wheel LAND ROVER DISCOVERY 1995 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 95 of 873

12ENGINE

14

REPAIR FLYWHEEL

Service repair no - 12.53.07

Remove

1.Disconnect battery negative lead.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

Assembly

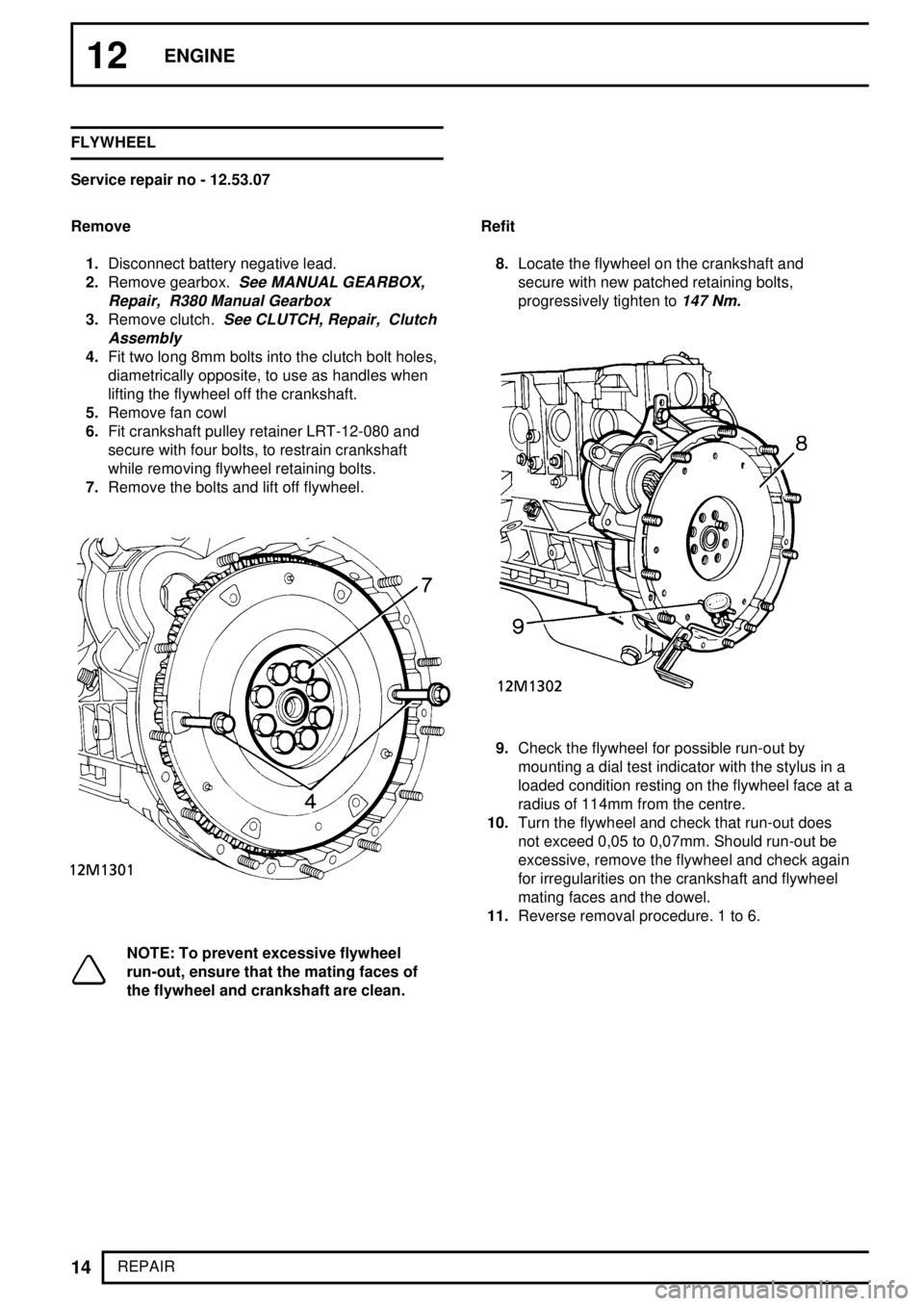

4.Fit two long 8mm bolts into the clutch bolt holes,

diametrically opposite, to use as handles when

lifting the flywheel off the crankshaft.

