engine coolant LAND ROVER DISCOVERY 1995 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 209 of 873

19FUEL SYSTEM

4

DESCRIPTION AND OPERATION OPERATION

Diesel engines operate by compression ignition. The

rapid compression of air in the cylinder during the

compression cycle heats the injected fuel, causing it

to self ignite. During cold starting, automatically

controlled glow plugs assist in raising the temperature

of the compressed air to ignition point.

A cold start advance unit advances the injection timing

to further assist starting. Idle quality is improved by

the high idle setting.

The engine is supplied with pre-compressed air by a

single stage turbocharger.

Exhaust gases passing over a turbine cause it to

rotate, driving a compressor mounted on the turbine

shaft. Air drawn from the cold air intake passes, via

the air cleaner, to the turbocharger where it is

compressed. The compressed air passes to the

cylinders via an intercooler, which reduces the

temperature of the compressed air, increasing its

density.

Fuel is drawn from the tank by a mechanical lift pump

and passes to the injection pump via a filter. In

addition to removing particle contamination from the

fuel, the filter incorporates a water separator, which

removes and stores both bound and unbound water.

The injection pump meters a precisely timed, exact

quantity of fuel to the injectors in response to throttle

variations, injection timing varying with engine speed.

Any excess fuel delivered to the injection pump is not

injected, passing back to the tank via the fuel return

line.

Fuel is injected in a finely atomised form into a

pre-combustion chamber in the cylinder head where it

ignites. The burning fuel expands rapidly into the main

combustion chamber, creating extreme turbulence

which mixes the burning fuel thoroughly with the

compressed air, providing complete combustion.

Cold Starting is assisted by glow plugs, a cold start

advance unit and a high idle setting.Glow plugs

Glow plug operation is controlled by a timer unit, start

relay and resistor. When the ignition is turned on the

timer unit is energised, the glow plugs start to operate

and a warning light on the dashboard illuminates,

remaining illuminated until the glow plugs are

automatically switched off.

The length of time the glow plugs will operate is

dependent on under bonnet temperature, which is

monitored by a sensor located in the timer unit.

Starting the engine results in the power supply to the

glow plugs passing through the resistor, which

reduces their operating temperature. The glow plugs

are cut out either by the temperature sensor in the

timer, or by a microswitch on the injection pump which

operates when the throttle is depressed.

Cold start advance

The cold start advance unit is connected to the engine

cooling system via hoses. It contains a temperature

sensitive element which is retracted when cold and

pulls the advance lever, via cable, towards the rear of

the pump against spring pressure. As coolant

temperature rises, the cold start element expands

releasing tension on the cable and allowing spring

pressure to move the advance lever forwards.

Page 210 of 873

Tdi

5

DESCRIPTION AND OPERATION Exhaust Gas Recirculation (EGR)

Operation of the EGR system is dependent on the

following:

a. Engine temperature - must be between 20°C

and 100°C approx.

b. Engine speed - must be between 630 and 2850

rev/min.

c. Engine load - calculated by throttle position

sensor.

d. EGR valve lift position.

e. Duration of engine idling.

Under varying engine speed and load conditions the

control unit sends a signal to open the vacuum

modulator which allows a vacuum to be applied above

the EGR valve diaphragm, the vacuum supply being

taken from a 'T' connector in the brake servo hose.

This process is controlled by an engine speed/load

map stored in the EGR control unit memory.

Engine speed is measured by monitoring the

waveform present on one phase of the generator.

Throttle position is measured via a sensor mounted on

the fuel injection pump throttle lever. Closed loop

control is achieved by allowing the control unit to

continually monitor EGR valve lift via a position sensor

mounted on the valve; this valve lift is compared with

the actual valve lift required on the control unit map

and adjusted if necessary.

With coolant temperature between 20°C and 100°C;

the engine having just returned to idle, EGR will shut

off after 25-30 seconds idling.

