bolt pattern LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 89 of 873

12ENGINE

8

REPAIR CAMSHAFT DRIVE BELT AND GEARS

Service repair no - 12.65.18

TIMING BELT

Remove

1.Remove front cover plate.

See Front Cover

Plate

2.Position engine at TDC on No. 1 cylinder.

3.If manual gearbox: Remove blanking plug from

flywheel housing and insert timing tool

LRT-12-044. If EDC - timing tool LRT-12-085

must be used.

If automatic gearbox:Sited to the rear of the

engine sump on engine backplate is a blanking

plate. Remove 2 blanking plate bolts and insert

timing tool LRT-12-044 into the larger bolt hole.

4.Engage timing tool pin with slot in flywheel.

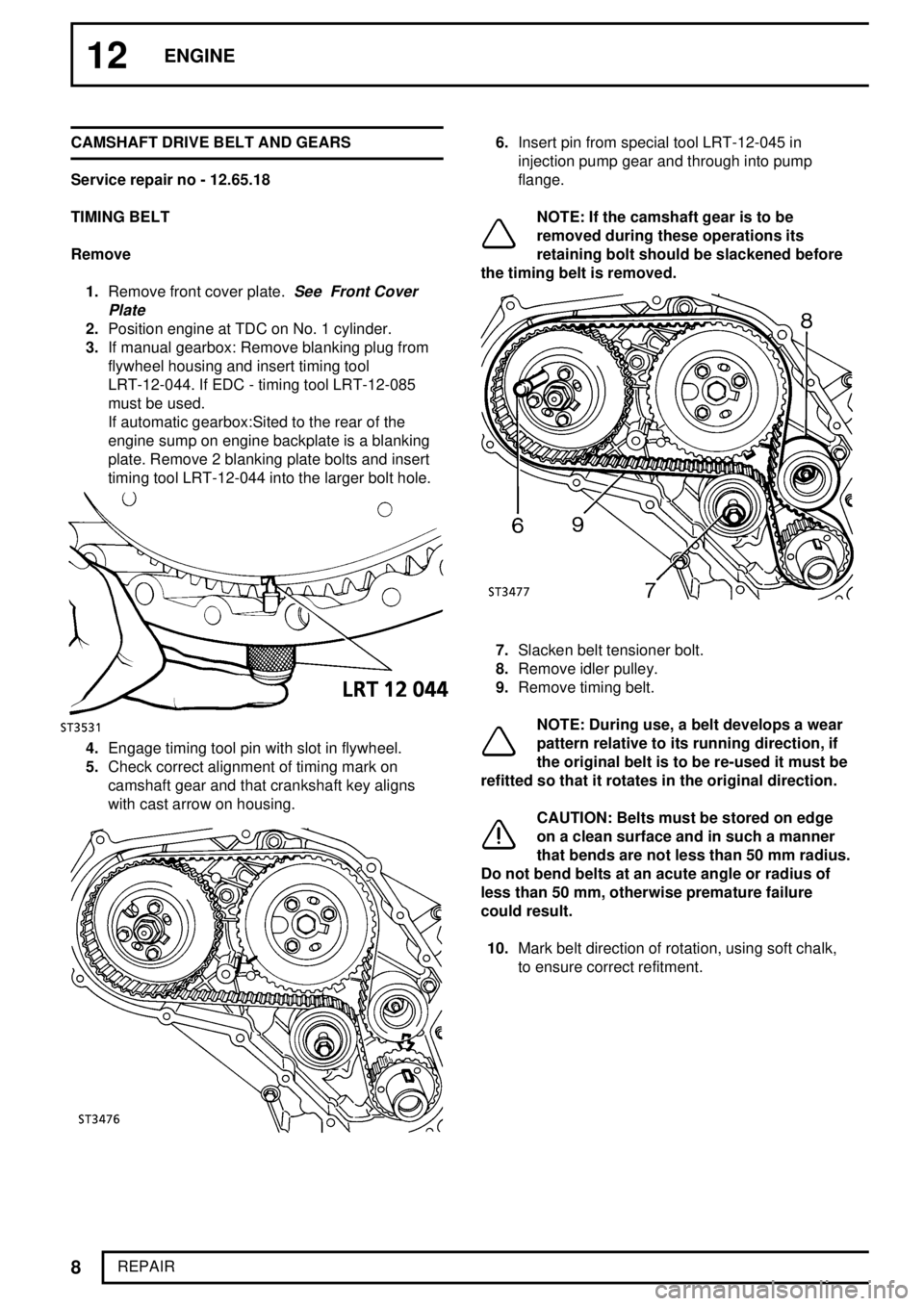

5.Check correct alignment of timing mark on

camshaft gear and that crankshaft key aligns

with cast arrow on housing.