5.Remove fan cowl

6.Fit crankshaft pulley retainer LRT-12-080 and

secure with four bolts, to restrain crankshaft

while removing flywheel retaining bolts.

7.Remove the bolts and lift off flywheel.

NOTE: To prevent excessive flywheel

run-out, ensure that the mating faces of

the flywheel and crankshaft are clean.Refit

8.Locate the flywheel on the crankshaft and

secure with new patched retaining bolts,

progressively tighten to

147 Nm.

9.Check the flywheel for possible run-out by

mounting a dial test indicator with the stylus in a

loaded condition resting on the flywheel face at a

radius of 114mm from the centre.

10.Turn the flywheel and check that run-out does

not exceed 0,05 to 0,07mm. Should run-out be

excessive, remove the flywheel and check again

for irregularities on the crankshaft and flywheel

mating faces and the dowel.

11.Reverse removal procedure. 1 to 6.

Page 96 of 873

Tdi

15

REPAIR CRANKSHAFT REAR OIL SEAL

Service repair no - 12.21.20

Remove

NOTE: The crankshaft rear oil seal is

retained in its own housing, if the seal

requires replacing the housing and seal

assembly (1) must be renewed complete with the

housing seal (3). Housing and seal assemblies are

supplied with their own former/seal guide (2)

already fitted. This former must not be removed

before fitting the assembly to the engine. If a seal

and housing assembly is received without a

former/guide fitted it must be returned to the

supplier. Used formers/guides must be discarded

immediately after use, under no circumstances

should they be reused on other assemblies.

1.Disconnect battery negative lead.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

Assembly

4.Remove flywheel.See Flywheel

5.Remove five bolts and withdraw seal housing

and seal assembly complete with gasket.

Refit

6.Insert slave studs to seal housing mounting face.

7.Position new seal housing gasket over slave

studs and crankshaft flange onto cylinder block.

Page 97 of 873

12ENGINE

16

REPAIR 8.Ensure housing seal is correctly seated in its

groove in new housing and seal assembly.

9.Fit new assembly, with former/guide in-situ, over

crankshaft flange, this action will eject

former/guide.

10.Secure assembly to cylinder block with five bolts

tightened to correct torque, removing slave studs

individually and inserting bolts.

11.Refit flywheel.