Page 211 of 873

19FUEL SYSTEM

6

DESCRIPTION AND OPERATION DESCRIPTION ELECTRONIC DIESEL CONTROL

The Electronic Diesel Control (EDC) 'drive by wire'

system derives its from the replacement of

conventional mechanical controls by electronic

components.

The EDC system supplies the exact amount of fuel to

the engine according to the prevailing engine

operating conditions. To monitor these conditions,

sensors are fitted to the engine to measure engine

parameters. Data from the sensors is received by the

Engine Control Module (ECM) which determines the

exact amount of fuel, injection timing and Exhaust

Gas Recirculation (EGR) required for any running

condition.

Safety and emergency features are built into the

system which protect the engine against overspeed

and overheating damage. In the event of component

failure the system is designed to compensate and

allow emergency start and limp home facilities to

operate. The ECM does this by substituting a default

value for the failed component which may result in a

noticeable loss in power but keeps the engine

running.FUEL SYSTEM COMPONENT LOCATION EDC

1. Vehicle speed sensor

2. No. 4 injector sensor

3. Coolant temperature sensor

4. Boost pressure sensor

5. Electro-pneumatic modulator

6. Airflow sensor

7. Engine speed sensor

8. Brake/clutch switches

9. Injector pump

10. Throttle position sensor

11. Engine control module

Page 214 of 873

Tdi

9

DESCRIPTION AND OPERATION OPERATION EDC

Under start up conditions, signals from the crank

speed and water temperature sensors are relayed to

the ECM to control starting fuel quantity and injection

timing. Once the engine has started the ECM initiates

a 'closed loop' monitoring system for fuel quantity,

injector timing and EGR relative to the appropriate

engine operating conditions.

As driver demand increases, signals from the throttle

position sensor are received by the ECM together with

crank speed and position pulses. The ECM signals

the injection pump to adjust fuel quantity and timing

relative to driver demand.

As engine coolant, fuel and air temperature changes

the ECM will correct fuel delivery and injection timing

for more efficient and accurate running. The ECM will

also make corrections for atmospheric pressure on

injection timing and EGR.

Electronic Control Unit (ECM)

The EDC system is controlled by the ECM located in

the drivers footwell on the 'A' post beneath the fascia.

The unit consists of a microprocessor with integrated

circuits and components and is connected to the main

harness by a 55 pin plug.

Inputs to the ECM from engine sensors control start of

injection, injected fuel quantity, fuel cut-off and EGR.

The ECM will also make corrections for engine

coolant, fuel and air temperature and atmospheric

pressure.Injection pump

The injection pump incorporates actuator controlled

injected fuel quantity and solenoid operated timing

which operate in response to ECM signals against

driver demand, engine speed, temperature and boost

pressure.

A fuel cut-off facility and fuel temperature sensor is

incorporated in the pump.

Injection timing sensor

An inductive sensor in No 4 injector body monitors

needle movement. This forms part of a 'closed loop'

system to control start of injection.

The system measures timing, relating the needle

movement signal to crank position (determined by

flywheel pulses from the engine speed sensor).

Air flow sensor

The Air Flow Sensor is mounted on a bracket

attached to the wheel arch valance, and connected by

hose to the air cleaner and turbo charger inlet.

The unit consists of a flap valve airflow sensor which

measures the fresh air flow into the engine. The

sensor informs the ECM and, provided that the other

conditions are met, will implement EGR.

Engine speed sensor

The engine speed sensor is an active inductive sensor

mounted on the flywheel housing. Pulses from the

sensor activated by radial slots in the flywheel give

engine speed and position information to the ECM.

