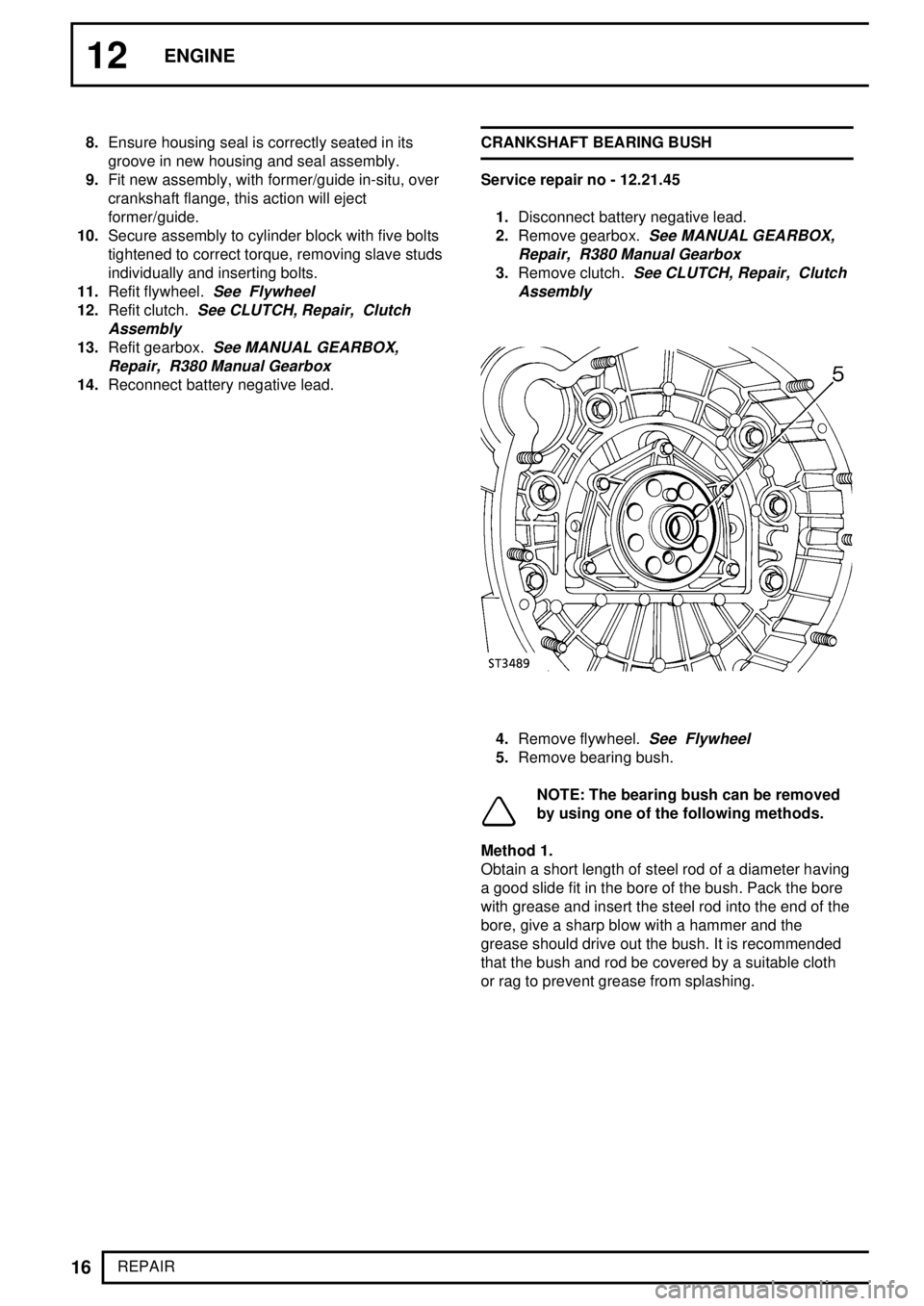

14.Reconnect battery negative lead.CRANKSHAFT BEARING BUSH

Service repair no - 12.21.45

1.Disconnect battery negative lead.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

Assembly

4.Remove flywheel.See Flywheel

5.Remove bearing bush.