See Flywheel

12.Refit clutch.See CLUTCH, Repair, Clutch

Assembly

13.Refit gearbox.See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

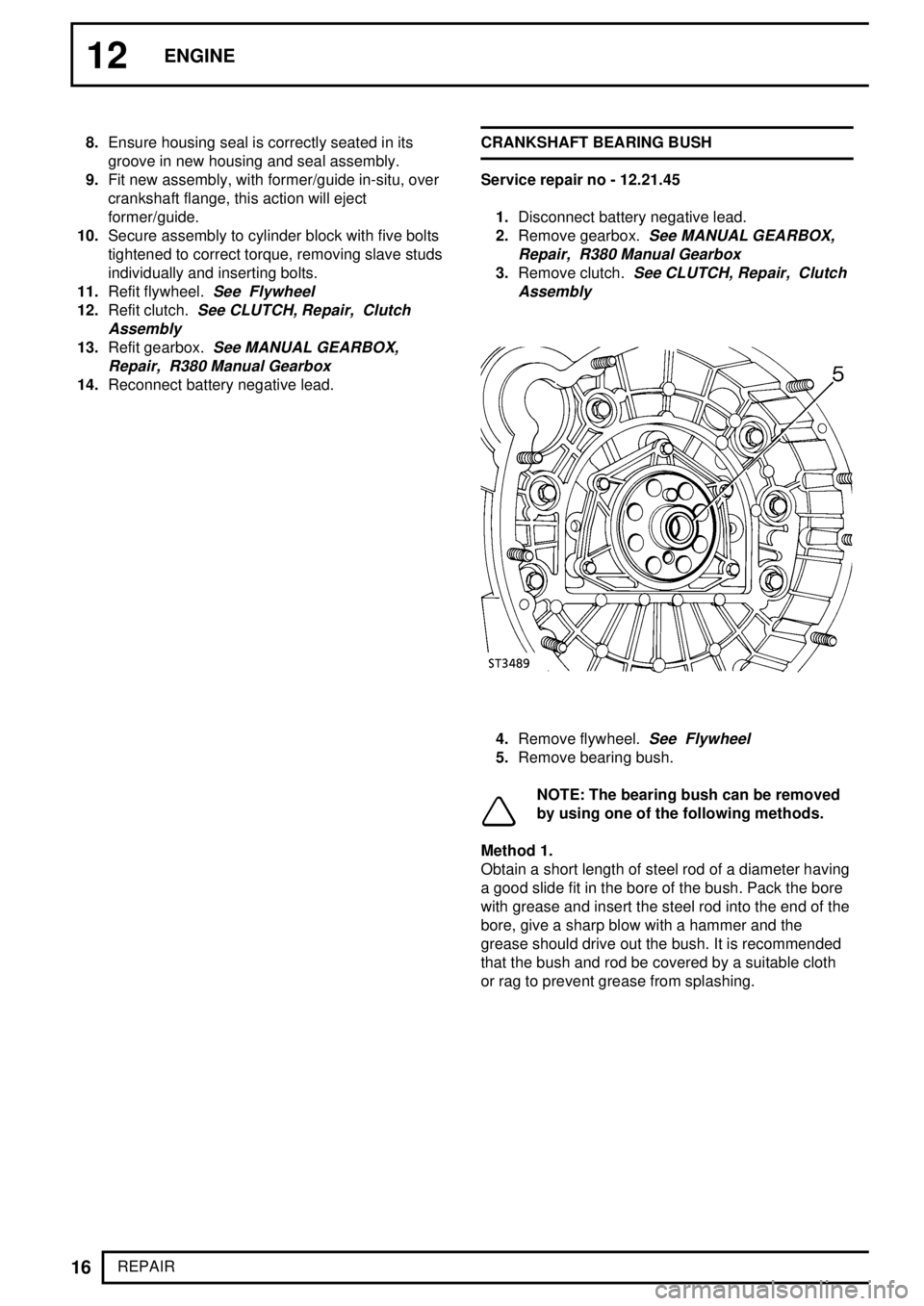

14.Reconnect battery negative lead.CRANKSHAFT BEARING BUSH

Service repair no - 12.21.45

1.Disconnect battery negative lead.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

Assembly

4.Remove flywheel.See Flywheel

5.Remove bearing bush.

NOTE: The bearing bush can be removed

by using one of the following methods.

Method 1.

Obtain a short length of steel rod of a diameter having

a good slide fit in the bore of the bush. Pack the bore

with grease and insert the steel rod into the end of the

bore, give a sharp blow with a hammer and the

grease should drive out the bush. It is recommended

that the bush and rod be covered by a suitable cloth

or rag to prevent grease from splashing.

Page 98 of 873

Tdi

17

REPAIR Method 2.

Thread the bore of the existing bush and using a

suitable bolt extract the bush. Thoroughly clean bush

location ensuring all swarf is removed.

Fitting

6.Fit new bush using a suitable shouldered drift,

inserting bush flush with end of crankshaft.

7.Refit flywheel.

See Flywheel

8.Refit clutch.See CLUTCH, Repair, Clutch

Assembly

9.Refit gearbox.See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

10.Reconnect battery negative lead.FLYWHEEL HOUSING

Service repair no - 12.53.01

Remove

1.Disconnect battery negative lead.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

Assembly

4.Remove flywheel.See Flywheel

5.Remove starter motor.

6.Remove two bolts from top of flywheel housing.

7.Remove four bolts from bottom of flywheel

housing.

8.Remove six inner bolts and lift off flywheel

housing.

Refit

9.Clean rear face of housing and mating face on

block, ensuring all old sealant is removed.

