oil capacities LAND ROVER DISCOVERY 1995 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 414 of 873

41TRANSFER GEARBOX

2

FAULT DIAGNOSIS PROCEDURE

Prior to road test

1.Check oil level in transfer box is correct.

2.Check tightness of level and drain plugs.

3.Check breather system for blockage. To validate

the system the pipe must be removed,

inspected, rectified as necessary and refitted.

4.Remove all traces of oil from exterior of transfer

box.

Take vehicle for short road test.

5.Identify source of leaks and rectify as follows.

Front or rear output seal leaking:-

1.Drain the oil and remove the leaking output

flange.

2.Inspect the seal track on the flange for surface

damage. If damaged renew component.

3.Remove and discard the oil seal.

4.Inspect the seal locating bore and remove any

sharp edges which may damage the new oil

seal.

5.Fit new seal.

6.Fit the output flange and all the other parts.

7.Add oil to correct level into the gearbox.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended Lubricants and

Fluids

Cover plate gasket leaking.

1.Drain the oil and remove the leaking cover plate.

2.Remove all traces of joint sealant from both joint

faces.

3.Degrease all components and apply a thin film of

Hylomar sealant, to both joint faces.

4.Apply thread sealant to the bolts which come

into contact with gearbox oil.

5.Refit cover plate.

CAUTION: Care must be taken not to

overtighten the fixings.Leak between the main and transfer gearboxes.

1.Site vehicle onto a ramp [hoist].

2.Select neutral in transfer box and select 4th gear

in the main gearbox.

3.Run engine at 2000 rpm with the clutch/drive

engaged.

4.Observe joint between the main and transfer

boxes.

5.If oil leak is found establish if it is gear oil.

6.If so, the leak is originating from the transfer box.

7.Check the two inner (main/transfer) bolts are oil

tight, as these holes are tapped through into the

main transfer case.

8.Remove the transfer box to inspect the

mainshaft collar seal track condition, and the

front face of the transfer case for porosity.

See

Repair, LT230T Transfer Gearbox

9.If these areas require servicing, the transfer

gearbox input seal must also be renewed.

CAUTION: Avoid damaging the new seal

lip and ensure the seal is fitted flush with

the machined face. Also ensure the new

seal is not damaged when refitting the transfer

gearbox.

10.If red A.T.F type oil is seen leaking during the

workshop test, investigate the main gearbox for

cause of leak.

Detent plug or electrical switch leaks.

1.Detent plugs and electrical switches do not

usually leak. It must be noted that they fit into

open tapped holes in the transfer case and

therefore should be considered when looking for

the source of the leak.

Page 417 of 873

TRANSFER GEARBOX

3

REPAIR Refit

36.Select 'P' in main gearbox, with low range and

differential lock selected in transfer gearbox.

37.Secure transfer gearbox to adaptor plate on

lifting hoist.

38.Ensure joint faces of transfer and main

gearboxes are clean and guide studs 18G 1425

are fitted.

39.Raise hoist until transfer gearbox can be located

over guide studs to main gearbox. At the same

time locate high/low lower link to yoke.

40.Remove guide studs and secure transfer

gearbox to main gearbox.41.Complete refitting by reversing removal

procedure, noting the following important points.

42.After removal of adaptor plate from transfer

gearbox, clean threads of four bottom cover

bolts, coat threads with Loctite 290 and fit

together with spring washers. Tighten to

25Nm

43.Add correct grade of oil to transfer gearbox to oil

level plug hole.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

44.Check main gearbox oil level.

45.Check operation of parking brake and adjust as

necessary.