NOTE: The bearing bush can be removed

by using one of the following methods.

Method 1.

Obtain a short length of steel rod of a diameter having

a good slide fit in the bore of the bush. Pack the bore

with grease and insert the steel rod into the end of the

bore, give a sharp blow with a hammer and the

grease should drive out the bush. It is recommended

that the bush and rod be covered by a suitable cloth

or rag to prevent grease from splashing.

Page 131 of 873

V8i

13

REPAIR

NOTE: Release bolts securing compressor

mounting bracket to engine and remove

bracket to enable temporary lifting eye

ETC 5964 to be fitted. Secure lifting eye to

mounting bracket fixing points with suitable bolts

of equivalent size, pitch and thread. Leave lifting

eye attached until engine is reinstalled in vehicle.

15.Place drain tray underneath vehicle.

16.Disconnect hose from reservoir to power

steering pump. Secure hose end above level of

fluid reservoir to avoid unnecessary loss of fluid.

17.Disconnect power steering pump to power

steering box hose. Seal hose and pump

openings with masking tape to prevent ingress of

dirt. Wipe away any fluid spillage from chassis or

steering box.

18.Disconnect fuel temperature and coolant

temperature sensor multi-plugs.

19.Disconnect leads from coil.

20.Identify each injector multi-plug for re-assembly

and disconnect plugs from injectors.

21.Manoeuvre harness from behind fuel rails and

place to one side clear of engine assembly.

22.Remove two clamps securing gearbox oil cooler

pipes to engine block.

23.Remove engine mounting fixings on both sides

of cylinder block.

24.Fit lifting chains to engine lifting eyes as shown

in illustration RR1780E.

1. L/H Front chain 356mm total overall length.

2. R/H Front chain 330mm total overall length.

3. R/H Rear chain 457mm total overall length.

NOTE: All chain dimensions are measured

from end of lifting hook to end of last link

in chain.

25.Fit chain lifting eye to a suitable engine hoist.

Raise hoist high enough to enable engine

mountings to be removed, and withdraw rubber

mountings.

26.Lower hoist until engine rests securely on engine

mounting brackets. Remove lifting chains and

hoist.

27.Disconnect two heater hoses located on top of

right hand rocker cover.

28.Remove ground strap from rear of left hand

cylinder head. DO NOT remove from retaining

clip.

29.Remove all electrical harnesses from retaining

clips at rear of engine.

30.Remove transmission breather pipes from

retaining clip on rear lifting eye.

31.Remove top two bolts securing bell housing to

cylinder block.

32.Raise front of vehicle, lower vehicle on to axle

stands.

33.Remove bell housing bottom cover. Remove

gasket from bell housing face.

34.Remove nuts securing exhaust downpipes to

manifolds, remove heat shield from right hand

side downpipe.

35.Remove electrical leads from starter motor

solenoid. Disconnect multi-plug from oil level

sensor on side of sump, if fitted.

NOTE: Instructions 37, 38 and 39 refer to

automatic vehicles only.

36.With assistance rotate engine at crankshaft

pulley until two access holes in drive plate/ring

gear assembly are visible.

37.Remove two bolts visible through access holes.

Mark one access hole and one bolt hole to

ensure unit is reassembled in its original position

38.Rotate crankshaft 180Ê until two remaining

access holes are visible, remove two bolts.

Page 190 of 873

17EMISSION CONTROL

4

DESCRIPTION AND OPERATION REV: 09/95 Evaporative emission control system - pre

advanced EVAPS.

The system is designed to prevent harmful fuel vapour

from escaping to the atmosphere. The system

consists of a vapour separator tank, connected to the

fuel tank and located between the body inner and

outer panels on the right hand side of the vehicle near

the rear wheel arch. An adsorbtion canister,

containing activated charcoal, is positioned in the

engine compartment attached to the front right

valance. The two components are connected by a

pipe running the length of the chassis.

A Pressure relief to atmosphere.

B From fuel tank to separator.

C To adsorbtion canister.

D Pressure relief valve.