Page 99 of 873

12ENGINE

18

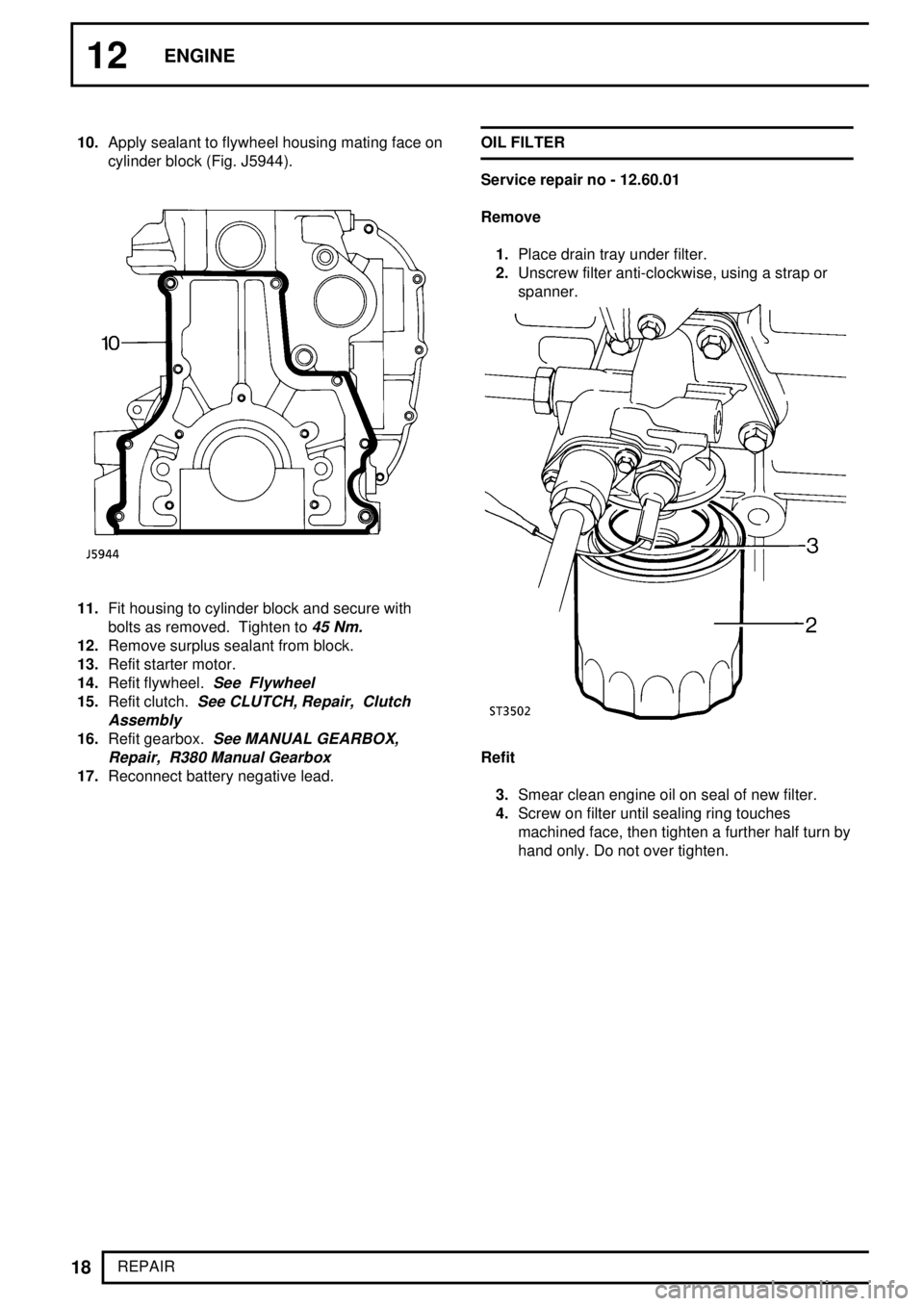

REPAIR 10.Apply sealant to flywheel housing mating face on

cylinder block (Fig. J5944).

11.Fit housing to cylinder block and secure with

bolts as removed. Tighten to

45 Nm.

12.Remove surplus sealant from block.

13.Refit starter motor.

14.Refit flywheel.

See Flywheel

15.Refit clutch.See CLUTCH, Repair, Clutch

Assembly

16.Refit gearbox.See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

17.Reconnect battery negative lead.OIL FILTER

Service repair no - 12.60.01

Remove

1.Place drain tray under filter.