Page 235 of 873

19FUEL SYSTEM

18

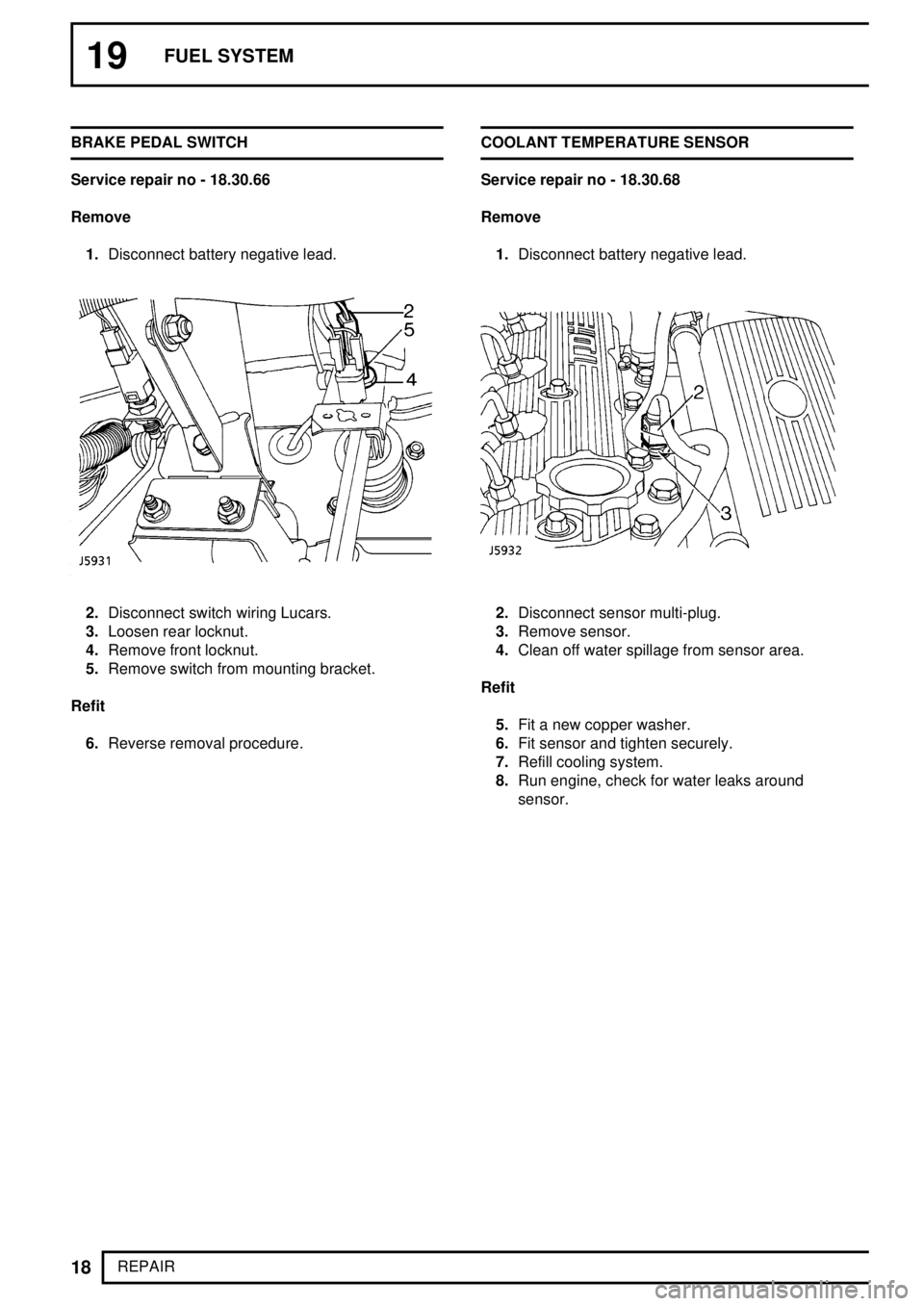

REPAIR BRAKE PEDAL SWITCH

Service repair no - 18.30.66

Remove

1.Disconnect battery negative lead.

2.Disconnect switch wiring Lucars.

3.Loosen rear locknut.

4.Remove front locknut.

5.Remove switch from mounting bracket.

