boot LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 78 of 873

10MAINTENANCE

16

MAINTENANCE

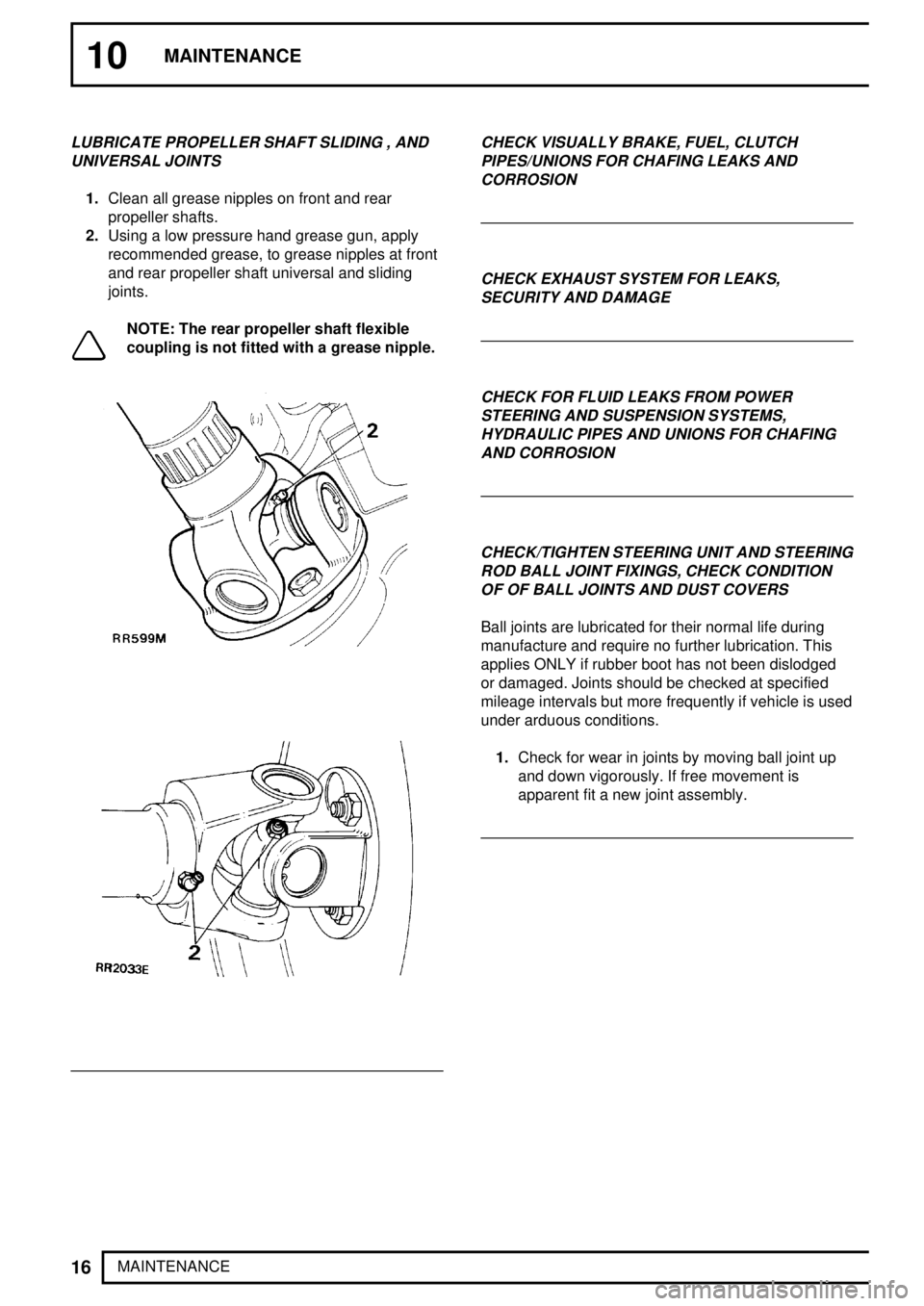

LUBRICATE PROPELLER SHAFT SLIDING , AND

UNIVERSAL JOINTS

1.Clean all grease nipples on front and rear

propeller shafts.