See SECTION 10, Maintenance,

Vehicle Interior

Page 440 of 873

ZF

3

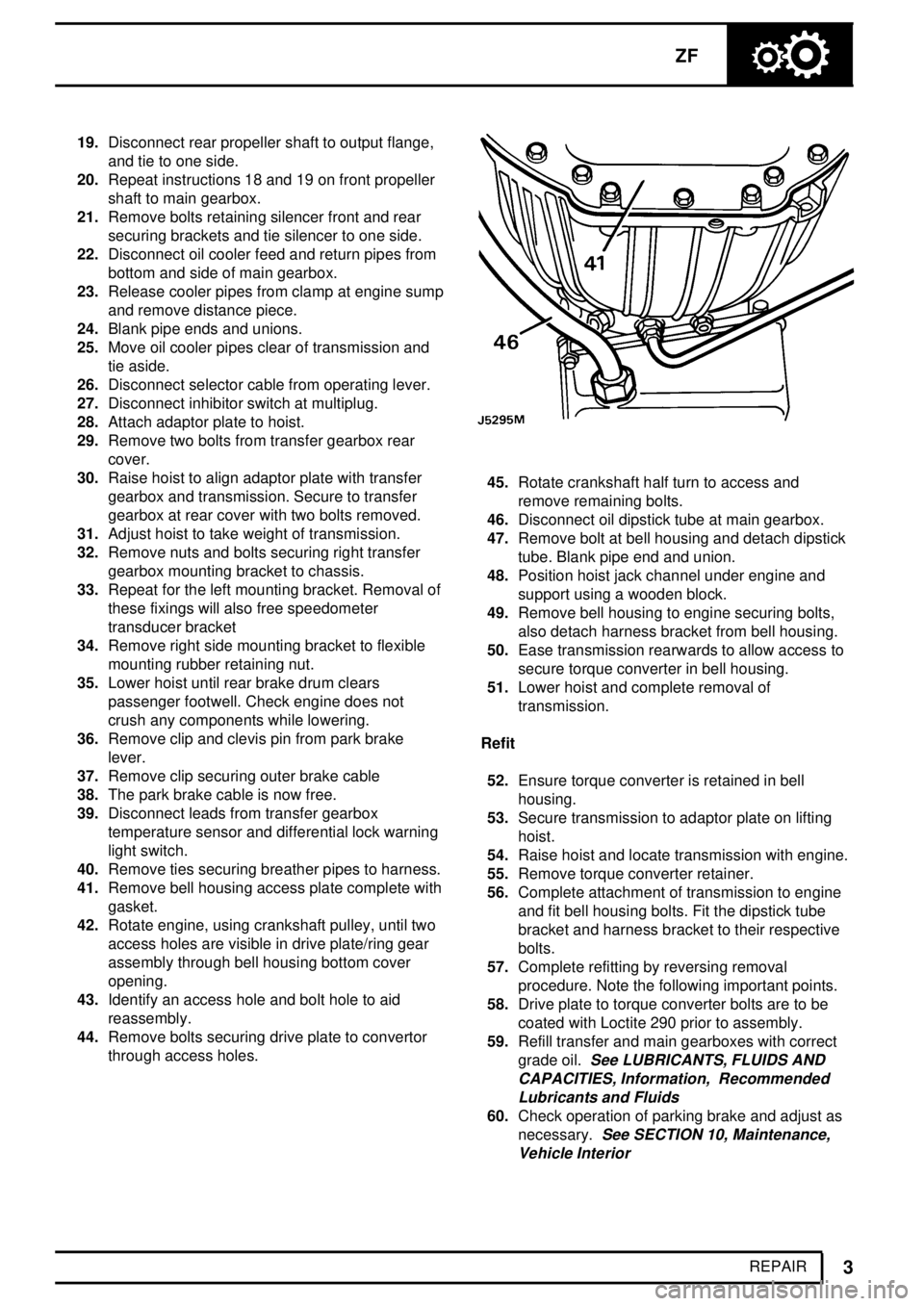

REPAIR 19.Disconnect rear propeller shaft to output flange,

and tie to one side.

20.Repeat instructions 18 and 19 on front propeller

shaft to main gearbox.

21.Remove bolts retaining silencer front and rear

securing brackets and tie silencer to one side.

22.Disconnect oil cooler feed and return pipes from

bottom and side of main gearbox.

23.Release cooler pipes from clamp at engine sump

and remove distance piece.

24.Blank pipe ends and unions.

25.Move oil cooler pipes clear of transmission and

tie aside.

26.Disconnect selector cable from operating lever.

27.Disconnect inhibitor switch at multiplug.

28.Attach adaptor plate to hoist.

29.Remove two bolts from transfer gearbox rear

cover.

30.Raise hoist to align adaptor plate with transfer

gearbox and transmission. Secure to transfer

gearbox at rear cover with two bolts removed.

31.Adjust hoist to take weight of transmission.

32.Remove nuts and bolts securing right transfer

gearbox mounting bracket to chassis.