2.Unscrew filter anti-clockwise, using a strap or

spanner.

Refit

3.Smear clean engine oil on seal of new filter.

4.Screw on filter until sealing ring touches

machined face, then tighten a further half turn by

hand only. Do not over tighten.

Page 105 of 873

Tdi

1

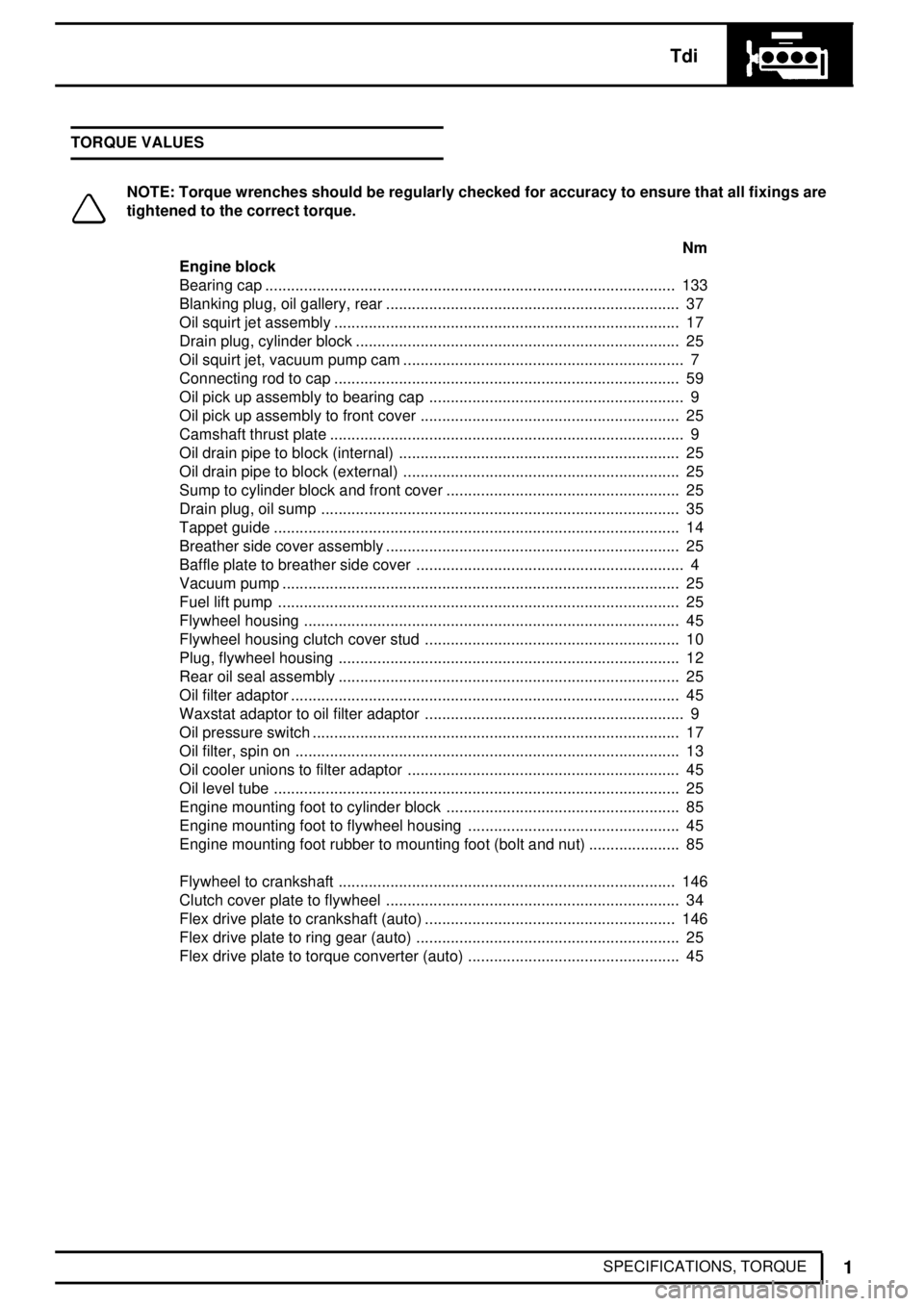

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Engine block

Bearing cap 133...............................................................................................