2.Using a low pressure hand grease gun, apply

recommended grease, to grease nipples at front

and rear propeller shaft universal and sliding

joints.

NOTE: The rear propeller shaft flexible

coupling is not fitted with a grease nipple.

CHECK VISUALLY BRAKE, FUEL, CLUTCH

PIPES/UNIONS FOR CHAFING LEAKS AND

CORROSION

CHECK EXHAUST SYSTEM FOR LEAKS,

SECURITY AND DAMAGE

CHECK FOR FLUID LEAKS FROM POWER

STEERING AND SUSPENSION SYSTEMS,

HYDRAULIC PIPES AND UNIONS FOR CHAFING

AND CORROSION

CHECK/TIGHTEN STEERING UNIT AND STEERING

ROD BALL JOINT FIXINGS, CHECK CONDITION

OF OF BALL JOINTS AND DUST COVERS

Ball joints are lubricated for their normal life during

manufacture and require no further lubrication. This

applies ONLY if rubber boot has not been dislodged

or damaged. Joints should be checked at specified

mileage intervals but more frequently if vehicle is used

under arduous conditions.

1.Check for wear in joints by moving ball joint up

and down vigorously. If free movement is

apparent fit a new joint assembly.

Page 397 of 873

CLUTCH

1

OVERHAUL MASTER CYLINDER

Service repair no - 30.20.07

1.Remove master cylinder.

See Repair, Master

Cylinder

Disassemble

2.Pull back and remove rubber sealing boot from

pushrod.

3.Depress push-rod and extract circlip.

4.Withdraw push-rod assembly.

5.Withdraw piston assembly.

6.Withdraw retainer and spring.

7.Remove two piston seals and piston washer.

Inspecting

8.Clean all components thoroughly using new

hydraulic fluid. Dry, using a lint-free cloth.

9.Examine cylinder bore and piston, ensure they

are smooth to touch with no corrosion, score

marks or ridges. If in doubt, fit new components.

10.Fit new seals and rubber boot. These items are

all included in master cylinder overhaul kit.

11.Ensure that feed and by-pass ports are not

obstructed.

12.Ensure reservoir cap vent is clear.

Assemble

NOTE: Cleanliness is essential, ensure

hands are free of grease or dirt. Lubricate

cylinder bore and rubber seals with new

hydraulic fluid before assembly.

13.Fit a new piston washer and thinner of two piston

seals, lip last, over piston nose, up against

drilled piston head. Fit thicker seal into piston

groove with lip facing towards seal at opposite

end.

14.Insert spring and retainer into master cylinder

bore.

15.Insert piston and seal assembly, ensuring that

seal lips do not bend back.

16.Reverse 3 and 4, correctly locating circlip.

17.Stretch new rubber boot over push-rod, pack

with rubber grease. Fit securely into locating

groove.

18.Operate push-rod several times to ensure free

movement of internal components.

19.Fit master cylinder.

Page 398 of 873

33CLUTCH

2

OVERHAUL SLAVE CYLINDER

Service repair no - 33.35.07

Overhaul

1.Remove slave cylinder.

See Repair, Slave

Cylinder

Disassemble

2.Withdraw rubber boot.

3.Withdraw push-rod.

4.Remove circlip.

5.Extract piston and seal assembly, applying low

pressure air to fluid inlet if necessary.

6.Withdraw spring.

7.Remove bleed valve.

Inspecting

8.Clean all components thoroughly using new

hydraulic fluid, and dry using lint-free cloth.

9.Examine cylinder bore and piston which must be

free from corrosion, scores and ridges.

10.Replace seal and rubber boot using appropriate

repair kit.

Assemble

NOTE: Cleanliness is essential, ensure

hands are free of grease or dirt.