E Pressure relief valve.

F Shut-off valve.

G "Speed Fit" connectors.A pressure relief valve is fitted in the hose which is

open to atmosphere. This valve acts as a safety valve

should a build-up of pressure occur in the system, for

example if a hose became blocked or kinked. The

volume of vapour emitted, in such an instance, would

be acceptable.

A pressure relief valve is also fitted in the hose

connected to the adsorbtion canister and releases

vapor to the canister when the pressure in the

separator reaches between 5 and 7 Kpa.

In the top of the separator a shut-off valve is

incorporated in the vapor exit port to prevent the

possible presence of any liquid fuel being transmitted

to the adsorbtion canister should the vehicle roll over.

The adsorbtion canister, which is connected by a hose

to the plenum chamber, absorbs and stores the fuel

vapour from the fuel tank while the engine is not

running. When the engine is started, the vapour is

purged from the canister by air drawn through an

orifice in the base of the canister and by the influence

of vacuum at the top. The vapour drawn into the

plenum chamber through a solenoid operated purge

valve is finally burnt in the combustion chambers.

The purge valve, which is attached to the adsorbtion

canister support bracket, is controlled by the Engine

Control Module ECM which determines the most

emission acceptable time at which purging should

take place. This will normally be at engine speeds

above idle and when the vehicle is in motion. A signal

from the ECM to the purge valve operates the

solenoid and opens the valve to purge the canister of

fuel vapour.

Page 194 of 873

17EMISSION CONTROL

8

DESCRIPTION AND OPERATION ADD: 09/95 System operation

The system is designed to prevent fuel vapour

escaping to atmosphere, and consists of four roll-over

valves fitted internally in the fuel tank, connected to

the liquid/vapour separator by a nylon line. The

separator is mounted to the side of the filler neck. An

EVAP canister is positioned in the engine

compartment mounted on the right front side valance.

The liquid/vapour separator and EVAP canister are

connected by a nylon line which runs the length of the

chassis.

Pressure/vacuum relief valves are incorporated into

the fuel filler cap and are designed to protect the fuel

tank from permanent deformation in the event of

system pressure or vacuum exceeding the system

operating parameters. There are no other relief or

one-way valves in the system.

A vent line flow restrictor known as an anti-trickle fill

valve is fitted to the filler pipe in the line between the

tank and EVAP canister. The function of this valve is

to prevent overfilling the tank by trickling fuel in,

thereby preserving the vapour space in the tank to

allow for fuel expansion during hot weather.

The valve achieves this by blocking the vent line

during the fuel filling process. The valve is operated

by the action of inserting the filler gun so that when

the fuel in the tank reaches the level of the filling

breather, flow cut off occurs due to fuel filling the filler

pipe.During normal vehicle operation and when the engine

is switched off, the venting system between the fuel

tank and EVAP canister is open to allow the free

passage of vapour.

The EVAP canister, which is connected by a nylon

hose to the plenum chamber, absorbs and stores the

fuel vapour from the fuel tank when the engine is not

running. With the engine running, vapour is purged

from the EVAP canister by allowing outside air to be

drawn through the EVAP canister vent solenoid and

link pipe by the influence of manifold vacuum to the

EVAP canister purge connection on the canister.

Filter pads are fitted above and below the charcoal

and in the EVAP canister vent solenoid to prevent the

ingress of foreign matter into the purge line.

The EVAP canister purge valve, which is fitted in the

line from the EVAP canister to the plenum, is

controlled by the ECM which determines the most

emission acceptable time at which purging should

take place. This will normally be at engine speeds

above idle and when the vehicle is in motion.

The EVAP canister vent solenoid is mounted on the

side of the EVAP canister bracket and is connected to

the EVAP canister by a length of large bore hose. The

ECVS is controlled by the ECM and is normally open.

The function of the ECVS is to block the air intake

side of the EVAP canister. When the system receives

an ECM signal the valve closes; this allows the

system leak check to take place. The leak check only

occurs when pre-determined vehicle operating

conditions are met.