Blanking plug, oil gallery, rear 37....................................................................

Oil squirt jet assembly 17................................................................................

Drain plug, cylinder block 25...........................................................................

Oil squirt jet, vacuum pump cam 7.................................................................

Connecting rod to cap 59................................................................................

Oil pick up assembly to bearing cap 9...........................................................

Oil pick up assembly to front cover 25............................................................

Camshaft thrust plate 9..................................................................................

Oil drain pipe to block (internal) 25.................................................................

Oil drain pipe to block (external) 25................................................................

Sump to cylinder block and front cover 25......................................................

Drain plug, oil sump 35...................................................................................

Tappet guide 14..............................................................................................

Breather side cover assembly 25....................................................................

Baffle plate to breather side cover 4..............................................................

Vacuum pump 25............................................................................................

Fuel lift pump 25.............................................................................................

Flywheel housing 45.......................................................................................

Flywheel housing clutch cover stud 10...........................................................

Plug, flywheel housing 12...............................................................................

Rear oil seal assembly 25...............................................................................

Oil filter adaptor 45..........................................................................................

Waxstat adaptor to oil filter adaptor 9............................................................

Oil pressure switch 17.....................................................................................

Oil filter, spin on 13.........................................................................................

Oil cooler unions to filter adaptor 45...............................................................

Oil level tube 25..............................................................................................

Engine mounting foot to cylinder block 85......................................................

Engine mounting foot to flywheel housing 45.................................................

Engine mounting foot rubber to mounting foot (bolt and nut) 85.....................

Flywheel to crankshaft 146..............................................................................

Clutch cover plate to flywheel 34....................................................................

Flex drive plate to crankshaft (auto) 146..........................................................

Flex drive plate to ring gear (auto) 25.............................................................

Flex drive plate to torque converter (auto) 45.................................................

Page 115 of 873

12ENGINE

2

FAULT DIAGNOSIS ENGINE NOISES

Excessive or obtrusive noise from the engine

compartment originates from three main sources:

A. The exhaust system, which makes an

unmistakable and easy to diagnose noise.

B. External components emit the greatest variety of

noises, but are also easy to diagnose by simply

removing the drive belt.

C. Engine internal mechanical noises which can

vary in volume and pitch and may be a

combination of, tapping - knocking or rumbling,

are the most difficult to diagnose. The following

is therefore a guide to diagnosis of engine

internal mechanical noises only.

Engine internal mechanical noises.

Single or multiple, light tapping noise, particularly

when engine is cold.

See Description and

operation, Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Suspect valve operating mechanism.

3.To confirm diagnosis, remove the rocker covers

and with the engine idling, insert a feeler gauge

of 0,015mm between each rocker and valve

stem. A faulty valve operating mechanism will

emit a different noise when the feeler gauge is

inserted.

See Repair, Rocker Shaft Renew

Heavy knocking noise (particularly on load and

when engine is hot).

See Description and

operation, Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Drain engine oil and filter, and examine

for metallic contamination.

3.Is the oil contaminated with metal particles?

YES - Suspect faulty big end bearings. To

confirm diagnosis, short out the ignition to

each spark plug in turn. The noise will

disappear or be reduced when the

cylinder with the faulty big end is shorted

out.

4.If noise is not conclusively diagnosed, check the

security of the flywheel and crankshaft front

pulley. Temporarily release the drive belt to

reduce general noise level and use a

stethoscope to locate source of noise.

Heavy rumbling noise (particularly during hard

acceleration).

See Description and operation,

Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Drain engine oil and filter, and examine

for metallic contamination.

3.Is the oil contaminated with metal particles?

YES - Suspect faulty main bearings. If noise is

not conclusively diagnosed, check the

security of the flywheel and crankshaft

front pulley. Temporarily release the drive

belt to reduce general noise level and use

a stethoscope to locate source of noise.

Page 126 of 873

12ENGINE

8

REPAIR CRANKSHAFT PULLEY ASSEMBLY

Service repair no - 12.21.01

1.Remove viscous coupling.

See COOLING

SYSTEM, Repair, Viscous Coupling, Fan

Blades, Pulley and Fan Cowl

2.Remove drive belt.See Drive Belt

3.Raise vehicle on ramp [hoist].

4.Remove bell housing bottom cover.

5.Remove engine undertray.

6.With assistance to stop flywheel rotation, remove

crankshaft pulley assembly retaining bolt.

7.Remove crankshaft pulley assembly.

8.If required: Place assembly in vice and remove

pulley.

9.Fit pulley to torsional vibration damper.

10.Lubricate seal face of assembly.

11.Fit pulley assembly.

12.With assistance to stop flywheel rotation, fit

retaining bolt. Tighten to

280 Nm.

13.Reverse removal procedure. 1 to 5.FRONT COVER OIL SEAL - RENEW

Service repair no - 12.21.14

1.Remove crankshaft pulley.

See Crankshaft

Pulley Assembly. Do not remove pulleys.

2.Remove eight screws and remove mud

excluder.

3.Fit button of 18G1328 to crankshaft, fit extractor

to seal.

4.Turn centre bolt of extractor to remove seal.

5.Remove seal from extractor.

6.Clean seal seating.

7.Lubricate outside diameter of seal.

8.Locate seal in front cover.

9.Fit adaptor 18G1291/5 to 18G1291/4.

10.Fit tool to seal.

11.Fit and tighten centre bolt to crankshaft, tighten

centre locknut to seat seal.

12.Slacken locknut and remove tool.

13.Lubricate seal lip.

14.Fit mud excluder and tighten screws.

15.Fit crankshaft pulley assembly.

Page 128 of 873

12ENGINE

10

REPAIR TIMING CHAIN AND CHAINWHEELS

Service repair no - 12.65.12

Remove

1.Remove front cover.

See Front Cover Gasket

2.Remove retaining bolt and washer, remove

distributor drive gear and spacer.

3.Ensure number one piston is at TDC.

4.Remove chainwheels and chain as an assembly.

See V8i Overhaul Manual.

Refit

5.Clean chainwheels and chain.

6.Fit chainwheels to chain, aligning timing marks.

7.Ensure camshaft key is fitted parallel to shaft

axis to ensure adequate lubrication to distributor

drive gear.

8.Engage chainwheel assembly on camshaft and

crankshaft keys, ensure chain wheels are fully

located.

9.Check alignment of timing marks with straight

edge.

10.Fit spacer with flange to front,

11.Fit distributor drive gear with groove towards

spacer.

