oil dipstick LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 60 of 873

09LUBRICANTS, FLUIDS AND CAPACITIES

4

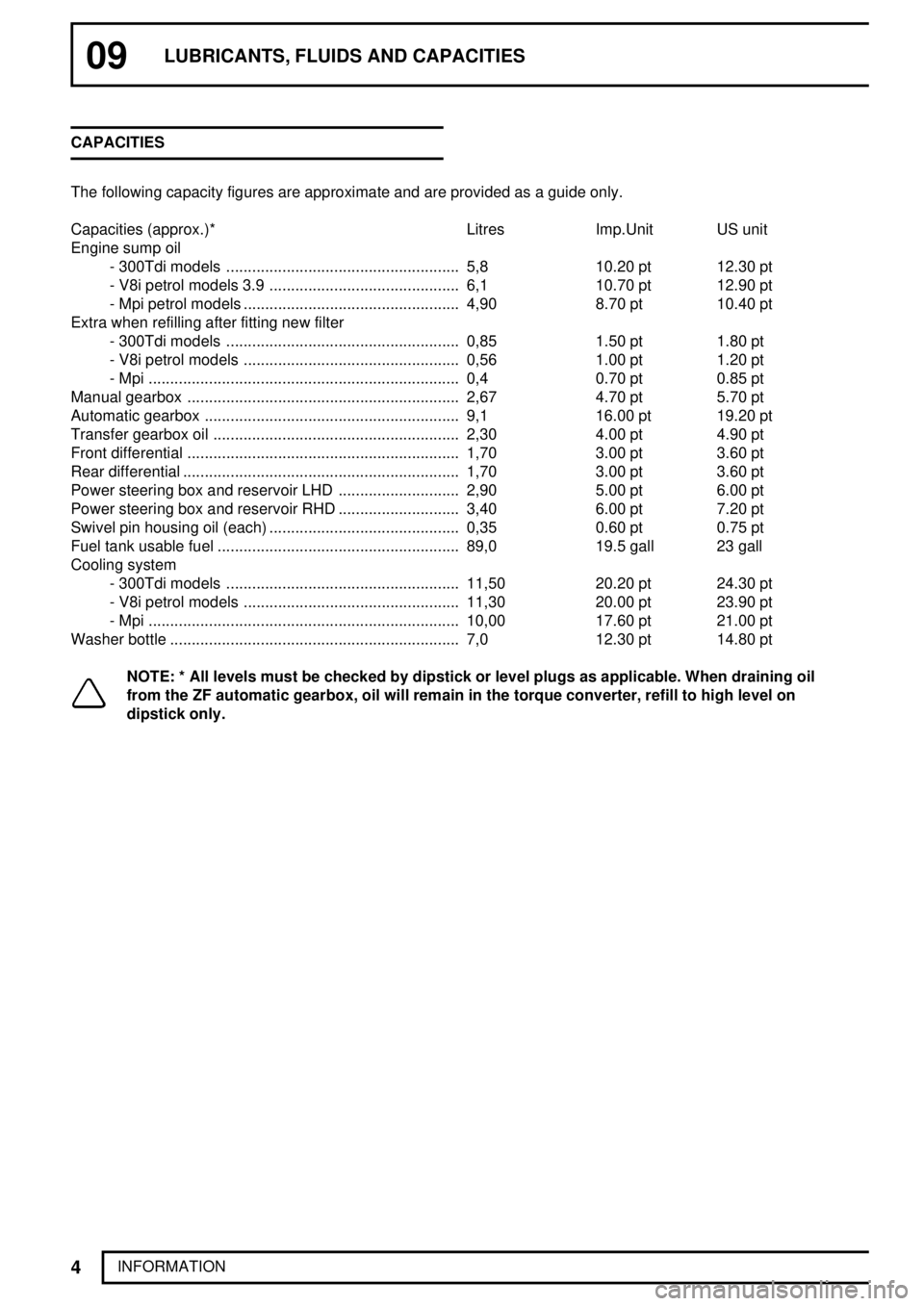

INFORMATION CAPACITIES

The following capacity figures are approximate and are provided as a guide only.

Capacities (approx.)* Litres Imp.Unit US unit

Engine sump oil

- 300Tdi models 5,8...................................................... 10.20 pt 12.30 pt

- V8i petrol models 3.9 6,1............................................ 10.70 pt 12.90 pt

- Mpi petrol models 4,90.................................................. 8.70 pt 10.40 pt

Extra when refilling after fitting new filter

- 300Tdi models 0,85...................................................... 1.50 pt 1.80 pt

- V8i petrol models 0,56.................................................. 1.00 pt 1.20 pt

- Mpi 0,4........................................................................ 0.70 pt 0.85 pt

Manual gearbox 2,67............................................................... 4.70 pt 5.70 pt

Automatic gearbox 9,1........................................................... 16.00 pt 19.20 pt

Transfer gearbox oil 2,30......................................................... 4.00 pt 4.90 pt

Front differential 1,70............................................................... 3.00 pt 3.60 pt

Rear differential 1,70................................................................ 3.00 pt 3.60 pt

Power steering box and reservoir LHD 2,90............................ 5.00 pt 6.00 pt

Power steering box and reservoir RHD 3,40............................ 6.00 pt 7.20 pt

Swivel pin housing oil (each) 0,35............................................ 0.60 pt 0.75 pt

Fuel tank usable fuel 89,0........................................................ 19.5 gall 23 gall

Cooling system

- 300Tdi models 11,50...................................................... 20.20 pt 24.30 pt

- V8i petrol models 11,30.................................................. 20.00 pt 23.90 pt

- Mpi 10,00........................................................................ 17.60 pt 21.00 pt

Washer bottle 7,0................................................................... 12.30 pt 14.80 pt

NOTE: * All levels must be checked by dipstick or level plugs as applicable. When draining oil

from the ZF automatic gearbox, oil will remain in the torque converter, refill to high level on

dipstick only.