Page 209 of 873

19FUEL SYSTEM

4

DESCRIPTION AND OPERATION OPERATION

Diesel engines operate by compression ignition. The

rapid compression of air in the cylinder during the

compression cycle heats the injected fuel, causing it

to self ignite. During cold starting, automatically

controlled glow plugs assist in raising the temperature

of the compressed air to ignition point.

A cold start advance unit advances the injection timing

to further assist starting. Idle quality is improved by

the high idle setting.

The engine is supplied with pre-compressed air by a

single stage turbocharger.

Exhaust gases passing over a turbine cause it to

rotate, driving a compressor mounted on the turbine

shaft. Air drawn from the cold air intake passes, via

the air cleaner, to the turbocharger where it is

compressed. The compressed air passes to the

cylinders via an intercooler, which reduces the

temperature of the compressed air, increasing its

density.

Fuel is drawn from the tank by a mechanical lift pump

and passes to the injection pump via a filter. In

addition to removing particle contamination from the

fuel, the filter incorporates a water separator, which

removes and stores both bound and unbound water.

The injection pump meters a precisely timed, exact

quantity of fuel to the injectors in response to throttle

variations, injection timing varying with engine speed.

Any excess fuel delivered to the injection pump is not

injected, passing back to the tank via the fuel return

line.

Fuel is injected in a finely atomised form into a

pre-combustion chamber in the cylinder head where it

ignites. The burning fuel expands rapidly into the main

combustion chamber, creating extreme turbulence

which mixes the burning fuel thoroughly with the

compressed air, providing complete combustion.

Cold Starting is assisted by glow plugs, a cold start

advance unit and a high idle setting.Glow plugs

Glow plug operation is controlled by a timer unit, start

relay and resistor. When the ignition is turned on the

timer unit is energised, the glow plugs start to operate

and a warning light on the dashboard illuminates,

remaining illuminated until the glow plugs are

automatically switched off.

The length of time the glow plugs will operate is

dependent on under bonnet temperature, which is

monitored by a sensor located in the timer unit.

Starting the engine results in the power supply to the

glow plugs passing through the resistor, which

reduces their operating temperature. The glow plugs

are cut out either by the temperature sensor in the

timer, or by a microswitch on the injection pump which

operates when the throttle is depressed.

Cold start advance

The cold start advance unit is connected to the engine

cooling system via hoses. It contains a temperature

sensitive element which is retracted when cold and

pulls the advance lever, via cable, towards the rear of

the pump against spring pressure. As coolant

temperature rises, the cold start element expands

releasing tension on the cable and allowing spring

pressure to move the advance lever forwards.

Page 217 of 873

19FUEL SYSTEM

2

ADJUSTMENT LOW AND HIGH IDLE SPEED

Adjust

The high idle speed (cold start idle) is

automatically set by the setting of the low idle

speed and can not be adjusted individually.

1.Check and adjust throttle cable.

2.Start engine and run it until normal operating

temperature is reached.

3.Using a suitable tachometer, check the engine

idle speed.

See ENGINE TUNING DATA,

Information, 300 Tdi Engine

4.If adjustment is necessary, loosen the locknut on

the injector pump.

5.Turn the adjustment screw either clockwise to

increase the engine speed or anti-clockwise to

decrease the speed. Run the engine at an

increased speed for a few seconds then check

the idle speed again.

6.When the correct speed has been achieved,

hold the adjuster screw steady while tightening

the locknut.