6.Insert pin from special tool LRT-12-045 in

injection pump gear and through into pump

flange.

NOTE: If the camshaft gear is to be

removed during these operations its

retaining bolt should be slackened before

the timing belt is removed.

7.Slacken belt tensioner bolt.

8.Remove idler pulley.

9.Remove timing belt.

NOTE: During use, a belt develops a wear

pattern relative to its running direction, if

the original belt is to be re-used it must be

refitted so that it rotates in the original direction.

CAUTION: Belts must be stored on edge

on a clean surface and in such a manner

that bends are not less than 50 mm radius.

Do not bend belts at an acute angle or radius of

less than 50 mm, otherwise premature failure

could result.

10.Mark belt direction of rotation, using soft chalk,

to ensure correct refitment.

Page 455 of 873

44AUTOMATIC GEARBOX

18

REPAIR REPLACING TORQUE CONVERTER

1.Remove gearbox and transfer box assembly.

See LT230T Transfer Gearbox

2.Place gearbox on bench. Remove torque

converter using torque converter handles

18G1501, taking care not to damage torque

converter/oil pump housing oil seal.

3.Fit new torque converter using torque converter

handles 18G1501. Check dimension from

converter fixing boss to converter housing face is

50 mm. This shows converter is correctly seated

in housing.

4.Refit gearbox and transfer box assembly.

See

LT230T Transfer Gearbox

ELIMINATING LEAKS ON PUMP HOUSING

1.Remove gearbox and transfer box assembly.

See LT230T Transfer Gearbox

2.Place gearbox on bench. Remove torque

converter using torque converter handles

18G1501, taking care not to damage torque

converter/oil pump housing oil seal.

3.Remove twelve hexagonal bolts (inner ring

pattern).

4.Remove bell housing and pump assembly,

discard gasket.

5.Remove eight hexagonal bolts on rear of pump.

Page 457 of 873

44AUTOMATIC GEARBOX

20

REPAIR ELIMINATING LEAKS BETWEEN GEARBOX

HOUSING AND INTERMEDIATE PLATE

1.Remove gearbox and transfer box assembly.

See LT230T Transfer Gearbox

2.Place gearbox on bench. Remove torque

converter using torque converter handles

18G1501, taking care not to damage torque

converter/oil pump housing oil seal.

3.Remove twelve hexagonal bolts (inner ring

pattern).

4.Remove bell housing/intermediate plate

assembly from gearbox case and discard

gasket.

5.Place new gasket onto intermediate plate using

Petroleum Jelly.

6.Before fitting bell housing assembly check that

thrust washer and axial cage are seated on A

clutch housing.

7.Fit bell housing assembly with disc washer to

gearcase. Tighten twelve bolts to

46Nm.

8.Place end-float gauge LST111 onto pump

housing and check that axial play is between

0.2-0.4 mm. Replace existing washer, situated at

rear of intermediate plate, with a suitable washer

to give required end-float.

9.Refit torque converter using torque converter

handles 18G1501. Checking that dimension

from converter fixing boss to converter housing

case is 50mm. This dimension shows converter

is properly seated.

10.Refit gearbox/transfer box assembly.

See

LT230T Transfer Gearbox

Page 458 of 873

ZF

21

REPAIR REPLACING PUMP

Service repair no - 44.32.01

1.Remove gearbox and transfer box assembly.

See LT230T Transfer Gearbox

2.Place gearbox on bench. Remove torque

converter using torque converter handles

18G1501, taking care not to damage torque

converter/oil pump housing oil seal.

3.Remove twelve bolts (inner ring pattern).

4.Remove bell housing and pump assembly from

gearbox case, discard gasket.

5.Remove eight bolts on rear of pump.

6.Screw in two bolts,diagonally opposite each

other, tap lightly using a soft headed mallet to

free pump assembly from intermediate plate.

7.Fit new pump assembly, aligning dowel with hole

in intermediate plate, press pump housing home.

8.Secure pump housing to intermediate plate

using eight hexagonal bolts. Tighten to

10 Nm.

9.Place bell housing and intermediate plate

assembly on bench, front face up. Using oil

pump rotation sleeve LST111, check that pump

gears rotate freely.

10.Before replacing intermediate plate/bell housing

assembly check that thrust washer and axial

cage are seated on A clutch housing.

11.Place new gasket and disc washer onto bell

housing and intermediate plate assembly using

a Petroleum Jelly.

12.Fit bell housing and intermediate plate assembly,

tighten twelve bolts to

46 Nm.