Refit

6.Reverse removal procedure.COOLANT TEMPERATURE SENSOR

Service repair no - 18.30.68

Remove

1.Disconnect battery negative lead.2.Disconnect sensor multi-plug.

3.Remove sensor.

4.Clean off water spillage from sensor area.

Refit

5.Fit a new copper washer.

6.Fit sensor and tighten securely.

7.Refill cooling system.

8.Run engine, check for water leaks around

sensor.

Page 237 of 873

MFI

1

DESCRIPTION AND OPERATION DESCRIPTION

Hot Wire Multiport Fuel Injection

The 'Hot Wire' Multiport fuel injection system derives

its name from the mass air flow sensor which uses

one cold wire and one electrically heated wire to

measure the volume of air entering the engine.

The function of the system is to supply the exact

amount of fuel directly into the intake manifold

according to the prevailing engine operating

conditions.

To monitor these conditions, various sensors are fitted

to the engine to measure engine parameters. Data

from the sensors is received by the Engine control

module (ECM), the ECM will then determine the exact

amount of fuel required at any condition.

The ECM having received data from the sensors

produces pulses, the length of which will determine

the simultaneous open time of each bank of injectors

in turn, which will govern the amount of fuel injected.

Engine control module - ECM

The Multiport fuel injection system is controlled by the

14 CUX Engine Control Module comprising of a

microprocessor with integrated circuits and

components mounted on printed circuit boards. The

ECM is connected to the main harness by a 40 pin

plug.

Injectors

The eight fuel injectors are fitted between the

pressurized fuel rail and inlet manifold. Each injector

comprises a solenoid operated needle valve with a

movable plunger rigidly attached to the nozzle valve.

When the solenoid is energized the plunger is

attracted off its seat and allows pressurized fuel into

the intake manifold.Engine coolant temperature sensor

The engine coolant temperature sensor is located in

the front of the thermostat housing. The sensor

provides engine coolant information to the ECM. The

ECM increases the injector opening time when cold to

provide improved driveability, and reduces the

opening time as the engine reaches normal operating

temperature.

Engine fuel temperature sensor

The engine fuel temperature sensor is located in the

rail on the RH side of the ram housing. The sensor

sends fuel temperature data to the ECM, the ECM on

receiving the data will adjust the injector open time

accordingly to produce good hot starting in high

ambient temperatures.

Idle air control valve

The idle air control valve is screwed into a housing

attached to the rear of the plenum chamber, between

the plenum chamber and bulkhead. The idle air

control valve has two windings which enable the

motor to be energised in both directions thus opening

or closing the air valve as required by the ECM.

The idle air control valve will open and allow extra air

into the plenum chamber to maintain engine idle

speed when the engine is under increased (Electrical

and Mechanical) loads.

The idle air control valve will control engine idle speed

when the vehicle is stationary.

Heated oxygen sensors (0

2sensors) - Catalyst

vehicles

The two heated oxygen sensors are located forward

of the catalysts mounted in the exhaust downpipes.

The sensors monitor the oxygen content of the

exhaust gases and provide feedback information of

the air/fuel ratio to the ECM. Each sensor is heated by

an electrical element to improve its response time

when the ignition is switched on.

Page 239 of 873

MFI

3

DESCRIPTION AND OPERATION Tune select resistor -

To suit individual market requirements a tune select

resistor is connected across pins 5 and 27 of the

ECM.

It is located adjacent to the ECM, and strapped to the

MFI cable assembly. The value of the resistor is

dependent on the market application:

Red wire, 180 ohms, Australia, Rest of world.

Green wire, 470 Ohms, UK and Europe - non catalyst.

Yellow wire 910 Ohms, Saudi non catalyst.