NOTE: The low idle speed control is the

only permitted adjustment in service. Any

additional adjustments required must be

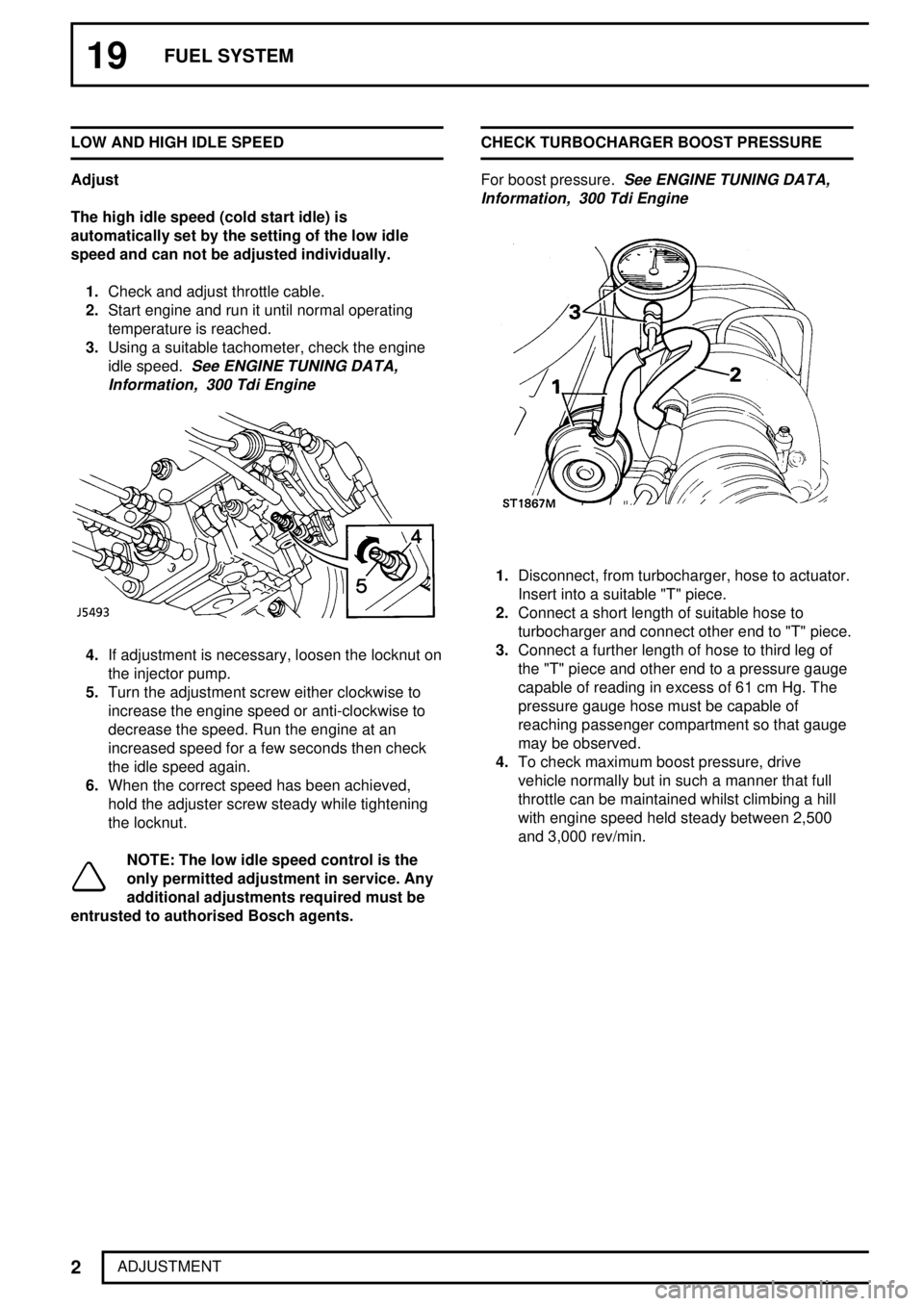

entrusted to authorised Bosch agents.CHECK TURBOCHARGER BOOST PRESSURE

For boost pressure.

See ENGINE TUNING DATA,

Information, 300 Tdi Engine

1.Disconnect, from turbocharger, hose to actuator.

Insert into a suitable "T" piece.

2.Connect a short length of suitable hose to

turbocharger and connect other end to "T" piece.

3.Connect a further length of hose to third leg of

the "T" piece and other end to a pressure gauge

capable of reading in excess of 61 cm Hg. The

pressure gauge hose must be capable of

reaching passenger compartment so that gauge

may be observed.

4.To check maximum boost pressure, drive

vehicle normally but in such a manner that full

throttle can be maintained whilst climbing a hill

with engine speed held steady between 2,500

and 3,000 rev/min.