11.Fit bleed valve. Do not overtighten.

12.Lubricate seals, piston and bore using new

hydraulic fluid.

13.Fit seal into piston groove, lip of seal towards

fluid inlet end of cylinder.

14.Enter piston assembly, spring first, into cylinder

bore. Ensure that seal lip does not fold back.

15.Secure with circlip.

16.Fill rubber boot with rubber grease.

17.Reverse removal procedure. 1 to 3.

Page 437 of 873

ZF

1

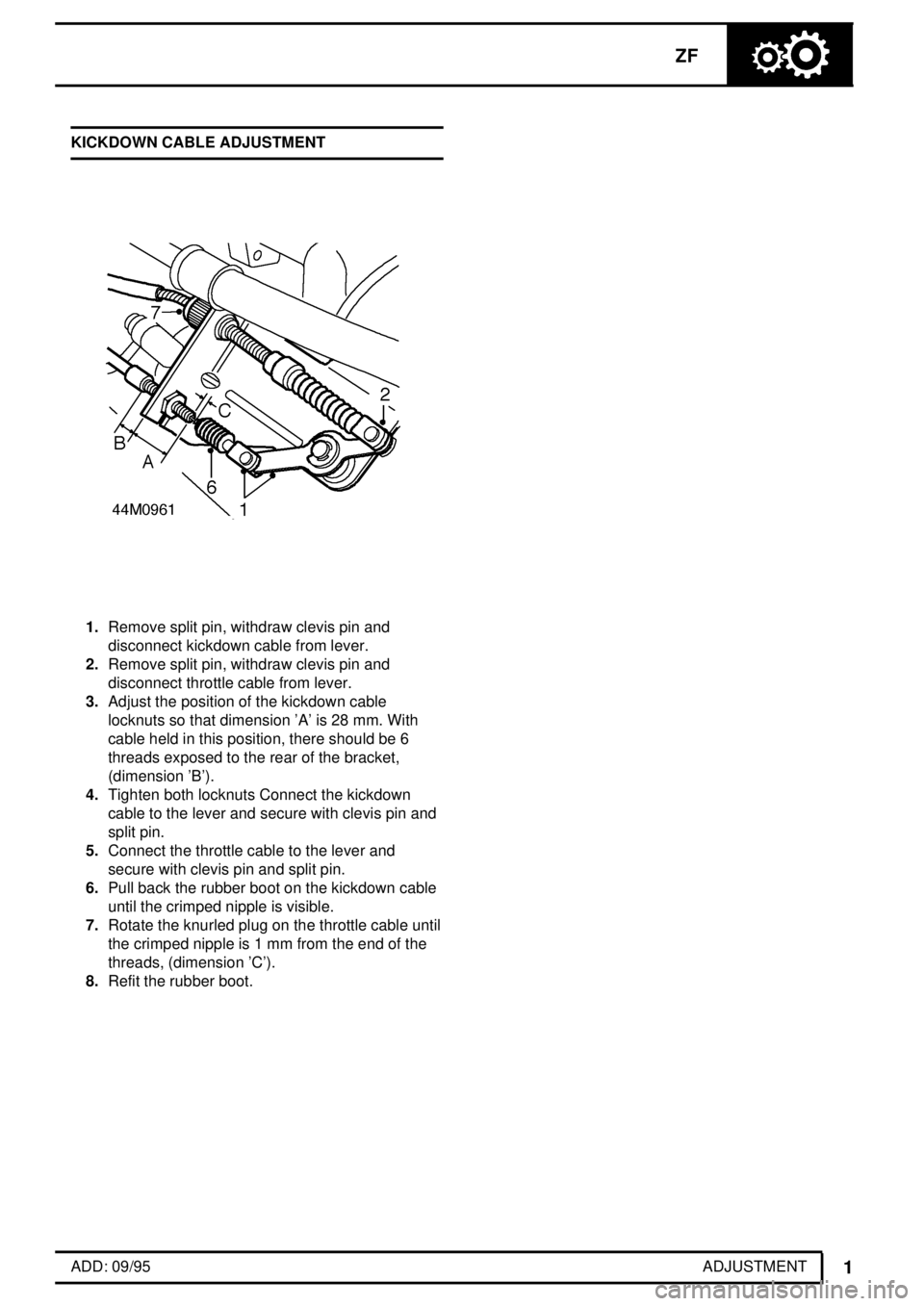

ADJUSTMENT ADD: 09/95 KICKDOWN CABLE ADJUSTMENT

1.Remove split pin, withdraw clevis pin and

disconnect kickdown cable from lever.

2.Remove split pin, withdraw clevis pin and

disconnect throttle cable from lever.

3.Adjust the position of the kickdown cable

locknuts so that dimension 'A' is 28 mm. With

cable held in this position, there should be 6

threads exposed to the rear of the bracket,

(dimension 'B').

4.Tighten both locknuts Connect the kickdown

cable to the lever and secure with clevis pin and

split pin.

5.Connect the throttle cable to the lever and

secure with clevis pin and split pin.

6.Pull back the rubber boot on the kickdown cable

until the crimped nipple is visible.

7.Rotate the knurled plug on the throttle cable until

the crimped nipple is 1 mm from the end of the

threads, (dimension 'C').

8.Refit the rubber boot.

Page 539 of 873

STEERING

13

FAULT DIAGNOSIS STEERING LINKAGE INSPECT

NOTE: When inspecting steering linkages

and ball joints for wear the following items

must be checked.

Steering ball joints

1.Check ball joint rubber boots for security, signs

of cracking or deterioration.

2.Check ball joint assemblies for seizure i.e. no

movement on ball joint and associated

assemblies.

3.Check for excessive wear. This will be evident

as extreme movement on track rod and steering

linkages. Renew parts as necessary.

See

Repair, Track Rod and Linkage See Repair,

Drag Link and Drag Link Ends

Steering linkages

4.Check all linkages for wear, deterioration and

damage. Renew parts as necessary.

See

Repair, Track Rod and Linkage See Repair,

Drag Link and Drag Link Ends

Page 555 of 873

STEERING

13

REPAIR

8.Disconnect ignition switch main feed multiplug.

9.Remove 4 nuts securing upper column to lower

mounting.

10.Remove 2 nuts securing lower mounting steady

bracket, remove bracket.

11.Remove pinch bolt securing upper column to

universal joint.

12.Remove 2 nuts and washes securing upper

column to upper mounting bracket.13.Carefully manoeuvre upper column out of

footwell, recover rubber boot.

NOTE: Do not carry out further

dismantling if upper column is removed

for access only.

14.Loosen but, do not remove screw securing

column switch assembly, withdraw assembly to

gain access to multiplugs.

15.Disconnect column switch multiplugs, remove

column switch assembly.

16.Disconnect ignition switch multiplug.

17.Remove shear bolts securing steering column

lock, remove lock and saddle; discard shear

bolts.

18.Withdraw bulb holder from column lock shroud.

19.Transfer components to new upper column,

connect multiplug.

NOTE: Do not shear column lock bolts at

this stage.

Page 556 of 873

57STEERING

14

REPAIR Refit

20.Manoeuvre upper column to position in footwell,

ensure splines in column and universal joint are

correctly engaged and rubber boot is fitted.

21.Fit but do not tighten universal joint pinch bolt.

22.Position upper column to upper mounting, fit

washers and nuts, do not tighten nuts.

23.Fit but do not tighten nuts and bolts securing

upper column to lower mounting.

24.Fit lower mounting steady bracket, fit but do not

tighten nuts and bolts.

25.Ensure upper column is aligned to mountings.

26.Tighten all nuts and bolts to

22 Nm.

27.Tighten universal joint pinch bolt to25 Nm.

28.Connect column switch multiplug.

29.Connect ignition switch multiplugs.

30.Fit rotary coupler.

See SUPPLEMENTARY

RESTRAINT SYSTEM, Repair, Rotary

Coupler

31.Fit steering wheel.See Steering Wheel

32.Reconnect battery negative lead.

33.Check steering column lock for correct

operation, tighten shear bolts until heads shear

off.

34.If fitted - position knee bolster, fit and tighten

screws.

35.Fit steering column shroud.

See Steering

Column Shroud

36.Fit driver's access panel.

Page 642 of 873

75SUPPLEMENTARY RESTRAINT SYSTEM

6

DESCRIPTION AND OPERATION AIRBAG STORAGE

Temporary storage

For temporary storage of the airbag module during

service, observe the following precautions:

Store the airbag module with the pad surface up.

Place the airbag module in designated storage area.

If no designated storage area is available, the module

may be stored in the boot of the vehicle from which it

was removed. Always lock the boot when module is

stored in it and inform workshop supervisor.

WARNING: If the airbag is improperly

stored face down, accidental deployment

could propel the unit with enough force to

cause serious injury.

Store the removed airbag module on a secure flat

surface away from heat, oil, grease, detergent or

water.

CAUTION: Improper handling or storage

can internally damage the airbag module,

making it inoperative. If you suspect the

airbag module has been damaged, install a new

unit.

Overnight storage

Airbag modules are classed as an explosive article

and as such they must be stored in a secure steel

cabinet which has been approved by the local

authority.

Page 760 of 873

AIR CONDITIONING

1

ADJUSTMENT GENERAL PRECAUTIONS

The refrigerant used in the air conditioning system is

HFC (Hydrofluorocarbon) R134a.

WARNING: R134a is a hazardous liquid

and when handled incorrectly can cause

serious injury. Suitable protective clothing

must be worn when carrying out servicing

operations on the air conditioning system.

WARNING: R134a is odourless and

colourless. Do not handle or discharge in

an enclosed area, or in any area where the

vapour or liquid can come in contact with naked

flame or hot metal. R134a is not flammable but

can form a highly toxic gas.

WARNING: Do not smoke or weld in areas

where R134a is in use. Inhalation of

concentrations of the vapour can cause

dizziness, disorientation. uncoordination,

narcosis, nausea or vomiting.

WARNING: Do not allow fluids other than

R134a or compressor lubricant to enter the

air conditioning system. Spontaneous

combustion may occur.

WARNING: R134a splashed on any part of

the body will cause immediate freezing of

that area. Also refrigerant cylinders and

replenishment trolleys when discharging will

freeze skin to them if contact is made.

WARNING: The refrigerant used in an air

conditioning system must be reclaimed in

accordance with the recommendations

given with a Refrigerant Recovery Recycling

Recharging Station.

NOTE: Suitable protective clothing

comprises: Wrap around safety glasses or

helmet, heatproof gloves, rubber apron or

waterproof overalls and rubber boots.REMEDIAL ACTIONS

1.If liquid R134a strikes the eye, do not rub it.

Gently run large quantities of eyewash over the

eye to raise the temperature. If eyewash is not

available cool, clean water may be used. Cover

eye with clean pad and seek immediate medical

attention.

2.If liquid R134a is splashed on the skin run large

quantities of water over the area as soon as

possible to raise the temperature. Carry out the

same actions if skin comes into contact with

discharging cylinders. Wrap affected parts in

blankets or similar material and seek immediate

medical attention.

3.If suspected of being overcome by inhalation of

R134a vapour seek fresh air. If unconscious

remove to fresh air. Apply artificial respiration

and/or oxygen and seek immediate medical

attention.

NOTE: Due to its low evaporating

temperature of -30°C, R134a should be

handled with care.

WARNING: Do not allow a refrigerant

container to be heated by a direct flame or

to be placed near any heating appliance. A

refrigerant container must not be heated above

50°C.

WARNING: Do not leave a container of

refrigerant without its cap fitted. Do not

transport a container of refrigerant that is

unrestrained, especially in the boot of a car.