White wire, 3K9 Ohms, European catalyst

Condenser fans

It should be noted that under high coolant

temperatures, when the engine is switched off, the

condenser fans will be activated and will run for

approximately ten minutes.Vehicle speed sensor

The vehicle speed sensor is located on the side of the

Transfer box adjacent to the parking brake. The

sensor provides road speed data to the ECM. The

ECM in turn detects vehicle movement from the road

speed input and ensures that idle air control mode is

disengaged. Should the vehicle speed sensor fail in

service the ECM idle air control would become erratic.

The sensor also provides road speed data to the

electric speedometer and cruise control ECU.

Inertia fuel shutoff switch

The inertia fuel shutoff switch is a mechanically

operated switch, located on the bulkhead adjacent to

the washer reservoir under bonnet [hood].

The switch is normally closed and is in line with the

fuel pump. In the event of a sudden impact the switch

opens, and disconnects the electrical feed to the fuel

pump. The switch is reset by pressing down the

button.

WARNING: Check the integrity of the fuel

system before the inertia switch is reset.

Relay modules

The two multiport fuel injection relays are located in

the RH footwell area behind the 'A' post panel. The

main relay module is energized via the ECM when the

ignition is switched on and supplies current to the

multiport fuel injection system. The fuel pump relay

module is energized by the ECM which in turn

operates the fuel pump to pressurize the fuel system.