33.Repeat for the left mounting bracket. Removal of

these fixings will also free speedometer

transducer bracket

34.Remove right side mounting bracket to flexible

mounting rubber retaining nut.

35.Lower hoist until rear brake drum clears

passenger footwell. Check engine does not

crush any components while lowering.

36.Remove clip and clevis pin from park brake

lever.

37.Remove clip securing outer brake cable

38.The park brake cable is now free.

39.Disconnect leads from transfer gearbox

temperature sensor and differential lock warning

light switch.

40.Remove ties securing breather pipes to harness.

41.Remove bell housing access plate complete with

gasket.

42.Rotate engine, using crankshaft pulley, until two

access holes are visible in drive plate/ring gear

assembly through bell housing bottom cover

opening.

43.Identify an access hole and bolt hole to aid

reassembly.

44.Remove bolts securing drive plate to convertor

through access holes.

45.Rotate crankshaft half turn to access and

remove remaining bolts.

46.Disconnect oil dipstick tube at main gearbox.

47.Remove bolt at bell housing and detach dipstick

tube. Blank pipe end and union.

48.Position hoist jack channel under engine and

support using a wooden block.

49.Remove bell housing to engine securing bolts,

also detach harness bracket from bell housing.

50.Ease transmission rearwards to allow access to

secure torque converter in bell housing.

51.Lower hoist and complete removal of

transmission.

Refit

52.Ensure torque converter is retained in bell

housing.

53.Secure transmission to adaptor plate on lifting

hoist.

54.Raise hoist and locate transmission with engine.

55.Remove torque converter retainer.

56.Complete attachment of transmission to engine

and fit bell housing bolts. Fit the dipstick tube

bracket and harness bracket to their respective

bolts.

57.Complete refitting by reversing removal

procedure. Note the following important points.

58.Drive plate to torque converter bolts are to be

coated with Loctite 290 prior to assembly.

59.Refill transfer and main gearboxes with correct

grade oil.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

60.Check operation of parking brake and adjust as

necessary.