12.Fit retaining bolt and washer. Tighten to

58 Nm.

13.Fit front cover.See Front Cover Gasket

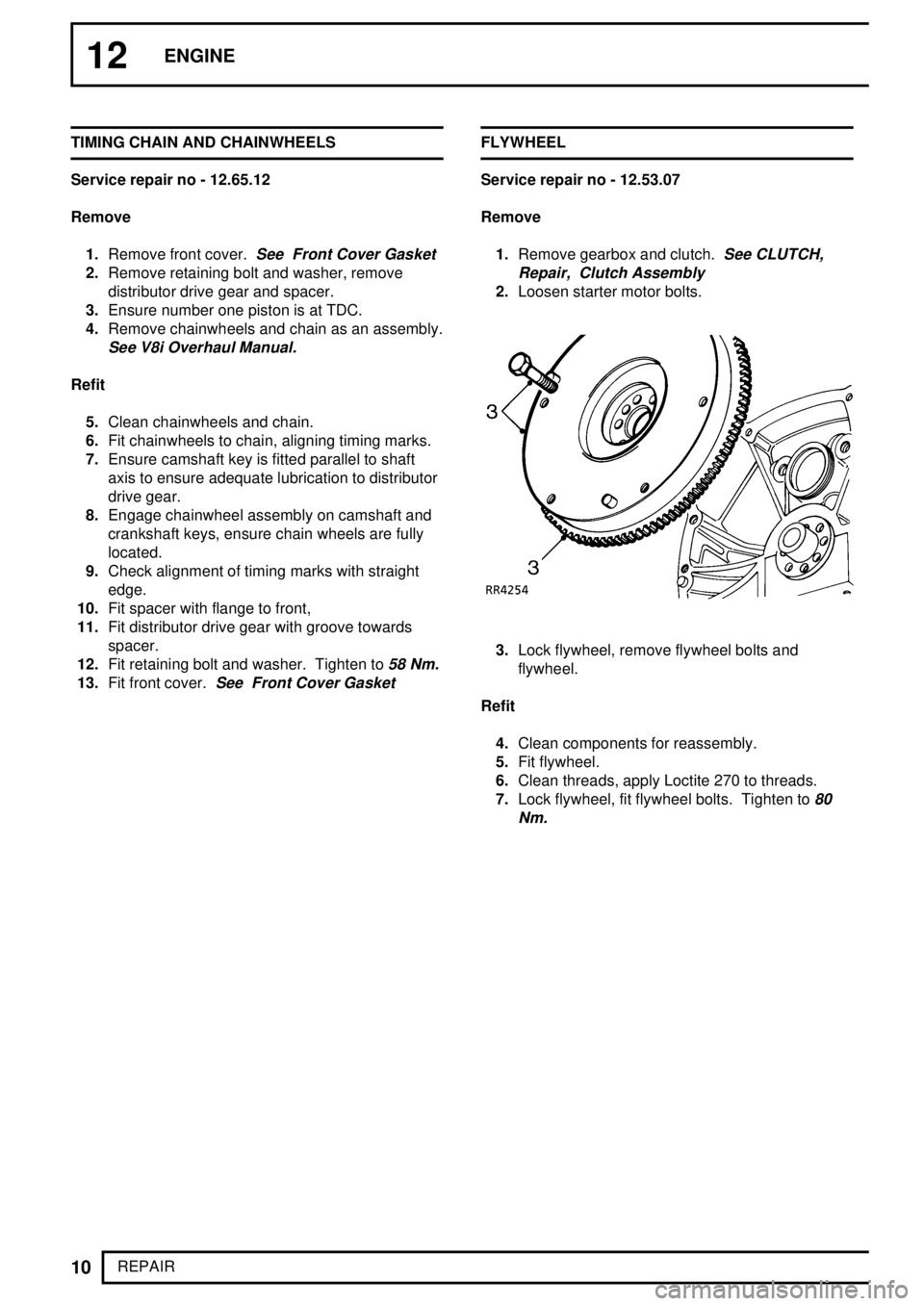

FLYWHEEL

Service repair no - 12.53.07

Remove

1.Remove gearbox and clutch.

See CLUTCH,

Repair, Clutch Assembly

2.Loosen starter motor bolts.

3.Lock flywheel, remove flywheel bolts and

flywheel.

Refit

4.Clean components for reassembly.

5.Fit flywheel.

6.Clean threads, apply Loctite 270 to threads.

7.Lock flywheel, fit flywheel bolts. Tighten to

80

Nm.

Page 129 of 873

V8i

11

REPAIR FLEXIBLE DRIVE PLATE AND RING GEAR

Service repair no - 12.53.13

Remove

1.Remove transmission.

See AUTOMATIC

GEARBOX, Repair, LT230T Transfer Gearbox

with Automatic Gearbox Assembly - V8i

2.Remove flexible drive plate and ring gear

assembly.

See V8i Overhaul Manual.

Refit

3.Clean all components for reassembly.

4.Fit ring gear and flexible drive plate assembly.

See V8i Overhaul Manual.

5.Fit transmission.CRANKSHAFT REAR OIL SEAL

Service repair no - 12.21.20

1.Automatic transmission, remove drive plate.

See Flexible Drive Plate and Ring Gear

OR manual transmission, remove flywheel.See

Flywheel

2.Remove sump.See Oil Sump

3.Remove rear main bearing cap.

4.Remove cross seals from cap.

5.Remove crankshaft rear oil seal.

6.Clean main bearing cap and oil seal area of

block.

7.Fit new cross seals to bearing cap.

8.Apply Hylomar SQ32M to block as illustrated.

9.Lubricate bearing shell and cross seals using

clean engine oil.

10.Fit bearing cap, do not tighten bolts.

11.Ensure cap is fully home and seated squarely on

the block.