Page 240 of 873

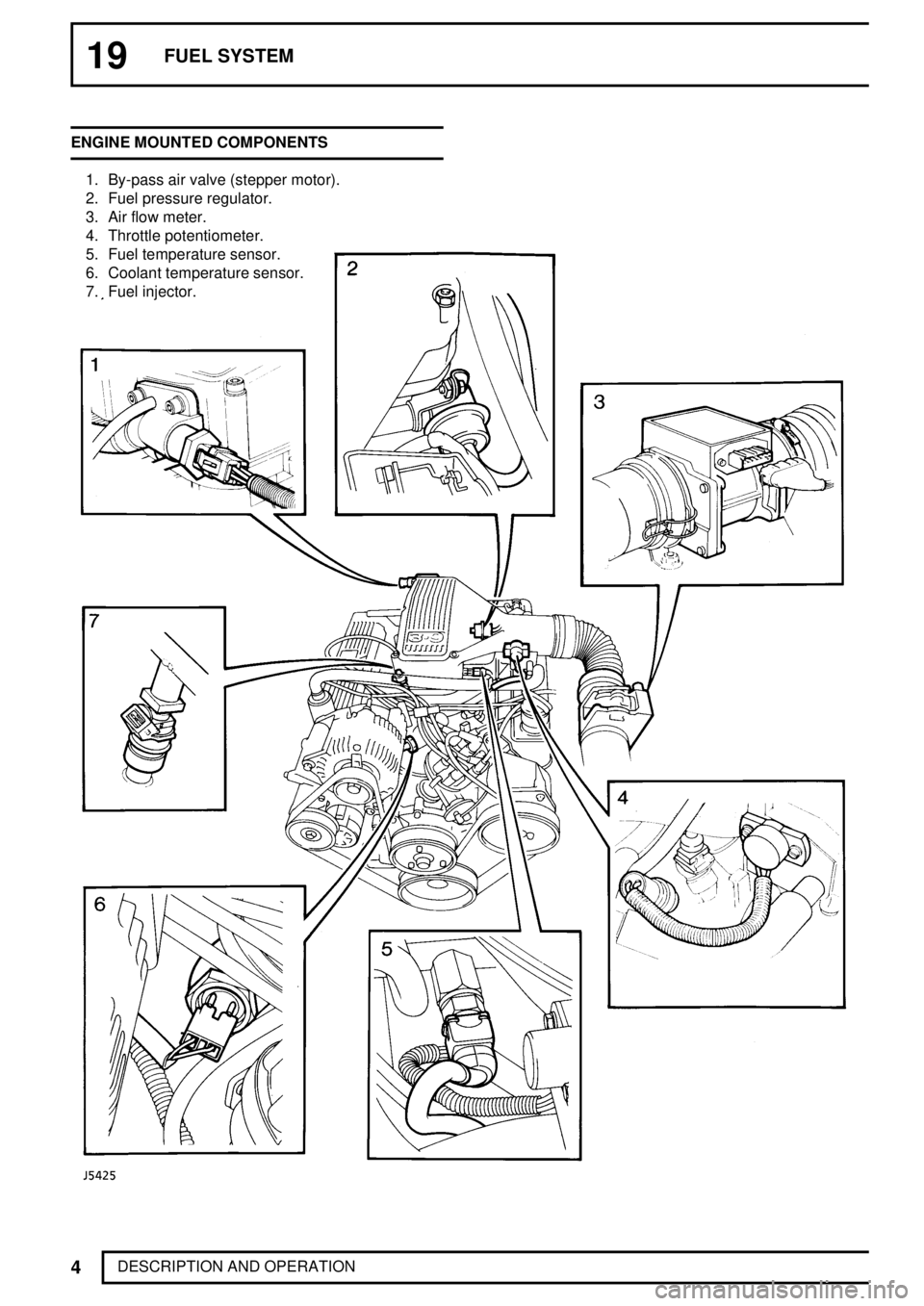

19FUEL SYSTEM

4

DESCRIPTION AND OPERATION ENGINE MOUNTED COMPONENTS

1. By-pass air valve (stepper motor).

2. Fuel pressure regulator.

3. Air flow meter.

4. Throttle potentiometer.

5. Fuel temperature sensor.

6. Coolant temperature sensor.

7. Fuel injector.

Page 252 of 873

19FUEL SYSTEM

6

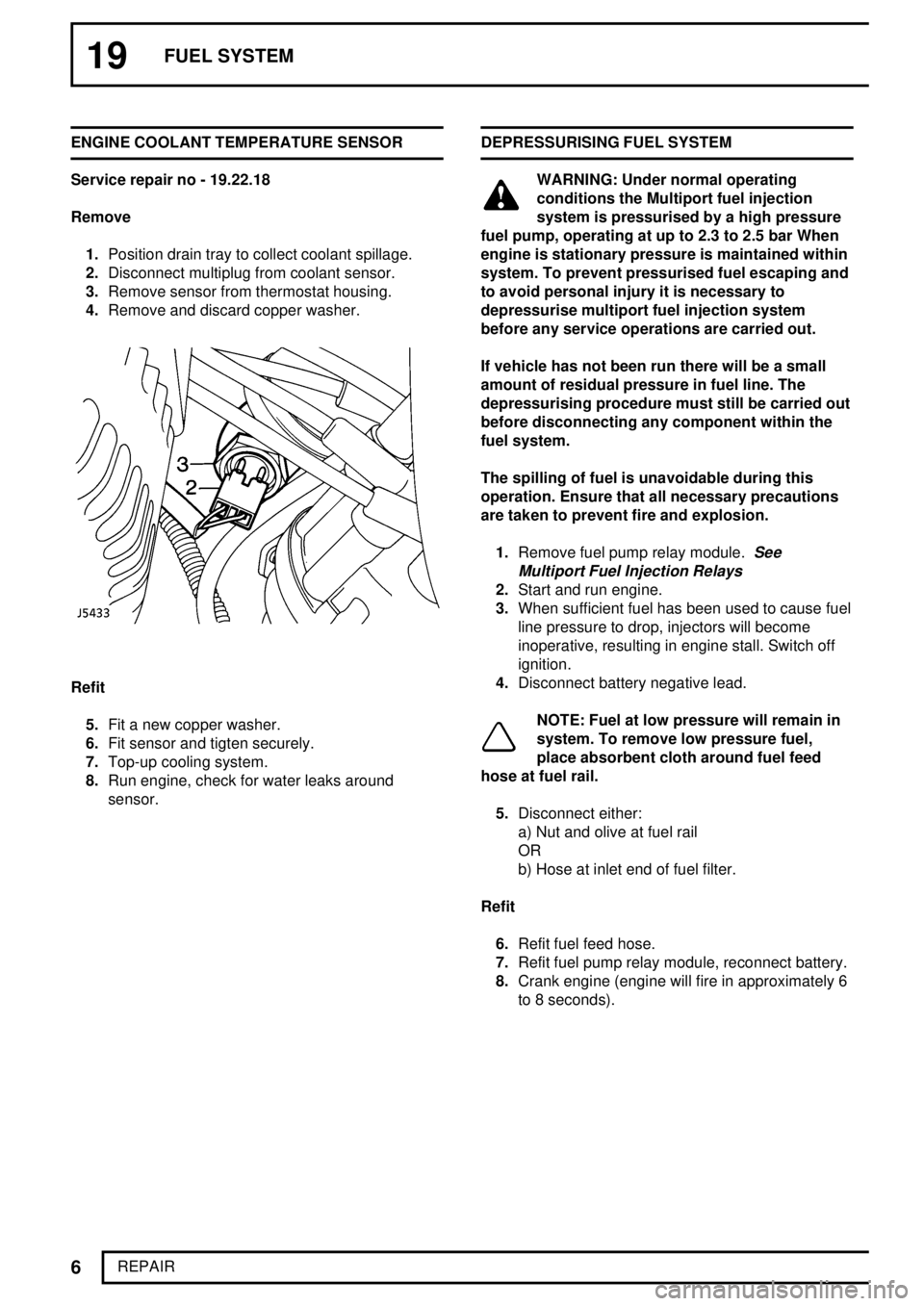

REPAIR ENGINE COOLANT TEMPERATURE SENSOR

Service repair no - 19.22.18

Remove

1.Position drain tray to collect coolant spillage.

2.Disconnect multiplug from coolant sensor.

3.Remove sensor from thermostat housing.

4.Remove and discard copper washer.

Refit

5.Fit a new copper washer.

6.Fit sensor and tigten securely.

7.Top-up cooling system.

8.Run engine, check for water leaks around

sensor.DEPRESSURISING FUEL SYSTEM

WARNING: Under normal operating

conditions the Multiport fuel injection

system is pressurised by a high pressure

fuel pump, operating at up to 2.3 to 2.5 bar When

engine is stationary pressure is maintained within

system. To prevent pressurised fuel escaping and

to avoid personal injury it is necessary to

depressurise multiport fuel injection system

before any service operations are carried out.

If vehicle has not been run there will be a small

amount of residual pressure in fuel line. The

depressurising procedure must still be carried out

before disconnecting any component within the

fuel system.

The spilling of fuel is unavoidable during this

operation. Ensure that all necessary precautions

are taken to prevent fire and explosion.

1.Remove fuel pump relay module.

See

Multiport Fuel Injection Relays

2.Start and run engine.

3.When sufficient fuel has been used to cause fuel

line pressure to drop, injectors will become

inoperative, resulting in engine stall. Switch off

ignition.

4.Disconnect battery negative lead.

NOTE: Fuel at low pressure will remain in

system. To remove low pressure fuel,

place absorbent cloth around fuel feed

hose at fuel rail.

5.Disconnect either:

a) Nut and olive at fuel rail

OR

b) Hose at inlet end of fuel filter.

Refit

6.Refit fuel feed hose.

7.Refit fuel pump relay module, reconnect battery.

8.Crank engine (engine will fire in approximately 6

to 8 seconds).

Page 273 of 873

19FUEL SYSTEM

2

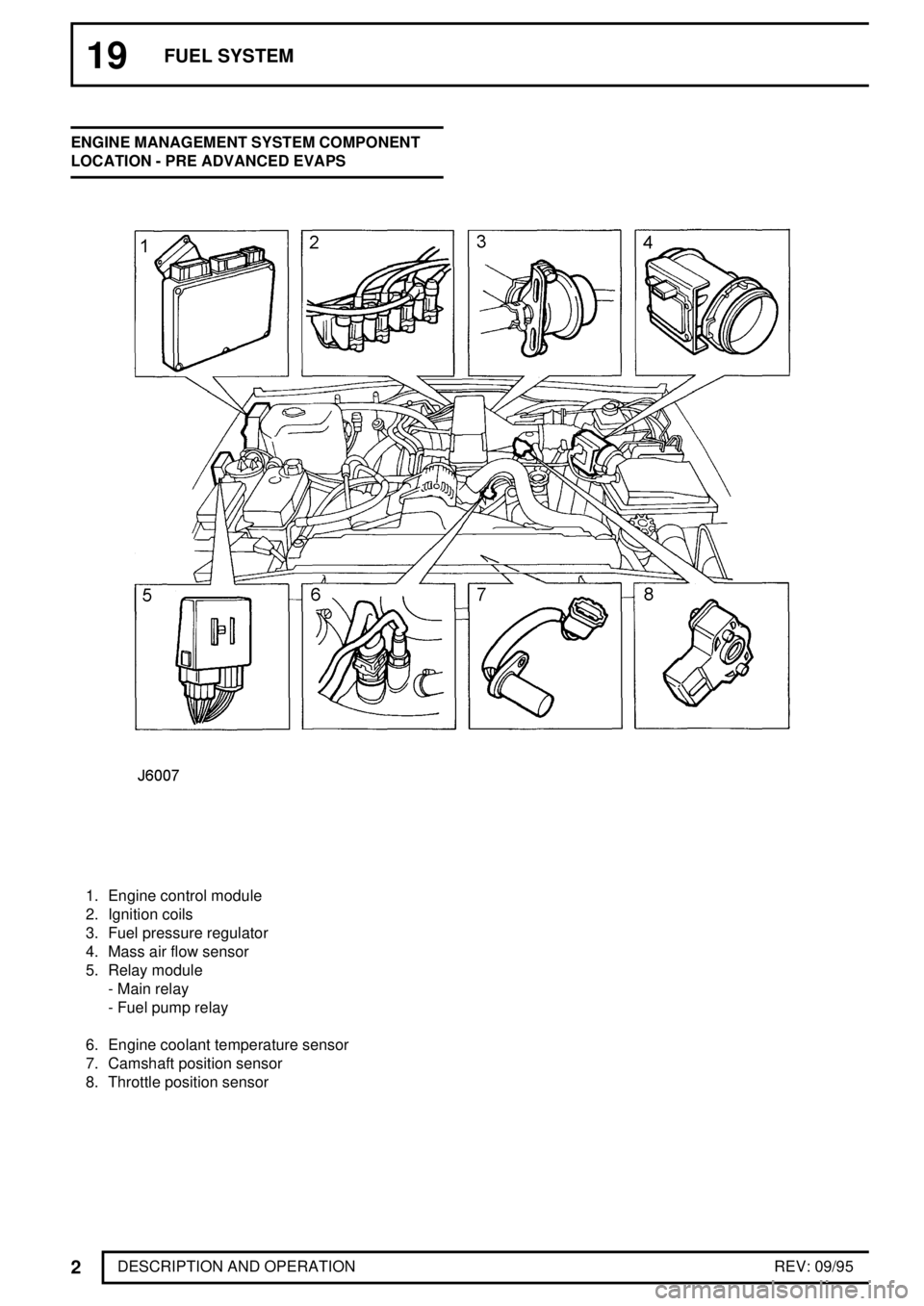

DESCRIPTION AND OPERATION REV: 09/95 ENGINE MANAGEMENT SYSTEM COMPONENT

LOCATION - PRE ADVANCED EVAPS

1. Engine control module

2. Ignition coils

3. Fuel pressure regulator

4. Mass air flow sensor

5. Relay module

- Main relay

- Fuel pump relay

6. Engine coolant temperature sensor

7. Camshaft position sensor

8. Throttle position sensor