See SECTION 10, Maintenance,

Vehicle Interior

Page 444 of 873

ZF

7

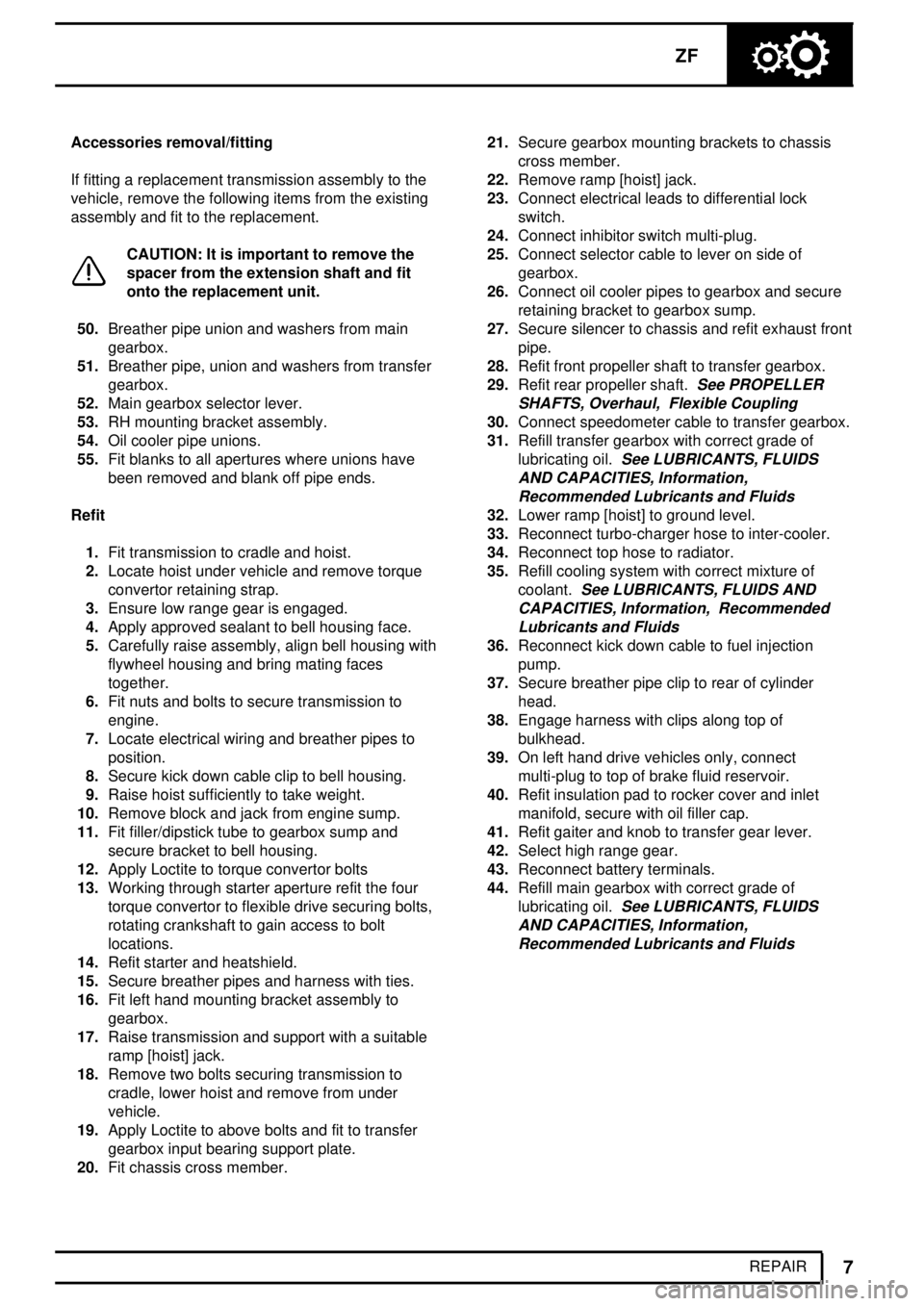

REPAIR Accessories removal/fitting

If fitting a replacement transmission assembly to the

vehicle, remove the following items from the existing

assembly and fit to the replacement.

CAUTION: It is important to remove the

spacer from the extension shaft and fit

onto the replacement unit.

50.Breather pipe union and washers from main

gearbox.

51.Breather pipe, union and washers from transfer

gearbox.

52.Main gearbox selector lever.

53.RH mounting bracket assembly.

54.Oil cooler pipe unions.

55.Fit blanks to all apertures where unions have

been removed and blank off pipe ends.

Refit

1.Fit transmission to cradle and hoist.

2.Locate hoist under vehicle and remove torque

convertor retaining strap.

3.Ensure low range gear is engaged.

4.Apply approved sealant to bell housing face.

5.Carefully raise assembly, align bell housing with

flywheel housing and bring mating faces

together.

6.Fit nuts and bolts to secure transmission to

engine.

7.Locate electrical wiring and breather pipes to

position.

8.Secure kick down cable clip to bell housing.

9.Raise hoist sufficiently to take weight.

10.Remove block and jack from engine sump.

11.Fit filler/dipstick tube to gearbox sump and

secure bracket to bell housing.

12.Apply Loctite to torque convertor bolts

13.Working through starter aperture refit the four

torque convertor to flexible drive securing bolts,

rotating crankshaft to gain access to bolt

locations.

14.Refit starter and heatshield.

15.Secure breather pipes and harness with ties.

16.Fit left hand mounting bracket assembly to

gearbox.

17.Raise transmission and support with a suitable

ramp [hoist] jack.

18.Remove two bolts securing transmission to

cradle, lower hoist and remove from under

vehicle.

19.Apply Loctite to above bolts and fit to transfer

gearbox input bearing support plate.

20.Fit chassis cross member.21.Secure gearbox mounting brackets to chassis

cross member.

22.Remove ramp [hoist] jack.

23.Connect electrical leads to differential lock

switch.

24.Connect inhibitor switch multi-plug.

25.Connect selector cable to lever on side of

gearbox.

26.Connect oil cooler pipes to gearbox and secure

retaining bracket to gearbox sump.

27.Secure silencer to chassis and refit exhaust front

pipe.

28.Refit front propeller shaft to transfer gearbox.

29.Refit rear propeller shaft.

See PROPELLER

SHAFTS, Overhaul, Flexible Coupling

30.Connect speedometer cable to transfer gearbox.

31.Refill transfer gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

32.Lower ramp [hoist] to ground level.