Page 71 of 873

MAINTENANCE

9

MAINTENANCE

CHECK CONDITION OF DRIVE BELT - V8i - Tdi -

Mpi

RENEW - V8i - Tdi

Renew drive belt V8i.See ENGINE, Repair, Drive

Belt Renew

Renew drive belt Tdi.See ENGINE, Repair, Drive

Belt Renew

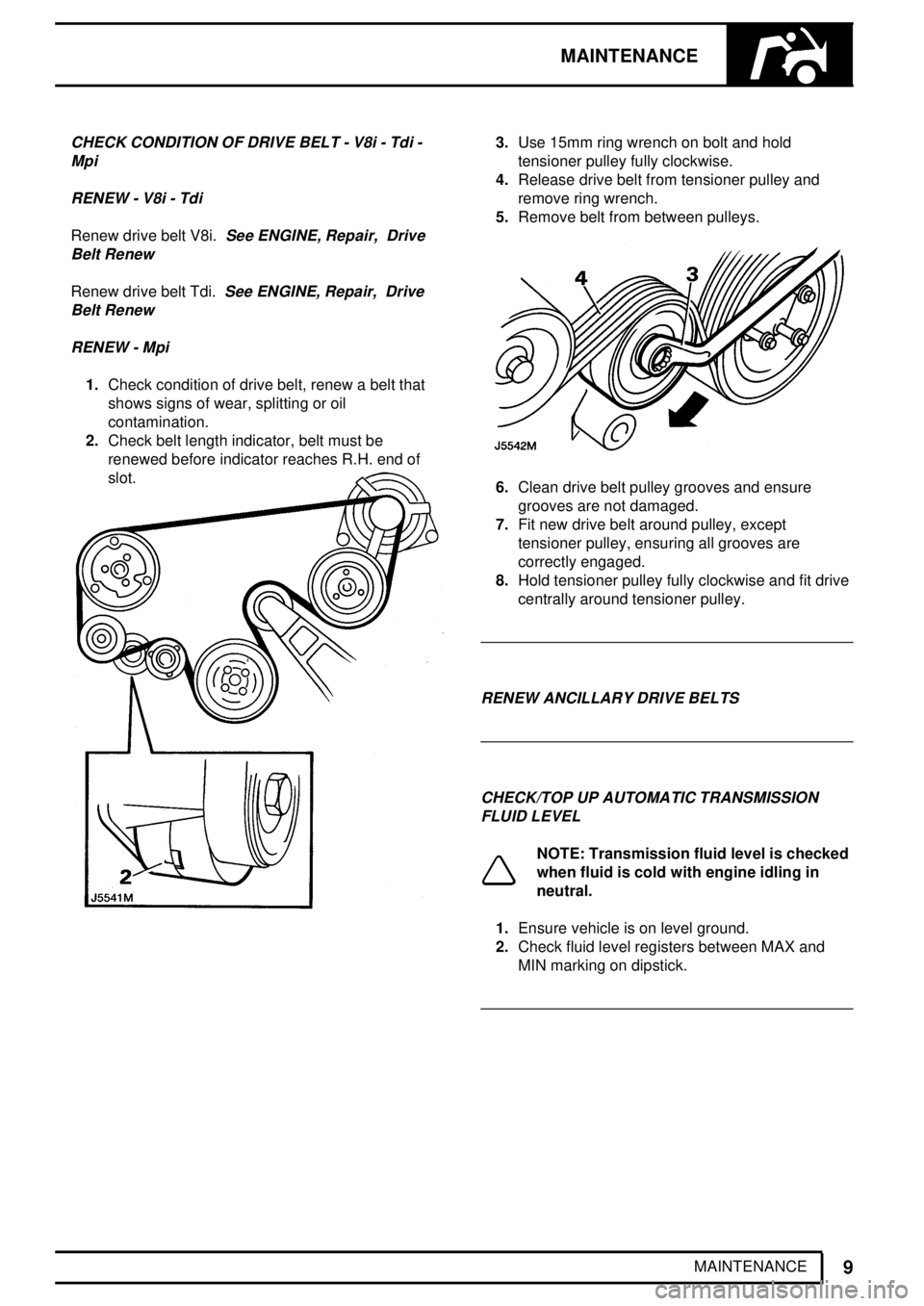

RENEW - Mpi

1.Check condition of drive belt, renew a belt that

shows signs of wear, splitting or oil

contamination.

2.Check belt length indicator, belt must be

renewed before indicator reaches R.H. end of

slot.

3.Use 15mm ring wrench on bolt and hold

tensioner pulley fully clockwise.

4.Release drive belt from tensioner pulley and

remove ring wrench.

5.Remove belt from between pulleys.

6.Clean drive belt pulley grooves and ensure

grooves are not damaged.

7.Fit new drive belt around pulley, except

tensioner pulley, ensuring all grooves are

correctly engaged.

8.Hold tensioner pulley fully clockwise and fit drive

centrally around tensioner pulley.

RENEW ANCILLARY DRIVE BELTS

CHECK/TOP UP AUTOMATIC TRANSMISSION

FLUID LEVEL

NOTE: Transmission fluid level is checked

when fluid is cold with engine idling in

neutral.

1.Ensure vehicle is on level ground.

2.Check fluid level registers between MAX and

MIN marking on dipstick.

Page 75 of 873

MAINTENANCE

13

MAINTENANCE

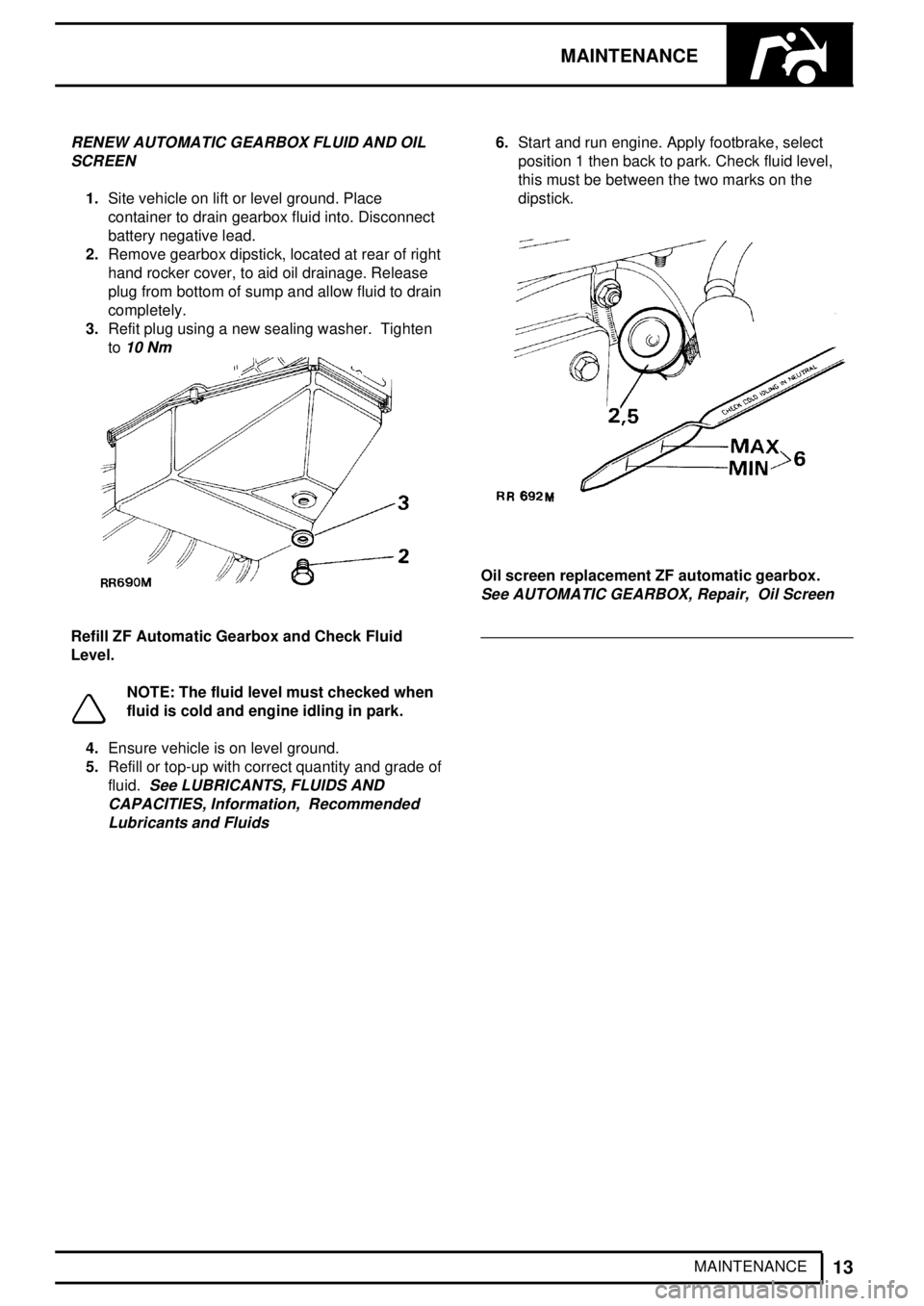

RENEW AUTOMATIC GEARBOX FLUID AND OIL

SCREEN

1.Site vehicle on lift or level ground. Place

container to drain gearbox fluid into. Disconnect

battery negative lead.

2.Remove gearbox dipstick, located at rear of right

hand rocker cover, to aid oil drainage. Release

plug from bottom of sump and allow fluid to drain

completely.

3.Refit plug using a new sealing washer. Tighten

to

10 Nm

Refill ZF Automatic Gearbox and Check Fluid

Level.

NOTE: The fluid level must checked when

fluid is cold and engine idling in park.

4.Ensure vehicle is on level ground.

5.Refill or top-up with correct quantity and grade of

fluid.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

6.Start and run engine. Apply footbrake, select

position 1 then back to park. Check fluid level,

this must be between the two marks on the

dipstick.

Oil screen replacement ZF automatic gearbox.

See AUTOMATIC GEARBOX, Repair, Oil Screen

Page 110 of 873

12ENGINE

2

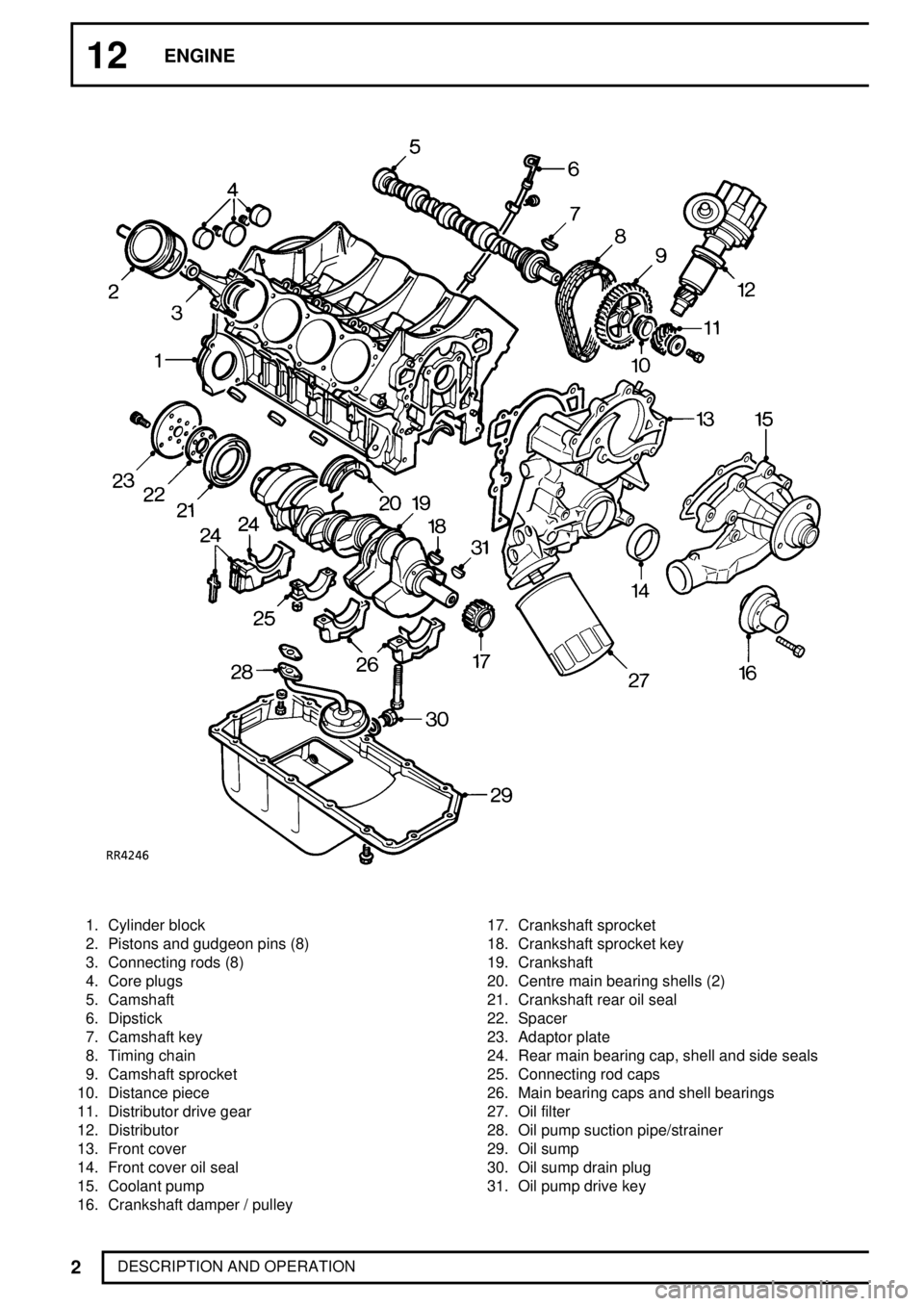

DESCRIPTION AND OPERATION

1. Cylinder block

2. Pistons and gudgeon pins (8)

3. Connecting rods (8)

4. Core plugs

5. Camshaft

6. Dipstick

7. Camshaft key

8. Timing chain

9. Camshaft sprocket

10. Distance piece

11. Distributor drive gear

12. Distributor

13. Front cover

14. Front cover oil seal

15. Coolant pump

16. Crankshaft damper / pulley17. Crankshaft sprocket

18. Crankshaft sprocket key

19. Crankshaft

20. Centre main bearing shells (2)

21. Crankshaft rear oil seal

22. Spacer

23. Adaptor plate

24. Rear main bearing cap, shell and side seals

25. Connecting rod caps

26. Main bearing caps and shell bearings

27. Oil filter

28. Oil pump suction pipe/strainer

29. Oil sump

30. Oil sump drain plug

31. Oil pump drive key

Page 124 of 873

12ENGINE

6

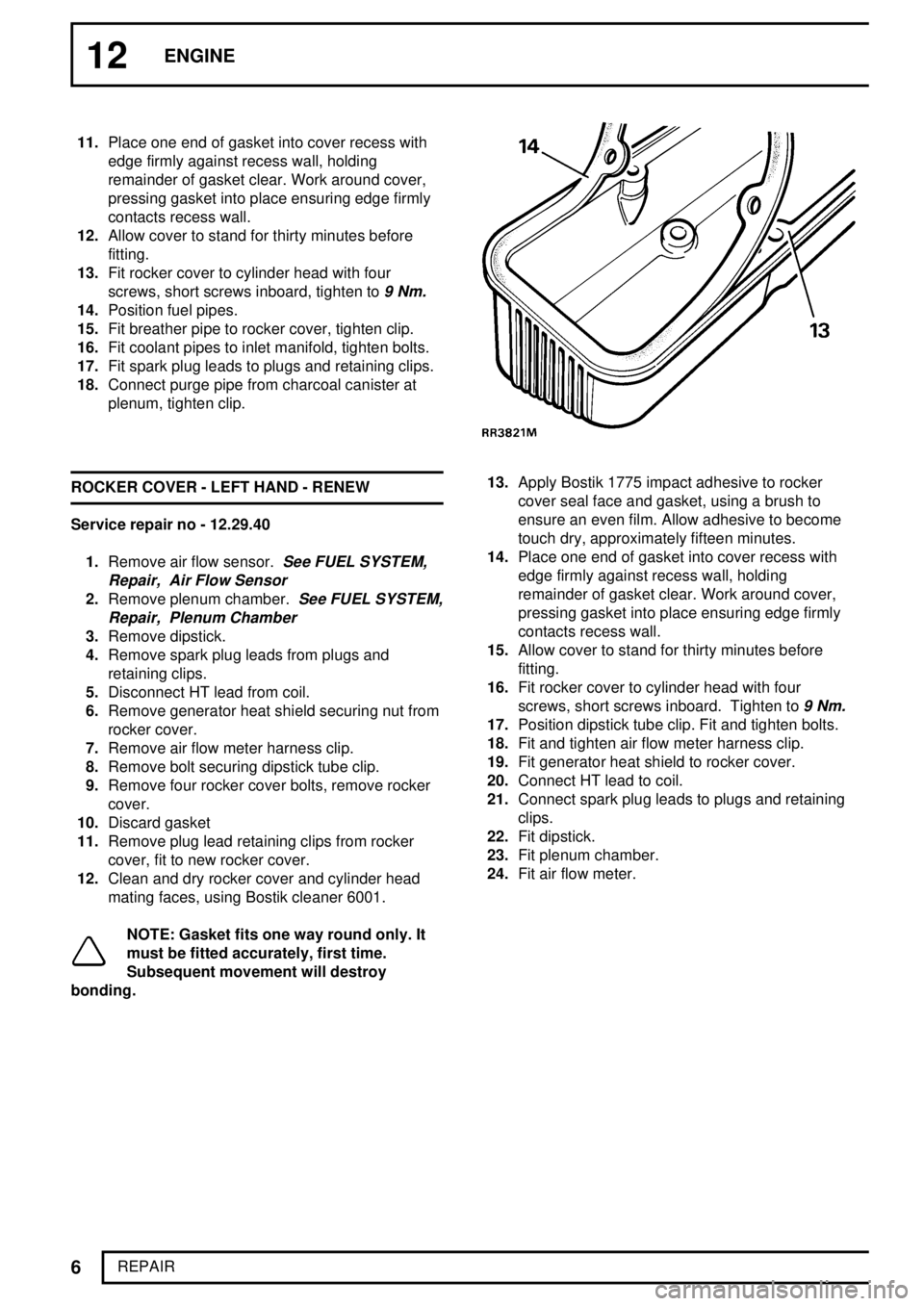

REPAIR 11.Place one end of gasket into cover recess with

edge firmly against recess wall, holding

remainder of gasket clear. Work around cover,

pressing gasket into place ensuring edge firmly

contacts recess wall.

12.Allow cover to stand for thirty minutes before

fitting.

13.Fit rocker cover to cylinder head with four

screws, short screws inboard, tighten to

9 Nm.

14.Position fuel pipes.

15.Fit breather pipe to rocker cover, tighten clip.

16.Fit coolant pipes to inlet manifold, tighten bolts.

17.Fit spark plug leads to plugs and retaining clips.

18.Connect purge pipe from charcoal canister at

plenum, tighten clip.

ROCKER COVER - LEFT HAND - RENEW

Service repair no - 12.29.40

1.Remove air flow sensor.

See FUEL SYSTEM,

Repair, Air Flow Sensor

2.Remove plenum chamber.See FUEL SYSTEM,

Repair, Plenum Chamber

3.Remove dipstick.

4.Remove spark plug leads from plugs and

retaining clips.

5.Disconnect HT lead from coil.

6.Remove generator heat shield securing nut from

rocker cover.

7.Remove air flow meter harness clip.

8.Remove bolt securing dipstick tube clip.

9.Remove four rocker cover bolts, remove rocker

cover.

10.Discard gasket

11.Remove plug lead retaining clips from rocker

cover, fit to new rocker cover.

12.Clean and dry rocker cover and cylinder head

mating faces, using Bostik cleaner 6001.

NOTE: Gasket fits one way round only. It

must be fitted accurately, first time.

Subsequent movement will destroy

bonding.

13.Apply Bostik 1775 impact adhesive to rocker

cover seal face and gasket, using a brush to

ensure an even film. Allow adhesive to become

touch dry, approximately fifteen minutes.

14.Place one end of gasket into cover recess with

edge firmly against recess wall, holding

remainder of gasket clear. Work around cover,

pressing gasket into place ensuring edge firmly

contacts recess wall.

15.Allow cover to stand for thirty minutes before

fitting.

16.Fit rocker cover to cylinder head with four

screws, short screws inboard. Tighten to

9 Nm.

17.Position dipstick tube clip. Fit and tighten bolts.

18.Fit and tighten air flow meter harness clip.

19.Fit generator heat shield to rocker cover.

20.Connect HT lead to coil.

21.Connect spark plug leads to plugs and retaining

clips.

22.Fit dipstick.

23.Fit plenum chamber.

24.Fit air flow meter.

Page 133 of 873

V8i

15

REPAIR OIL SUMP

Service repair no - 12.60.44

Remove

1.Drain engine oil

See SECTION 10,

Maintenance, Under Vehicle Maintenance

2.Fit drain plug. Tighten to40 Nm.

3.If fitted, disconnect low oil level sensor multiplug.

4.Remove bolt securing dipstick tube to rocker

cover.

5.Working form the centre outwards, progressively

loosen and remove 17 bolts securing sump.

Remove sump.

6.Remove all traces of sealant from mating

surfaces of sump, cylinder block and front cover,

using a suitable solvent or plastic scraper.

7.Degrease mating surfaces of sump, cylinder

block and front cover.Refit

8.Apply RTV Hylosil White sealant to mating

surface of sump.

9.Position sump, tighten bolts finger tight.

10.Tighten bolts progressively in sequence shown.

Tighten to

18 Nm.

11.Fit bolt securing dipstick tube to rocker cover.

12.If fitted, connect low oil level sensor multiplug.

Page 154 of 873

12ENGINE

4

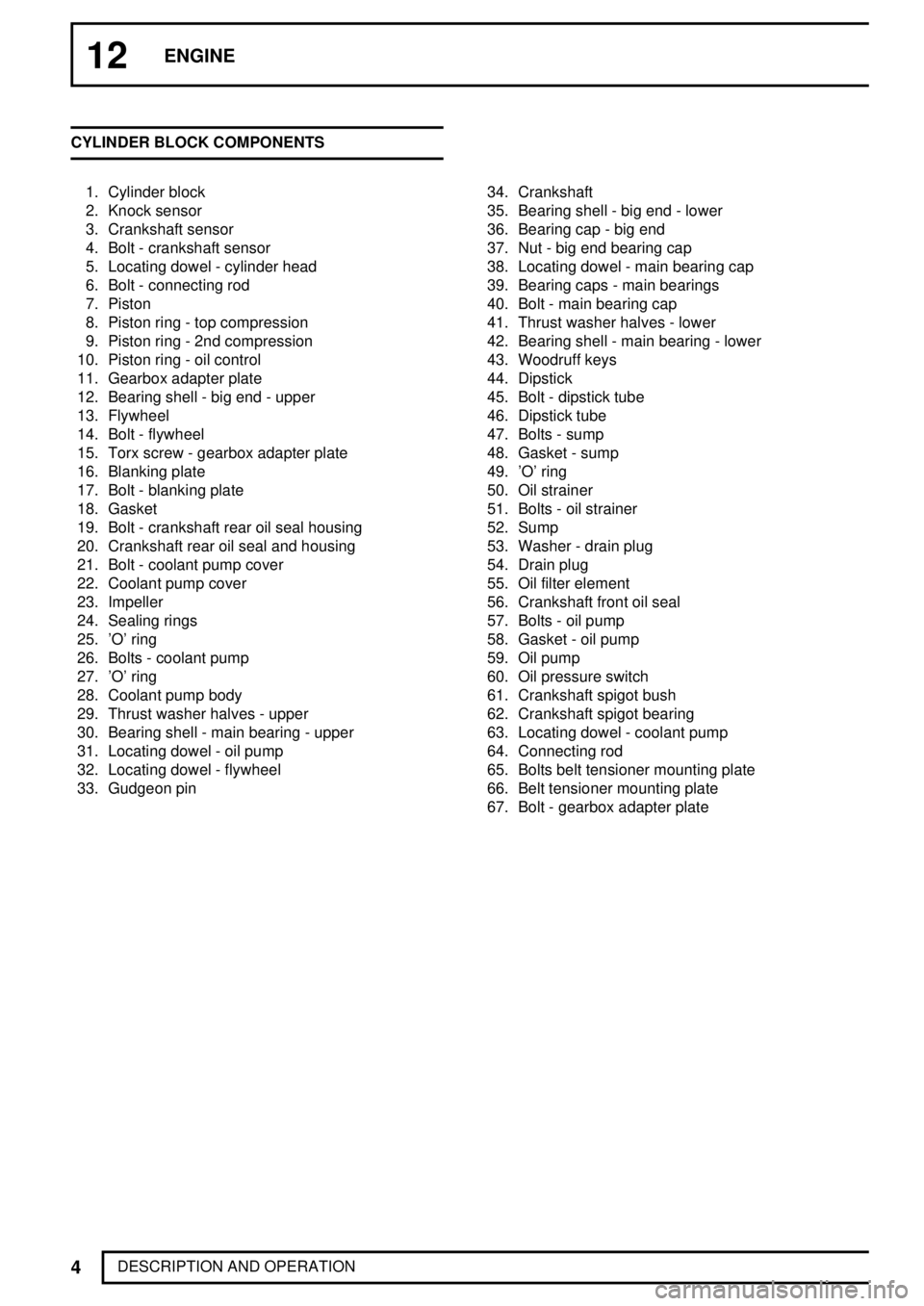

DESCRIPTION AND OPERATION CYLINDER BLOCK COMPONENTS

1. Cylinder block

2. Knock sensor

3. Crankshaft sensor

4. Bolt - crankshaft sensor

5. Locating dowel - cylinder head

6. Bolt - connecting rod

7. Piston

8. Piston ring - top compression

9. Piston ring - 2nd compression

10. Piston ring - oil control

11. Gearbox adapter plate

12. Bearing shell - big end - upper

13. Flywheel

14. Bolt - flywheel

15. Torx screw - gearbox adapter plate

16. Blanking plate

17. Bolt - blanking plate

18. Gasket

19. Bolt - crankshaft rear oil seal housing

20. Crankshaft rear oil seal and housing

21. Bolt - coolant pump cover

22. Coolant pump cover

23. Impeller

24. Sealing rings

25. 'O' ring

26. Bolts - coolant pump

27. 'O' ring

28. Coolant pump body

29. Thrust washer halves - upper

30. Bearing shell - main bearing - upper

31. Locating dowel - oil pump

32. Locating dowel - flywheel

33. Gudgeon pin34. Crankshaft

35. Bearing shell - big end - lower

36. Bearing cap - big end

37. Nut - big end bearing cap

38. Locating dowel - main bearing cap

39. Bearing caps - main bearings

40. Bolt - main bearing cap

41. Thrust washer halves - lower

42. Bearing shell - main bearing - lower

43. Woodruff keys

44. Dipstick

45. Bolt - dipstick tube

46. Dipstick tube

47. Bolts - sump

48. Gasket - sump

49. 'O' ring

50. Oil strainer

51. Bolts - oil strainer

52. Sump

53. Washer - drain plug

54. Drain plug

55. Oil filter element

56. Crankshaft front oil seal

57. Bolts - oil pump

58. Gasket - oil pump

59. Oil pump

60. Oil pressure switch

61. Crankshaft spigot bush

62. Crankshaft spigot bearing

63. Locating dowel - coolant pump

64. Connecting rod

65. Bolts belt tensioner mounting plate

66. Belt tensioner mounting plate

67. Bolt - gearbox adapter plate

Page 439 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual 44AUTOMATIC GEARBOX

2

REPAIR 1.Site vehicle on a four post ramp [hoist].

2.Disconnect battery negative lead.

3.Remove fan cowl securing screws and release

cowl from radiator.

4.Loosen securing clip an LAND ROVER DISCOVERY 1995 Workshop Manual 44AUTOMATIC GEARBOX

2

REPAIR 1.Site vehicle on a four post ramp [hoist].

2.Disconnect battery negative lead.

3.Remove fan cowl securing screws and release

cowl from radiator.

4.Loosen securing clip an](/img/64/57248/w960_57248-438.png)

44AUTOMATIC GEARBOX

2

REPAIR 1.Site vehicle on a four post ramp [hoist].

2.Disconnect battery negative lead.

3.Remove fan cowl securing screws and release

cowl from radiator.

4.Loosen securing clip and disconnect air flow

hose from plenum chamber.

5.Disconnect stepper motor hose from top of

plenum chamber.

6.Disconnect kickdown cable from throttle linkage

and release from clipping.7.Release two gearbox breather pipes from clip

located on lifting eye at rear of right hand

cylinder head.

8.Remove dipstick from main gearbox oil filler

tube.

9.Working inside vehicle detach transfer gear lever

gaiter from console, unscrew knob and withdraw

gaiter and knob.

10.Raise vehicle on ramp [hoist].

11.Remove drain plugs and drain oil from transfer

gearbox and main gearbox. Refit plugs.

12.Detach heat shield at front exhaust pipe to

manifold.

13.Disconnect electrics to Lambda sensors.

14.Remove catalytic converter assembly.

15.Remove chassis cross-member from under

gearbox.16.Remove heat shield from speedometer cable at

transfer gearbox.

17.Remove clamp and disconnect speedometer

cable from transfer gearbox. Tie cable to one

side.

18.Mark for reassembly propeller shaft to transfer

gearbox mating flanges.

Page 440 of 873

ZF

3

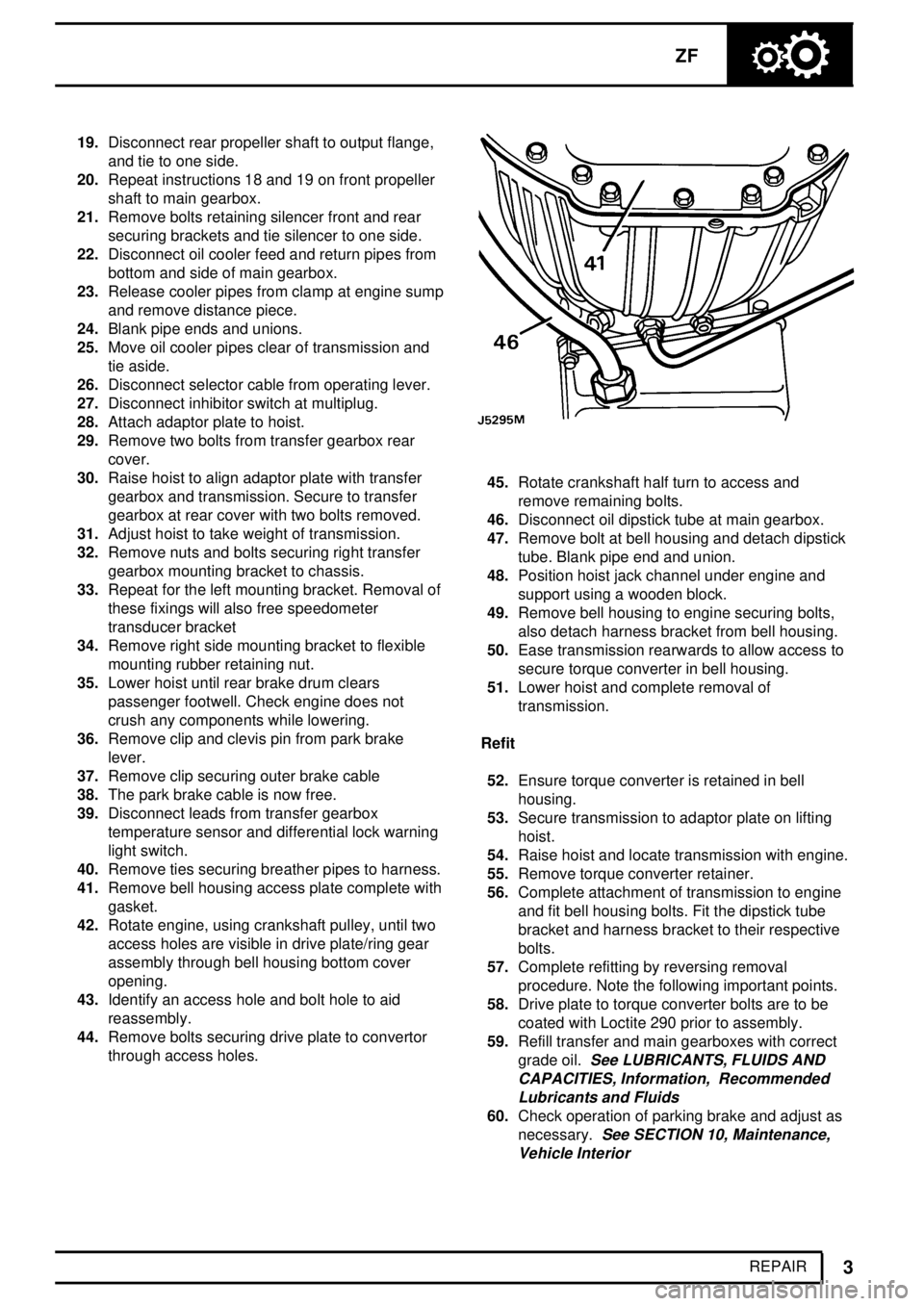

REPAIR 19.Disconnect rear propeller shaft to output flange,

and tie to one side.

20.Repeat instructions 18 and 19 on front propeller

shaft to main gearbox.

21.Remove bolts retaining silencer front and rear

securing brackets and tie silencer to one side.

22.Disconnect oil cooler feed and return pipes from

bottom and side of main gearbox.

23.Release cooler pipes from clamp at engine sump

and remove distance piece.

24.Blank pipe ends and unions.

25.Move oil cooler pipes clear of transmission and

tie aside.

26.Disconnect selector cable from operating lever.

27.Disconnect inhibitor switch at multiplug.

28.Attach adaptor plate to hoist.

29.Remove two bolts from transfer gearbox rear

cover.

30.Raise hoist to align adaptor plate with transfer

gearbox and transmission. Secure to transfer

gearbox at rear cover with two bolts removed.

31.Adjust hoist to take weight of transmission.

32.Remove nuts and bolts securing right transfer

gearbox mounting bracket to chassis.

33.Repeat for the left mounting bracket. Removal of

these fixings will also free speedometer

transducer bracket

34.Remove right side mounting bracket to flexible

mounting rubber retaining nut.

35.Lower hoist until rear brake drum clears

passenger footwell. Check engine does not

crush any components while lowering.

36.Remove clip and clevis pin from park brake

lever.

37.Remove clip securing outer brake cable

38.The park brake cable is now free.

39.Disconnect leads from transfer gearbox

temperature sensor and differential lock warning

light switch.

40.Remove ties securing breather pipes to harness.

41.Remove bell housing access plate complete with

gasket.

42.Rotate engine, using crankshaft pulley, until two

access holes are visible in drive plate/ring gear

assembly through bell housing bottom cover

opening.

43.Identify an access hole and bolt hole to aid

reassembly.

44.Remove bolts securing drive plate to convertor

through access holes.

45.Rotate crankshaft half turn to access and

remove remaining bolts.

46.Disconnect oil dipstick tube at main gearbox.

47.Remove bolt at bell housing and detach dipstick

tube. Blank pipe end and union.

48.Position hoist jack channel under engine and

support using a wooden block.

49.Remove bell housing to engine securing bolts,

also detach harness bracket from bell housing.

50.Ease transmission rearwards to allow access to

secure torque converter in bell housing.

51.Lower hoist and complete removal of

transmission.

Refit

52.Ensure torque converter is retained in bell

housing.

53.Secure transmission to adaptor plate on lifting

hoist.

54.Raise hoist and locate transmission with engine.

55.Remove torque converter retainer.

56.Complete attachment of transmission to engine

and fit bell housing bolts. Fit the dipstick tube

bracket and harness bracket to their respective

bolts.

57.Complete refitting by reversing removal

procedure. Note the following important points.

58.Drive plate to torque converter bolts are to be

coated with Loctite 290 prior to assembly.

59.Refill transfer and main gearboxes with correct

grade oil.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

60.Check operation of parking brake and adjust as

necessary.

See SECTION 10, Maintenance,

Vehicle Interior

Page 443 of 873

44AUTOMATIC GEARBOX

6

REPAIR 13.Remove starter.

14.Working through starter aperture note position of

torque converter flexible drive plate to facilitate

refitting.

15.Remove the four torque convertor to flexible

drive securing bolts, rotating engine to gain

access to each individual bolt.

16.Raise vehicle on four post ramp [hoist].

17.Drain lubrication oil from transfer and main

gearboxes.

18.Disconnect speedometer cable from transfer

gearbox and disconnect associated clipping.

19.Remove rear propeller shaft.

See PROPELLER

SHAFTS, Overhaul, Flexible Coupling

20.Disconnect front propeller shaft at transfer

gearbox and tie to one side.

21.Remove exhaust front pipe.

22.Remove bolts securing front and centre silencer

mounting brackets and tie silencer to one side.

23.Disconnect oil cooler pipes from gearbox.

24.Blank off pipes and union connections.

25.Remove bolt securing retaining bracket to sump

and move cooler pipes aside.

26.Disconnect selector cable from lever on side of

gearbox.

27.Disconnect inhibitor switch multi-plug.

28.Disconnect park brake cable from linkage to park

brake lever.

29.Disconnect electrical connections from

differential lock switch on transfer gearbox.

30.Remove two lower bolts from transfer gearbox

input bearing support plate.

31.Assemble approved support cradle to

transmission hoist.32.Raise hoist and secure cradle to transfer

gearbox input bearing support plate using bolts

removed.

33.Disconnect gearbox mounting brackets from

chassis cross member.

34.Remove chassis cross member.

35.Lower transmission sufficiently to allow access

to items attached to top of gearbox.

36.Remove left hand gearbox mounting bracket

assembly.

37.Remove ties from breather pipes and harness.

38.Remove nut securing gearbox oil filler/dip stick

tube to bell housing.

39.Release union nut at gearbox sump and remove

filler/dipstick tube. Fit blanking plugs.

40.Support engine using a wooden block with a

suitable ramp [hoist] jack.

41.Remove nut securing kick down cable bracket to

bell housing.

42.Remove two bolts securing top of bell housing to

flywheel housing.

43.Remove nuts securing bell housing to flywheel

housing and withdraw transmission assembly

from engine.

44.Fit a suitable torque converter retaining strap to

the bell housing.

45.Remove hoist and transmission from under

vehicle.

46.Fit lifting eyes to transmission.

47.Using suitable chains and lifting tackle take

weight of transmission assembly.

48.Remove bolts securing transmission cradle to

transfer box and withdraw hoist complete with

cradle.

49.Refit bolts to cover plate.