33.Reconnect turbo-charger hose to inter-cooler.

34.Reconnect top hose to radiator.

35.Refill cooling system with correct mixture of

coolant.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

36.Reconnect kick down cable to fuel injection

pump.

37.Secure breather pipe clip to rear of cylinder

head.

38.Engage harness with clips along top of

bulkhead.

39.On left hand drive vehicles only, connect

multi-plug to top of brake fluid reservoir.

40.Refit insulation pad to rocker cover and inlet

manifold, secure with oil filler cap.

41.Refit gaiter and knob to transfer gear lever.

42.Select high range gear.

43.Reconnect battery terminals.

44.Refill main gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

Page 446 of 873

![LAND ROVER DISCOVERY 1995 User Guide ZF

9

REPAIR OIL SUMP

Service repair no - 44.24.05

Remove

1.Site vehicle on a four post ramp [hoist].

2.Disconnect battery negative lead.

3.Raise vehicle.

4.Drain oil and refit plug with new seal.

5.De LAND ROVER DISCOVERY 1995 User Guide ZF

9

REPAIR OIL SUMP

Service repair no - 44.24.05

Remove

1.Site vehicle on a four post ramp [hoist].

2.Disconnect battery negative lead.

3.Raise vehicle.

4.Drain oil and refit plug with new seal.

5.De](/img/64/57248/w960_57248-445.png)

ZF

9

REPAIR OIL SUMP

Service repair no - 44.24.05

Remove

1.Site vehicle on a four post ramp [hoist].

2.Disconnect battery negative lead.

3.Raise vehicle.

4.Drain oil and refit plug with new seal.

5.Detach heat shield at front exhaust pipe to

manifold.

6.Disconnect electrics from Lambda sensors.

7.Remove catalytic converter assembly.

8.Remove chassis cross-member from under

gearbox.

9.Disconnect dipstick tube at oil sump. Loosen

securing bolt at bell housing and move dipstick

aside.

10.Remove clamps securing oil sump. Note their

locations for refit and withdraw sump.

11.Remove gasket and clean gasket mating faces.Refit

12.Refit oil sump using a new gasket.

13.Connect dipstick tube to oil sump and tighten

bolt at bell housing.

14.Refit chassis cross member.

15.Refit catalytic converter assembly

16.Connect electrics to Lambda sensors.

17.Connect heat shield front pipe to manifold.

18.Connect battery.

19.Refill gearbox using correct grade of oil.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended Lubricants and

Fluids

Page 447 of 873

![LAND ROVER DISCOVERY 1995 User Guide 44AUTOMATIC GEARBOX

10

REPAIR OIL SCREEN

Service repair no - 44.24.07

Renew

1.Site vehicle on a four post ramp [hoist].

2.Disconnect battery negative lead.

3.Raise vehicle.

4.Drain oil and refit plug LAND ROVER DISCOVERY 1995 User Guide 44AUTOMATIC GEARBOX

10

REPAIR OIL SCREEN

Service repair no - 44.24.07

Renew

1.Site vehicle on a four post ramp [hoist].

2.Disconnect battery negative lead.

3.Raise vehicle.

4.Drain oil and refit plug](/img/64/57248/w960_57248-446.png)

44AUTOMATIC GEARBOX

10

REPAIR OIL SCREEN

Service repair no - 44.24.07

Renew

1.Site vehicle on a four post ramp [hoist].

2.Disconnect battery negative lead.

3.Raise vehicle.

4.Drain oil and refit plug with new seal.

5.Detach heat shield at front exhaust pipe to

manifold.

6.Disconnect electrics from Lambda sensors.

7.Remove catalytic converter assembly.

8.Remove chassis cross-member from under

gearbox.

9.Disconnect dipstick tube at oil sump. Loosen

securing bolt at bell housing and move dipstick

aside.

10.Remove clamps securing oil sump. Note their

locations for refit and withdraw sump.

11.Remove gasket and clean gasket mating faces.

12.Remove securing screws and detach oil screen

and suction pipe, taking care to retain suction

pipe spacer, discard 'O' ring seal.13.Detach suction pipe from oil screen, discard 'O'

ring seal.

14.Clean oil screen and blow out with airline.

15.Clean suction pipe.

16.Fit new 'O' ring seals to oil screen using light

grease to aid assembly.

17.Fit oil screen and suction pipe with spacer and

secure with three bolts.

18.Refit oil sump using a new gasket.

19.Connect dipstick tube to oil sump and tighten

bolt at bell housing.

20.Refit chassis cross-member.

21.Refit catalytic converter assembly

22.Connect electrics to Lambda sensors.

23.Connect heat shield front pipe to manifold.

24.Connect battery.

25.Refill gearbox oil system using correct grade of

oil.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

Page 449 of 873

44AUTOMATIC GEARBOX

12

REPAIR Oil seal replacement

14.Remove circlips and springs from control unit.

Note locations of long and short springs.

15.Using seal replacer/remover LST113 remove

and discard seals.

16.Clean control unit, springs and circlips and check

that they are satisfactory for further use.

17.Fit new seals to control unit using LST113,

ensure seals are fully seated.

18.Fit springs to locations noted during removal and

secure with circlips.

Refit

19.Fit control unit to gearbox, locating throttle valve

behind cam and engaging selector quadrant with

manual valve.

20.Loosely fit securing screws.21.Manually open throttle linkage to full throttle

position.

22.Engage special tool LST 109 between control

unit and throttle valve pin.

23.Set correct distance between control unit and

cam.

24.Remove special tool and close throttle.

25.Fit new 'O' ring seals to oil screen using light

grease to aid assembly.

26.Fit oil screen and suction pipe with spacer and

secure with three bolts.

27.Refit oil pan using a new gasket.

28.Connect dipstick tube to oil sump and tighten

bolt at bell housing.

29.Refit chassis cross member.

30.Refit catalytic converter assembly

31.Connect electrics to Lambda sensors.

32.Connect heat shield front pipe to manifold.

33.Connect battery.

34.Refill gearbox oil system using correct grade of

oil.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

Page 450 of 873

![LAND ROVER DISCOVERY 1995 User Guide ZF

13

REPAIR KICKDOWN CABLE

Service repair no - 44.15.01

Remove

1.Site vehicle on a four post ramp [hoist].

2.Select neutral N gear lever.

3.Disconnect battery negative lead.

4.Disconnect kickdown c LAND ROVER DISCOVERY 1995 User Guide ZF

13

REPAIR KICKDOWN CABLE

Service repair no - 44.15.01

Remove

1.Site vehicle on a four post ramp [hoist].

2.Select neutral N gear lever.

3.Disconnect battery negative lead.

4.Disconnect kickdown c](/img/64/57248/w960_57248-449.png)

ZF

13

REPAIR KICKDOWN CABLE

Service repair no - 44.15.01

Remove

1.Site vehicle on a four post ramp [hoist].

2.Select neutral 'N' gear lever.

3.Disconnect battery negative lead.

4.Disconnect kickdown cable at throttle linkage.

5.Release outer cable locknut.

6.Disconnect cable from mounting bracket.

7.Release cable from bracket attached to cylinder

head.

8.Feed cable through to underside of vehicle.

9.Raise vehicle on ramp [hoist].

10.Drain oil and refit plug with new seal.

11.Detach heat shield at front exhaust pipe to

manifold.

12.Disconnect electrics from Lambda sensors.

13.Remove catalytic converter assembly.

14.Remove chassis cross-member from under

gearbox.

15.Disconnect dipstick tube at oil sump. Loosen

securing bolt at bell housing and move dipstick

aside.

16.Remove clamps securing oil sump. Note their

locations for refit, and withdraw sump.

17.Pull kickdown inner cable to fully open valve

cam. Wedge cam in this position.

18.Release cable from cam by pushing inner cable

into outer casing and detaching cable nipple

from cam.

19.Using special tool LST112 compress cable tangs

and remove cable from gearbox.

20.If cable is to be refitted remove 'O' ring seal and

clean cable assembly.

Refit

21.Fit new 'O' ring seal to cable and lubricate seal.

22.Fit cable to gearbox casing ensuring it is

correctly seated.

23.Fit inner cable nipple to its location on cam.

NOTE: When a new cable is fitted, to help

locate nipple to cam, introduce a curve

into the cable. Do not bend or kink cable.24.Remove wedge from cam and ensure nipple

remains engaged.

25.Feed free end of cable assembly into engine

compartment.

26.Refit oil pan using a new gasket.

27.Connect dipstick tube to oil sump and tighten

bolt at bell housing.

28.Refit chassis cross-member

29.Refit catalytic converter assembly

30.Connect electrics to Lambda sensors.

31.Connect heat shield front pipe to manifold.

32.Lower vehicle on ramp [hoist].

33.Fit cable to bracket at cylinder head.

34.Locate cable in mounting bracket, do not tighten

locknut.

35.Fit cable to throttle linkage.

36.Ensure throttle linkage is fully closed.

37.Adjust outer cable to achieve a gap of 0,25 to

1,25mm (dimension 'A') between end of outer

cable and crimped collar on inner cable.

38.Tighten locknuts and recheck gap.

NOTE: If fitting a new cable, and collar on

inner cable is loose, measure distance 'B'

on old cable. Crimp collar on new cable to

this dimension.

39.Reconnect battery negative lead.

40.Refill gearbox oil using correct grade of oil.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended Lubricants and

Fluids

Page 451 of 873

44AUTOMATIC GEARBOX

14

REPAIR EXTENSION HOUSING

Service repair no - 44.20.18

Remove

1.Remove transfer gearbox.

See TRANSFER

GEARBOX, Repair, LT230T Transfer Gearbox

2.Drain oil from automatic gearbox.

3.Remove bolts securing left hand mounting

bracket to extension housing and withdraw

bracket.

4.Remove transfer gear lever housing securing

bolts and move housing aside.

5.Remove securing bolts and withdraw extension

housing from over coupling shaft. Remove and

discard gasket.

6.Place extension housing on bench and remove

oil seal.

7.Ensure that all surfaces are clean and housing is

free from damage. If damage is found and

housing has to be renewed remove dowels from

face of existing housing and fit to new housing.

8.Using special tool LST108 fit new oil seal to

housing.Refit

9.Fit extension housing to gearbox, with a new

gasket, ensuring oil seal is not damaged by

extension shaft.

10.Secure housing with nine bolts. Tighten to

23

Nm.

11.Refit transfer gear lever housing to top of

extension housing. Tighten to

25 Nm.

12.Refit mounting bracket to extension housing.

Tighten to

52 Nm.

13.Refit transfer gear box.See TRANSFER

GEARBOX, Repair, LT230T Transfer Gearbox

14.Refill automatic gearbox lubrication system with

correct grade of oil.

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended Lubricants and Fluids

Page 452 of 873

ZF

15

REPAIR GOVERNOR ASSEMBLY

Service repair no - 44.22.01

Remove

1.Remove transfer gearbox.

See TRANSFER

GEARBOX, Repair, LT230T Transfer Gearbox

2.Drain oil from automatic gearbox.

3.Remove bolts securing left hand mounting

bracket to extension housing and withdraw

bracket.

4.Remove transfer gear lever housing securing

bolts and move housing aside.

5.Remove extension housing ensuring seal is not

damaged, remove and discard gasket.

6.Remove extension shaft retaining bolt, withdraw

shaft and discard 'O' ring seal. If Tdi vehicle

remove spacer.

7.Remove governor assembly.

8.Remove park gear from governor assembly.

9.Detach governor housing.

10.Remove security clip and counter weight.

11.Remove and discard 'O' ring seal from output

shaft and three seal rings from 'F' clutch

housing.

12.Clean all components.

13.If necessary detach parking pawl by removing

guide plates and withdrawing mechanism.Refit

14.Refit parking pawl mechanism if removed.

15.Fit and lubricate new seal rings to 'F' clutch

housing shaft, ensure they are correctly seated.

16.Apply petroleum jelly to a new 'O' ring seal. Fit to

output shaft

17.Fit park gear to governor assembly tightening

screws to correct torque.

18.Fit governor assembly to output shaft.

19.Fit extension shaft with spacer if Tdi. Fit new 'O'

ring under bolt head.

20.Fit extension housing, avoid damaging seal.

Tighten to

23 Nm.

21.Refit transfer gear lever housing to extension

housing.

22.Refit mounting bracket to extension housing.

Tighten to

52 Nm.

23.Refit transfer gearbox.See TRANSFER

GEARBOX, Repair, LT230T Transfer Gearbox

24.Refill automatic gearbox with correct grade of oil.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids